Real-time Data Processing with Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensing Evolution and Objectives

Piezoelectric sensing technology has undergone significant evolution since its discovery in the late 19th century. The journey from basic piezoelectric materials to advanced real-time data processing systems represents a remarkable progression in sensing capabilities. Initially, piezoelectric effects were primarily used in simple transducers and actuators. However, as the understanding of materials science and electrical engineering advanced, so did the applications of piezoelectric sensors.

The early 20th century saw the development of quartz crystal resonators, which laid the foundation for precise frequency control in electronic devices. This breakthrough paved the way for more sophisticated piezoelectric sensing applications. By the mid-20th century, piezoelectric sensors found their way into industrial and military applications, particularly in pressure and acceleration measurements.

The advent of semiconductor technology in the latter half of the 20th century brought about a revolution in piezoelectric sensing. Integration of piezoelectric sensors with microelectronics enabled the creation of more compact, sensitive, and versatile sensing systems. This integration marked the beginning of modern piezoelectric sensing, where real-time data processing became a possibility.

In recent decades, the focus has shifted towards developing advanced piezoelectric materials and improving signal processing techniques. New materials like lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) have expanded the range of sensing applications. Simultaneously, advancements in digital signal processing and data analytics have enhanced the ability to extract meaningful information from piezoelectric sensor outputs in real-time.

The current objectives in piezoelectric sensing and real-time data processing are multifaceted. One primary goal is to enhance the sensitivity and accuracy of sensors while minimizing noise and interference. This involves developing more efficient piezoelectric materials and refining sensor designs to capture even the slightest variations in physical parameters.

Another crucial objective is to improve the speed and efficiency of data processing. As applications demand increasingly rapid response times, there is a push towards developing algorithms and hardware capable of processing vast amounts of sensor data with minimal latency. This includes leveraging edge computing and artificial intelligence to enable real-time decision-making based on sensor inputs.

Miniaturization and energy efficiency form another key focus area. The aim is to create smaller, more power-efficient piezoelectric sensing systems that can be integrated into a wide range of devices and environments. This is particularly important for applications in wearable technology, IoT devices, and autonomous systems.

Lastly, there is a growing emphasis on developing multi-modal sensing capabilities. By combining piezoelectric sensors with other sensing technologies and advanced data fusion techniques, researchers aim to create more comprehensive and context-aware sensing systems. This holistic approach to sensing and data processing is expected to open up new possibilities in fields such as healthcare, structural health monitoring, and smart manufacturing.

The early 20th century saw the development of quartz crystal resonators, which laid the foundation for precise frequency control in electronic devices. This breakthrough paved the way for more sophisticated piezoelectric sensing applications. By the mid-20th century, piezoelectric sensors found their way into industrial and military applications, particularly in pressure and acceleration measurements.

The advent of semiconductor technology in the latter half of the 20th century brought about a revolution in piezoelectric sensing. Integration of piezoelectric sensors with microelectronics enabled the creation of more compact, sensitive, and versatile sensing systems. This integration marked the beginning of modern piezoelectric sensing, where real-time data processing became a possibility.

In recent decades, the focus has shifted towards developing advanced piezoelectric materials and improving signal processing techniques. New materials like lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) have expanded the range of sensing applications. Simultaneously, advancements in digital signal processing and data analytics have enhanced the ability to extract meaningful information from piezoelectric sensor outputs in real-time.

The current objectives in piezoelectric sensing and real-time data processing are multifaceted. One primary goal is to enhance the sensitivity and accuracy of sensors while minimizing noise and interference. This involves developing more efficient piezoelectric materials and refining sensor designs to capture even the slightest variations in physical parameters.

Another crucial objective is to improve the speed and efficiency of data processing. As applications demand increasingly rapid response times, there is a push towards developing algorithms and hardware capable of processing vast amounts of sensor data with minimal latency. This includes leveraging edge computing and artificial intelligence to enable real-time decision-making based on sensor inputs.

Miniaturization and energy efficiency form another key focus area. The aim is to create smaller, more power-efficient piezoelectric sensing systems that can be integrated into a wide range of devices and environments. This is particularly important for applications in wearable technology, IoT devices, and autonomous systems.

Lastly, there is a growing emphasis on developing multi-modal sensing capabilities. By combining piezoelectric sensors with other sensing technologies and advanced data fusion techniques, researchers aim to create more comprehensive and context-aware sensing systems. This holistic approach to sensing and data processing is expected to open up new possibilities in fields such as healthcare, structural health monitoring, and smart manufacturing.

Market Demand for Real-time Data Processing

The market demand for real-time data processing with piezoelectric sensors has been experiencing significant growth across various industries. This surge is primarily driven by the increasing need for instant insights and rapid decision-making capabilities in sectors such as manufacturing, healthcare, automotive, and aerospace.

In the manufacturing sector, real-time data processing from piezoelectric sensors enables predictive maintenance, quality control, and process optimization. Companies are leveraging this technology to reduce downtime, improve product quality, and enhance overall operational efficiency. The automotive industry is also embracing this technology for applications like tire pressure monitoring, engine performance analysis, and advanced driver assistance systems.

The healthcare sector has shown a growing interest in real-time data processing with piezoelectric sensors for patient monitoring, rehabilitation, and medical diagnostics. These sensors provide continuous, non-invasive measurements of vital signs and movement patterns, allowing for more accurate and timely interventions.

In the aerospace industry, real-time data processing from piezoelectric sensors is crucial for structural health monitoring of aircraft components, enhancing safety and reducing maintenance costs. The technology is also being applied in smart infrastructure projects for monitoring the structural integrity of bridges, buildings, and other critical structures.

The Internet of Things (IoT) and Industry 4.0 initiatives are further fueling the demand for real-time data processing capabilities. As more devices become interconnected, the ability to process and analyze data in real-time becomes increasingly valuable for optimizing operations and improving decision-making processes.

The market for real-time data processing with piezoelectric sensors is expected to continue its growth trajectory in the coming years. Factors contributing to this growth include advancements in sensor technology, increasing adoption of edge computing, and the development of more sophisticated data analytics algorithms.

However, challenges such as data security concerns, integration complexities, and the need for specialized expertise may impact market growth. Companies and organizations looking to implement these solutions will need to address these challenges to fully realize the benefits of real-time data processing with piezoelectric sensors.

As the technology matures and becomes more accessible, new applications and use cases are likely to emerge, further expanding the market potential. The convergence of real-time data processing with artificial intelligence and machine learning is expected to create even more opportunities for innovation and value creation across industries.

In the manufacturing sector, real-time data processing from piezoelectric sensors enables predictive maintenance, quality control, and process optimization. Companies are leveraging this technology to reduce downtime, improve product quality, and enhance overall operational efficiency. The automotive industry is also embracing this technology for applications like tire pressure monitoring, engine performance analysis, and advanced driver assistance systems.

The healthcare sector has shown a growing interest in real-time data processing with piezoelectric sensors for patient monitoring, rehabilitation, and medical diagnostics. These sensors provide continuous, non-invasive measurements of vital signs and movement patterns, allowing for more accurate and timely interventions.

In the aerospace industry, real-time data processing from piezoelectric sensors is crucial for structural health monitoring of aircraft components, enhancing safety and reducing maintenance costs. The technology is also being applied in smart infrastructure projects for monitoring the structural integrity of bridges, buildings, and other critical structures.

The Internet of Things (IoT) and Industry 4.0 initiatives are further fueling the demand for real-time data processing capabilities. As more devices become interconnected, the ability to process and analyze data in real-time becomes increasingly valuable for optimizing operations and improving decision-making processes.

The market for real-time data processing with piezoelectric sensors is expected to continue its growth trajectory in the coming years. Factors contributing to this growth include advancements in sensor technology, increasing adoption of edge computing, and the development of more sophisticated data analytics algorithms.

However, challenges such as data security concerns, integration complexities, and the need for specialized expertise may impact market growth. Companies and organizations looking to implement these solutions will need to address these challenges to fully realize the benefits of real-time data processing with piezoelectric sensors.

As the technology matures and becomes more accessible, new applications and use cases are likely to emerge, further expanding the market potential. The convergence of real-time data processing with artificial intelligence and machine learning is expected to create even more opportunities for innovation and value creation across industries.

Current Challenges in Piezoelectric Sensor Technology

Piezoelectric sensor technology has made significant strides in recent years, yet several challenges persist in achieving optimal real-time data processing capabilities. One of the primary obstacles is the inherent noise sensitivity of piezoelectric sensors. These devices are susceptible to various forms of interference, including electromagnetic noise, mechanical vibrations, and thermal fluctuations. This sensitivity can lead to signal distortion and reduced accuracy in data interpretation, particularly in high-precision applications.

Another significant challenge lies in the limited bandwidth of current piezoelectric sensor systems. While these sensors excel at detecting rapid changes in pressure or force, they often struggle to maintain consistent performance across a wide frequency range. This limitation can result in data loss or misinterpretation, especially when dealing with complex, multi-frequency signals in real-time processing scenarios.

The issue of sensor drift presents a further hurdle in long-term data acquisition and processing. Piezoelectric sensors are prone to gradual changes in their baseline output over time, which can introduce errors in measurements and complicate data analysis. This drift can be attributed to various factors, including temperature variations, material aging, and environmental conditions, making it challenging to maintain consistent sensor performance over extended periods.

Power consumption remains a critical concern, particularly in wireless and portable applications. The need for continuous real-time data processing often conflicts with the desire for low-power operation, creating a significant design challenge. Balancing processing capabilities with energy efficiency is crucial for the widespread adoption of piezoelectric sensor technology in battery-powered devices and IoT applications.

Data integration and fusion pose additional challenges in multi-sensor systems. Combining data from multiple piezoelectric sensors with other sensor types (e.g., accelerometers, gyroscopes) in real-time requires sophisticated algorithms and processing capabilities. Ensuring seamless integration and accurate interpretation of diverse data streams remains a complex task, especially in dynamic environments where sensor inputs may vary rapidly.

Lastly, the miniaturization of piezoelectric sensors and associated processing units presents ongoing challenges. As applications demand smaller form factors, maintaining sensor sensitivity and processing power while reducing size becomes increasingly difficult. This miniaturization effort often involves trade-offs between performance, power consumption, and physical dimensions, requiring innovative solutions in both sensor design and data processing techniques.

Another significant challenge lies in the limited bandwidth of current piezoelectric sensor systems. While these sensors excel at detecting rapid changes in pressure or force, they often struggle to maintain consistent performance across a wide frequency range. This limitation can result in data loss or misinterpretation, especially when dealing with complex, multi-frequency signals in real-time processing scenarios.

The issue of sensor drift presents a further hurdle in long-term data acquisition and processing. Piezoelectric sensors are prone to gradual changes in their baseline output over time, which can introduce errors in measurements and complicate data analysis. This drift can be attributed to various factors, including temperature variations, material aging, and environmental conditions, making it challenging to maintain consistent sensor performance over extended periods.

Power consumption remains a critical concern, particularly in wireless and portable applications. The need for continuous real-time data processing often conflicts with the desire for low-power operation, creating a significant design challenge. Balancing processing capabilities with energy efficiency is crucial for the widespread adoption of piezoelectric sensor technology in battery-powered devices and IoT applications.

Data integration and fusion pose additional challenges in multi-sensor systems. Combining data from multiple piezoelectric sensors with other sensor types (e.g., accelerometers, gyroscopes) in real-time requires sophisticated algorithms and processing capabilities. Ensuring seamless integration and accurate interpretation of diverse data streams remains a complex task, especially in dynamic environments where sensor inputs may vary rapidly.

Lastly, the miniaturization of piezoelectric sensors and associated processing units presents ongoing challenges. As applications demand smaller form factors, maintaining sensor sensitivity and processing power while reducing size becomes increasingly difficult. This miniaturization effort often involves trade-offs between performance, power consumption, and physical dimensions, requiring innovative solutions in both sensor design and data processing techniques.

Existing Real-time Processing Solutions

01 Signal processing and analysis techniques

Various signal processing and analysis techniques are employed to extract meaningful information from piezoelectric sensor data. These methods include filtering, amplification, and advanced algorithms for noise reduction and feature extraction. The processed data is then used for applications such as vibration analysis, structural health monitoring, and fault detection.- Signal processing and analysis techniques: Various signal processing and analysis techniques are employed to extract meaningful information from piezoelectric sensor data. These methods include filtering, amplification, and advanced algorithms for noise reduction and feature extraction. The processed data is then used for applications such as vibration analysis, structural health monitoring, and fault detection.

- Data acquisition and conversion systems: Specialized data acquisition systems are used to collect and convert analog signals from piezoelectric sensors into digital format. These systems often incorporate high-resolution analog-to-digital converters, multiplexers, and microcontrollers to efficiently capture and process sensor data in real-time.

- Machine learning and AI integration: Machine learning algorithms and artificial intelligence techniques are increasingly being applied to piezoelectric sensor data processing. These advanced methods enable improved pattern recognition, predictive maintenance, and anomaly detection in various applications, enhancing the overall performance and reliability of sensor-based systems.

- Wireless sensor networks and IoT integration: Piezoelectric sensors are being integrated into wireless sensor networks and Internet of Things (IoT) ecosystems. This integration allows for distributed data processing, remote monitoring, and real-time data analysis across multiple sensors, enabling more comprehensive and efficient monitoring of complex systems.

- Energy harvesting and self-powered sensors: Advancements in piezoelectric sensor technology have led to the development of energy harvesting systems and self-powered sensors. These innovations utilize the piezoelectric effect to generate power from ambient vibrations, enabling long-term, maintenance-free operation of sensor networks in remote or inaccessible locations.

02 Data acquisition and conversion systems

Specialized data acquisition systems are designed to capture and convert analog signals from piezoelectric sensors into digital format. These systems often incorporate high-resolution analog-to-digital converters, multiplexers, and microcontrollers to efficiently collect and process data from multiple sensors simultaneously.Expand Specific Solutions03 Machine learning and AI integration

Machine learning algorithms and artificial intelligence techniques are increasingly being applied to piezoelectric sensor data processing. These advanced methods enable improved pattern recognition, predictive maintenance, and anomaly detection in various applications, such as industrial monitoring and smart infrastructure.Expand Specific Solutions04 Wireless sensor networks and IoT integration

Piezoelectric sensors are being integrated into wireless sensor networks and Internet of Things (IoT) ecosystems. This integration allows for real-time data transmission, remote monitoring, and cloud-based data processing, enabling more efficient and scalable sensor data management and analysis.Expand Specific Solutions05 Energy harvesting and self-powered systems

Piezoelectric sensors are being developed with integrated energy harvesting capabilities, allowing them to generate power from ambient vibrations. This enables the creation of self-powered sensor systems that can operate autonomously for extended periods, reducing maintenance requirements and expanding their potential applications.Expand Specific Solutions

Key Players in Piezoelectric Sensing Industry

The real-time data processing with piezoelectric sensors market is in a growth phase, driven by increasing demand for high-performance sensing solutions across various industries. The global market size is projected to expand significantly in the coming years, fueled by advancements in sensor technology and growing applications in automotive, aerospace, and industrial sectors. While the technology is relatively mature, ongoing research and development efforts by key players are enhancing its capabilities and expanding its potential use cases. Companies like PCB Piezotronics, Kistler Holding AG, and Texas Instruments are at the forefront of innovation, developing advanced sensor solutions and data processing techniques. Academic institutions such as Chongqing University and Industrial Technology Research Institute are also contributing to the field through research collaborations and technology transfer initiatives.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced solutions for real-time data processing with piezoelectric sensors, particularly in automotive and industrial applications. Their MEMS (Micro-Electro-Mechanical Systems) accelerometers and gyroscopes incorporate piezoelectric sensing elements, offering high-speed data acquisition with sampling rates up to 6.4 kHz for real-time motion and vibration analysis[1]. Bosch's engine management systems utilize piezoelectric pressure sensors for real-time combustion monitoring, enabling precise control of fuel injection and ignition timing with response times under 100 μs[2]. The company's Inertial Measurement Units (IMUs) combine multiple piezoelectric sensors with integrated signal processing, providing real-time 6-axis motion sensing for autonomous vehicles and robotics applications[3]. Bosch also offers industrial condition monitoring solutions using piezoelectric vibration sensors, with edge computing capabilities for real-time analysis and predictive maintenance[4].

Strengths: Extensive automotive and industrial expertise, high-performance sensing solutions, and integrated systems approach. Weaknesses: Some solutions may be optimized for specific industries, potentially limiting broader applicability, and may have higher costs for non-automotive applications.

Kistler Holding AG

Technical Solution: Kistler Holding AG has developed advanced piezoelectric sensor systems for real-time data processing in various applications. Their technology utilizes high-performance quartz sensors and integrated electronics for precise measurements. The company's PiezoSmart® technology enables automatic sensor recognition and simplified setup, reducing configuration time by up to 70%[1]. Kistler's real-time data processing solutions incorporate advanced signal conditioning and amplification techniques, allowing for high-speed data acquisition rates of up to 1 MHz[2]. Their systems also feature built-in digital signal processing capabilities, enabling on-board data analysis and filtering to reduce latency and improve overall system responsiveness[3].

Strengths: High precision measurements, fast data acquisition rates, and integrated signal processing. Weaknesses: Potentially higher cost compared to simpler sensor solutions, and may require specialized knowledge for optimal implementation.

Core Innovations in Piezoelectric Data Processing

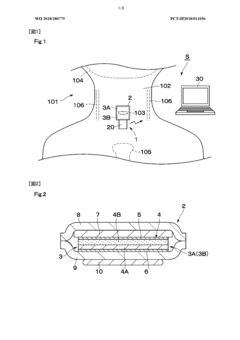

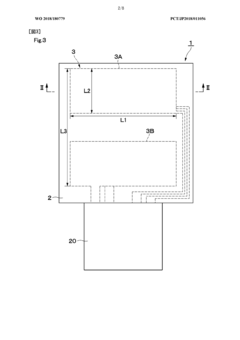

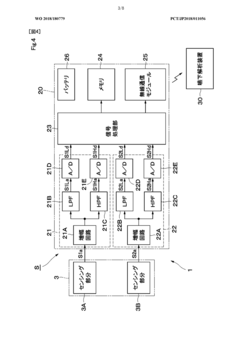

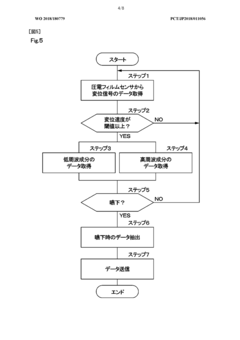

Swallowing analysis system

PatentWO2018180779A1

Innovation

- A swallowing analysis system utilizing a piezoelectric element attached to the anterior neck, which detects displacement signals associated with swallowing, separates signals into low and high frequency components, and wirelessly transmits data for real-time analysis, reducing power consumption and eliminating cable-related issues.

Method and device for monitoring an aircraft structure

PatentWO2006111679A2

Innovation

- A permanent monitoring system using piezoelectric sensors powered by avionics to record and process acoustic measurements of impacts and stresses throughout an aircraft's life, both on the ground and in flight, allowing for continuous data collection and analysis of transient phenomena.

Energy Harvesting Potential of Piezoelectric Sensors

Piezoelectric sensors have emerged as a promising technology for energy harvesting, offering the potential to convert mechanical energy from vibrations, pressure, or strain into electrical energy. This capability opens up new possibilities for self-powered devices and systems, particularly in applications where traditional power sources are impractical or insufficient.

The energy harvesting potential of piezoelectric sensors is rooted in their unique material properties. When subjected to mechanical stress, these materials generate an electric charge, a phenomenon known as the piezoelectric effect. This direct conversion of mechanical energy to electrical energy can be harnessed to power low-energy devices or supplement existing power sources.

In the context of real-time data processing, the energy harvesting capabilities of piezoelectric sensors present several advantages. Firstly, they can potentially eliminate or reduce the need for external power sources in sensor networks, leading to more autonomous and sustainable systems. This is particularly valuable in remote or hard-to-reach locations where regular battery replacement is challenging.

Furthermore, the energy harvesting potential of piezoelectric sensors aligns well with the growing trend of Internet of Things (IoT) devices and edge computing. These applications often require distributed, low-power sensors that can operate independently for extended periods. By harvesting energy from their environment, piezoelectric sensors can extend the operational life of such devices and reduce maintenance requirements.

Recent advancements in materials science and nanofabrication techniques have significantly improved the energy conversion efficiency of piezoelectric materials. Novel piezoelectric nanostructures, such as nanowires and nanofibers, have demonstrated enhanced energy harvesting capabilities compared to bulk materials. These developments are paving the way for more efficient and compact energy harvesting solutions.

However, challenges remain in fully realizing the energy harvesting potential of piezoelectric sensors for real-time data processing applications. One key issue is the typically low power output of individual piezoelectric elements, which may be insufficient for powering more energy-intensive processing tasks. To address this, researchers are exploring various strategies, including the use of piezoelectric arrays, hybrid energy harvesting systems, and advanced power management circuits.

Another consideration is the need to balance energy harvesting with the primary sensing function of piezoelectric devices. Optimizing the design and configuration of piezoelectric sensors to effectively perform both energy harvesting and sensing tasks simultaneously is an active area of research. This dual functionality could lead to more efficient and compact sensor systems for real-time data processing applications.

The energy harvesting potential of piezoelectric sensors is rooted in their unique material properties. When subjected to mechanical stress, these materials generate an electric charge, a phenomenon known as the piezoelectric effect. This direct conversion of mechanical energy to electrical energy can be harnessed to power low-energy devices or supplement existing power sources.

In the context of real-time data processing, the energy harvesting capabilities of piezoelectric sensors present several advantages. Firstly, they can potentially eliminate or reduce the need for external power sources in sensor networks, leading to more autonomous and sustainable systems. This is particularly valuable in remote or hard-to-reach locations where regular battery replacement is challenging.

Furthermore, the energy harvesting potential of piezoelectric sensors aligns well with the growing trend of Internet of Things (IoT) devices and edge computing. These applications often require distributed, low-power sensors that can operate independently for extended periods. By harvesting energy from their environment, piezoelectric sensors can extend the operational life of such devices and reduce maintenance requirements.

Recent advancements in materials science and nanofabrication techniques have significantly improved the energy conversion efficiency of piezoelectric materials. Novel piezoelectric nanostructures, such as nanowires and nanofibers, have demonstrated enhanced energy harvesting capabilities compared to bulk materials. These developments are paving the way for more efficient and compact energy harvesting solutions.

However, challenges remain in fully realizing the energy harvesting potential of piezoelectric sensors for real-time data processing applications. One key issue is the typically low power output of individual piezoelectric elements, which may be insufficient for powering more energy-intensive processing tasks. To address this, researchers are exploring various strategies, including the use of piezoelectric arrays, hybrid energy harvesting systems, and advanced power management circuits.

Another consideration is the need to balance energy harvesting with the primary sensing function of piezoelectric devices. Optimizing the design and configuration of piezoelectric sensors to effectively perform both energy harvesting and sensing tasks simultaneously is an active area of research. This dual functionality could lead to more efficient and compact sensor systems for real-time data processing applications.

Cybersecurity in Real-time Sensor Networks

Cybersecurity in real-time sensor networks has become a critical concern as the adoption of piezoelectric sensors for real-time data processing continues to grow. These networks, which rely on the rapid transmission and analysis of sensitive data, are increasingly vulnerable to a wide range of cyber threats. The interconnected nature of these systems, often operating in industrial or critical infrastructure environments, makes them attractive targets for malicious actors seeking to disrupt operations or gain unauthorized access to valuable information.

One of the primary challenges in securing real-time sensor networks is the need to balance robust security measures with the low-latency requirements of real-time data processing. Traditional security protocols and encryption methods may introduce unacceptable delays, compromising the effectiveness of the sensor network. As a result, researchers and industry professionals are developing specialized security solutions tailored to the unique needs of these systems.

Authentication and access control mechanisms play a crucial role in protecting real-time sensor networks. Implementing strong authentication protocols ensures that only authorized devices and users can interact with the network, reducing the risk of unauthorized access or data manipulation. However, these mechanisms must be designed to operate efficiently within the constraints of real-time processing, utilizing lightweight cryptographic algorithms and optimized key management systems.

Data integrity and confidentiality are also paramount concerns in real-time sensor networks. Encryption techniques must be carefully selected to provide adequate protection without introducing significant processing overhead. Many organizations are exploring the use of hardware-based encryption solutions, leveraging the capabilities of specialized chips to offload cryptographic operations from the main processor.

Network segmentation and intrusion detection systems (IDS) are increasingly being deployed to enhance the security of real-time sensor networks. By dividing the network into smaller, isolated segments, organizations can limit the potential impact of a security breach and more easily monitor for suspicious activities. Advanced IDS solutions, specifically designed for industrial control systems and sensor networks, can detect anomalies in real-time data streams and alert operators to potential security threats.

As the threat landscape continues to evolve, machine learning and artificial intelligence are being integrated into cybersecurity solutions for real-time sensor networks. These technologies can help identify complex attack patterns, predict potential vulnerabilities, and automate response mechanisms to emerging threats. However, the implementation of AI-driven security measures must be carefully balanced against the need for transparency and human oversight in critical systems.

One of the primary challenges in securing real-time sensor networks is the need to balance robust security measures with the low-latency requirements of real-time data processing. Traditional security protocols and encryption methods may introduce unacceptable delays, compromising the effectiveness of the sensor network. As a result, researchers and industry professionals are developing specialized security solutions tailored to the unique needs of these systems.

Authentication and access control mechanisms play a crucial role in protecting real-time sensor networks. Implementing strong authentication protocols ensures that only authorized devices and users can interact with the network, reducing the risk of unauthorized access or data manipulation. However, these mechanisms must be designed to operate efficiently within the constraints of real-time processing, utilizing lightweight cryptographic algorithms and optimized key management systems.

Data integrity and confidentiality are also paramount concerns in real-time sensor networks. Encryption techniques must be carefully selected to provide adequate protection without introducing significant processing overhead. Many organizations are exploring the use of hardware-based encryption solutions, leveraging the capabilities of specialized chips to offload cryptographic operations from the main processor.

Network segmentation and intrusion detection systems (IDS) are increasingly being deployed to enhance the security of real-time sensor networks. By dividing the network into smaller, isolated segments, organizations can limit the potential impact of a security breach and more easily monitor for suspicious activities. Advanced IDS solutions, specifically designed for industrial control systems and sensor networks, can detect anomalies in real-time data streams and alert operators to potential security threats.

As the threat landscape continues to evolve, machine learning and artificial intelligence are being integrated into cybersecurity solutions for real-time sensor networks. These technologies can help identify complex attack patterns, predict potential vulnerabilities, and automate response mechanisms to emerging threats. However, the implementation of AI-driven security measures must be carefully balanced against the need for transparency and human oversight in critical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!