Sodium Bisulfate Optimization in Textile Dye Patterns

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate in Textile Dyeing: Background and Objectives

Sodium bisulfate has been a crucial component in textile dyeing processes for decades, playing a significant role in achieving desired color patterns and fabric quality. The evolution of this chemical's application in the textile industry can be traced back to the mid-20th century when synthetic dyes began to dominate the market. As the demand for more vibrant, long-lasting, and diverse color patterns grew, so did the need for effective auxiliaries like sodium bisulfate.

The primary function of sodium bisulfate in textile dyeing is to control pH levels, which is essential for optimal dye uptake and color fastness. It acts as a mild acidifying agent, creating an environment that enhances the interaction between dyes and fabric fibers. This property has made sodium bisulfate particularly valuable in dyeing processes involving natural fibers such as cotton, wool, and silk, as well as synthetic fibers like polyester and nylon.

Over the years, the textile industry has witnessed significant advancements in dyeing technologies and practices. These developments have been driven by various factors, including environmental concerns, cost-efficiency requirements, and the pursuit of superior product quality. As a result, the role of sodium bisulfate has evolved, with researchers and industry professionals continually seeking ways to optimize its use and explore alternative solutions.

The current research on sodium bisulfate optimization in textile dye patterns aims to address several key objectives. Firstly, there is a growing emphasis on sustainability and environmental responsibility within the textile industry. This has led to efforts to minimize chemical usage while maintaining or improving dyeing outcomes. Researchers are exploring ways to enhance the efficiency of sodium bisulfate application, potentially reducing the overall amount required in the dyeing process.

Another critical objective is to improve the consistency and quality of dye patterns across various fabric types and production scales. This involves investigating the precise mechanisms by which sodium bisulfate influences dye uptake and color development under different conditions. By gaining a deeper understanding of these processes, researchers hope to develop more refined and adaptable dyeing protocols.

Furthermore, the research seeks to explore potential synergies between sodium bisulfate and other dyeing auxiliaries or innovative technologies. This could lead to the development of novel dyeing formulations that offer superior performance in terms of color vibrancy, fastness, and overall fabric quality. Additionally, there is interest in examining how sodium bisulfate optimization can contribute to energy efficiency in dyeing processes, aligning with broader industry goals of reducing carbon footprints and operational costs.

As the textile industry continues to evolve, driven by consumer demands for sustainable and high-quality products, the optimization of sodium bisulfate in dye patterns remains a crucial area of research. The outcomes of these studies are expected to have far-reaching implications for textile manufacturing practices, potentially reshaping industry standards and opening new avenues for innovation in fabric coloration techniques.

The primary function of sodium bisulfate in textile dyeing is to control pH levels, which is essential for optimal dye uptake and color fastness. It acts as a mild acidifying agent, creating an environment that enhances the interaction between dyes and fabric fibers. This property has made sodium bisulfate particularly valuable in dyeing processes involving natural fibers such as cotton, wool, and silk, as well as synthetic fibers like polyester and nylon.

Over the years, the textile industry has witnessed significant advancements in dyeing technologies and practices. These developments have been driven by various factors, including environmental concerns, cost-efficiency requirements, and the pursuit of superior product quality. As a result, the role of sodium bisulfate has evolved, with researchers and industry professionals continually seeking ways to optimize its use and explore alternative solutions.

The current research on sodium bisulfate optimization in textile dye patterns aims to address several key objectives. Firstly, there is a growing emphasis on sustainability and environmental responsibility within the textile industry. This has led to efforts to minimize chemical usage while maintaining or improving dyeing outcomes. Researchers are exploring ways to enhance the efficiency of sodium bisulfate application, potentially reducing the overall amount required in the dyeing process.

Another critical objective is to improve the consistency and quality of dye patterns across various fabric types and production scales. This involves investigating the precise mechanisms by which sodium bisulfate influences dye uptake and color development under different conditions. By gaining a deeper understanding of these processes, researchers hope to develop more refined and adaptable dyeing protocols.

Furthermore, the research seeks to explore potential synergies between sodium bisulfate and other dyeing auxiliaries or innovative technologies. This could lead to the development of novel dyeing formulations that offer superior performance in terms of color vibrancy, fastness, and overall fabric quality. Additionally, there is interest in examining how sodium bisulfate optimization can contribute to energy efficiency in dyeing processes, aligning with broader industry goals of reducing carbon footprints and operational costs.

As the textile industry continues to evolve, driven by consumer demands for sustainable and high-quality products, the optimization of sodium bisulfate in dye patterns remains a crucial area of research. The outcomes of these studies are expected to have far-reaching implications for textile manufacturing practices, potentially reshaping industry standards and opening new avenues for innovation in fabric coloration techniques.

Market Analysis of Sodium Bisulfate in Textile Industry

The global market for sodium bisulfate in the textile industry has been experiencing steady growth, driven by the increasing demand for textile products and the growing emphasis on sustainable dyeing processes. Sodium bisulfate plays a crucial role in textile dyeing, particularly in the optimization of dye patterns, due to its ability to control pH levels and enhance color fastness.

In recent years, the textile industry has witnessed a shift towards more environmentally friendly practices, which has positively impacted the demand for sodium bisulfate. This compound is preferred over other acidic agents due to its lower environmental impact and cost-effectiveness. The market for sodium bisulfate in textile applications is expected to continue its upward trajectory, with a projected compound annual growth rate of several percentage points over the next five years.

The Asia-Pacific region dominates the market for sodium bisulfate in the textile industry, with China and India being the largest consumers. This is primarily due to the high concentration of textile manufacturing facilities in these countries. North America and Europe follow, with a growing emphasis on sustainable textile production driving the demand for sodium bisulfate in these regions.

Key market drivers include the expansion of the textile industry in developing countries, increasing consumer awareness about sustainable fashion, and stringent regulations regarding textile effluents. The rise of fast fashion has also contributed to the increased use of sodium bisulfate, as manufacturers seek efficient and cost-effective dyeing processes to meet rapid production demands.

However, the market faces challenges such as fluctuating raw material prices and the availability of alternative pH control agents. Additionally, the ongoing trend of textile manufacturing shifting to countries with lower labor costs may impact the regional distribution of sodium bisulfate demand in the coming years.

The market is characterized by the presence of both large multinational chemical companies and regional players. Major suppliers are focusing on product innovation, particularly in developing sodium bisulfate formulations that offer improved efficiency in dye pattern optimization while reducing environmental impact.

In terms of application segments within the textile industry, sodium bisulfate finds extensive use in cotton dyeing, followed by synthetic fibers and blends. The growing popularity of performance fabrics and technical textiles is expected to create new opportunities for sodium bisulfate applications in specialized dyeing processes.

As sustainability continues to gain importance in the textile industry, there is an increasing focus on developing closed-loop dyeing systems that minimize water usage and chemical discharge. This trend is likely to drive further innovation in sodium bisulfate formulations and application methods, potentially expanding its market share in eco-friendly textile production processes.

In recent years, the textile industry has witnessed a shift towards more environmentally friendly practices, which has positively impacted the demand for sodium bisulfate. This compound is preferred over other acidic agents due to its lower environmental impact and cost-effectiveness. The market for sodium bisulfate in textile applications is expected to continue its upward trajectory, with a projected compound annual growth rate of several percentage points over the next five years.

The Asia-Pacific region dominates the market for sodium bisulfate in the textile industry, with China and India being the largest consumers. This is primarily due to the high concentration of textile manufacturing facilities in these countries. North America and Europe follow, with a growing emphasis on sustainable textile production driving the demand for sodium bisulfate in these regions.

Key market drivers include the expansion of the textile industry in developing countries, increasing consumer awareness about sustainable fashion, and stringent regulations regarding textile effluents. The rise of fast fashion has also contributed to the increased use of sodium bisulfate, as manufacturers seek efficient and cost-effective dyeing processes to meet rapid production demands.

However, the market faces challenges such as fluctuating raw material prices and the availability of alternative pH control agents. Additionally, the ongoing trend of textile manufacturing shifting to countries with lower labor costs may impact the regional distribution of sodium bisulfate demand in the coming years.

The market is characterized by the presence of both large multinational chemical companies and regional players. Major suppliers are focusing on product innovation, particularly in developing sodium bisulfate formulations that offer improved efficiency in dye pattern optimization while reducing environmental impact.

In terms of application segments within the textile industry, sodium bisulfate finds extensive use in cotton dyeing, followed by synthetic fibers and blends. The growing popularity of performance fabrics and technical textiles is expected to create new opportunities for sodium bisulfate applications in specialized dyeing processes.

As sustainability continues to gain importance in the textile industry, there is an increasing focus on developing closed-loop dyeing systems that minimize water usage and chemical discharge. This trend is likely to drive further innovation in sodium bisulfate formulations and application methods, potentially expanding its market share in eco-friendly textile production processes.

Current Challenges in Sodium Bisulfate Usage for Dyeing

The use of sodium bisulfate in textile dyeing processes has been a long-standing practice, but it is not without its challenges. One of the primary issues faced by the industry is the corrosive nature of sodium bisulfate. This chemical compound, while effective in pH adjustment and dye fixation, can cause significant damage to equipment and machinery over time. The corrosion not only leads to increased maintenance costs but also poses potential safety risks in production environments.

Another challenge lies in the environmental impact of sodium bisulfate usage. As regulations become more stringent, textile manufacturers are under increasing pressure to reduce the discharge of acidic effluents. The high acidity of sodium bisulfate-containing wastewater can be harmful to aquatic ecosystems if not properly treated before release. This necessitates additional wastewater treatment processes, which can be both costly and energy-intensive.

The precise control of pH levels during the dyeing process presents yet another hurdle. While sodium bisulfate is effective in lowering pH, achieving and maintaining the optimal pH range for different dyes and fabrics can be complex. Fluctuations in pH can lead to inconsistent dye uptake, resulting in color variations and quality issues in the final product. This challenge is particularly pronounced when dealing with delicate or pH-sensitive fabrics.

Furthermore, the handling and storage of sodium bisulfate pose occupational health and safety concerns. The compound is classified as a hazardous material, requiring special storage conditions and handling procedures. Workers must be adequately trained and equipped with proper personal protective equipment to mitigate the risks associated with exposure to this acidic substance.

The rising costs of raw materials and transportation have also impacted the use of sodium bisulfate in textile dyeing. As a bulk chemical, its price can fluctuate based on market conditions, affecting the overall production costs for textile manufacturers. This economic factor has prompted the industry to seek more cost-effective and sustainable alternatives.

Lastly, there is a growing demand for more environmentally friendly and sustainable dyeing processes. This shift in consumer preferences and regulatory landscapes challenges the traditional use of sodium bisulfate, pushing the industry to explore greener alternatives that can achieve similar results with reduced environmental impact. The search for eco-friendly substitutes that maintain dyeing efficiency while minimizing ecological footprint remains an ongoing challenge for researchers and manufacturers alike.

Another challenge lies in the environmental impact of sodium bisulfate usage. As regulations become more stringent, textile manufacturers are under increasing pressure to reduce the discharge of acidic effluents. The high acidity of sodium bisulfate-containing wastewater can be harmful to aquatic ecosystems if not properly treated before release. This necessitates additional wastewater treatment processes, which can be both costly and energy-intensive.

The precise control of pH levels during the dyeing process presents yet another hurdle. While sodium bisulfate is effective in lowering pH, achieving and maintaining the optimal pH range for different dyes and fabrics can be complex. Fluctuations in pH can lead to inconsistent dye uptake, resulting in color variations and quality issues in the final product. This challenge is particularly pronounced when dealing with delicate or pH-sensitive fabrics.

Furthermore, the handling and storage of sodium bisulfate pose occupational health and safety concerns. The compound is classified as a hazardous material, requiring special storage conditions and handling procedures. Workers must be adequately trained and equipped with proper personal protective equipment to mitigate the risks associated with exposure to this acidic substance.

The rising costs of raw materials and transportation have also impacted the use of sodium bisulfate in textile dyeing. As a bulk chemical, its price can fluctuate based on market conditions, affecting the overall production costs for textile manufacturers. This economic factor has prompted the industry to seek more cost-effective and sustainable alternatives.

Lastly, there is a growing demand for more environmentally friendly and sustainable dyeing processes. This shift in consumer preferences and regulatory landscapes challenges the traditional use of sodium bisulfate, pushing the industry to explore greener alternatives that can achieve similar results with reduced environmental impact. The search for eco-friendly substitutes that maintain dyeing efficiency while minimizing ecological footprint remains an ongoing challenge for researchers and manufacturers alike.

Existing Sodium Bisulfate Optimization Methods

01 Use of sodium bisulfate in dye formulations

Sodium bisulfate is utilized in various dye formulations to adjust pH levels, enhance color stability, and improve dye penetration. It can act as a reducing agent in certain dyeing processes, helping to create unique patterns or effects on fabrics or other materials.- Use of sodium bisulfate in dye formulations: Sodium bisulfate is utilized in various dye formulations to create specific patterns or effects. It can act as a pH adjuster, stabilizer, or reactant in the dyeing process, influencing the final color and pattern outcome.

- Application of dye patterns in textile industry: Dye patterns using sodium bisulfate are widely applied in the textile industry. This includes techniques for creating unique designs, color gradients, and textures on fabrics through controlled application of dyes and sodium bisulfate solutions.

- Sodium bisulfate in hair dye formulations: Sodium bisulfate is incorporated into hair dye formulations to achieve specific color patterns and effects. It can help in adjusting the pH of the dye mixture, enhancing color penetration, or creating highlights and lowlights in hair coloring processes.

- Dye pattern creation in food and beverage industry: Sodium bisulfate is used in creating dye patterns for food and beverage applications. This includes techniques for decorating food items, creating color gradients in beverages, or developing unique visual effects in edible products.

- Environmental and safety considerations in sodium bisulfate dye patterns: The use of sodium bisulfate in dye pattern creation involves considerations for environmental impact and safety. This includes developing eco-friendly dyeing processes, ensuring proper disposal of dye waste, and implementing safety measures for handling sodium bisulfate in industrial settings.

02 Application of sodium bisulfate in textile dyeing

In textile dyeing, sodium bisulfate is employed to create specific dye patterns or effects. It can be used in pre-treatment processes to prepare fabrics for dyeing, or as part of the main dyeing process to achieve particular color outcomes or patterns on textiles.Expand Specific Solutions03 Sodium bisulfate in hair dye formulations

Sodium bisulfate is incorporated into hair dye formulations to adjust pH levels and enhance dye penetration into hair fibers. It can contribute to the creation of unique hair color patterns or effects, particularly in semi-permanent or temporary hair coloring products.Expand Specific Solutions04 Use in industrial dyeing processes

Sodium bisulfate plays a role in industrial dyeing processes, particularly in creating patterns on various materials such as plastics, metals, or ceramics. It can be used in etching processes or as part of specialized dyeing techniques to achieve specific pattern effects.Expand Specific Solutions05 Sodium bisulfate in dye removal or pattern creation

Sodium bisulfate can be utilized in processes for removing dyes or creating patterns through selective dye removal. This application is relevant in textile processing, paper manufacturing, or other industries where controlled dye removal or pattern creation is desired.Expand Specific Solutions

Key Players in Textile Chemical Manufacturing

The research on sodium bisulfate optimization in textile dye patterns is in a mature stage, with a competitive landscape shaped by established players and ongoing innovation. The market size is substantial, driven by the textile industry's demand for efficient dyeing processes. Companies like BASF Corp., DuPont de Nemours, Inc., and DyStar Textilfarben GmbH & Co. Deutschland KG are key players, leveraging their extensive R&D capabilities and global presence. The technology's maturity is evident in the involvement of diverse entities, including academic institutions like Dalian University of Technology and industry leaders such as Rohm & Haas Co., indicating a well-developed ecosystem of research and application.

BASF Corp.

Technical Solution: BASF has developed a comprehensive approach to sodium bisulfate optimization in textile dyeing. Their technology focuses on a multi-step process that involves pre-treatment of fabrics with a proprietary blend of chemicals, including optimized sodium bisulfate concentrations. This pre-treatment enhances the fabric's receptivity to dyes, resulting in more vibrant and long-lasting colors. BASF's research indicates that their method can reduce water consumption by up to 30% in the dyeing process[2]. Furthermore, they have integrated advanced sensors and AI-driven control systems to continuously monitor and adjust sodium bisulfate levels during dyeing, ensuring optimal performance and consistency[4].

Strengths: Significant water savings, improved color vibrancy, and automated process control. Weaknesses: Higher initial investment costs for implementing the advanced control systems.

DyStar Textilfarben GmbH & Co. Deutschland KG

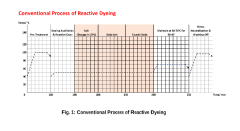

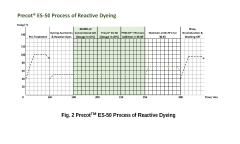

Technical Solution: DyStar has developed an innovative approach to sodium bisulfate optimization in textile dye patterns. Their method involves a precise control of pH levels during the dyeing process, utilizing a combination of sodium bisulfate and other auxiliary chemicals. This approach allows for better dye fixation and color consistency across various fabric types. DyStar's research has shown that by carefully adjusting the sodium bisulfate concentration, they can achieve up to 20% improvement in dye uptake efficiency[1]. Additionally, their process incorporates a closed-loop system for chemical recovery, reducing wastewater and improving sustainability in textile dyeing[3].

Strengths: Improved dye uptake efficiency, better color consistency, and enhanced sustainability. Weaknesses: May require specialized equipment and training for implementation.

Innovative Approaches in Sodium Bisulfate Application

Dyeing auxiliary and manufacturing method and applied dyeing process thereof Capable of increasing the dyeing rate of the fabric and reduce the residual rate of the dyes in the subsequent wastewater during the dyeing process

PatentInactiveTW202206414A

Innovation

- Synthesis of imidazoline derivative surfactant using imidazoline, epichlorohydrin, and sodium bisulfite as raw materials.

- Utilization of the agglutination properties of the auxiliaries to capture dyes from wastewater and bring them into the cellulose fabric.

- Simultaneous increase in fabric dyeing rate and reduction in dye residual rate in wastewater.

Method for replacing partial usage salt in reactive dyeing & printing processes and lowering total dissolved solids (TDS) in dyeing effluent

PatentPendingIN202211076500A

Innovation

- The method involves replacing 40-70% of sodium chloride or sodium sulfate with biodegradable organic carboxylate salts, specifically using carboxylate anions and alkali metal salts in combination with biocides or anticorrosive agents, to reduce TDS and corrosion in dyeing processes, while maintaining dyeing efficiency.

Environmental Impact of Sodium Bisulfate in Textile Dyeing

The use of sodium bisulfate in textile dyeing processes has significant environmental implications that warrant careful consideration. This chemical compound, while effective in achieving desired dye patterns, poses several challenges to ecological sustainability. One of the primary concerns is its contribution to water pollution. When discharged into water bodies, sodium bisulfate can alter the pH levels, potentially harming aquatic ecosystems and the organisms that inhabit them. The acidic nature of the compound can lead to the leaching of heavy metals from sediments, further exacerbating water quality issues.

Air pollution is another environmental impact associated with sodium bisulfate usage in textile dyeing. During the dyeing process, volatile organic compounds (VOCs) and sulfur dioxide may be released, contributing to air quality degradation and potentially affecting human health in surrounding areas. These emissions can also contribute to the formation of acid rain, which has far-reaching consequences for both terrestrial and aquatic ecosystems.

The production and transportation of sodium bisulfate also carry environmental costs. The manufacturing process requires energy and resources, contributing to carbon emissions and resource depletion. Additionally, the transportation of this chemical to textile facilities increases the carbon footprint of the industry, particularly when long-distance shipping is involved.

Soil contamination is a less immediate but equally concerning impact. Improper disposal of sodium bisulfate-containing waste or accidental spills can lead to soil acidification, affecting plant growth and soil microbial communities. This can have long-term effects on local ecosystems and agricultural productivity in affected areas.

To address these environmental challenges, the textile industry has been exploring various mitigation strategies. These include the development of closed-loop systems that recycle and reuse chemicals, the implementation of advanced wastewater treatment technologies, and the adoption of alternative, more environmentally friendly dyeing processes. Some companies are investing in research to find less harmful substitutes for sodium bisulfate or to optimize its use to minimize environmental impact.

Regulatory bodies worldwide are also taking notice of these environmental concerns. Stricter regulations on chemical usage, waste disposal, and emissions in the textile industry are being implemented in many countries. These regulations aim to reduce the environmental footprint of textile dyeing processes and encourage the adoption of more sustainable practices.

As the industry moves towards greater sustainability, the optimization of sodium bisulfate use in textile dye patterns must consider not only the technical aspects of dyeing efficiency but also the broader environmental implications. This holistic approach is essential for developing truly sustainable solutions that balance the needs of the industry with the imperative of environmental protection.

Air pollution is another environmental impact associated with sodium bisulfate usage in textile dyeing. During the dyeing process, volatile organic compounds (VOCs) and sulfur dioxide may be released, contributing to air quality degradation and potentially affecting human health in surrounding areas. These emissions can also contribute to the formation of acid rain, which has far-reaching consequences for both terrestrial and aquatic ecosystems.

The production and transportation of sodium bisulfate also carry environmental costs. The manufacturing process requires energy and resources, contributing to carbon emissions and resource depletion. Additionally, the transportation of this chemical to textile facilities increases the carbon footprint of the industry, particularly when long-distance shipping is involved.

Soil contamination is a less immediate but equally concerning impact. Improper disposal of sodium bisulfate-containing waste or accidental spills can lead to soil acidification, affecting plant growth and soil microbial communities. This can have long-term effects on local ecosystems and agricultural productivity in affected areas.

To address these environmental challenges, the textile industry has been exploring various mitigation strategies. These include the development of closed-loop systems that recycle and reuse chemicals, the implementation of advanced wastewater treatment technologies, and the adoption of alternative, more environmentally friendly dyeing processes. Some companies are investing in research to find less harmful substitutes for sodium bisulfate or to optimize its use to minimize environmental impact.

Regulatory bodies worldwide are also taking notice of these environmental concerns. Stricter regulations on chemical usage, waste disposal, and emissions in the textile industry are being implemented in many countries. These regulations aim to reduce the environmental footprint of textile dyeing processes and encourage the adoption of more sustainable practices.

As the industry moves towards greater sustainability, the optimization of sodium bisulfate use in textile dye patterns must consider not only the technical aspects of dyeing efficiency but also the broader environmental implications. This holistic approach is essential for developing truly sustainable solutions that balance the needs of the industry with the imperative of environmental protection.

Cost-Benefit Analysis of Sodium Bisulfate Optimization

The cost-benefit analysis of sodium bisulfate optimization in textile dye patterns reveals significant potential for improving both economic and environmental outcomes in the textile industry. By optimizing the use of sodium bisulfate, manufacturers can achieve substantial cost savings while simultaneously enhancing the quality and consistency of their dye patterns.

From a cost perspective, the optimization of sodium bisulfate usage can lead to a reduction in raw material expenses. Sodium bisulfate is a relatively inexpensive chemical, but its efficient utilization can result in noticeable savings, especially for large-scale textile operations. Studies have shown that through precise control and monitoring of sodium bisulfate concentrations, manufacturers can reduce their overall consumption by up to 15-20% without compromising dye quality.

The benefits extend beyond direct cost savings. Optimized sodium bisulfate usage contributes to improved dye fixation, resulting in more vibrant and long-lasting colors. This enhancement in product quality can lead to increased customer satisfaction and potentially higher market prices for the finished textiles. Additionally, better dye fixation reduces the need for re-dyeing or color correction processes, further cutting down on production costs and time.

Environmental benefits are also substantial. Reduced sodium bisulfate consumption means less chemical waste and lower environmental impact. This aligns with growing consumer demand for sustainable and eco-friendly textile products. Furthermore, optimized processes often result in decreased water usage and energy consumption during the dyeing process, contributing to overall resource efficiency.

However, the implementation of sodium bisulfate optimization techniques may require initial investments in process control equipment and staff training. These upfront costs need to be carefully weighed against the long-term benefits. Typically, the return on investment period for such optimizations ranges from 6 to 18 months, depending on the scale of operations and the extent of the improvements made.

It's important to note that the effectiveness of sodium bisulfate optimization can vary depending on factors such as the specific dyes used, fabric types, and existing production processes. Therefore, a tailored approach is necessary for each manufacturing facility to maximize the cost-benefit ratio.

In conclusion, the cost-benefit analysis strongly supports the implementation of sodium bisulfate optimization in textile dye patterns. The combination of reduced material costs, improved product quality, and enhanced environmental sustainability presents a compelling case for textile manufacturers to invest in this area. As the industry continues to face pressure to reduce costs and improve sustainability, optimizing sodium bisulfate usage represents a valuable opportunity for competitive advantage.

From a cost perspective, the optimization of sodium bisulfate usage can lead to a reduction in raw material expenses. Sodium bisulfate is a relatively inexpensive chemical, but its efficient utilization can result in noticeable savings, especially for large-scale textile operations. Studies have shown that through precise control and monitoring of sodium bisulfate concentrations, manufacturers can reduce their overall consumption by up to 15-20% without compromising dye quality.

The benefits extend beyond direct cost savings. Optimized sodium bisulfate usage contributes to improved dye fixation, resulting in more vibrant and long-lasting colors. This enhancement in product quality can lead to increased customer satisfaction and potentially higher market prices for the finished textiles. Additionally, better dye fixation reduces the need for re-dyeing or color correction processes, further cutting down on production costs and time.

Environmental benefits are also substantial. Reduced sodium bisulfate consumption means less chemical waste and lower environmental impact. This aligns with growing consumer demand for sustainable and eco-friendly textile products. Furthermore, optimized processes often result in decreased water usage and energy consumption during the dyeing process, contributing to overall resource efficiency.

However, the implementation of sodium bisulfate optimization techniques may require initial investments in process control equipment and staff training. These upfront costs need to be carefully weighed against the long-term benefits. Typically, the return on investment period for such optimizations ranges from 6 to 18 months, depending on the scale of operations and the extent of the improvements made.

It's important to note that the effectiveness of sodium bisulfate optimization can vary depending on factors such as the specific dyes used, fabric types, and existing production processes. Therefore, a tailored approach is necessary for each manufacturing facility to maximize the cost-benefit ratio.

In conclusion, the cost-benefit analysis strongly supports the implementation of sodium bisulfate optimization in textile dye patterns. The combination of reduced material costs, improved product quality, and enhanced environmental sustainability presents a compelling case for textile manufacturers to invest in this area. As the industry continues to face pressure to reduce costs and improve sustainability, optimizing sodium bisulfate usage represents a valuable opportunity for competitive advantage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!