Nanorobotics Manufacturing Materials: Selection And Toxicology Data

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanorobotics Materials Background and Objectives

Nanorobotics represents a cutting-edge field at the intersection of nanotechnology, robotics, and materials science. The development of nanorobots holds immense potential for revolutionizing various sectors, particularly in medicine, manufacturing, and environmental remediation. As we delve into the background of nanorobotics materials, it is crucial to understand the historical context and the evolving objectives that drive this field forward.

The concept of nanorobotics emerged in the late 20th century, inspired by Richard Feynman's visionary lecture "There's Plenty of Room at the Bottom" in 1959. Since then, advancements in nanotechnology and miniaturization have paved the way for the practical realization of nanorobots. The primary goal of nanorobotics is to create functional machines at the nanoscale, capable of performing specific tasks with unprecedented precision and efficiency.

The selection of appropriate materials for nanorobotics manufacturing is a critical aspect that determines the functionality, durability, and biocompatibility of these miniature devices. Traditional materials used in macro-scale robotics often prove inadequate at the nanoscale due to unique physical and chemical properties that emerge at this level. Consequently, researchers are exploring a wide range of novel materials, including carbon nanotubes, DNA origami, and smart polymers, to construct nanorobots with desired characteristics.

One of the key objectives in nanorobotics materials research is to develop materials that can withstand the harsh environments in which nanorobots are expected to operate. This includes resistance to chemical reactions, mechanical stress, and temperature fluctuations. Additionally, there is a growing emphasis on creating materials that can respond to external stimuli, enabling the development of intelligent and adaptive nanorobots.

The toxicological aspects of nanorobotics materials have gained significant attention in recent years. As these devices are intended for use in biological systems and the environment, ensuring their safety is paramount. Researchers are focusing on understanding the potential toxic effects of nanomaterials on living organisms and ecosystems. This involves comprehensive studies on the biodegradability, bioaccumulation, and long-term effects of nanorobotics materials.

The overarching objective of nanorobotics materials research is to strike a balance between functionality and safety. This entails developing materials that not only possess the required mechanical, electrical, and chemical properties but also demonstrate minimal toxicity and environmental impact. Achieving this balance is crucial for the widespread adoption and ethical implementation of nanorobotics technology across various applications.

As the field progresses, there is an increasing focus on sustainable and bio-inspired materials for nanorobotics. Researchers are looking towards nature for inspiration, studying biological systems that operate at the nanoscale to develop more efficient and compatible nanorobotic materials. This bio-mimetic approach holds promise for creating nanorobots that can seamlessly integrate with living systems while minimizing adverse effects.

The concept of nanorobotics emerged in the late 20th century, inspired by Richard Feynman's visionary lecture "There's Plenty of Room at the Bottom" in 1959. Since then, advancements in nanotechnology and miniaturization have paved the way for the practical realization of nanorobots. The primary goal of nanorobotics is to create functional machines at the nanoscale, capable of performing specific tasks with unprecedented precision and efficiency.

The selection of appropriate materials for nanorobotics manufacturing is a critical aspect that determines the functionality, durability, and biocompatibility of these miniature devices. Traditional materials used in macro-scale robotics often prove inadequate at the nanoscale due to unique physical and chemical properties that emerge at this level. Consequently, researchers are exploring a wide range of novel materials, including carbon nanotubes, DNA origami, and smart polymers, to construct nanorobots with desired characteristics.

One of the key objectives in nanorobotics materials research is to develop materials that can withstand the harsh environments in which nanorobots are expected to operate. This includes resistance to chemical reactions, mechanical stress, and temperature fluctuations. Additionally, there is a growing emphasis on creating materials that can respond to external stimuli, enabling the development of intelligent and adaptive nanorobots.

The toxicological aspects of nanorobotics materials have gained significant attention in recent years. As these devices are intended for use in biological systems and the environment, ensuring their safety is paramount. Researchers are focusing on understanding the potential toxic effects of nanomaterials on living organisms and ecosystems. This involves comprehensive studies on the biodegradability, bioaccumulation, and long-term effects of nanorobotics materials.

The overarching objective of nanorobotics materials research is to strike a balance between functionality and safety. This entails developing materials that not only possess the required mechanical, electrical, and chemical properties but also demonstrate minimal toxicity and environmental impact. Achieving this balance is crucial for the widespread adoption and ethical implementation of nanorobotics technology across various applications.

As the field progresses, there is an increasing focus on sustainable and bio-inspired materials for nanorobotics. Researchers are looking towards nature for inspiration, studying biological systems that operate at the nanoscale to develop more efficient and compatible nanorobotic materials. This bio-mimetic approach holds promise for creating nanorobots that can seamlessly integrate with living systems while minimizing adverse effects.

Market Analysis for Nanorobotics Applications

The nanorobotics market is experiencing rapid growth and diversification across multiple industries. The global market for nanorobotics applications is projected to reach significant value in the coming years, driven by advancements in nanotechnology, increasing investment in research and development, and growing demand for minimally invasive medical procedures.

In the healthcare sector, nanorobotics applications show immense potential. These microscopic robots can be used for targeted drug delivery, precision surgery, and early disease detection. The ability to navigate through the human body at the cellular level opens up new possibilities for treating various conditions, including cancer and cardiovascular diseases. This segment of the market is expected to witness substantial growth due to the aging population and the rising prevalence of chronic diseases.

The electronics and semiconductor industry is another key area for nanorobotics applications. Nanorobots can be utilized in the manufacturing of advanced microchips, enabling the creation of smaller, more efficient electronic devices. As the demand for miniaturization in consumer electronics continues to rise, the market for nanorobotics in this sector is anticipated to expand significantly.

Environmental applications of nanorobotics are also gaining traction. These tiny machines can be employed for water purification, air quality monitoring, and soil remediation. The increasing focus on sustainability and environmental protection is likely to drive demand for nanorobotics solutions in this field.

In the manufacturing sector, nanorobotics offers the potential for enhanced quality control, precision assembly, and material manipulation at the nanoscale. This could lead to the development of new materials with unique properties and improved manufacturing processes across various industries.

The defense and aerospace industries are exploring nanorobotics applications for surveillance, reconnaissance, and damage repair in hard-to-reach areas. The ability of nanorobots to operate in extreme environments makes them valuable assets in these sectors.

Despite the promising market outlook, challenges remain. Concerns regarding the potential toxicity of nanomaterials used in nanorobotics manufacturing and their long-term effects on human health and the environment need to be addressed. Regulatory frameworks and safety standards for nanorobotics applications are still evolving, which may impact market growth in certain regions.

As research in nanorobotics manufacturing materials progresses, addressing toxicology data and material selection will be crucial for market acceptance and regulatory approval. The development of biocompatible and environmentally friendly nanomaterials will be a key factor in expanding the market potential of nanorobotics across various applications.

In the healthcare sector, nanorobotics applications show immense potential. These microscopic robots can be used for targeted drug delivery, precision surgery, and early disease detection. The ability to navigate through the human body at the cellular level opens up new possibilities for treating various conditions, including cancer and cardiovascular diseases. This segment of the market is expected to witness substantial growth due to the aging population and the rising prevalence of chronic diseases.

The electronics and semiconductor industry is another key area for nanorobotics applications. Nanorobots can be utilized in the manufacturing of advanced microchips, enabling the creation of smaller, more efficient electronic devices. As the demand for miniaturization in consumer electronics continues to rise, the market for nanorobotics in this sector is anticipated to expand significantly.

Environmental applications of nanorobotics are also gaining traction. These tiny machines can be employed for water purification, air quality monitoring, and soil remediation. The increasing focus on sustainability and environmental protection is likely to drive demand for nanorobotics solutions in this field.

In the manufacturing sector, nanorobotics offers the potential for enhanced quality control, precision assembly, and material manipulation at the nanoscale. This could lead to the development of new materials with unique properties and improved manufacturing processes across various industries.

The defense and aerospace industries are exploring nanorobotics applications for surveillance, reconnaissance, and damage repair in hard-to-reach areas. The ability of nanorobots to operate in extreme environments makes them valuable assets in these sectors.

Despite the promising market outlook, challenges remain. Concerns regarding the potential toxicity of nanomaterials used in nanorobotics manufacturing and their long-term effects on human health and the environment need to be addressed. Regulatory frameworks and safety standards for nanorobotics applications are still evolving, which may impact market growth in certain regions.

As research in nanorobotics manufacturing materials progresses, addressing toxicology data and material selection will be crucial for market acceptance and regulatory approval. The development of biocompatible and environmentally friendly nanomaterials will be a key factor in expanding the market potential of nanorobotics across various applications.

Current Challenges in Nanorobotics Material Science

The field of nanorobotics material science faces several significant challenges that hinder the development and application of nanorobots. One of the primary obstacles is the selection of suitable materials for nanorobot construction. The materials must possess specific properties to function effectively at the nanoscale, including biocompatibility, durability, and responsiveness to external stimuli. However, finding materials that meet all these criteria while maintaining the required nanoscale dimensions remains a formidable task.

Another critical challenge lies in the manufacturing processes for nanorobotic materials. Traditional manufacturing techniques often prove inadequate when working at the nanoscale, necessitating the development of novel fabrication methods. These new techniques must ensure precise control over material properties and structures at the molecular level, which is essential for creating functional nanorobots.

The toxicological aspects of nanorobotics materials present a significant concern, particularly for applications in biological systems. As nanorobots are designed to interact with living organisms, the potential toxic effects of the materials used in their construction must be thoroughly investigated. This includes understanding how these materials behave in biological environments, their potential for accumulation in tissues, and any long-term effects on cellular functions.

Furthermore, the stability and degradation of nanorobotics materials in various environments pose additional challenges. Materials must maintain their integrity and functionality under diverse conditions, yet also be capable of controlled degradation or removal from the system when their task is complete. Balancing these conflicting requirements demands innovative material design and engineering approaches.

The characterization and quality control of nanorobotics materials represent another significant hurdle. Existing analytical techniques may not be sufficient to fully assess the properties and behavior of materials at the nanoscale, necessitating the development of new characterization methods. Ensuring consistency and reproducibility in material production is crucial for the reliable performance of nanorobots.

Lastly, the scalability of nanorobotics material production presents a considerable challenge. While laboratory-scale synthesis may be achievable, scaling up production to meet potential commercial demands requires overcoming numerous technical and economic barriers. This includes developing cost-effective manufacturing processes and ensuring the consistent quality of materials produced in large quantities.

Another critical challenge lies in the manufacturing processes for nanorobotic materials. Traditional manufacturing techniques often prove inadequate when working at the nanoscale, necessitating the development of novel fabrication methods. These new techniques must ensure precise control over material properties and structures at the molecular level, which is essential for creating functional nanorobots.

The toxicological aspects of nanorobotics materials present a significant concern, particularly for applications in biological systems. As nanorobots are designed to interact with living organisms, the potential toxic effects of the materials used in their construction must be thoroughly investigated. This includes understanding how these materials behave in biological environments, their potential for accumulation in tissues, and any long-term effects on cellular functions.

Furthermore, the stability and degradation of nanorobotics materials in various environments pose additional challenges. Materials must maintain their integrity and functionality under diverse conditions, yet also be capable of controlled degradation or removal from the system when their task is complete. Balancing these conflicting requirements demands innovative material design and engineering approaches.

The characterization and quality control of nanorobotics materials represent another significant hurdle. Existing analytical techniques may not be sufficient to fully assess the properties and behavior of materials at the nanoscale, necessitating the development of new characterization methods. Ensuring consistency and reproducibility in material production is crucial for the reliable performance of nanorobots.

Lastly, the scalability of nanorobotics material production presents a considerable challenge. While laboratory-scale synthesis may be achievable, scaling up production to meet potential commercial demands requires overcoming numerous technical and economic barriers. This includes developing cost-effective manufacturing processes and ensuring the consistent quality of materials produced in large quantities.

Existing Nanorobotics Material Selection Strategies

01 Nanomaterials for nanorobotics manufacturing

Various nanomaterials are used in the manufacturing of nanorobots, including carbon nanotubes, graphene, and metallic nanoparticles. These materials offer unique properties such as high strength, conductivity, and biocompatibility, which are essential for nanorobotics applications. The selection and processing of these materials are crucial for ensuring the functionality and safety of nanorobots.- Nanomaterials for nanorobotics manufacturing: Various nanomaterials are used in the manufacturing of nanorobots, including carbon nanotubes, graphene, and metallic nanoparticles. These materials offer unique properties such as high strength, conductivity, and biocompatibility, which are essential for nanorobot functionality. The selection and processing of these materials are crucial for optimizing nanorobot performance and minimizing potential toxicity.

- Toxicological assessment of nanorobotics materials: Evaluating the toxicity of materials used in nanorobotics is critical for ensuring their safety in biological applications. This involves studying the potential harmful effects of nanomaterials on living organisms and the environment. Advanced toxicological testing methods, including in vitro and in vivo studies, are employed to assess the biocompatibility and potential long-term effects of nanorobotics materials.

- Biocompatible materials for medical nanorobotics: The development of biocompatible materials is crucial for medical applications of nanorobotics. These materials must be non-toxic, non-immunogenic, and capable of functioning within biological systems without causing adverse effects. Research focuses on creating biodegradable and bioresorbable materials that can safely dissolve in the body after completing their intended tasks.

- Manufacturing processes for nanorobotics: Advanced manufacturing techniques are employed in the production of nanorobots, including lithography, 3D printing at the nanoscale, and self-assembly methods. These processes must be optimized to ensure precise control over the nanorobot structure and composition while minimizing the introduction of contaminants or defects that could affect toxicity or performance.

- Environmental impact and safety regulations: The potential environmental impact of nanorobotics materials and their manufacturing processes is a growing concern. Research is focused on developing eco-friendly materials and production methods to minimize environmental risks. Additionally, regulatory frameworks are being established to govern the safe development, use, and disposal of nanorobotics materials, addressing both human health and environmental safety concerns.

02 Toxicological assessment of nanorobotics materials

Evaluating the toxicity of materials used in nanorobotics is critical for ensuring their safety in biological applications. This involves studying the potential harmful effects of nanomaterials on living organisms and the environment. Advanced toxicological testing methods, including in vitro and in vivo studies, are employed to assess the biocompatibility and potential risks associated with nanorobotics materials.Expand Specific Solutions03 Manufacturing processes for nanorobots

Specialized manufacturing techniques are developed for producing nanorobots with precise control over their structure and properties. These processes may include molecular self-assembly, lithography, and advanced 3D printing methods. The manufacturing approach must ensure the integrity of the nanorobot's components while minimizing potential contamination or structural defects that could affect performance or safety.Expand Specific Solutions04 Biocompatibility and biodegradability of nanorobotics materials

Developing biocompatible and biodegradable materials for nanorobotics is essential for medical applications. These materials should perform their intended functions without causing adverse reactions in biological systems and degrade safely after use. Research focuses on creating nanorobots that can operate effectively within the body and then be eliminated or absorbed without leaving harmful residues.Expand Specific Solutions05 Environmental impact and safety regulations for nanorobotics

Addressing the potential environmental impact of nanorobotics materials and establishing safety regulations are crucial aspects of the field. This includes developing protocols for the safe handling, use, and disposal of nanomaterials, as well as assessing their long-term effects on ecosystems. Regulatory frameworks are being created to ensure responsible development and application of nanorobotics technologies.Expand Specific Solutions

Key Players in Nanorobotics Material Development

The research on nanorobotics manufacturing materials is in an early developmental stage, with a growing market potential as nanotechnology advances. The global nanorobotics market is projected to expand significantly in the coming years, driven by applications in medicine, manufacturing, and environmental monitoring. While the technology is still emerging, several key players are making strides in this field. Companies like Hunan Morning Nano Robot Co., Ltd. and research institutions such as The Shenzhen Institutes of Advanced Technology are at the forefront of nanorobotics development. Universities like Southern University of Science & Technology and Nanjing Tech University are contributing to fundamental research. The involvement of diverse organizations indicates a competitive landscape with opportunities for innovation and collaboration as the technology matures.

Hunan Morning Nano Robot Co., Ltd.

Technical Solution: Hunan Morning Nano Robot Co., Ltd. specializes in the development of nanorobotic systems for medical applications. Their research focuses on biocompatible materials for nanorobot manufacturing, particularly utilizing DNA origami techniques to create programmable nanostructures[1]. The company has developed a novel approach to synthesize gold nanoparticles functionalized with specific DNA sequences, allowing for precise assembly and control of nanorobots in biological environments[2]. Their nanorobots are designed to target specific cells or tissues, with potential applications in drug delivery and cancer treatment[3].

Strengths: Expertise in DNA-based nanorobot design, high precision in targeting specific cells. Weaknesses: Limited scalability for mass production, potential immunogenicity of DNA-based materials.

The Regents of the University of California

Technical Solution: The University of California's research on nanorobotics manufacturing materials focuses on developing biodegradable and biocompatible polymers for medical nanorobots. Their team has pioneered the use of polylactic-co-glycolic acid (PLGA) nanoparticles as a base material for nanorobot construction[4]. These PLGA nanorobots are designed to degrade safely in the body after completing their tasks, reducing long-term toxicity concerns. The university has also made significant progress in functionalizing these nanoparticles with targeting ligands and incorporating magnetic nanoparticles for external control[5]. Recent toxicology studies have shown minimal inflammatory responses in animal models, supporting the safety profile of their nanorobot designs[6].

Strengths: Advanced biodegradable materials, comprehensive toxicology data. Weaknesses: Slower degradation may limit applications requiring rapid clearance, potential variability in degradation rates.

Core Innovations in Nanorobotics Material Engineering

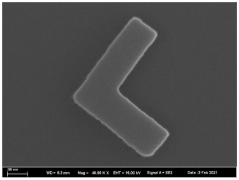

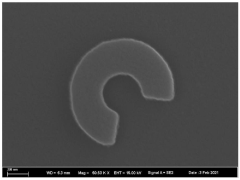

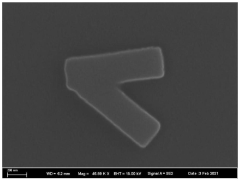

A magnetic micro-nano robot and its preparation method and application

PatentActiveCN113401863B

Innovation

- Nanoimprinting technology is used to form magnetic micro-nano robots through multiple reuses of soft and hard templates. Combined with ultrasonic vibration, the magnetic materials and biocompatible materials are shed, forming a two-dimensional micro-nano robot, which is suitable for mass production.

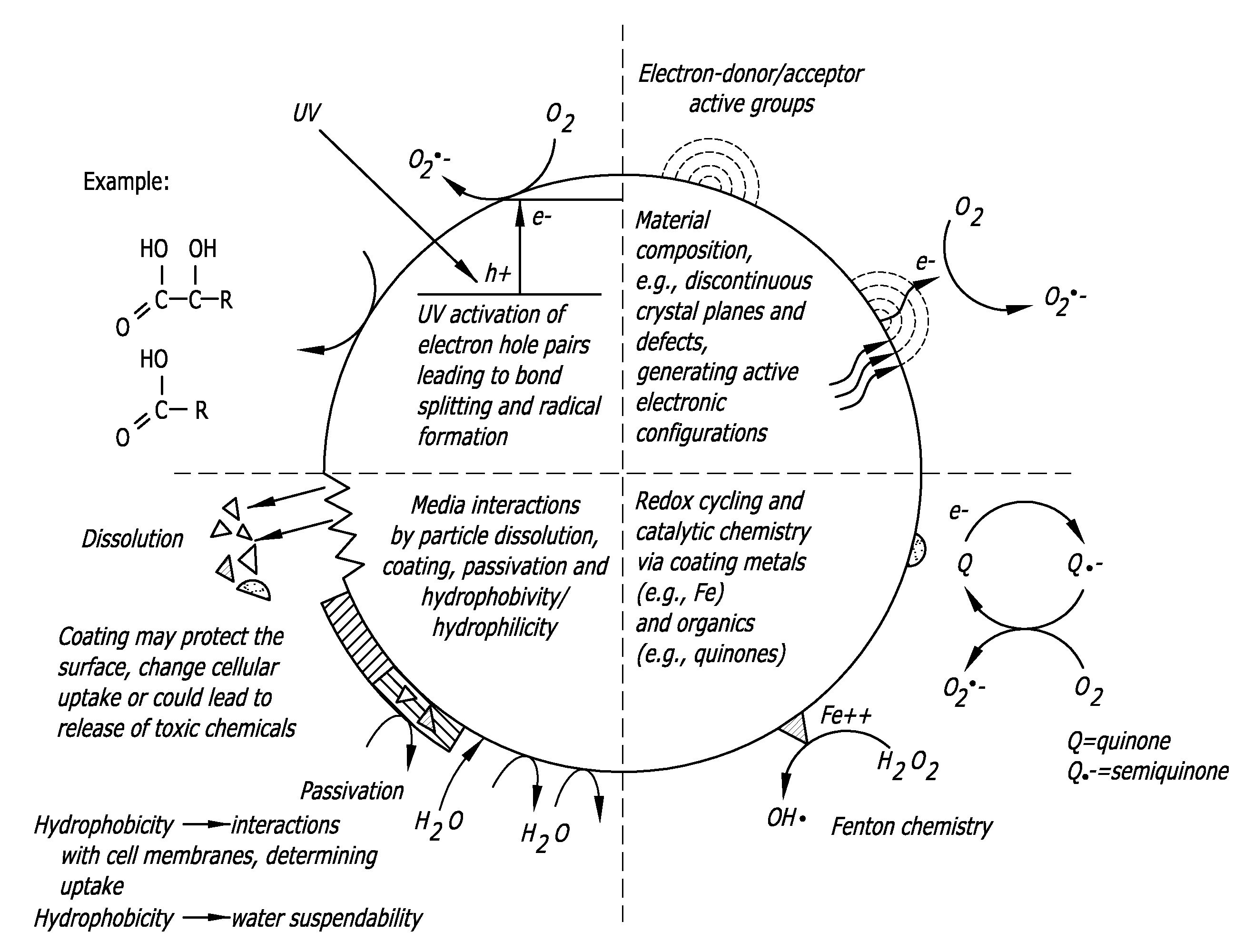

Accessing the Toxic Potential of Nanomaterials

PatentInactiveUS20080295187A1

Innovation

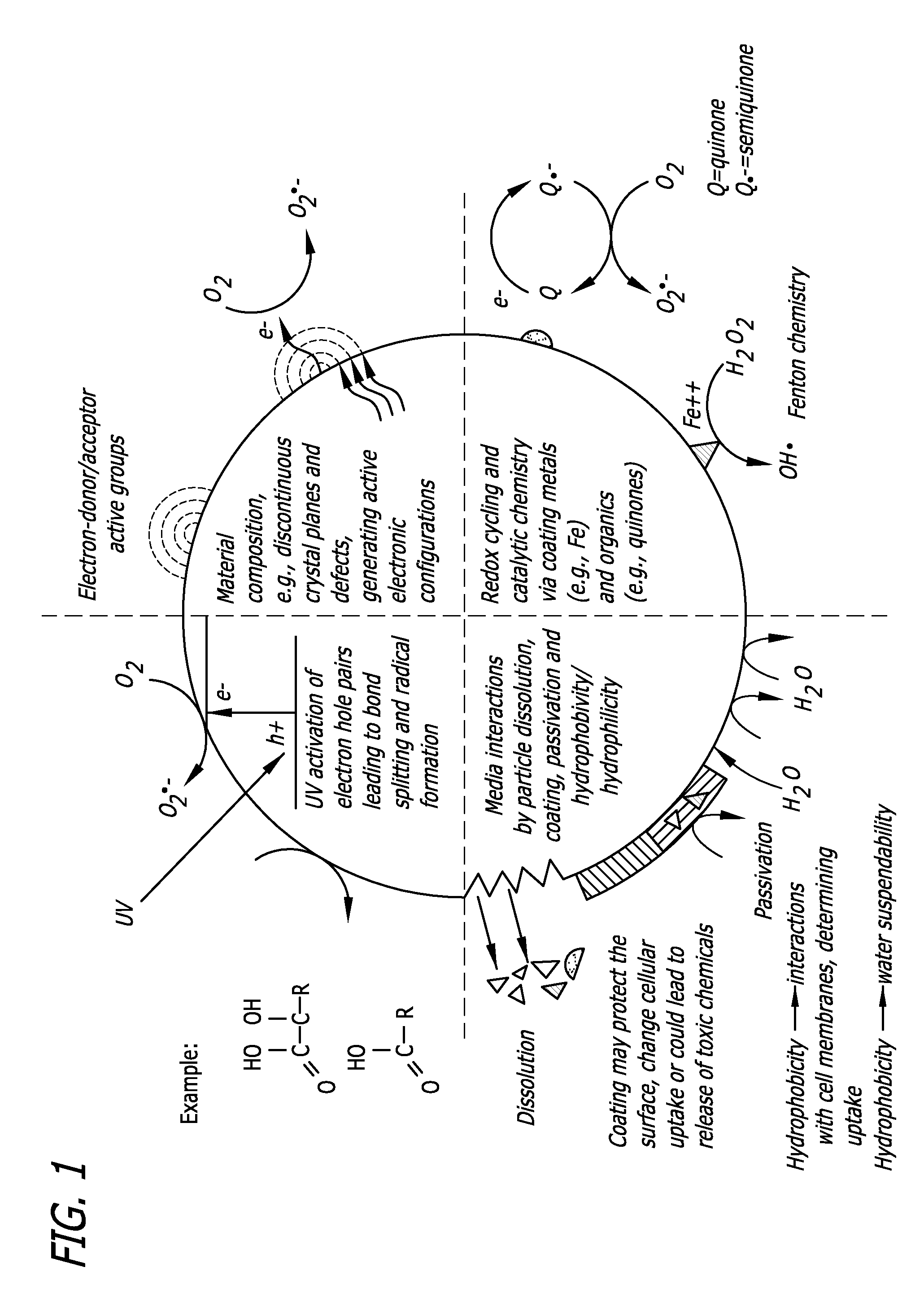

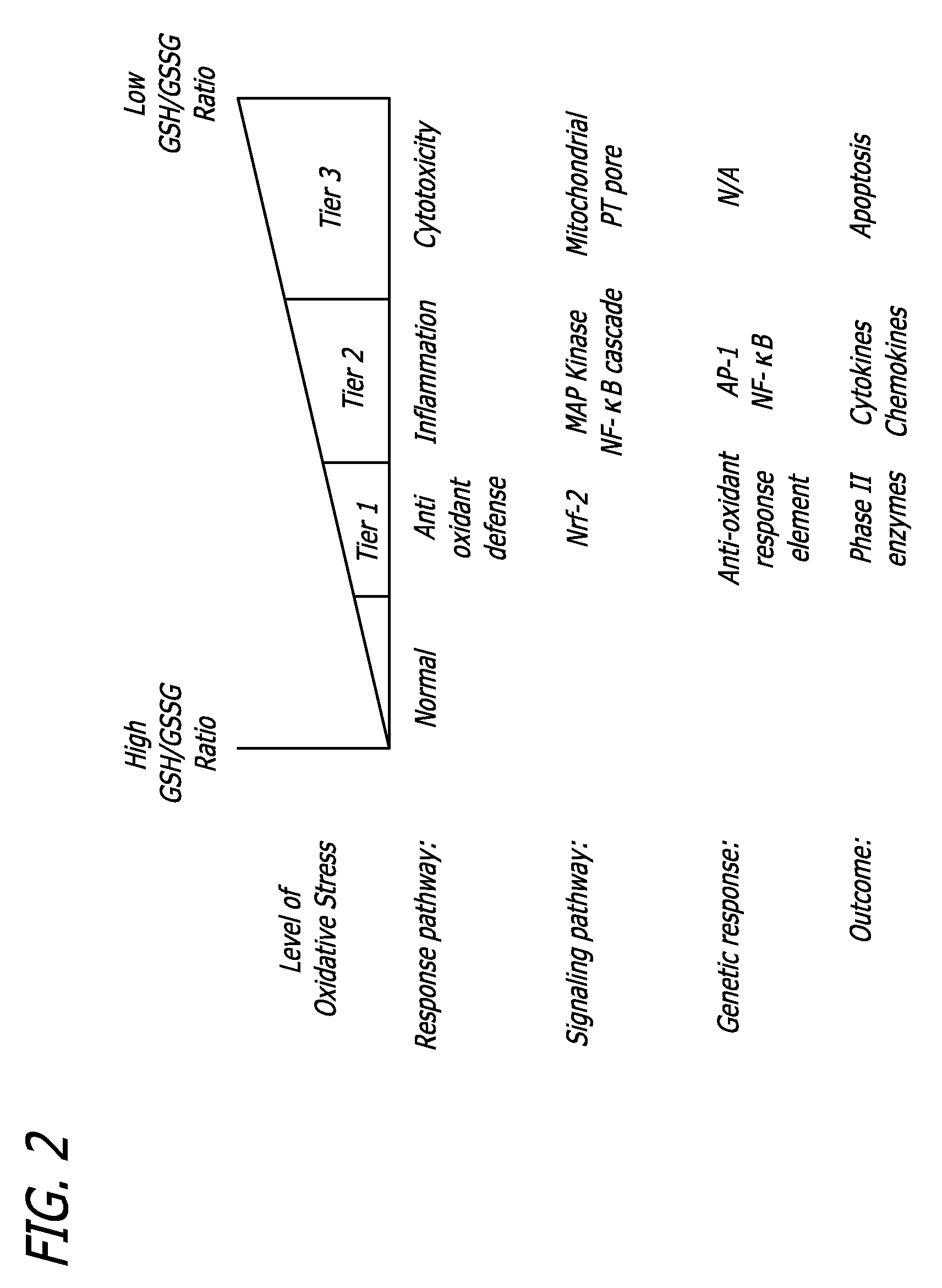

- A method is developed to assess the toxicity of nanomaterials by measuring reactive oxygen species (ROS) production, phase II antioxidant molecule expression, activation of pro-inflammatory cascades, mitochondrial perturbation, and cellular uptake, using various cell types and assays to predict potential adverse biological effects.

Toxicological Assessment of Nanorobotics Materials

The toxicological assessment of nanorobotics materials is a critical aspect of ensuring the safety and biocompatibility of these advanced technologies. As nanorobots are designed to operate within biological systems, understanding their potential toxicity is paramount for their successful development and application.

Nanorobotics materials encompass a wide range of substances, including metals, polymers, and composite materials. Each of these materials presents unique toxicological considerations that must be thoroughly evaluated. Metal-based nanorobots, for instance, may pose risks related to ion release and oxidative stress, while polymer-based systems might introduce concerns about biodegradation and potential accumulation in tissues.

One of the primary challenges in assessing the toxicity of nanorobotics materials is their size-dependent behavior. At the nanoscale, materials can exhibit properties significantly different from their bulk counterparts, potentially altering their interactions with biological systems. This necessitates the development of specialized toxicological assessment methods that can accurately capture these unique characteristics.

In vitro studies play a crucial role in the initial stages of toxicological assessment. These studies typically involve exposing cell cultures to nanorobotics materials and evaluating various endpoints, such as cell viability, oxidative stress markers, and inflammatory responses. However, it is essential to recognize the limitations of in vitro models and complement them with in vivo studies to gain a more comprehensive understanding of potential toxicity.

Animal models are invaluable for assessing the systemic effects of nanorobotics materials. These studies can provide insights into biodistribution, clearance mechanisms, and long-term toxicity. However, careful consideration must be given to the selection of appropriate animal models that can accurately represent human physiology and potential exposure scenarios.

The toxicological assessment of nanorobotics materials must also consider the potential for unintended interactions with biological systems. This includes evaluating the impact on cellular processes, such as protein folding and gene expression, as well as assessing the potential for nanorobots to interfere with normal physiological functions.

Furthermore, the environmental fate and potential ecological impacts of nanorobotics materials must be addressed. This involves studying their persistence, degradation pathways, and potential accumulation in various environmental compartments. Such assessments are crucial for developing responsible disposal methods and mitigating any potential environmental risks associated with the widespread use of nanorobots.

As the field of nanorobotics continues to advance, it is imperative to develop standardized protocols and guidelines for toxicological assessments. This will ensure consistency in evaluating the safety of different nanorobotics materials and facilitate regulatory approval processes. Collaboration between toxicologists, materials scientists, and nanorobotics engineers is essential for developing comprehensive and effective toxicological assessment strategies.

Nanorobotics materials encompass a wide range of substances, including metals, polymers, and composite materials. Each of these materials presents unique toxicological considerations that must be thoroughly evaluated. Metal-based nanorobots, for instance, may pose risks related to ion release and oxidative stress, while polymer-based systems might introduce concerns about biodegradation and potential accumulation in tissues.

One of the primary challenges in assessing the toxicity of nanorobotics materials is their size-dependent behavior. At the nanoscale, materials can exhibit properties significantly different from their bulk counterparts, potentially altering their interactions with biological systems. This necessitates the development of specialized toxicological assessment methods that can accurately capture these unique characteristics.

In vitro studies play a crucial role in the initial stages of toxicological assessment. These studies typically involve exposing cell cultures to nanorobotics materials and evaluating various endpoints, such as cell viability, oxidative stress markers, and inflammatory responses. However, it is essential to recognize the limitations of in vitro models and complement them with in vivo studies to gain a more comprehensive understanding of potential toxicity.

Animal models are invaluable for assessing the systemic effects of nanorobotics materials. These studies can provide insights into biodistribution, clearance mechanisms, and long-term toxicity. However, careful consideration must be given to the selection of appropriate animal models that can accurately represent human physiology and potential exposure scenarios.

The toxicological assessment of nanorobotics materials must also consider the potential for unintended interactions with biological systems. This includes evaluating the impact on cellular processes, such as protein folding and gene expression, as well as assessing the potential for nanorobots to interfere with normal physiological functions.

Furthermore, the environmental fate and potential ecological impacts of nanorobotics materials must be addressed. This involves studying their persistence, degradation pathways, and potential accumulation in various environmental compartments. Such assessments are crucial for developing responsible disposal methods and mitigating any potential environmental risks associated with the widespread use of nanorobots.

As the field of nanorobotics continues to advance, it is imperative to develop standardized protocols and guidelines for toxicological assessments. This will ensure consistency in evaluating the safety of different nanorobotics materials and facilitate regulatory approval processes. Collaboration between toxicologists, materials scientists, and nanorobotics engineers is essential for developing comprehensive and effective toxicological assessment strategies.

Regulatory Framework for Nanorobotics in Medicine

The regulatory framework for nanorobotics in medicine is a complex and evolving landscape that aims to ensure the safety and efficacy of these innovative technologies while promoting their development and adoption. As nanorobotics continues to advance, regulatory bodies worldwide are working to establish comprehensive guidelines and standards to govern their use in medical applications.

At the forefront of this regulatory effort is the need to address the unique challenges posed by nanorobotics, including their size, potential for interaction with biological systems, and the novel materials used in their construction. Regulatory agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are developing specific guidelines for the evaluation and approval of nanorobotic medical devices.

One key aspect of the regulatory framework is the classification of nanorobotic devices based on their intended use and risk profile. This classification system helps determine the level of regulatory scrutiny and the requirements for pre-market approval. For instance, nanorobots designed for diagnostic purposes may face different regulatory hurdles compared to those intended for therapeutic interventions.

Safety assessment protocols for nanorobotics are being established, focusing on potential toxicity, biocompatibility, and long-term effects on human health. These protocols often involve extensive in vitro and in vivo testing, as well as advanced computational modeling to predict potential interactions within the human body.

The regulatory framework also addresses manufacturing standards for nanorobotics, ensuring consistency, quality, and reproducibility in production. Good Manufacturing Practices (GMP) specific to nanorobotic devices are being developed to maintain high standards throughout the manufacturing process.

Ethical considerations play a significant role in the regulatory landscape of nanorobotics in medicine. Guidelines are being established to address issues such as patient privacy, data security, and the potential for unintended consequences of nanorobotic interventions.

International collaboration is crucial in developing a harmonized regulatory approach to nanorobotics. Organizations like the International Organization for Standardization (ISO) are working on creating global standards for nanotechnology and nanorobotics, which will facilitate cross-border research, development, and commercialization of these technologies.

As the field of nanorobotics continues to evolve, regulatory frameworks must remain flexible and adaptable to accommodate new discoveries and applications. Ongoing dialogue between researchers, industry stakeholders, and regulatory bodies is essential to ensure that regulations keep pace with technological advancements while maintaining the highest standards of patient safety and ethical practice.

At the forefront of this regulatory effort is the need to address the unique challenges posed by nanorobotics, including their size, potential for interaction with biological systems, and the novel materials used in their construction. Regulatory agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) are developing specific guidelines for the evaluation and approval of nanorobotic medical devices.

One key aspect of the regulatory framework is the classification of nanorobotic devices based on their intended use and risk profile. This classification system helps determine the level of regulatory scrutiny and the requirements for pre-market approval. For instance, nanorobots designed for diagnostic purposes may face different regulatory hurdles compared to those intended for therapeutic interventions.

Safety assessment protocols for nanorobotics are being established, focusing on potential toxicity, biocompatibility, and long-term effects on human health. These protocols often involve extensive in vitro and in vivo testing, as well as advanced computational modeling to predict potential interactions within the human body.

The regulatory framework also addresses manufacturing standards for nanorobotics, ensuring consistency, quality, and reproducibility in production. Good Manufacturing Practices (GMP) specific to nanorobotic devices are being developed to maintain high standards throughout the manufacturing process.

Ethical considerations play a significant role in the regulatory landscape of nanorobotics in medicine. Guidelines are being established to address issues such as patient privacy, data security, and the potential for unintended consequences of nanorobotic interventions.

International collaboration is crucial in developing a harmonized regulatory approach to nanorobotics. Organizations like the International Organization for Standardization (ISO) are working on creating global standards for nanotechnology and nanorobotics, which will facilitate cross-border research, development, and commercialization of these technologies.

As the field of nanorobotics continues to evolve, regulatory frameworks must remain flexible and adaptable to accommodate new discoveries and applications. Ongoing dialogue between researchers, industry stakeholders, and regulatory bodies is essential to ensure that regulations keep pace with technological advancements while maintaining the highest standards of patient safety and ethical practice.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!