Enhanced Ergonomics in Wearable Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Evolution and Objectives

Piezoelectric sensors have undergone significant evolution since their inception in the early 20th century. Initially discovered by the Curie brothers in 1880, the piezoelectric effect has been harnessed for various sensing applications. The technology has progressed from simple quartz crystals to advanced synthetic materials, enabling a wide range of applications in industries such as automotive, aerospace, and healthcare.

In the context of wearable technology, piezoelectric sensors have gained prominence due to their ability to convert mechanical stress into electrical signals, making them ideal for monitoring human body movements and physiological parameters. The evolution of these sensors in wearable applications has been driven by the need for miniaturization, flexibility, and improved sensitivity.

Early wearable piezoelectric sensors were rigid and bulky, limiting their practical use in everyday scenarios. However, advancements in materials science and fabrication techniques have led to the development of flexible and stretchable piezoelectric materials, such as polyvinylidene fluoride (PVDF) and its copolymers. These innovations have paved the way for more comfortable and unobtrusive wearable devices.

The objectives of enhanced ergonomics in wearable piezoelectric sensors are multifaceted. Primarily, researchers aim to improve the user experience by developing sensors that seamlessly integrate with the human body. This involves creating sensors that are lightweight, flexible, and capable of conforming to various body contours without causing discomfort or restricting movement.

Another key objective is to enhance the durability and reliability of these sensors in real-world conditions. Wearable devices are subjected to constant movement, sweat, and environmental factors, necessitating the development of robust sensor designs that can withstand these challenges while maintaining accurate measurements over extended periods.

Improving the sensitivity and accuracy of piezoelectric sensors in wearable applications is also a critical goal. Researchers are exploring novel materials and sensor architectures to enhance the signal-to-noise ratio and minimize interference from external factors. This is particularly important for applications requiring precise measurements, such as health monitoring and sports performance analysis.

Furthermore, the integration of piezoelectric sensors with other sensing modalities and wireless communication technologies is a significant objective. This aims to create comprehensive wearable systems capable of collecting and transmitting a wide range of physiological and environmental data in real-time, enabling more sophisticated and personalized applications in healthcare, fitness, and human-computer interaction.

In the context of wearable technology, piezoelectric sensors have gained prominence due to their ability to convert mechanical stress into electrical signals, making them ideal for monitoring human body movements and physiological parameters. The evolution of these sensors in wearable applications has been driven by the need for miniaturization, flexibility, and improved sensitivity.

Early wearable piezoelectric sensors were rigid and bulky, limiting their practical use in everyday scenarios. However, advancements in materials science and fabrication techniques have led to the development of flexible and stretchable piezoelectric materials, such as polyvinylidene fluoride (PVDF) and its copolymers. These innovations have paved the way for more comfortable and unobtrusive wearable devices.

The objectives of enhanced ergonomics in wearable piezoelectric sensors are multifaceted. Primarily, researchers aim to improve the user experience by developing sensors that seamlessly integrate with the human body. This involves creating sensors that are lightweight, flexible, and capable of conforming to various body contours without causing discomfort or restricting movement.

Another key objective is to enhance the durability and reliability of these sensors in real-world conditions. Wearable devices are subjected to constant movement, sweat, and environmental factors, necessitating the development of robust sensor designs that can withstand these challenges while maintaining accurate measurements over extended periods.

Improving the sensitivity and accuracy of piezoelectric sensors in wearable applications is also a critical goal. Researchers are exploring novel materials and sensor architectures to enhance the signal-to-noise ratio and minimize interference from external factors. This is particularly important for applications requiring precise measurements, such as health monitoring and sports performance analysis.

Furthermore, the integration of piezoelectric sensors with other sensing modalities and wireless communication technologies is a significant objective. This aims to create comprehensive wearable systems capable of collecting and transmitting a wide range of physiological and environmental data in real-time, enabling more sophisticated and personalized applications in healthcare, fitness, and human-computer interaction.

Wearable Ergonomics Market Analysis

The wearable ergonomics market has experienced significant growth in recent years, driven by increasing awareness of health and wellness, technological advancements, and the rising demand for personalized healthcare solutions. The global market for wearable ergonomic devices, including piezoelectric sensors, is projected to expand at a robust pace over the coming years.

A key factor fueling market growth is the growing prevalence of musculoskeletal disorders and repetitive strain injuries, particularly in workplace settings. This has led to a surge in demand for ergonomic solutions that can monitor and improve posture, reduce physical strain, and enhance overall comfort during daily activities. Wearable piezoelectric sensors, with their ability to detect and measure pressure and movement, are well-positioned to address these needs.

The healthcare sector represents a significant portion of the wearable ergonomics market, with applications ranging from rehabilitation and physical therapy to chronic pain management. The integration of piezoelectric sensors in wearable devices allows for real-time monitoring of patient movements, providing valuable data for healthcare professionals to tailor treatment plans and track progress.

In the sports and fitness industry, there is a growing trend towards performance optimization and injury prevention. Wearable ergonomic devices equipped with piezoelectric sensors offer athletes and fitness enthusiasts the ability to monitor their form, track biomechanical data, and receive instant feedback on their movements. This has created a substantial market opportunity for manufacturers of advanced wearable sensors.

The industrial sector is another key market for wearable ergonomics, with a focus on improving workplace safety and productivity. Companies are increasingly investing in wearable technologies to monitor employee posture, detect potentially hazardous movements, and provide ergonomic guidance to reduce the risk of workplace injuries.

Consumer electronics companies are also entering the wearable ergonomics market, integrating piezoelectric sensors into everyday items such as smartwatches, clothing, and shoes. This trend is expected to drive market growth as consumers become more health-conscious and seek ways to improve their daily comfort and well-being.

Geographically, North America and Europe currently dominate the wearable ergonomics market, owing to high healthcare expenditure, advanced technological infrastructure, and stringent workplace safety regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing awareness of ergonomic health, rising disposable incomes, and rapid industrialization in countries like China and India.

A key factor fueling market growth is the growing prevalence of musculoskeletal disorders and repetitive strain injuries, particularly in workplace settings. This has led to a surge in demand for ergonomic solutions that can monitor and improve posture, reduce physical strain, and enhance overall comfort during daily activities. Wearable piezoelectric sensors, with their ability to detect and measure pressure and movement, are well-positioned to address these needs.

The healthcare sector represents a significant portion of the wearable ergonomics market, with applications ranging from rehabilitation and physical therapy to chronic pain management. The integration of piezoelectric sensors in wearable devices allows for real-time monitoring of patient movements, providing valuable data for healthcare professionals to tailor treatment plans and track progress.

In the sports and fitness industry, there is a growing trend towards performance optimization and injury prevention. Wearable ergonomic devices equipped with piezoelectric sensors offer athletes and fitness enthusiasts the ability to monitor their form, track biomechanical data, and receive instant feedback on their movements. This has created a substantial market opportunity for manufacturers of advanced wearable sensors.

The industrial sector is another key market for wearable ergonomics, with a focus on improving workplace safety and productivity. Companies are increasingly investing in wearable technologies to monitor employee posture, detect potentially hazardous movements, and provide ergonomic guidance to reduce the risk of workplace injuries.

Consumer electronics companies are also entering the wearable ergonomics market, integrating piezoelectric sensors into everyday items such as smartwatches, clothing, and shoes. This trend is expected to drive market growth as consumers become more health-conscious and seek ways to improve their daily comfort and well-being.

Geographically, North America and Europe currently dominate the wearable ergonomics market, owing to high healthcare expenditure, advanced technological infrastructure, and stringent workplace safety regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing awareness of ergonomic health, rising disposable incomes, and rapid industrialization in countries like China and India.

Challenges in Wearable Piezoelectric Sensors

Wearable piezoelectric sensors face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the trade-off between sensor sensitivity and user comfort. Highly sensitive sensors often require rigid materials and structures, which can be uncomfortable when worn for extended periods. This discomfort can lead to user non-compliance and inaccurate data collection.

Another challenge lies in the integration of these sensors into everyday clothing and accessories. The sensors must be durable enough to withstand regular wear and tear, including exposure to sweat, movement, and washing cycles. However, achieving this durability without compromising sensor performance or increasing bulk remains a significant hurdle for researchers and manufacturers.

Power management presents another obstacle in the development of wearable piezoelectric sensors. While these sensors can generate small amounts of electricity through mechanical stress, this energy is often insufficient to power the entire sensing and data transmission system. Balancing power consumption with sensor functionality and data accuracy is a complex task that requires innovative solutions.

The variability in human physiology and movement patterns also poses challenges for wearable piezoelectric sensors. Sensors must be designed to accommodate a wide range of body types and movement styles while maintaining consistent performance. This variability can lead to inconsistencies in data collection and interpretation, potentially limiting the reliability of the sensors in clinical or research applications.

Environmental factors such as temperature, humidity, and electromagnetic interference can significantly impact the performance of wearable piezoelectric sensors. Developing sensors that can maintain accuracy and reliability across diverse environmental conditions remains a key challenge in the field.

Data processing and interpretation present additional hurdles. The continuous stream of data generated by wearable sensors requires sophisticated algorithms to filter out noise, identify relevant patterns, and translate raw data into actionable insights. Developing these algorithms while ensuring real-time processing capabilities and low power consumption is a complex undertaking.

Lastly, the miniaturization of sensors and associated electronics while maintaining or improving performance is an ongoing challenge. Smaller sensors are generally more comfortable and less obtrusive, but miniaturization can lead to reduced sensitivity or increased susceptibility to interference. Striking the right balance between size, performance, and user comfort continues to be a key focus for researchers in this field.

Another challenge lies in the integration of these sensors into everyday clothing and accessories. The sensors must be durable enough to withstand regular wear and tear, including exposure to sweat, movement, and washing cycles. However, achieving this durability without compromising sensor performance or increasing bulk remains a significant hurdle for researchers and manufacturers.

Power management presents another obstacle in the development of wearable piezoelectric sensors. While these sensors can generate small amounts of electricity through mechanical stress, this energy is often insufficient to power the entire sensing and data transmission system. Balancing power consumption with sensor functionality and data accuracy is a complex task that requires innovative solutions.

The variability in human physiology and movement patterns also poses challenges for wearable piezoelectric sensors. Sensors must be designed to accommodate a wide range of body types and movement styles while maintaining consistent performance. This variability can lead to inconsistencies in data collection and interpretation, potentially limiting the reliability of the sensors in clinical or research applications.

Environmental factors such as temperature, humidity, and electromagnetic interference can significantly impact the performance of wearable piezoelectric sensors. Developing sensors that can maintain accuracy and reliability across diverse environmental conditions remains a key challenge in the field.

Data processing and interpretation present additional hurdles. The continuous stream of data generated by wearable sensors requires sophisticated algorithms to filter out noise, identify relevant patterns, and translate raw data into actionable insights. Developing these algorithms while ensuring real-time processing capabilities and low power consumption is a complex undertaking.

Lastly, the miniaturization of sensors and associated electronics while maintaining or improving performance is an ongoing challenge. Smaller sensors are generally more comfortable and less obtrusive, but miniaturization can lead to reduced sensitivity or increased susceptibility to interference. Striking the right balance between size, performance, and user comfort continues to be a key focus for researchers in this field.

Current Ergonomic Solutions for Piezoelectric Sensors

01 Ergonomic design of wearable piezoelectric sensors

Wearable piezoelectric sensors are designed with ergonomics in mind to ensure comfort and usability. This includes considerations for sensor placement, size, and shape to minimize interference with the user's daily activities. The design also focuses on flexibility and adaptability to different body types and movements.- Ergonomic design of wearable piezoelectric sensors: Wearable piezoelectric sensors are designed with ergonomic considerations to ensure comfort and usability. This includes optimizing the shape, size, and placement of sensors to conform to the human body. The design focuses on minimizing interference with natural movements while maximizing sensor effectiveness.

- Integration of piezoelectric sensors in clothing and accessories: Piezoelectric sensors are seamlessly integrated into various wearable items such as clothing, shoes, and accessories. This integration allows for continuous monitoring of physiological parameters or movement without compromising the user's comfort or style. The sensors are designed to be unobtrusive and resistant to daily wear and tear.

- Flexible and stretchable piezoelectric sensor materials: Advanced materials are used to create flexible and stretchable piezoelectric sensors that can adapt to body movements. These materials allow the sensors to maintain functionality while bending, stretching, or conforming to various body shapes, enhancing comfort and reducing the risk of sensor detachment during use.

- User interface and data visualization for wearable piezoelectric sensors: Ergonomic user interfaces are developed to display and interpret data collected by wearable piezoelectric sensors. These interfaces are designed to be intuitive, easily readable, and accessible on various devices. The focus is on presenting complex sensor data in a user-friendly manner to enhance the overall user experience.

- Power management and energy harvesting in wearable piezoelectric sensors: Efficient power management systems are incorporated into wearable piezoelectric sensor designs to extend battery life and improve overall usability. Some designs also utilize the piezoelectric effect for energy harvesting, converting body movements into electrical energy to power the sensors, thereby reducing the need for frequent charging.

02 Integration of piezoelectric sensors in clothing and accessories

Piezoelectric sensors are seamlessly integrated into various wearable items such as clothing, shoes, and accessories. This integration allows for continuous monitoring of physiological parameters without compromising the user's comfort or style. The sensors are designed to be unobtrusive and resistant to daily wear and tear.Expand Specific Solutions03 Data processing and analysis for wearable piezoelectric sensors

Advanced algorithms and data processing techniques are employed to analyze the signals from wearable piezoelectric sensors. These methods help in filtering noise, interpreting complex data patterns, and providing meaningful insights into the user's health and activity levels. The processing can be done on-device or through connected systems for real-time feedback.Expand Specific Solutions04 Power management and energy harvesting in piezoelectric wearables

Innovative power management solutions are implemented in wearable piezoelectric sensors to extend battery life and improve overall efficiency. Some designs incorporate energy harvesting techniques, utilizing the piezoelectric effect to generate power from the user's movements, thereby reducing the need for frequent charging.Expand Specific Solutions05 User interface and feedback mechanisms for piezoelectric wearables

Wearable piezoelectric sensors are equipped with intuitive user interfaces and feedback mechanisms. These may include haptic feedback, visual displays, or integration with smartphone apps to provide users with easy access to their data and actionable insights. The interfaces are designed to be user-friendly and customizable to individual preferences.Expand Specific Solutions

Key Players in Wearable Piezoelectric Industry

The research on enhanced ergonomics in wearable piezoelectric sensors is in a growth phase, with increasing market potential as wearable technology gains popularity. The global market for piezoelectric sensors is expanding, driven by applications in healthcare, consumer electronics, and industrial sectors. Companies like Murata Manufacturing, Sumitomo Riko, and TDK Electronics are at the forefront of this technology, leveraging their expertise in piezoelectric materials and sensor development. Academic institutions such as Shanghai Jiao Tong University and Case Western Reserve University are contributing to advancements in sensor design and ergonomics. While the technology is maturing, there is still room for innovation in miniaturization, flexibility, and integration with other wearable components.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed ultra-thin piezoelectric sensors with enhanced flexibility and conformability for wearable applications. Their MEMS-based piezoelectric sensors utilize advanced materials like lead zirconate titanate (PZT) to achieve high sensitivity and reliability. The sensors are designed with a focus on miniaturization, achieving thicknesses as low as 0.2mm [1]. Murata has also implemented innovative electrode patterns and flexible substrate materials to improve the sensors' ability to conform to curved body surfaces, enhancing comfort and signal quality in wearable devices [2]. Additionally, they have developed low-power signal processing circuits integrated with the sensors to optimize energy efficiency in battery-powered wearables [3].

Strengths: Industry-leading miniaturization and flexibility, high sensitivity, and integrated power-efficient electronics. Weaknesses: Potential higher cost due to advanced materials and manufacturing processes.

Samsung Electro-Mechanics Co., Ltd.

Technical Solution: Samsung Electro-Mechanics has made significant advancements in wearable piezoelectric sensors, focusing on miniaturization and integration with consumer electronics. Their approach involves developing multi-layer ceramic capacitors (MLCCs) with piezoelectric properties, allowing for highly compact and sensitive sensors [13]. Samsung has also implemented innovative packaging techniques, such as system-in-package (SiP) solutions, to integrate piezoelectric sensors with other components like microprocessors and wireless communication modules [14]. This integration enhances overall device ergonomics by reducing the total size and weight of wearable products. Additionally, Samsung has developed flexible printed circuit board (PCB) technologies that allow piezoelectric sensors to be embedded directly into curved or bendable surfaces, improving comfort and adaptability in wearable devices [15].

Strengths: High level of integration with other electronic components, advanced miniaturization techniques, and flexible PCB technologies. Weaknesses: Potential trade-offs between miniaturization and sensor performance in some applications.

Innovative Designs for Comfort and Flexibility

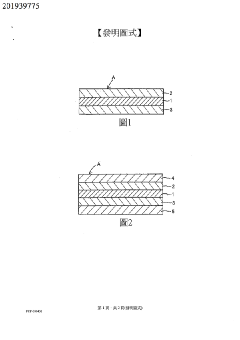

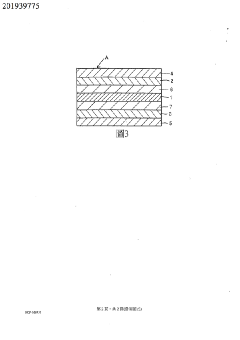

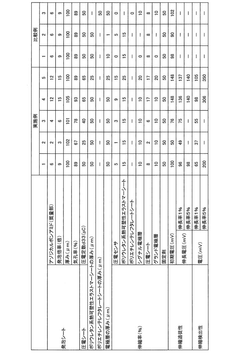

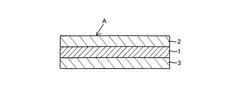

Piezoelectric sensor capable of smoothly following extension of measured body and precisely measuring movement of measured body

PatentActiveTW201939775A

Innovation

- The piezoelectric sensor uses a porous synthetic resin sheet as the piezoelectric material, providing flexibility and improved conformability to the measured body.

- The sensor incorporates flexible adhesive resin with conductive particles in both electrode layers, allowing for better extension and movement following.

- The design enables precise measurement of movement in the surface direction of the mounting surface, expanding the sensor's capabilities.

Piezoelectric sensor

PatentWO2018047878A1

Innovation

- A piezoelectric sensor is designed with a porous synthetic resin sheet, a signal electrode layer, and a ground electrode layer, both containing conductive fine particles and stretchable binder resins, allowing for elasticity and accurate movement detection even when the surface expands or contracts.

Materials Science Advancements for Wearables

Recent advancements in materials science have significantly contributed to the development of wearable piezoelectric sensors with enhanced ergonomics. The focus on improving the comfort and usability of these sensors has led to the exploration of novel materials and fabrication techniques.

Flexible and stretchable materials have emerged as key enablers for ergonomic wearable sensors. Researchers have made substantial progress in developing piezoelectric polymers, such as polyvinylidene fluoride (PVDF) and its copolymers, which can be easily integrated into textiles or directly applied to the skin. These materials offer excellent flexibility and conformability, allowing sensors to adapt to body movements without causing discomfort.

Nanocomposites have also played a crucial role in enhancing the performance of wearable piezoelectric sensors. By incorporating nanomaterials like carbon nanotubes, graphene, or metal nanoparticles into piezoelectric polymers, researchers have achieved improved sensitivity and mechanical properties. These nanocomposites can be tailored to specific applications, balancing flexibility and sensor performance.

Advancements in thin-film deposition techniques have enabled the fabrication of ultra-thin piezoelectric layers on flexible substrates. Methods such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) allow for precise control over film thickness and composition, resulting in highly sensitive and conformable sensors.

Biocompatible and skin-friendly materials have gained significant attention in the development of wearable sensors. Researchers have explored the use of natural polymers, such as cellulose and silk, as substrates for piezoelectric sensors. These materials not only offer excellent biocompatibility but also provide a more comfortable interface with the skin.

Self-healing materials represent another promising avenue for enhancing the durability and longevity of wearable sensors. By incorporating self-healing polymers or microcapsules containing healing agents, researchers aim to develop sensors that can recover from mechanical damage, ensuring long-term reliability in everyday use.

The integration of multifunctional materials has opened up new possibilities for wearable piezoelectric sensors. For instance, materials that combine piezoelectric properties with thermoelectric or photovoltaic capabilities allow for the development of self-powered sensors that can harvest energy from various environmental sources.

As research in materials science continues to advance, we can expect further improvements in the ergonomics and functionality of wearable piezoelectric sensors. The development of materials with enhanced biocompatibility, durability, and multifunctionality will pave the way for more comfortable and efficient wearable devices, expanding their applications in healthcare, sports, and personal monitoring.

Flexible and stretchable materials have emerged as key enablers for ergonomic wearable sensors. Researchers have made substantial progress in developing piezoelectric polymers, such as polyvinylidene fluoride (PVDF) and its copolymers, which can be easily integrated into textiles or directly applied to the skin. These materials offer excellent flexibility and conformability, allowing sensors to adapt to body movements without causing discomfort.

Nanocomposites have also played a crucial role in enhancing the performance of wearable piezoelectric sensors. By incorporating nanomaterials like carbon nanotubes, graphene, or metal nanoparticles into piezoelectric polymers, researchers have achieved improved sensitivity and mechanical properties. These nanocomposites can be tailored to specific applications, balancing flexibility and sensor performance.

Advancements in thin-film deposition techniques have enabled the fabrication of ultra-thin piezoelectric layers on flexible substrates. Methods such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) allow for precise control over film thickness and composition, resulting in highly sensitive and conformable sensors.

Biocompatible and skin-friendly materials have gained significant attention in the development of wearable sensors. Researchers have explored the use of natural polymers, such as cellulose and silk, as substrates for piezoelectric sensors. These materials not only offer excellent biocompatibility but also provide a more comfortable interface with the skin.

Self-healing materials represent another promising avenue for enhancing the durability and longevity of wearable sensors. By incorporating self-healing polymers or microcapsules containing healing agents, researchers aim to develop sensors that can recover from mechanical damage, ensuring long-term reliability in everyday use.

The integration of multifunctional materials has opened up new possibilities for wearable piezoelectric sensors. For instance, materials that combine piezoelectric properties with thermoelectric or photovoltaic capabilities allow for the development of self-powered sensors that can harvest energy from various environmental sources.

As research in materials science continues to advance, we can expect further improvements in the ergonomics and functionality of wearable piezoelectric sensors. The development of materials with enhanced biocompatibility, durability, and multifunctionality will pave the way for more comfortable and efficient wearable devices, expanding their applications in healthcare, sports, and personal monitoring.

User Experience and Adoption Factors

The adoption of wearable piezoelectric sensors is heavily influenced by user experience and ergonomic factors. These devices, designed to be worn on the body for extended periods, must prioritize comfort and ease of use to ensure widespread acceptance and long-term utilization. The integration of enhanced ergonomics in wearable piezoelectric sensors addresses several key aspects that directly impact user experience and adoption rates.

Comfort is a primary consideration in the design of wearable sensors. Users are more likely to adopt and consistently use devices that do not cause discomfort or irritation during prolonged wear. Ergonomic improvements focus on developing lightweight, flexible materials that conform to the body's contours, minimizing pressure points and skin irritation. Advanced textile integration techniques allow for seamless incorporation of sensors into everyday clothing, further enhancing comfort and wearability.

Usability plays a crucial role in user adoption. Intuitive interfaces and simple operation procedures encourage users to engage with the technology more frequently. Ergonomic enhancements in this area include user-friendly controls, clear visual feedback mechanisms, and streamlined data access. The development of companion mobile applications with intuitive dashboards further simplifies the user experience, making data interpretation and device management more accessible to a broader audience.

Aesthetics also significantly influence user adoption, particularly for devices worn visibly. Ergonomic design considerations extend to the visual appeal of wearable sensors, balancing functionality with style. Sleek, unobtrusive designs that blend seamlessly with various fashion styles are more likely to be embraced by users across different demographics.

Durability and maintenance requirements are additional factors affecting long-term adoption. Ergonomic improvements in this area focus on developing robust, water-resistant designs that can withstand daily wear and tear. Easy cleaning and maintenance procedures encourage consistent use and prolong device lifespan, contributing to higher user satisfaction and retention rates.

Customization options enhance the personal relevance of wearable sensors, positively impacting user experience and adoption. Ergonomic advancements allow for modular designs and adjustable components, enabling users to tailor the device to their specific needs and preferences. This personalization extends to data presentation and analysis, with customizable alerts and reporting features that align with individual health and fitness goals.

The integration of enhanced ergonomics in wearable piezoelectric sensors addresses critical user experience factors, significantly influencing adoption rates and long-term usage. By prioritizing comfort, usability, aesthetics, durability, and customization, manufacturers can create devices that seamlessly integrate into users' lives, driving broader acceptance and utilization of this innovative technology across various applications and user groups.

Comfort is a primary consideration in the design of wearable sensors. Users are more likely to adopt and consistently use devices that do not cause discomfort or irritation during prolonged wear. Ergonomic improvements focus on developing lightweight, flexible materials that conform to the body's contours, minimizing pressure points and skin irritation. Advanced textile integration techniques allow for seamless incorporation of sensors into everyday clothing, further enhancing comfort and wearability.

Usability plays a crucial role in user adoption. Intuitive interfaces and simple operation procedures encourage users to engage with the technology more frequently. Ergonomic enhancements in this area include user-friendly controls, clear visual feedback mechanisms, and streamlined data access. The development of companion mobile applications with intuitive dashboards further simplifies the user experience, making data interpretation and device management more accessible to a broader audience.

Aesthetics also significantly influence user adoption, particularly for devices worn visibly. Ergonomic design considerations extend to the visual appeal of wearable sensors, balancing functionality with style. Sleek, unobtrusive designs that blend seamlessly with various fashion styles are more likely to be embraced by users across different demographics.

Durability and maintenance requirements are additional factors affecting long-term adoption. Ergonomic improvements in this area focus on developing robust, water-resistant designs that can withstand daily wear and tear. Easy cleaning and maintenance procedures encourage consistent use and prolong device lifespan, contributing to higher user satisfaction and retention rates.

Customization options enhance the personal relevance of wearable sensors, positively impacting user experience and adoption. Ergonomic advancements allow for modular designs and adjustable components, enabling users to tailor the device to their specific needs and preferences. This personalization extends to data presentation and analysis, with customizable alerts and reporting features that align with individual health and fitness goals.

The integration of enhanced ergonomics in wearable piezoelectric sensors addresses critical user experience factors, significantly influencing adoption rates and long-term usage. By prioritizing comfort, usability, aesthetics, durability, and customization, manufacturers can create devices that seamlessly integrate into users' lives, driving broader acceptance and utilization of this innovative technology across various applications and user groups.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!