K24 Engine and IoT: Revolutionizing Real-Time Diagnostics

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine IoT Integration Background and Objectives

The K24 engine, a marvel of modern automotive engineering, has been at the forefront of internal combustion technology for decades. As we enter an era of increased connectivity and data-driven decision-making, the integration of Internet of Things (IoT) technology with the K24 engine presents a revolutionary opportunity to transform real-time diagnostics and engine management.

The evolution of the K24 engine has been marked by continuous improvements in performance, efficiency, and reliability. However, the advent of IoT technology opens up new avenues for enhancing these attributes through advanced monitoring and control systems. This convergence of mechanical engineering and digital technology represents a significant leap forward in automotive innovation.

The primary objective of integrating IoT with the K24 engine is to create a smart, self-monitoring powerplant capable of providing real-time diagnostics and predictive maintenance alerts. This integration aims to optimize engine performance, reduce downtime, and extend the overall lifespan of the engine. By leveraging IoT sensors and data analytics, we can gain unprecedented insights into engine behavior under various operating conditions.

Another key goal is to enhance fuel efficiency and reduce emissions through more precise engine management. IoT-enabled systems can continuously monitor and adjust engine parameters in real-time, ensuring optimal combustion and minimizing waste. This not only improves the environmental footprint of vehicles equipped with K24 engines but also helps manufacturers meet increasingly stringent emissions regulations.

The integration of IoT technology also paves the way for advanced driver assistance systems and autonomous driving capabilities. By providing a constant stream of engine performance data, IoT integration can contribute to more accurate vehicle control algorithms and safer driving experiences. This aligns with the broader trend towards connected and autonomous vehicles in the automotive industry.

Furthermore, the K24 engine IoT integration aims to revolutionize the way vehicle maintenance is approached. By enabling predictive maintenance based on real-time data analysis, we can shift from scheduled maintenance to condition-based maintenance, potentially reducing costs and improving vehicle reliability. This proactive approach to engine care represents a paradigm shift in automotive maintenance practices.

In conclusion, the integration of IoT technology with the K24 engine represents a convergence of traditional mechanical engineering and cutting-edge digital innovation. This fusion aims to create a more intelligent, efficient, and reliable powertrain that can adapt to the evolving demands of modern transportation. As we explore this technological frontier, we anticipate significant advancements in engine performance, diagnostics, and overall vehicle management.

The evolution of the K24 engine has been marked by continuous improvements in performance, efficiency, and reliability. However, the advent of IoT technology opens up new avenues for enhancing these attributes through advanced monitoring and control systems. This convergence of mechanical engineering and digital technology represents a significant leap forward in automotive innovation.

The primary objective of integrating IoT with the K24 engine is to create a smart, self-monitoring powerplant capable of providing real-time diagnostics and predictive maintenance alerts. This integration aims to optimize engine performance, reduce downtime, and extend the overall lifespan of the engine. By leveraging IoT sensors and data analytics, we can gain unprecedented insights into engine behavior under various operating conditions.

Another key goal is to enhance fuel efficiency and reduce emissions through more precise engine management. IoT-enabled systems can continuously monitor and adjust engine parameters in real-time, ensuring optimal combustion and minimizing waste. This not only improves the environmental footprint of vehicles equipped with K24 engines but also helps manufacturers meet increasingly stringent emissions regulations.

The integration of IoT technology also paves the way for advanced driver assistance systems and autonomous driving capabilities. By providing a constant stream of engine performance data, IoT integration can contribute to more accurate vehicle control algorithms and safer driving experiences. This aligns with the broader trend towards connected and autonomous vehicles in the automotive industry.

Furthermore, the K24 engine IoT integration aims to revolutionize the way vehicle maintenance is approached. By enabling predictive maintenance based on real-time data analysis, we can shift from scheduled maintenance to condition-based maintenance, potentially reducing costs and improving vehicle reliability. This proactive approach to engine care represents a paradigm shift in automotive maintenance practices.

In conclusion, the integration of IoT technology with the K24 engine represents a convergence of traditional mechanical engineering and cutting-edge digital innovation. This fusion aims to create a more intelligent, efficient, and reliable powertrain that can adapt to the evolving demands of modern transportation. As we explore this technological frontier, we anticipate significant advancements in engine performance, diagnostics, and overall vehicle management.

Market Demand for Smart Engine Diagnostics

The market demand for smart engine diagnostics has been experiencing significant growth in recent years, driven by the increasing complexity of modern engines and the growing emphasis on vehicle performance, efficiency, and environmental sustainability. As vehicles become more sophisticated, traditional diagnostic methods are proving inadequate to address the intricate issues that arise in modern engines. This has created a substantial need for advanced diagnostic solutions that can provide real-time insights into engine performance and potential problems.

The automotive industry has been at the forefront of this demand, with manufacturers, fleet operators, and service centers seeking innovative ways to improve vehicle maintenance and reduce downtime. The integration of IoT technology with engine diagnostics offers a promising solution to these challenges, enabling continuous monitoring and predictive maintenance capabilities. This has led to a surge in interest for smart diagnostic systems that can analyze engine data in real-time and provide actionable insights to drivers, mechanics, and fleet managers.

Consumer demand for smart engine diagnostics is also on the rise, as vehicle owners become more tech-savvy and seek greater control over their vehicle's performance and maintenance. The ability to receive instant notifications about potential issues and access detailed performance data has become increasingly appealing to consumers, driving the adoption of smart diagnostic solutions in the personal vehicle market.

In the commercial sector, the demand for smart engine diagnostics is particularly strong. Fleet operators are recognizing the potential of these systems to optimize their operations, reduce fuel consumption, and minimize vehicle downtime. The ability to predict and prevent engine failures before they occur can result in significant cost savings and improved operational efficiency for businesses that rely heavily on vehicle fleets.

The market for smart engine diagnostics is also being propelled by regulatory pressures and environmental concerns. As governments worldwide implement stricter emissions standards, there is a growing need for advanced diagnostic tools that can ensure engines are operating at peak efficiency and within regulatory limits. This has created a substantial market opportunity for diagnostic solutions that can monitor and optimize engine performance in real-time, helping vehicle owners and operators comply with evolving environmental regulations.

Furthermore, the rise of electric and hybrid vehicles has introduced new complexities in engine diagnostics, creating additional demand for smart solutions that can effectively monitor and manage these advanced powertrain systems. As the automotive industry continues its transition towards electrification, the market for specialized diagnostic tools for electric and hybrid engines is expected to expand rapidly.

The automotive industry has been at the forefront of this demand, with manufacturers, fleet operators, and service centers seeking innovative ways to improve vehicle maintenance and reduce downtime. The integration of IoT technology with engine diagnostics offers a promising solution to these challenges, enabling continuous monitoring and predictive maintenance capabilities. This has led to a surge in interest for smart diagnostic systems that can analyze engine data in real-time and provide actionable insights to drivers, mechanics, and fleet managers.

Consumer demand for smart engine diagnostics is also on the rise, as vehicle owners become more tech-savvy and seek greater control over their vehicle's performance and maintenance. The ability to receive instant notifications about potential issues and access detailed performance data has become increasingly appealing to consumers, driving the adoption of smart diagnostic solutions in the personal vehicle market.

In the commercial sector, the demand for smart engine diagnostics is particularly strong. Fleet operators are recognizing the potential of these systems to optimize their operations, reduce fuel consumption, and minimize vehicle downtime. The ability to predict and prevent engine failures before they occur can result in significant cost savings and improved operational efficiency for businesses that rely heavily on vehicle fleets.

The market for smart engine diagnostics is also being propelled by regulatory pressures and environmental concerns. As governments worldwide implement stricter emissions standards, there is a growing need for advanced diagnostic tools that can ensure engines are operating at peak efficiency and within regulatory limits. This has created a substantial market opportunity for diagnostic solutions that can monitor and optimize engine performance in real-time, helping vehicle owners and operators comply with evolving environmental regulations.

Furthermore, the rise of electric and hybrid vehicles has introduced new complexities in engine diagnostics, creating additional demand for smart solutions that can effectively monitor and manage these advanced powertrain systems. As the automotive industry continues its transition towards electrification, the market for specialized diagnostic tools for electric and hybrid engines is expected to expand rapidly.

K24 Engine and IoT Technology Current Status

The K24 engine and Internet of Things (IoT) technologies have made significant strides in recent years, revolutionizing the field of real-time diagnostics in automotive and industrial applications. The current status of these technologies reflects a convergence of advanced mechanical engineering and cutting-edge digital connectivity.

K24 engines, known for their efficiency and performance, have evolved to incorporate sophisticated sensors and monitoring systems. These engines now feature an array of embedded sensors that continuously collect data on various parameters such as temperature, pressure, fuel consumption, and emissions. This real-time data collection forms the foundation for advanced diagnostics and predictive maintenance capabilities.

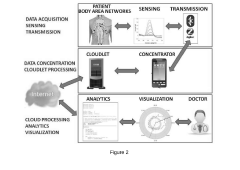

The integration of IoT technology with K24 engines has further enhanced their diagnostic capabilities. IoT platforms enable seamless connectivity between the engine's sensors and cloud-based analytics systems. This connectivity allows for real-time data transmission, storage, and analysis, providing unprecedented insights into engine performance and health.

Current IoT solutions for K24 engines utilize advanced protocols such as MQTT (Message Queuing Telemetry Transport) and CoAP (Constrained Application Protocol) to ensure efficient and reliable data transfer. These protocols are designed to operate in environments with limited bandwidth and intermittent connectivity, making them ideal for mobile applications like vehicles.

Machine learning algorithms and artificial intelligence have been incorporated into the IoT ecosystem for K24 engines. These technologies enable predictive analytics, anomaly detection, and automated decision-making processes. By analyzing historical data and real-time inputs, these systems can predict potential failures, optimize performance, and recommend maintenance schedules with high accuracy.

Edge computing has emerged as a critical component in the current K24 engine and IoT landscape. By processing data closer to the source, edge computing reduces latency and enables faster response times for critical diagnostics. This approach also helps in managing the vast amounts of data generated by engine sensors, reducing the strain on network bandwidth and cloud resources.

Cybersecurity measures have become increasingly sophisticated to protect the sensitive data generated by K24 engines and transmitted through IoT networks. Encryption protocols, secure boot processes, and intrusion detection systems are now standard features in these systems, ensuring the integrity and confidentiality of diagnostic data.

The current status of K24 engine and IoT technology also reflects a growing trend towards standardization and interoperability. Industry consortiums and regulatory bodies are working towards establishing common protocols and data formats to facilitate seamless integration across different platforms and manufacturers.

In summary, the current state of K24 engine and IoT technology for real-time diagnostics represents a highly advanced and rapidly evolving ecosystem. The integration of sophisticated sensors, robust connectivity, advanced analytics, and enhanced security measures has created a powerful platform for revolutionizing engine diagnostics and maintenance practices.

K24 engines, known for their efficiency and performance, have evolved to incorporate sophisticated sensors and monitoring systems. These engines now feature an array of embedded sensors that continuously collect data on various parameters such as temperature, pressure, fuel consumption, and emissions. This real-time data collection forms the foundation for advanced diagnostics and predictive maintenance capabilities.

The integration of IoT technology with K24 engines has further enhanced their diagnostic capabilities. IoT platforms enable seamless connectivity between the engine's sensors and cloud-based analytics systems. This connectivity allows for real-time data transmission, storage, and analysis, providing unprecedented insights into engine performance and health.

Current IoT solutions for K24 engines utilize advanced protocols such as MQTT (Message Queuing Telemetry Transport) and CoAP (Constrained Application Protocol) to ensure efficient and reliable data transfer. These protocols are designed to operate in environments with limited bandwidth and intermittent connectivity, making them ideal for mobile applications like vehicles.

Machine learning algorithms and artificial intelligence have been incorporated into the IoT ecosystem for K24 engines. These technologies enable predictive analytics, anomaly detection, and automated decision-making processes. By analyzing historical data and real-time inputs, these systems can predict potential failures, optimize performance, and recommend maintenance schedules with high accuracy.

Edge computing has emerged as a critical component in the current K24 engine and IoT landscape. By processing data closer to the source, edge computing reduces latency and enables faster response times for critical diagnostics. This approach also helps in managing the vast amounts of data generated by engine sensors, reducing the strain on network bandwidth and cloud resources.

Cybersecurity measures have become increasingly sophisticated to protect the sensitive data generated by K24 engines and transmitted through IoT networks. Encryption protocols, secure boot processes, and intrusion detection systems are now standard features in these systems, ensuring the integrity and confidentiality of diagnostic data.

The current status of K24 engine and IoT technology also reflects a growing trend towards standardization and interoperability. Industry consortiums and regulatory bodies are working towards establishing common protocols and data formats to facilitate seamless integration across different platforms and manufacturers.

In summary, the current state of K24 engine and IoT technology for real-time diagnostics represents a highly advanced and rapidly evolving ecosystem. The integration of sophisticated sensors, robust connectivity, advanced analytics, and enhanced security measures has created a powerful platform for revolutionizing engine diagnostics and maintenance practices.

Existing K24 IoT Diagnostic Solutions

01 IoT-based real-time engine diagnostics

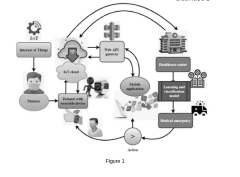

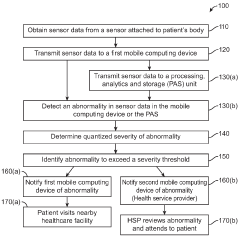

Integration of IoT technology with K24 engines for real-time monitoring and diagnostics. This system collects and analyzes data from various engine sensors to provide instant feedback on engine performance, potential issues, and maintenance needs.- IoT-based real-time engine diagnostics: Integration of IoT technology with K24 engines for real-time monitoring and diagnostics. This system collects and analyzes data from various engine sensors to provide instant feedback on engine performance, potential issues, and maintenance needs.

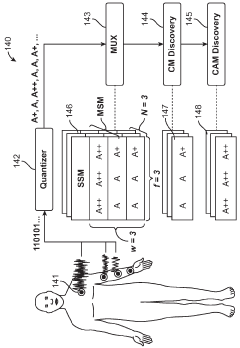

- Advanced sensor networks for K24 engines: Implementation of sophisticated sensor networks specifically designed for K24 engines. These sensors continuously monitor critical engine parameters such as temperature, pressure, and fuel efficiency, enabling precise diagnostics and predictive maintenance.

- Cloud-based data analysis for engine performance: Utilization of cloud computing platforms to process and analyze large volumes of data collected from K24 engines. This approach enables complex diagnostics, pattern recognition, and predictive analytics to optimize engine performance and longevity.

- Machine learning algorithms for engine fault detection: Application of machine learning algorithms to analyze engine data and detect potential faults or anomalies. These algorithms can learn from historical data to improve accuracy in predicting engine issues and recommending appropriate maintenance actions.

- Mobile app integration for real-time engine monitoring: Development of mobile applications that interface with the K24 engine's IoT system. These apps provide real-time engine status updates, alerts, and diagnostic information to users, enabling remote monitoring and timely maintenance decisions.

02 Advanced sensor networks for K24 engines

Implementation of sophisticated sensor networks specifically designed for K24 engines. These sensors continuously monitor various engine parameters such as temperature, pressure, and fuel consumption, enabling precise diagnostics and predictive maintenance.Expand Specific Solutions03 Cloud-based data processing for engine diagnostics

Utilization of cloud computing platforms to process and analyze large volumes of data collected from K24 engines. This approach enables more complex diagnostic algorithms and machine learning models to be applied, improving the accuracy and speed of fault detection and performance optimization.Expand Specific Solutions04 Mobile applications for K24 engine monitoring

Development of mobile applications that allow users to access real-time diagnostics and performance data of their K24 engines remotely. These apps provide user-friendly interfaces for monitoring engine health, receiving alerts, and scheduling maintenance.Expand Specific Solutions05 AI-powered predictive maintenance for K24 engines

Integration of artificial intelligence and machine learning algorithms to analyze engine data and predict potential failures or maintenance needs. This system can recommend proactive maintenance schedules and optimize engine performance based on historical and real-time data.Expand Specific Solutions

Key Players in Engine IoT Solutions

The research on K24 Engine and IoT for real-time diagnostics is in an emerging stage, with the market showing significant growth potential. The technology is still evolving, with varying levels of maturity across different applications. Key players like Huawei Technologies and Turkcell are driving innovation in IoT connectivity, while companies such as XCMG Excavator Machinery and Chengdu Aircraft Industrial Group are likely focusing on engine-specific applications. The integration of IoT with K24 engines for diagnostics is attracting interest from diverse sectors, including automotive, aerospace, and industrial equipment manufacturing, indicating a broad market scope.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an advanced IoT platform for K24 engine diagnostics, integrating edge computing and AI. Their solution utilizes a network of sensors to collect real-time data from K24 engines, which is then processed using Huawei's Kunpeng AI chips. This enables immediate analysis of engine performance, predicting potential issues before they occur. The system employs 5G technology for ultra-low latency data transmission, allowing for near-instantaneous diagnostics and decision-making[1][3]. Huawei's platform also incorporates blockchain technology to ensure data integrity and security in the diagnostics process[5].

Strengths: Strong 5G infrastructure, advanced AI capabilities, and comprehensive IoT ecosystem. Weaknesses: Potential geopolitical challenges in some markets, and reliance on global semiconductor supply chains.

Turkcell Teknoloji Arastirma ve Gelistirme AS

Technical Solution: Turkcell has developed a cutting-edge IoT solution for K24 engine diagnostics, leveraging their expertise in telecommunications. Their system utilizes a dense network of IoT sensors embedded within K24 engines, collecting data on various parameters such as temperature, pressure, and vibration. This data is transmitted in real-time using Turkcell's robust 4.5G and 5G networks, ensuring minimal latency. The company's cloud-based analytics platform employs machine learning algorithms to process the incoming data, providing instant insights into engine health and performance[2]. Turkcell's solution also includes a user-friendly mobile application for remote monitoring and alerts[4].

Strengths: Strong telecommunications infrastructure, expertise in IoT and data analytics. Weaknesses: Limited global presence compared to some competitors, potential challenges in scaling to different markets.

Core Innovations in Engine IoT Integration

IoT based patient remote health diagnosis device

PatentPendingIN202341036037A

Innovation

- An IoT-based patient remote health diagnosis device that integrates medical sensors to measure vital signs and utilizes data analytics and connectivity for real-time data transmission and analysis, enabling healthcare professionals to remotely monitor and diagnose patients' conditions, while ensuring patient privacy and data security.

Systems and methods for remote health monitoring and managementusing internet of things sensors

PatentPendingIN202243011921A

Innovation

- The Amrita IoT Medical (AIM) Smart-edge system, which includes IoT-vitals sensing nodes, a wireless transmission circuitry, a local gateway, and a processor for rapid data summarization and criticality alert computation, enables context-aware, healthcare domain-specific intelligence for remote health monitoring, using ZigBee, Bluetooth, or WiFi for short-range networks and cellular or Internet networks for long-range communication, and hosts a Hospital Information System (HIS) for data storage and analytics.

Cybersecurity in Engine IoT Systems

Cybersecurity in Engine IoT Systems has become a critical concern as the integration of IoT technology with K24 engines for real-time diagnostics advances. The interconnected nature of these systems presents both opportunities and vulnerabilities that must be addressed to ensure the integrity and reliability of engine performance data.

One of the primary challenges in securing Engine IoT systems is the protection of data transmission between sensors, control units, and cloud-based analytics platforms. Encryption protocols such as TLS/SSL are widely implemented to safeguard data in transit, but the resource constraints of some IoT devices may limit the use of robust encryption methods. This necessitates the development of lightweight cryptographic algorithms that can provide adequate security without compromising the real-time responsiveness of the diagnostic system.

Authentication and access control mechanisms form another crucial layer of defense. Multi-factor authentication and role-based access control systems are being deployed to ensure that only authorized personnel can interact with the engine's IoT infrastructure. However, the distributed nature of these systems, often spanning multiple geographic locations and organizational boundaries, complicates the implementation of consistent access policies.

Network segmentation and firewalls play a vital role in isolating Engine IoT systems from potential threats. By creating separate network zones for different components of the system, administrators can limit the potential impact of a security breach. Software-defined networking (SDN) approaches are being explored to provide more dynamic and granular control over network traffic, allowing for rapid response to emerging threats.

Intrusion detection and prevention systems (IDS/IPS) tailored for IoT environments are being developed to monitor for anomalous behavior that could indicate a cyberattack. These systems employ machine learning algorithms to establish baseline patterns of engine operation and network traffic, enabling them to identify deviations that may signal a security incident.

Secure firmware updates and patch management processes are essential for maintaining the security posture of Engine IoT systems over time. Over-the-air (OTA) update capabilities are being integrated into modern engine management systems, but these must be designed with robust authentication and integrity checks to prevent the introduction of malicious code.

As the threat landscape continues to evolve, ongoing research is focused on developing adaptive security measures that can respond to new attack vectors. This includes the exploration of blockchain technology for creating tamper-evident logs of engine diagnostics and the use of artificial intelligence for predictive threat analysis.

One of the primary challenges in securing Engine IoT systems is the protection of data transmission between sensors, control units, and cloud-based analytics platforms. Encryption protocols such as TLS/SSL are widely implemented to safeguard data in transit, but the resource constraints of some IoT devices may limit the use of robust encryption methods. This necessitates the development of lightweight cryptographic algorithms that can provide adequate security without compromising the real-time responsiveness of the diagnostic system.

Authentication and access control mechanisms form another crucial layer of defense. Multi-factor authentication and role-based access control systems are being deployed to ensure that only authorized personnel can interact with the engine's IoT infrastructure. However, the distributed nature of these systems, often spanning multiple geographic locations and organizational boundaries, complicates the implementation of consistent access policies.

Network segmentation and firewalls play a vital role in isolating Engine IoT systems from potential threats. By creating separate network zones for different components of the system, administrators can limit the potential impact of a security breach. Software-defined networking (SDN) approaches are being explored to provide more dynamic and granular control over network traffic, allowing for rapid response to emerging threats.

Intrusion detection and prevention systems (IDS/IPS) tailored for IoT environments are being developed to monitor for anomalous behavior that could indicate a cyberattack. These systems employ machine learning algorithms to establish baseline patterns of engine operation and network traffic, enabling them to identify deviations that may signal a security incident.

Secure firmware updates and patch management processes are essential for maintaining the security posture of Engine IoT systems over time. Over-the-air (OTA) update capabilities are being integrated into modern engine management systems, but these must be designed with robust authentication and integrity checks to prevent the introduction of malicious code.

As the threat landscape continues to evolve, ongoing research is focused on developing adaptive security measures that can respond to new attack vectors. This includes the exploration of blockchain technology for creating tamper-evident logs of engine diagnostics and the use of artificial intelligence for predictive threat analysis.

Environmental Impact of Smart Engine Technologies

The integration of smart engine technologies, particularly in the context of the K24 Engine and IoT for real-time diagnostics, has significant implications for environmental sustainability. These advancements offer potential benefits in reducing emissions, improving fuel efficiency, and optimizing overall engine performance, which collectively contribute to a smaller environmental footprint.

One of the primary environmental advantages of smart engine technologies is the reduction in fuel consumption. By leveraging real-time data and advanced analytics, these systems can optimize engine operation, leading to more efficient fuel usage. This not only reduces the overall carbon footprint but also conserves finite fossil fuel resources, aligning with global efforts to mitigate climate change.

Emissions reduction is another crucial environmental benefit of smart engine technologies. Through continuous monitoring and adjustment of engine parameters, these systems can minimize harmful emissions such as carbon dioxide, nitrogen oxides, and particulate matter. This improvement in air quality has far-reaching effects on both human health and ecosystem preservation, particularly in urban areas where air pollution is a significant concern.

The implementation of IoT in engine diagnostics also contributes to more sustainable maintenance practices. By enabling predictive maintenance, these technologies help prevent catastrophic failures and extend engine life spans. This approach reduces the need for premature replacements and the associated environmental costs of manufacturing new engines, including resource extraction and energy consumption.

Furthermore, smart engine technologies facilitate the transition towards more sustainable transportation models. They enable the integration of alternative fuels and hybrid systems, paving the way for cleaner energy sources in the automotive and industrial sectors. This adaptability is crucial for meeting increasingly stringent environmental regulations and supporting the global shift towards low-carbon economies.

However, it is important to consider the potential environmental drawbacks of these technologies. The production and disposal of electronic components used in smart engine systems can have negative environmental impacts if not managed properly. Additionally, the increased reliance on data centers for processing and storing engine data contributes to growing energy demands in the IT sector.

In conclusion, while smart engine technologies offer significant environmental benefits through improved efficiency and reduced emissions, a holistic approach is necessary to ensure their overall positive impact. This includes considering the entire lifecycle of these technologies, from production to disposal, and balancing their benefits against potential environmental costs. As these technologies continue to evolve, ongoing research and development should focus on maximizing their environmental advantages while minimizing any associated negative impacts.

One of the primary environmental advantages of smart engine technologies is the reduction in fuel consumption. By leveraging real-time data and advanced analytics, these systems can optimize engine operation, leading to more efficient fuel usage. This not only reduces the overall carbon footprint but also conserves finite fossil fuel resources, aligning with global efforts to mitigate climate change.

Emissions reduction is another crucial environmental benefit of smart engine technologies. Through continuous monitoring and adjustment of engine parameters, these systems can minimize harmful emissions such as carbon dioxide, nitrogen oxides, and particulate matter. This improvement in air quality has far-reaching effects on both human health and ecosystem preservation, particularly in urban areas where air pollution is a significant concern.

The implementation of IoT in engine diagnostics also contributes to more sustainable maintenance practices. By enabling predictive maintenance, these technologies help prevent catastrophic failures and extend engine life spans. This approach reduces the need for premature replacements and the associated environmental costs of manufacturing new engines, including resource extraction and energy consumption.

Furthermore, smart engine technologies facilitate the transition towards more sustainable transportation models. They enable the integration of alternative fuels and hybrid systems, paving the way for cleaner energy sources in the automotive and industrial sectors. This adaptability is crucial for meeting increasingly stringent environmental regulations and supporting the global shift towards low-carbon economies.

However, it is important to consider the potential environmental drawbacks of these technologies. The production and disposal of electronic components used in smart engine systems can have negative environmental impacts if not managed properly. Additionally, the increased reliance on data centers for processing and storing engine data contributes to growing energy demands in the IT sector.

In conclusion, while smart engine technologies offer significant environmental benefits through improved efficiency and reduced emissions, a holistic approach is necessary to ensure their overall positive impact. This includes considering the entire lifecycle of these technologies, from production to disposal, and balancing their benefits against potential environmental costs. As these technologies continue to evolve, ongoing research and development should focus on maximizing their environmental advantages while minimizing any associated negative impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!