K24 Engine: Shaping the Future of Vehicle Customization

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has become a cornerstone in vehicle customization due to its robust design and adaptability.

In its early stages, the K24A1 variant debuted with 160 horsepower and 161 lb-ft of torque. This initial offering set the stage for a series of improvements that would follow. The subsequent K24A2 and K24A4 versions saw incremental power increases, reaching up to 200 horsepower in certain applications, demonstrating Honda's commitment to continuous refinement.

A significant milestone in the K24's evolution came with the introduction of i-VTEC technology. This innovative system combined VTEC (Variable Valve Timing and Lift Electronic Control) with VTC (Variable Timing Control), allowing for improved performance across a broader range of engine speeds. The integration of i-VTEC marked a turning point in the engine's capabilities, enhancing both power output and fuel efficiency.

The mid-2000s saw the emergence of the K24A3 and K24Z variants, which further pushed the boundaries of performance. These iterations featured enhanced cylinder heads, revised camshaft profiles, and optimized intake and exhaust systems. Such improvements not only boosted stock performance but also laid the groundwork for extensive aftermarket modifications.

As environmental concerns gained prominence, Honda adapted the K24 to meet stricter emissions standards. The introduction of direct injection in later models exemplified this shift, offering improved fuel economy without sacrificing power. This adaptation ensured the K24's relevance in an increasingly eco-conscious automotive landscape.

The engine's evolution also saw it branching into diverse applications beyond the Accord. Its versatility allowed for successful integration into various Honda and Acura models, including the CR-V, Element, and TSX. This widespread adoption across different vehicle platforms further cemented the K24's reputation as a highly adaptable powerplant.

Throughout its lifespan, the K24 has maintained a balance between reliability and performance potential. This characteristic has made it a favorite among enthusiasts for engine swaps and high-performance builds. The engine's robust construction and relatively simple design have allowed for significant power increases through aftermarket modifications, sometimes doubling or tripling the stock output.

The latest iterations of the K24, such as the K24W found in more recent Honda models, represent the culmination of nearly two decades of development. These modern versions incorporate advanced materials, refined manufacturing techniques, and cutting-edge engine management systems, pushing the boundaries of what's possible from a 2.4-liter displacement.

In its early stages, the K24A1 variant debuted with 160 horsepower and 161 lb-ft of torque. This initial offering set the stage for a series of improvements that would follow. The subsequent K24A2 and K24A4 versions saw incremental power increases, reaching up to 200 horsepower in certain applications, demonstrating Honda's commitment to continuous refinement.

A significant milestone in the K24's evolution came with the introduction of i-VTEC technology. This innovative system combined VTEC (Variable Valve Timing and Lift Electronic Control) with VTC (Variable Timing Control), allowing for improved performance across a broader range of engine speeds. The integration of i-VTEC marked a turning point in the engine's capabilities, enhancing both power output and fuel efficiency.

The mid-2000s saw the emergence of the K24A3 and K24Z variants, which further pushed the boundaries of performance. These iterations featured enhanced cylinder heads, revised camshaft profiles, and optimized intake and exhaust systems. Such improvements not only boosted stock performance but also laid the groundwork for extensive aftermarket modifications.

As environmental concerns gained prominence, Honda adapted the K24 to meet stricter emissions standards. The introduction of direct injection in later models exemplified this shift, offering improved fuel economy without sacrificing power. This adaptation ensured the K24's relevance in an increasingly eco-conscious automotive landscape.

The engine's evolution also saw it branching into diverse applications beyond the Accord. Its versatility allowed for successful integration into various Honda and Acura models, including the CR-V, Element, and TSX. This widespread adoption across different vehicle platforms further cemented the K24's reputation as a highly adaptable powerplant.

Throughout its lifespan, the K24 has maintained a balance between reliability and performance potential. This characteristic has made it a favorite among enthusiasts for engine swaps and high-performance builds. The engine's robust construction and relatively simple design have allowed for significant power increases through aftermarket modifications, sometimes doubling or tripling the stock output.

The latest iterations of the K24, such as the K24W found in more recent Honda models, represent the culmination of nearly two decades of development. These modern versions incorporate advanced materials, refined manufacturing techniques, and cutting-edge engine management systems, pushing the boundaries of what's possible from a 2.4-liter displacement.

Market Demand Analysis

The K24 engine has sparked significant interest in the vehicle customization market, driven by a growing demand for personalized and high-performance automotive experiences. This market segment has seen steady growth over the past decade, with enthusiasts and professionals alike seeking ways to enhance their vehicles' power, efficiency, and uniqueness.

The aftermarket parts industry for K24 engines has experienced a surge in demand, particularly among Honda and Acura owners. This trend is fueled by the engine's reputation for reliability, versatility, and potential for modification. The market for K24-specific performance parts, including intake systems, exhaust components, and engine management solutions, has expanded considerably, reflecting the engine's popularity among tuning enthusiasts.

Vehicle customization shops specializing in K24 engine swaps and modifications have reported increased business, indicating a robust market for comprehensive engine upgrades. This demand extends beyond traditional Honda platforms, with enthusiasts exploring K24 swaps in various vehicle makes and models, further broadening the market potential.

The rise of social media and online automotive communities has played a crucial role in driving market demand for K24 engine customization. These platforms have facilitated knowledge sharing, showcasing successful builds, and creating a culture of aspiration around K24-powered vehicles. This digital ecosystem has not only increased awareness but also stimulated demand for K24-related products and services.

Performance metrics and dyno results shared by K24 enthusiasts have demonstrated significant power gains achievable through customization, further fueling market interest. The ability to substantially increase horsepower and torque outputs while maintaining reliability has made the K24 an attractive option for both street and track applications.

Environmental considerations have also influenced market demand, with some enthusiasts turning to K24 engine swaps as a way to modernize older vehicles while potentially improving fuel efficiency and reducing emissions. This trend aligns with broader automotive industry shifts towards more sustainable practices, even within the customization sector.

The market for K24 engine customization extends beyond individual consumers to include racing teams and professional builders. These segments demand high-end, specialized components and services, contributing to the growth of a premium market niche within the K24 customization landscape.

As vehicle manufacturers continue to shift towards electrification, the K24 engine represents a last bastion of highly customizable internal combustion technology for many enthusiasts. This factor has created a sense of urgency in the market, with consumers and businesses alike investing in K24 projects as a way to preserve and celebrate traditional automotive engineering.

The aftermarket parts industry for K24 engines has experienced a surge in demand, particularly among Honda and Acura owners. This trend is fueled by the engine's reputation for reliability, versatility, and potential for modification. The market for K24-specific performance parts, including intake systems, exhaust components, and engine management solutions, has expanded considerably, reflecting the engine's popularity among tuning enthusiasts.

Vehicle customization shops specializing in K24 engine swaps and modifications have reported increased business, indicating a robust market for comprehensive engine upgrades. This demand extends beyond traditional Honda platforms, with enthusiasts exploring K24 swaps in various vehicle makes and models, further broadening the market potential.

The rise of social media and online automotive communities has played a crucial role in driving market demand for K24 engine customization. These platforms have facilitated knowledge sharing, showcasing successful builds, and creating a culture of aspiration around K24-powered vehicles. This digital ecosystem has not only increased awareness but also stimulated demand for K24-related products and services.

Performance metrics and dyno results shared by K24 enthusiasts have demonstrated significant power gains achievable through customization, further fueling market interest. The ability to substantially increase horsepower and torque outputs while maintaining reliability has made the K24 an attractive option for both street and track applications.

Environmental considerations have also influenced market demand, with some enthusiasts turning to K24 engine swaps as a way to modernize older vehicles while potentially improving fuel efficiency and reducing emissions. This trend aligns with broader automotive industry shifts towards more sustainable practices, even within the customization sector.

The market for K24 engine customization extends beyond individual consumers to include racing teams and professional builders. These segments demand high-end, specialized components and services, contributing to the growth of a premium market niche within the K24 customization landscape.

As vehicle manufacturers continue to shift towards electrification, the K24 engine represents a last bastion of highly customizable internal combustion technology for many enthusiasts. This factor has created a sense of urgency in the market, with consumers and businesses alike investing in K24 projects as a way to preserve and celebrate traditional automotive engineering.

Technical Challenges

The K24 engine, renowned for its versatility and performance, faces several technical challenges in the realm of vehicle customization. One of the primary obstacles is achieving optimal balance between power output and fuel efficiency. As enthusiasts seek to enhance the engine's performance, maintaining or improving fuel economy becomes increasingly difficult, requiring advanced engineering solutions.

Another significant challenge lies in the thermal management of highly customized K24 engines. Increased power output often leads to higher operating temperatures, necessitating more sophisticated cooling systems. This becomes particularly crucial in high-performance applications where sustained power delivery is essential.

The integration of modern electronic control systems with the K24 engine presents another hurdle. While the engine's basic architecture is robust, adapting it to work seamlessly with cutting-edge engine management systems, drive-by-wire technology, and advanced diagnostics can be complex. This integration is vital for meeting stringent emissions standards while still allowing for performance customization.

Material selection and durability pose additional challenges, especially when pushing the engine beyond its original design parameters. Customizers must carefully consider the use of aftermarket components and their impact on long-term reliability. Balancing performance gains with component longevity requires extensive testing and validation.

Noise, vibration, and harshness (NVH) management becomes more challenging as the engine is modified for higher output. Maintaining acceptable levels of refinement while significantly increasing power can be a delicate balancing act, often requiring innovative solutions in engine mounting and exhaust system design.

The aftermarket ecosystem surrounding the K24 engine, while extensive, also presents challenges in terms of part compatibility and quality control. Ensuring that various aftermarket components work harmoniously together and meet OEM-level quality standards is crucial for both performance and reliability.

Lastly, the evolving regulatory landscape, particularly concerning emissions and fuel efficiency standards, poses ongoing challenges for K24 engine customization. Adapting high-performance builds to comply with increasingly stringent regulations requires continuous innovation in areas such as combustion efficiency, exhaust after-treatment, and engine control strategies.

Another significant challenge lies in the thermal management of highly customized K24 engines. Increased power output often leads to higher operating temperatures, necessitating more sophisticated cooling systems. This becomes particularly crucial in high-performance applications where sustained power delivery is essential.

The integration of modern electronic control systems with the K24 engine presents another hurdle. While the engine's basic architecture is robust, adapting it to work seamlessly with cutting-edge engine management systems, drive-by-wire technology, and advanced diagnostics can be complex. This integration is vital for meeting stringent emissions standards while still allowing for performance customization.

Material selection and durability pose additional challenges, especially when pushing the engine beyond its original design parameters. Customizers must carefully consider the use of aftermarket components and their impact on long-term reliability. Balancing performance gains with component longevity requires extensive testing and validation.

Noise, vibration, and harshness (NVH) management becomes more challenging as the engine is modified for higher output. Maintaining acceptable levels of refinement while significantly increasing power can be a delicate balancing act, often requiring innovative solutions in engine mounting and exhaust system design.

The aftermarket ecosystem surrounding the K24 engine, while extensive, also presents challenges in terms of part compatibility and quality control. Ensuring that various aftermarket components work harmoniously together and meet OEM-level quality standards is crucial for both performance and reliability.

Lastly, the evolving regulatory landscape, particularly concerning emissions and fuel efficiency standards, poses ongoing challenges for K24 engine customization. Adapting high-performance builds to comply with increasingly stringent regulations requires continuous innovation in areas such as combustion efficiency, exhaust after-treatment, and engine control strategies.

Current K24 Solutions

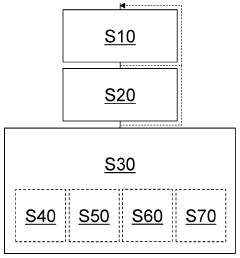

01 Engine Control Unit (ECU) Customization

Customizing the Engine Control Unit (ECU) is a key aspect of K24 engine modification. This involves reprogramming the ECU to optimize fuel injection, ignition timing, and other parameters for improved performance. Advanced ECU customization can include features like adjustable rev limits, launch control, and custom mapping for different fuel types or boost levels.- Engine Control Unit (ECU) Customization: Customizing the Engine Control Unit (ECU) is a key aspect of K24 engine modification. This involves reprogramming the ECU to optimize fuel injection, ignition timing, and other parameters for improved performance. Advanced ECU customization can include features like adjustable rev limits, launch control, and custom mapping for different fuel types or boost levels.

- Intake and Exhaust System Modifications: Enhancing the K24 engine's breathing capabilities through intake and exhaust system modifications is crucial for increased power output. This can include installing high-flow air intakes, larger throttle bodies, performance headers, and free-flowing exhaust systems. These modifications work together to reduce restrictions and improve overall engine efficiency.

- Forced Induction Implementation: Adding forced induction, such as turbocharging or supercharging, is a popular method to significantly increase the K24 engine's power output. This involves careful selection and integration of components like turbochargers, intercoolers, and blow-off valves, along with necessary fueling and ECU adjustments to handle the increased air intake.

- Internal Engine Component Upgrades: Upgrading internal engine components is essential for building a high-performance K24 engine. This can include installing forged pistons, stronger connecting rods, performance camshafts, and valvetrain upgrades. These modifications improve the engine's ability to handle increased power and higher RPMs while maintaining reliability.

- Fuel System Enhancements: Upgrading the fuel system is crucial when increasing the K24 engine's power output. This involves installing larger fuel injectors, high-flow fuel pumps, and adjustable fuel pressure regulators. Advanced fuel system modifications may include switching to E85 or other high-performance fuel types, requiring appropriate sensor and ECU calibrations.

02 Intake and Exhaust System Modifications

Enhancing the K24 engine's breathing capabilities through intake and exhaust system modifications is crucial for increased power output. This can include installing high-flow air intakes, larger throttle bodies, performance headers, and free-flowing exhaust systems. These modifications work together to reduce restriction and improve overall engine efficiency.Expand Specific Solutions03 Forced Induction Implementation

Adding forced induction, such as turbocharging or supercharging, is a popular method to significantly increase the K24 engine's power output. This involves careful selection and integration of components like turbochargers, intercoolers, and blow-off valves, along with necessary fueling and ECU adjustments to handle the increased air intake.Expand Specific Solutions04 Internal Engine Component Upgrades

Upgrading internal engine components is essential for building a high-performance K24 engine. This can include installing forged pistons, stronger connecting rods, performance camshafts, and valvetrain upgrades. These modifications improve the engine's ability to handle increased power and higher RPMs while maintaining reliability.Expand Specific Solutions05 Fuel System Enhancements

Upgrading the fuel system is crucial when increasing the K24 engine's power output. This involves installing larger fuel injectors, high-flow fuel pumps, and adjustable fuel pressure regulators. Advanced fuel system modifications may include switching to alternative fuels or implementing multi-stage injection systems for optimal performance across different operating conditions.Expand Specific Solutions

Key Industry Players

The K24 Engine technology is shaping the future of vehicle customization in a rapidly evolving automotive landscape. The market is in a growth phase, with increasing demand for personalized and high-performance vehicles. The global market size for custom engines is expanding, driven by enthusiasts and performance-oriented consumers. Technologically, the K24 Engine is reaching maturity, with companies like GM Global Technology Operations, Zhejiang Geely, and Hyundai Motor Co. leading innovation. Established players such as Ford Global Technologies and BMW are also investing in this technology, while emerging companies like NIO and Chery Automobile are entering the market, indicating a competitive and dynamic environment.

GM Global Technology Operations LLC

Technical Solution: GM's approach to K24 Engine customization focuses on modular design and advanced manufacturing techniques. They have developed a flexible engine architecture that allows for easy customization of key components such as cylinder heads, intake manifolds, and fuel injection systems. This modular approach enables GM to quickly adapt the K24 Engine to different vehicle models and performance requirements[1]. Additionally, GM has implemented advanced 3D printing and rapid prototyping techniques to accelerate the development and testing of customized engine components[2]. Their system also incorporates AI-driven optimization algorithms to fine-tune engine parameters for specific vehicle applications, ensuring optimal performance and efficiency across a wide range of driving conditions[3].

Strengths: Modular design allows for rapid customization; Advanced manufacturing techniques reduce development time; AI-driven optimization enhances performance. Weaknesses: Potential increased complexity in production; Higher initial investment in flexible manufacturing systems.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's K24 Engine customization strategy focuses on their Smart Stream technology platform. They have developed a modular engine architecture that allows for easy adaptation to different vehicle sizes and performance requirements. Hyundai's approach incorporates Continuously Variable Valve Duration (CVVD) technology, which enables precise control of valve timing and duration for optimal performance and efficiency[10]. They have also implemented a low-pressure exhaust gas recirculation system and an integrated thermal management system to enhance fuel efficiency and reduce emissions. Hyundai's customization process is supported by advanced CAE (Computer-Aided Engineering) tools and AI-driven optimization algorithms to fine-tune engine parameters for specific vehicle applications[11]. Additionally, they have invested in flexible manufacturing systems that allow for rapid production changes to meet varying market demands.

Strengths: Innovative CVVD technology offers precise control; Advanced thermal management improves efficiency; Flexible manufacturing enables quick adaptation. Weaknesses: Potential increased complexity due to advanced valve control systems; Higher initial investment in flexible manufacturing.

K24 Innovations

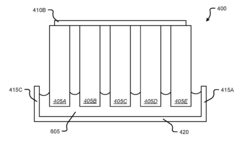

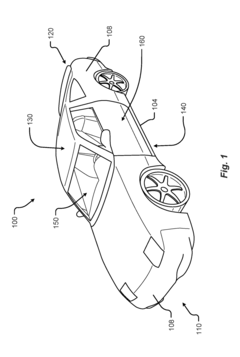

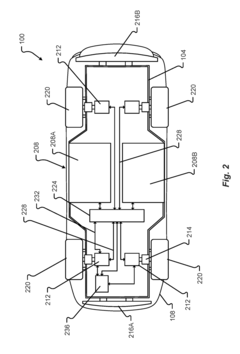

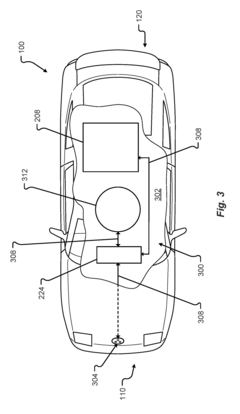

Thermally conductive potting for module retainer and thermal link

PatentInactiveUS20180261813A1

Innovation

- A modular vehicle frame with interchangeable subsystems and power sources, including a power source module with thermally conductive potting material, allowing quick exchange and integration of components, and interconnecting features for energy sharing and enhanced safety.

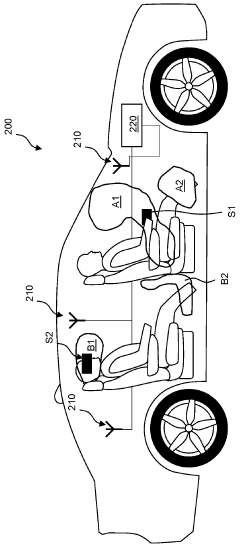

INDIVIDUALIZATION OF A VEHICLE, ESPECIALLY THE VEHICLE INTERIOR

PatentPendingDE102022129560A1

Innovation

- A method and system that utilize a smart device's ID to automate vehicle interior customization, determining its position and type, and adjusting settings such as lighting, displays, and climate based on user-specific data.

Customization Trends

The automotive industry is witnessing a significant shift towards vehicle customization, driven by consumer demand for personalized driving experiences. This trend is particularly evident in the aftermarket sector, where enthusiasts and performance-oriented drivers seek to modify their vehicles for enhanced performance, aesthetics, and functionality.

The K24 engine, known for its versatility and robust design, has become a focal point in this customization trend. Originally developed by Honda, the K24 has found its way into a variety of vehicles and has become a popular choice for engine swaps and modifications. Its adaptability and potential for performance upgrades have made it a favorite among car enthusiasts and tuners.

One of the key factors driving the customization trend is the increasing availability of aftermarket parts and accessories specifically designed for the K24 engine. These components allow for a wide range of modifications, from simple bolt-on upgrades to complete engine rebuilds. The aftermarket industry has responded to this demand by developing a diverse ecosystem of products, including high-performance camshafts, turbocharger kits, and engine management systems.

The rise of digital technologies has also played a crucial role in shaping customization trends. Advanced engine tuning software and diagnostic tools have made it easier for enthusiasts to optimize their K24 engines for specific performance goals. This democratization of engine tuning has led to a growing community of DIY modifiers who share knowledge and experiences online, further fueling the customization trend.

Another significant trend is the integration of K24 engines into non-Honda vehicles. This cross-platform compatibility has opened up new possibilities for customization, allowing enthusiasts to create unique hybrid builds that combine the best attributes of different vehicle platforms. This trend has led to the development of specialized mounting kits and adapters, enabling smoother integration of the K24 into a variety of chassis.

Environmental concerns and regulations have also influenced customization trends, with a growing focus on improving fuel efficiency and reducing emissions without sacrificing performance. This has led to innovations in engine management systems and the development of eco-friendly performance upgrades, aligning the customization trend with broader sustainability goals in the automotive industry.

As the customization trend continues to evolve, we can expect to see further innovations in K24 engine modifications, driven by advancements in materials science, manufacturing techniques, and digital technologies. The future of vehicle customization, shaped by the versatility of engines like the K24, promises to offer even more exciting possibilities for enthusiasts and performance-oriented drivers.

The K24 engine, known for its versatility and robust design, has become a focal point in this customization trend. Originally developed by Honda, the K24 has found its way into a variety of vehicles and has become a popular choice for engine swaps and modifications. Its adaptability and potential for performance upgrades have made it a favorite among car enthusiasts and tuners.

One of the key factors driving the customization trend is the increasing availability of aftermarket parts and accessories specifically designed for the K24 engine. These components allow for a wide range of modifications, from simple bolt-on upgrades to complete engine rebuilds. The aftermarket industry has responded to this demand by developing a diverse ecosystem of products, including high-performance camshafts, turbocharger kits, and engine management systems.

The rise of digital technologies has also played a crucial role in shaping customization trends. Advanced engine tuning software and diagnostic tools have made it easier for enthusiasts to optimize their K24 engines for specific performance goals. This democratization of engine tuning has led to a growing community of DIY modifiers who share knowledge and experiences online, further fueling the customization trend.

Another significant trend is the integration of K24 engines into non-Honda vehicles. This cross-platform compatibility has opened up new possibilities for customization, allowing enthusiasts to create unique hybrid builds that combine the best attributes of different vehicle platforms. This trend has led to the development of specialized mounting kits and adapters, enabling smoother integration of the K24 into a variety of chassis.

Environmental concerns and regulations have also influenced customization trends, with a growing focus on improving fuel efficiency and reducing emissions without sacrificing performance. This has led to innovations in engine management systems and the development of eco-friendly performance upgrades, aligning the customization trend with broader sustainability goals in the automotive industry.

As the customization trend continues to evolve, we can expect to see further innovations in K24 engine modifications, driven by advancements in materials science, manufacturing techniques, and digital technologies. The future of vehicle customization, shaped by the versatility of engines like the K24, promises to offer even more exciting possibilities for enthusiasts and performance-oriented drivers.

Environmental Impact

The K24 engine's impact on vehicle customization has significant environmental implications that warrant careful consideration. As this engine gains popularity in the automotive aftermarket, its environmental footprint becomes increasingly relevant.

One of the primary environmental concerns is the potential increase in fuel consumption and emissions. While the K24 engine is known for its performance capabilities, extensive modifications to enhance power output may lead to reduced fuel efficiency and increased carbon emissions. This is particularly true when enthusiasts prioritize performance over eco-friendly considerations.

However, the K24 engine also presents opportunities for environmental improvements. Its adaptability allows for the integration of advanced fuel management systems and emission control technologies. Aftermarket companies are developing eco-conscious upgrades that balance performance gains with reduced environmental impact, such as more efficient fuel injection systems and catalytic converters designed specifically for modified K24 engines.

The longevity of K24-powered vehicles is another factor to consider. By extending the lifespan of older vehicles through engine swaps and upgrades, the K24 potentially reduces the demand for new vehicle production, thereby lowering the overall environmental impact associated with manufacturing processes and resource extraction.

Recycling and remanufacturing of K24 engine components also play a crucial role in minimizing environmental impact. As the engine becomes more prevalent in the customization scene, a robust aftermarket for refurbished parts is emerging, promoting circular economy principles within the automotive industry.

The trend towards electrification in the automotive sector raises questions about the long-term environmental viability of combustion engine customization. However, the K24's adaptability may position it as a platform for hybrid conversions, potentially bridging the gap between traditional combustion engines and fully electric powertrains.

Lastly, the environmental impact of K24 engine customization extends beyond the vehicle itself. The manufacturing and distribution of aftermarket parts, as well as the energy consumed in workshops during customization processes, contribute to the overall environmental footprint. As such, the industry is increasingly focusing on sustainable practices in production and installation to mitigate these effects.

One of the primary environmental concerns is the potential increase in fuel consumption and emissions. While the K24 engine is known for its performance capabilities, extensive modifications to enhance power output may lead to reduced fuel efficiency and increased carbon emissions. This is particularly true when enthusiasts prioritize performance over eco-friendly considerations.

However, the K24 engine also presents opportunities for environmental improvements. Its adaptability allows for the integration of advanced fuel management systems and emission control technologies. Aftermarket companies are developing eco-conscious upgrades that balance performance gains with reduced environmental impact, such as more efficient fuel injection systems and catalytic converters designed specifically for modified K24 engines.

The longevity of K24-powered vehicles is another factor to consider. By extending the lifespan of older vehicles through engine swaps and upgrades, the K24 potentially reduces the demand for new vehicle production, thereby lowering the overall environmental impact associated with manufacturing processes and resource extraction.

Recycling and remanufacturing of K24 engine components also play a crucial role in minimizing environmental impact. As the engine becomes more prevalent in the customization scene, a robust aftermarket for refurbished parts is emerging, promoting circular economy principles within the automotive industry.

The trend towards electrification in the automotive sector raises questions about the long-term environmental viability of combustion engine customization. However, the K24's adaptability may position it as a platform for hybrid conversions, potentially bridging the gap between traditional combustion engines and fully electric powertrains.

Lastly, the environmental impact of K24 engine customization extends beyond the vehicle itself. The manufacturing and distribution of aftermarket parts, as well as the energy consumed in workshops during customization processes, contribute to the overall environmental footprint. As such, the industry is increasingly focusing on sustainable practices in production and installation to mitigate these effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!