Quality Control in Manufacturing Using Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric QC Evolution

The evolution of piezoelectric sensors in quality control for manufacturing has been marked by significant technological advancements and expanding applications. Initially developed in the early 20th century, piezoelectric materials were primarily used for sonar and other acoustic applications. However, their unique properties of generating an electric charge in response to mechanical stress soon found utility in various industrial processes.

In the 1950s and 1960s, piezoelectric sensors began to be integrated into manufacturing quality control systems, primarily for vibration monitoring in machinery. These early applications were limited by the sensitivity and durability of the sensors, as well as the complexity of signal processing required to interpret the data.

The 1970s and 1980s saw a rapid expansion in the use of piezoelectric sensors for quality control. Improvements in materials science led to the development of more robust and sensitive piezoelectric crystals, while advances in electronics enabled more sophisticated signal analysis. This period marked the beginning of widespread adoption in industries such as automotive and aerospace manufacturing, where precise measurements of force, pressure, and acceleration were critical for ensuring product quality.

The 1990s brought about miniaturization and integration of piezoelectric sensors, allowing for their incorporation into smaller and more complex manufacturing systems. This era also saw the development of smart sensors with built-in signal conditioning and processing capabilities, greatly enhancing their versatility and ease of use in quality control applications.

The turn of the millennium ushered in the era of Industry 4.0, where piezoelectric sensors became integral components of interconnected manufacturing systems. The ability to provide real-time, high-precision measurements made these sensors invaluable in automated quality control processes. Advanced data analytics and machine learning algorithms were developed to interpret the vast amounts of data generated by these sensors, enabling predictive maintenance and adaptive manufacturing processes.

In recent years, the focus has shifted towards developing piezoelectric sensors with enhanced durability, wider operating temperature ranges, and improved resistance to harsh industrial environments. Novel piezoelectric materials, such as lead-free ceramics and polymer-based composites, have emerged to address environmental concerns and expand the application range of these sensors in quality control.

The latest developments in piezoelectric sensor technology for quality control include the integration of wireless communication capabilities, allowing for more flexible and scalable sensor networks in manufacturing environments. Additionally, the combination of piezoelectric sensing with other technologies, such as optical and MEMS-based sensors, is opening up new possibilities for multi-modal quality control systems that can detect and analyze a wider range of manufacturing defects and variations.

In the 1950s and 1960s, piezoelectric sensors began to be integrated into manufacturing quality control systems, primarily for vibration monitoring in machinery. These early applications were limited by the sensitivity and durability of the sensors, as well as the complexity of signal processing required to interpret the data.

The 1970s and 1980s saw a rapid expansion in the use of piezoelectric sensors for quality control. Improvements in materials science led to the development of more robust and sensitive piezoelectric crystals, while advances in electronics enabled more sophisticated signal analysis. This period marked the beginning of widespread adoption in industries such as automotive and aerospace manufacturing, where precise measurements of force, pressure, and acceleration were critical for ensuring product quality.

The 1990s brought about miniaturization and integration of piezoelectric sensors, allowing for their incorporation into smaller and more complex manufacturing systems. This era also saw the development of smart sensors with built-in signal conditioning and processing capabilities, greatly enhancing their versatility and ease of use in quality control applications.

The turn of the millennium ushered in the era of Industry 4.0, where piezoelectric sensors became integral components of interconnected manufacturing systems. The ability to provide real-time, high-precision measurements made these sensors invaluable in automated quality control processes. Advanced data analytics and machine learning algorithms were developed to interpret the vast amounts of data generated by these sensors, enabling predictive maintenance and adaptive manufacturing processes.

In recent years, the focus has shifted towards developing piezoelectric sensors with enhanced durability, wider operating temperature ranges, and improved resistance to harsh industrial environments. Novel piezoelectric materials, such as lead-free ceramics and polymer-based composites, have emerged to address environmental concerns and expand the application range of these sensors in quality control.

The latest developments in piezoelectric sensor technology for quality control include the integration of wireless communication capabilities, allowing for more flexible and scalable sensor networks in manufacturing environments. Additionally, the combination of piezoelectric sensing with other technologies, such as optical and MEMS-based sensors, is opening up new possibilities for multi-modal quality control systems that can detect and analyze a wider range of manufacturing defects and variations.

Market Demand Analysis

The market demand for quality control solutions using piezoelectric sensors in manufacturing has been steadily increasing in recent years. This growth is primarily driven by the rising need for precision and efficiency in various industrial sectors, including automotive, aerospace, electronics, and medical devices manufacturing.

In the automotive industry, piezoelectric sensors are becoming increasingly crucial for ensuring the quality of components such as engine parts, transmissions, and safety systems. The stringent safety regulations and the push for more fuel-efficient vehicles have amplified the demand for high-precision quality control measures. Similarly, the aerospace sector relies heavily on these sensors to maintain the highest standards of safety and performance in aircraft manufacturing.

The electronics industry, particularly in the production of smartphones, tablets, and other consumer electronics, has seen a surge in the adoption of piezoelectric sensor-based quality control systems. These sensors play a vital role in detecting minute defects in components, ensuring the reliability and longevity of electronic devices.

In the medical device manufacturing sector, the demand for piezoelectric sensor-based quality control is driven by the need for extreme precision and compliance with strict regulatory standards. These sensors are essential in producing implantable devices, surgical instruments, and diagnostic equipment where even the slightest imperfection can have critical consequences.

The global market for quality control systems in manufacturing, including those utilizing piezoelectric sensors, is projected to experience significant growth. This expansion is fueled by the increasing adoption of Industry 4.0 technologies and the growing emphasis on automation and data-driven decision-making in manufacturing processes.

Furthermore, the trend towards miniaturization in various industries has created a demand for more sensitive and precise quality control methods. Piezoelectric sensors, with their ability to detect minute vibrations and changes in pressure, are well-suited to meet these evolving needs.

The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is expected to witness the highest growth in demand for these quality control solutions. This is attributed to the rapid industrialization, increasing manufacturing activities, and the adoption of advanced technologies in these countries.

However, the market also faces challenges such as the high initial investment required for implementing these advanced quality control systems and the need for skilled personnel to operate and maintain them. Despite these challenges, the long-term benefits of improved product quality, reduced waste, and increased operational efficiency continue to drive the adoption of piezoelectric sensor-based quality control solutions in manufacturing.

In the automotive industry, piezoelectric sensors are becoming increasingly crucial for ensuring the quality of components such as engine parts, transmissions, and safety systems. The stringent safety regulations and the push for more fuel-efficient vehicles have amplified the demand for high-precision quality control measures. Similarly, the aerospace sector relies heavily on these sensors to maintain the highest standards of safety and performance in aircraft manufacturing.

The electronics industry, particularly in the production of smartphones, tablets, and other consumer electronics, has seen a surge in the adoption of piezoelectric sensor-based quality control systems. These sensors play a vital role in detecting minute defects in components, ensuring the reliability and longevity of electronic devices.

In the medical device manufacturing sector, the demand for piezoelectric sensor-based quality control is driven by the need for extreme precision and compliance with strict regulatory standards. These sensors are essential in producing implantable devices, surgical instruments, and diagnostic equipment where even the slightest imperfection can have critical consequences.

The global market for quality control systems in manufacturing, including those utilizing piezoelectric sensors, is projected to experience significant growth. This expansion is fueled by the increasing adoption of Industry 4.0 technologies and the growing emphasis on automation and data-driven decision-making in manufacturing processes.

Furthermore, the trend towards miniaturization in various industries has created a demand for more sensitive and precise quality control methods. Piezoelectric sensors, with their ability to detect minute vibrations and changes in pressure, are well-suited to meet these evolving needs.

The Asia-Pacific region, particularly countries like China, Japan, and South Korea, is expected to witness the highest growth in demand for these quality control solutions. This is attributed to the rapid industrialization, increasing manufacturing activities, and the adoption of advanced technologies in these countries.

However, the market also faces challenges such as the high initial investment required for implementing these advanced quality control systems and the need for skilled personnel to operate and maintain them. Despite these challenges, the long-term benefits of improved product quality, reduced waste, and increased operational efficiency continue to drive the adoption of piezoelectric sensor-based quality control solutions in manufacturing.

Current Challenges

The implementation of piezoelectric sensors for quality control in manufacturing faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is the sensitivity of these sensors to environmental factors such as temperature fluctuations, humidity, and electromagnetic interference. These external influences can lead to inaccurate readings and false positives, compromising the reliability of quality control processes.

Another major challenge lies in the integration of piezoelectric sensor systems with existing manufacturing infrastructure. Many production lines are not designed to accommodate advanced sensing technologies, requiring substantial modifications and investments. This integration complexity often results in resistance from manufacturers due to concerns about production downtime and initial costs.

Data interpretation and analysis present another hurdle in the effective use of piezoelectric sensors. The vast amount of data generated by these sensors can be overwhelming, and extracting meaningful insights requires sophisticated algorithms and data processing capabilities. Many manufacturers lack the expertise or resources to effectively manage and interpret this data, limiting the potential benefits of the technology.

Calibration and maintenance of piezoelectric sensor systems pose ongoing challenges. Regular recalibration is necessary to ensure accuracy, but this process can be time-consuming and may require specialized knowledge. Additionally, the durability of piezoelectric materials in harsh manufacturing environments is a concern, as sensor degradation over time can lead to decreased performance and increased maintenance costs.

Standardization is another critical issue facing the industry. The lack of uniform standards for piezoelectric sensor implementation in quality control applications makes it difficult for manufacturers to compare different solutions and ensure compatibility across various systems. This absence of standardization also complicates the development of universal training programs and best practices.

Cost remains a significant barrier to widespread adoption, particularly for small and medium-sized enterprises. While the long-term benefits of improved quality control are clear, the initial investment in piezoelectric sensor technology, including hardware, software, and training, can be prohibitive for many companies operating on tight budgets.

Lastly, there are challenges related to the limitations of current piezoelectric sensor technology itself. These include constraints in measuring certain types of materials or detecting specific defects, as well as limitations in sensor size and placement that may restrict their application in certain manufacturing processes. Overcoming these technological limitations requires ongoing research and development efforts to expand the capabilities and versatility of piezoelectric sensors in quality control applications.

Another major challenge lies in the integration of piezoelectric sensor systems with existing manufacturing infrastructure. Many production lines are not designed to accommodate advanced sensing technologies, requiring substantial modifications and investments. This integration complexity often results in resistance from manufacturers due to concerns about production downtime and initial costs.

Data interpretation and analysis present another hurdle in the effective use of piezoelectric sensors. The vast amount of data generated by these sensors can be overwhelming, and extracting meaningful insights requires sophisticated algorithms and data processing capabilities. Many manufacturers lack the expertise or resources to effectively manage and interpret this data, limiting the potential benefits of the technology.

Calibration and maintenance of piezoelectric sensor systems pose ongoing challenges. Regular recalibration is necessary to ensure accuracy, but this process can be time-consuming and may require specialized knowledge. Additionally, the durability of piezoelectric materials in harsh manufacturing environments is a concern, as sensor degradation over time can lead to decreased performance and increased maintenance costs.

Standardization is another critical issue facing the industry. The lack of uniform standards for piezoelectric sensor implementation in quality control applications makes it difficult for manufacturers to compare different solutions and ensure compatibility across various systems. This absence of standardization also complicates the development of universal training programs and best practices.

Cost remains a significant barrier to widespread adoption, particularly for small and medium-sized enterprises. While the long-term benefits of improved quality control are clear, the initial investment in piezoelectric sensor technology, including hardware, software, and training, can be prohibitive for many companies operating on tight budgets.

Lastly, there are challenges related to the limitations of current piezoelectric sensor technology itself. These include constraints in measuring certain types of materials or detecting specific defects, as well as limitations in sensor size and placement that may restrict their application in certain manufacturing processes. Overcoming these technological limitations requires ongoing research and development efforts to expand the capabilities and versatility of piezoelectric sensors in quality control applications.

Existing QC Solutions

01 Testing and calibration methods

Various testing and calibration methods are employed to ensure the quality of piezoelectric sensors. These methods may include frequency response testing, sensitivity measurements, and linearity checks. Advanced techniques such as impedance analysis and laser vibrometry can be used to characterize sensor performance accurately.- Testing and calibration methods: Various testing and calibration methods are employed to ensure the quality of piezoelectric sensors. These methods may include frequency response testing, sensitivity measurements, and linearity checks. Advanced techniques such as impedance analysis and laser vibrometry can be used to characterize sensor performance accurately.

- Manufacturing process control: Quality control in piezoelectric sensor production involves careful monitoring and control of the manufacturing process. This includes precise material selection, controlled deposition of piezoelectric layers, and optimized electrode placement. Advanced manufacturing techniques such as microfabrication and thin-film deposition are often employed to enhance sensor quality and consistency.

- Environmental and stress testing: Piezoelectric sensors undergo rigorous environmental and stress testing to ensure reliability in various operating conditions. This may include temperature cycling, humidity exposure, vibration testing, and shock resistance evaluation. Such tests help identify potential failure modes and improve sensor durability.

- Signal processing and noise reduction: Quality control measures for piezoelectric sensors often involve advanced signal processing techniques to improve sensor output quality. This includes noise reduction algorithms, filtering methods, and signal amplification techniques. Implementation of these methods helps enhance sensor sensitivity and accuracy in various applications.

- Structural design optimization: The quality of piezoelectric sensors is significantly influenced by their structural design. Optimization techniques such as finite element analysis and computer-aided design are used to improve sensor geometry, electrode configuration, and overall structure. This process aims to enhance sensor performance, sensitivity, and reliability while minimizing potential defects or weaknesses.

02 Manufacturing process control

Quality control in piezoelectric sensor production involves careful monitoring and control of the manufacturing process. This includes precise material selection, controlled deposition or growth of piezoelectric materials, and accurate electrode patterning. In-line inspection and process parameter optimization are crucial for maintaining consistent sensor quality.Expand Specific Solutions03 Environmental and reliability testing

Piezoelectric sensors undergo rigorous environmental and reliability testing to ensure their performance under various conditions. This may include temperature cycling, humidity exposure, vibration testing, and accelerated life testing. Such tests help identify potential failure modes and validate the sensor's long-term stability and reliability.Expand Specific Solutions04 Signal processing and noise reduction

Quality control of piezoelectric sensors often involves optimizing signal processing techniques and implementing effective noise reduction methods. This may include the use of advanced filtering algorithms, signal amplification, and shielding techniques to improve the signal-to-noise ratio and overall sensor performance.Expand Specific Solutions05 Packaging and integration quality assurance

The quality of piezoelectric sensor packaging and integration is crucial for overall performance. This involves ensuring proper sealing, electrical connections, and mechanical mounting. Advanced inspection techniques such as X-ray imaging and acoustic microscopy may be used to verify the integrity of sensor packages and their integration into larger systems.Expand Specific Solutions

Key Industry Players

The quality control market in manufacturing using piezoelectric sensors is in a growth phase, driven by increasing demand for high-precision monitoring in smart manufacturing. The global market size is projected to expand significantly, with key players like DENSO Corp., Endress+Hauser, and Robert Bosch GmbH leading innovation. These companies, along with emerging players such as Ionix Advanced Technologies and QASS GmbH, are advancing sensor technology maturity through R&D in materials, miniaturization, and signal processing. The competitive landscape is characterized by a mix of established industrial giants and specialized sensor manufacturers, with ongoing collaborations between industry and research institutions like Fraunhofer-Gesellschaft and ITRI driving technological progress.

DENSO Corp.

Technical Solution: DENSO Corp. has developed an innovative quality control system for manufacturing using piezoelectric sensors, particularly focused on the automotive industry. Their approach integrates piezoelectric sensors into key points of the production line to monitor vibration, pressure, and acoustic emissions during assembly and testing processes[2]. DENSO's system utilizes advanced signal processing techniques and artificial intelligence to analyze sensor data in real-time, enabling the detection of subtle defects in components and assemblies[4]. The company has also developed specialized sensors capable of withstanding the harsh conditions often found in automotive manufacturing environments, such as high temperatures and exposure to chemicals[6]. DENSO's quality control solution has been implemented across their global manufacturing facilities, significantly reducing defect rates and improving overall product quality.

Strengths: Tailored for automotive industry requirements, robust sensors for harsh manufacturing environments, and global implementation experience. Weaknesses: May be less adaptable to non-automotive manufacturing sectors, potentially high initial investment costs for smaller manufacturers.

Ionix Advanced Technologies Ltd.

Technical Solution: Ionix Advanced Technologies Ltd. has pioneered a novel approach to quality control in manufacturing using high-temperature piezoelectric sensors. Their proprietary HotSense™ technology enables continuous monitoring of industrial processes in extreme environments up to 400°C[2]. This innovation allows for real-time quality control in previously challenging manufacturing scenarios, such as in the production of steel, glass, and ceramics. Ionix's sensors are designed to withstand harsh conditions while maintaining high sensitivity and accuracy[4]. The company has developed a comprehensive data acquisition and analysis platform that integrates with their sensors, providing manufacturers with actionable insights to optimize their processes and reduce waste[6].

Strengths: Unique capability for high-temperature applications, robust sensor design for harsh environments. Weaknesses: Potentially limited to specific high-temperature manufacturing processes, may require significant adaptation for integration into existing production lines.

Core Piezo Innovations

In-Process Monitoring for Composite Parts Quality Control Using Piezoelectric Wafer Active Sensors (PWAS) Technologies

PatentInactiveUS20120280414A1

Innovation

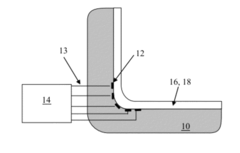

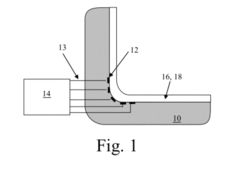

- Embedding piezoelectric wafer active sensors (PWAS) into molds allows for in-situ, non-intrusive monitoring of composite materials during curing, using methods like thickness mode, electromechanical impedance spectroscopy, and phased arrays to detect defects such as air bubbles, delamination, and resin cure status without adhesives or couplants, enabling reusable molds for improved quality control.

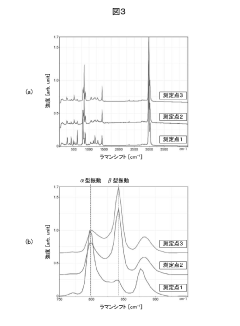

Quality management method for polymer piezoelectric material, manufacturing method for resin composition, manufacturing method for cable or tube, manufacturing method for piezoelectric element, manufacturing method for pyroelectric type sensor, and manufacturing method for nonvolatile thin film memory

PatentActiveJP2022080001A

Innovation

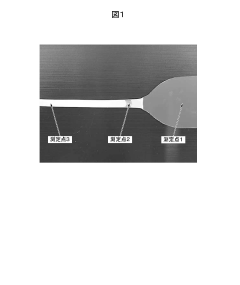

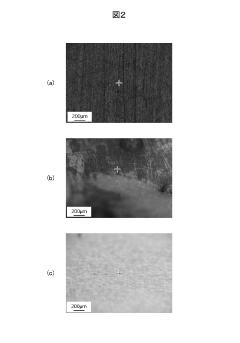

- Irradiate the polymeric piezoelectric material with a laser beam to measure the Raman spectrum, diagnosing piezoelectric performance based on the intensity of specific peaks, allowing non-destructive quality control and retention of original shape information.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing piezoelectric sensors for quality control in manufacturing. Manufacturers must adhere to various standards and regulations to ensure the safety, reliability, and effectiveness of their quality control processes.

One of the primary regulatory bodies governing the use of piezoelectric sensors in manufacturing is the International Electrotechnical Commission (IEC). The IEC has established several standards relevant to piezoelectric sensors, including IEC 60747-14-4, which specifies the measurement methods for piezoelectric sensors. Compliance with these standards ensures that the sensors meet specific performance criteria and can be reliably used in quality control applications.

In the United States, the Occupational Safety and Health Administration (OSHA) has regulations that indirectly affect the use of piezoelectric sensors in manufacturing. OSHA's standards for machine guarding and equipment safety must be considered when integrating these sensors into production lines. Additionally, the Food and Drug Administration (FDA) has specific requirements for quality control in industries such as pharmaceuticals and medical devices, which may impact the implementation of piezoelectric sensor-based systems.

The European Union's Machinery Directive (2006/42/EC) is another important regulatory framework that manufacturers must consider. This directive sets out essential health and safety requirements for machinery, including quality control equipment. Piezoelectric sensor systems used in manufacturing must comply with these requirements to be legally marketed and used within the EU.

Environmental regulations also play a role in the use of piezoelectric sensors for quality control. The Restriction of Hazardous Substances (RoHS) directive, for instance, limits the use of certain hazardous materials in electrical and electronic equipment. Manufacturers must ensure that their piezoelectric sensor systems comply with these restrictions.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the US, may also apply to quality control systems that collect and process data using piezoelectric sensors. Manufacturers must implement appropriate data protection measures and ensure compliance with these regulations when handling sensitive production data.

To maintain regulatory compliance, manufacturers should establish a comprehensive quality management system that incorporates regular audits, documentation of processes, and continuous monitoring of regulatory changes. This approach helps ensure that the use of piezoelectric sensors for quality control remains in line with evolving regulatory requirements across different jurisdictions.

One of the primary regulatory bodies governing the use of piezoelectric sensors in manufacturing is the International Electrotechnical Commission (IEC). The IEC has established several standards relevant to piezoelectric sensors, including IEC 60747-14-4, which specifies the measurement methods for piezoelectric sensors. Compliance with these standards ensures that the sensors meet specific performance criteria and can be reliably used in quality control applications.

In the United States, the Occupational Safety and Health Administration (OSHA) has regulations that indirectly affect the use of piezoelectric sensors in manufacturing. OSHA's standards for machine guarding and equipment safety must be considered when integrating these sensors into production lines. Additionally, the Food and Drug Administration (FDA) has specific requirements for quality control in industries such as pharmaceuticals and medical devices, which may impact the implementation of piezoelectric sensor-based systems.

The European Union's Machinery Directive (2006/42/EC) is another important regulatory framework that manufacturers must consider. This directive sets out essential health and safety requirements for machinery, including quality control equipment. Piezoelectric sensor systems used in manufacturing must comply with these requirements to be legally marketed and used within the EU.

Environmental regulations also play a role in the use of piezoelectric sensors for quality control. The Restriction of Hazardous Substances (RoHS) directive, for instance, limits the use of certain hazardous materials in electrical and electronic equipment. Manufacturers must ensure that their piezoelectric sensor systems comply with these restrictions.

Data privacy and security regulations, such as the General Data Protection Regulation (GDPR) in the EU and the California Consumer Privacy Act (CCPA) in the US, may also apply to quality control systems that collect and process data using piezoelectric sensors. Manufacturers must implement appropriate data protection measures and ensure compliance with these regulations when handling sensitive production data.

To maintain regulatory compliance, manufacturers should establish a comprehensive quality management system that incorporates regular audits, documentation of processes, and continuous monitoring of regulatory changes. This approach helps ensure that the use of piezoelectric sensors for quality control remains in line with evolving regulatory requirements across different jurisdictions.

Cost-Benefit Analysis

The implementation of piezoelectric sensors for quality control in manufacturing processes presents a compelling cost-benefit proposition. Initial investment costs for sensor hardware, installation, and integration with existing systems can be substantial. However, these upfront expenses are often outweighed by long-term savings and operational improvements.

One of the primary benefits is the reduction in defective products and waste. Piezoelectric sensors enable real-time monitoring and detection of manufacturing anomalies, allowing for immediate corrective actions. This leads to a significant decrease in scrap rates and rework costs. Studies have shown that implementing advanced sensor-based quality control systems can reduce defect rates by up to 30%, translating to substantial cost savings over time.

Enhanced product quality resulting from piezoelectric sensor implementation can lead to increased customer satisfaction and brand reputation. This, in turn, can drive sales growth and potentially command premium pricing, further improving the return on investment. Additionally, the ability to consistently produce high-quality goods can reduce warranty claims and associated costs.

Operational efficiency gains represent another key benefit. Piezoelectric sensors enable predictive maintenance by detecting early signs of equipment wear or malfunction. This proactive approach can significantly reduce unplanned downtime and extend the lifespan of manufacturing equipment. Some industries report up to 20% reduction in maintenance costs and 50% decrease in unexpected breakdowns after implementing sensor-based monitoring systems.

Labor costs can also be optimized through the use of piezoelectric sensors. Automated quality control reduces the need for manual inspections, allowing reallocation of human resources to more value-added tasks. While this may require initial training investments, it often results in improved workforce productivity and job satisfaction.

Energy efficiency improvements are another consideration. Piezoelectric sensors can help optimize machine operations, reducing energy consumption in manufacturing processes. This not only lowers utility costs but also aligns with sustainability goals, potentially opening access to green manufacturing incentives or certifications.

When evaluating the cost-benefit analysis, it's crucial to consider the scalability of piezoelectric sensor solutions. As production volumes increase, the per-unit cost of quality control typically decreases, enhancing the overall return on investment. Furthermore, the data collected by these sensors can provide valuable insights for continuous process improvement, driving ongoing efficiency gains and cost reductions.

One of the primary benefits is the reduction in defective products and waste. Piezoelectric sensors enable real-time monitoring and detection of manufacturing anomalies, allowing for immediate corrective actions. This leads to a significant decrease in scrap rates and rework costs. Studies have shown that implementing advanced sensor-based quality control systems can reduce defect rates by up to 30%, translating to substantial cost savings over time.

Enhanced product quality resulting from piezoelectric sensor implementation can lead to increased customer satisfaction and brand reputation. This, in turn, can drive sales growth and potentially command premium pricing, further improving the return on investment. Additionally, the ability to consistently produce high-quality goods can reduce warranty claims and associated costs.

Operational efficiency gains represent another key benefit. Piezoelectric sensors enable predictive maintenance by detecting early signs of equipment wear or malfunction. This proactive approach can significantly reduce unplanned downtime and extend the lifespan of manufacturing equipment. Some industries report up to 20% reduction in maintenance costs and 50% decrease in unexpected breakdowns after implementing sensor-based monitoring systems.

Labor costs can also be optimized through the use of piezoelectric sensors. Automated quality control reduces the need for manual inspections, allowing reallocation of human resources to more value-added tasks. While this may require initial training investments, it often results in improved workforce productivity and job satisfaction.

Energy efficiency improvements are another consideration. Piezoelectric sensors can help optimize machine operations, reducing energy consumption in manufacturing processes. This not only lowers utility costs but also aligns with sustainability goals, potentially opening access to green manufacturing incentives or certifications.

When evaluating the cost-benefit analysis, it's crucial to consider the scalability of piezoelectric sensor solutions. As production volumes increase, the per-unit cost of quality control typically decreases, enhancing the overall return on investment. Furthermore, the data collected by these sensors can provide valuable insights for continuous process improvement, driving ongoing efficiency gains and cost reductions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!