Sodium Bisulfate Dynamics in Cement Industry Improvements

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cement Industry NaHSO4 Utilization Background

The cement industry has long been a significant contributor to global carbon emissions, accounting for approximately 8% of worldwide CO2 emissions. In recent years, there has been a growing emphasis on sustainable practices and reducing the environmental impact of cement production. This has led to increased interest in innovative solutions, including the utilization of sodium bisulfate (NaHSO4) in cement manufacturing processes.

Sodium bisulfate, a byproduct of various industrial processes, has emerged as a potential resource for improving cement production efficiency and reducing environmental impact. Historically, NaHSO4 was often considered a waste product, but its unique chemical properties have sparked interest in its application within the cement industry.

The use of sodium bisulfate in cement production can be traced back to the early 2000s when researchers began exploring its potential as a cement additive. Initial studies focused on its ability to modify cement properties, such as setting time and strength development. As environmental concerns grew more pressing, the focus shifted towards investigating NaHSO4's potential to reduce CO2 emissions and improve overall sustainability in cement manufacturing.

Over the past decade, there has been a notable increase in research and development efforts aimed at optimizing the use of sodium bisulfate in cement production. These efforts have been driven by a combination of factors, including stricter environmental regulations, rising energy costs, and the cement industry's commitment to reducing its carbon footprint.

The integration of NaHSO4 into cement production processes has shown promise in several areas. It has been found to enhance the reactivity of cement clinker, potentially reducing the energy required for cement production. Additionally, sodium bisulfate has demonstrated the ability to improve the workability of cement mixtures and contribute to the development of high-performance concrete.

As the cement industry continues to evolve, the role of sodium bisulfate in improving production processes and environmental performance is becoming increasingly important. Research institutions, cement manufacturers, and chemical companies are collaborating to develop innovative applications for NaHSO4 in cement production, exploring its potential to address key challenges facing the industry.

The growing interest in sodium bisulfate utilization aligns with broader trends in the cement industry, including the push for circular economy principles and the development of alternative cementitious materials. As such, understanding the background and potential of NaHSO4 in cement production is crucial for stakeholders looking to drive innovation and sustainability in this critical sector.

Sodium bisulfate, a byproduct of various industrial processes, has emerged as a potential resource for improving cement production efficiency and reducing environmental impact. Historically, NaHSO4 was often considered a waste product, but its unique chemical properties have sparked interest in its application within the cement industry.

The use of sodium bisulfate in cement production can be traced back to the early 2000s when researchers began exploring its potential as a cement additive. Initial studies focused on its ability to modify cement properties, such as setting time and strength development. As environmental concerns grew more pressing, the focus shifted towards investigating NaHSO4's potential to reduce CO2 emissions and improve overall sustainability in cement manufacturing.

Over the past decade, there has been a notable increase in research and development efforts aimed at optimizing the use of sodium bisulfate in cement production. These efforts have been driven by a combination of factors, including stricter environmental regulations, rising energy costs, and the cement industry's commitment to reducing its carbon footprint.

The integration of NaHSO4 into cement production processes has shown promise in several areas. It has been found to enhance the reactivity of cement clinker, potentially reducing the energy required for cement production. Additionally, sodium bisulfate has demonstrated the ability to improve the workability of cement mixtures and contribute to the development of high-performance concrete.

As the cement industry continues to evolve, the role of sodium bisulfate in improving production processes and environmental performance is becoming increasingly important. Research institutions, cement manufacturers, and chemical companies are collaborating to develop innovative applications for NaHSO4 in cement production, exploring its potential to address key challenges facing the industry.

The growing interest in sodium bisulfate utilization aligns with broader trends in the cement industry, including the push for circular economy principles and the development of alternative cementitious materials. As such, understanding the background and potential of NaHSO4 in cement production is crucial for stakeholders looking to drive innovation and sustainability in this critical sector.

Market Analysis for NaHSO4 in Cement Production

The global market for sodium bisulfate (NaHSO4) in cement production has been experiencing steady growth, driven by the increasing demand for high-performance cement and the need for efficient cement additives. Sodium bisulfate plays a crucial role in cement manufacturing processes, primarily as a set retarder and a grinding aid, contributing to improved cement quality and production efficiency.

The cement industry's expansion, particularly in developing economies, has been a significant factor in the growing demand for sodium bisulfate. Countries like China, India, and Brazil have been at the forefront of this growth, with their rapid urbanization and infrastructure development projects fueling the need for cement and, consequently, cement additives like NaHSO4.

In terms of market size, the global sodium bisulfate market for cement production is estimated to be a substantial segment within the broader cement additives market. The cement additives market as a whole has been valued in the billions of dollars, with sodium bisulfate representing a significant portion of this value due to its versatile applications in cement manufacturing.

The market for NaHSO4 in cement production is characterized by a mix of large multinational chemical companies and regional suppliers. Key players in this market include companies with strong capabilities in sulfuric acid production, as sodium bisulfate is often a byproduct of this process. These companies have been focusing on expanding their production capacities to meet the growing demand from the cement industry.

Regional market dynamics play a crucial role in the sodium bisulfate market for cement production. While Asia-Pacific remains the largest market due to its booming construction sector, North America and Europe also represent significant markets, driven by the need for high-performance cement in infrastructure projects and the renovation of existing structures.

The market is also influenced by environmental regulations and sustainability trends in the cement industry. As cement manufacturers strive to reduce their carbon footprint and improve energy efficiency, the demand for additives like sodium bisulfate that can enhance cement performance and reduce clinker content has been increasing.

Looking ahead, the market for sodium bisulfate in cement production is expected to continue its growth trajectory. Factors such as ongoing urbanization in developing countries, the need for more durable and sustainable construction materials, and technological advancements in cement manufacturing are likely to drive this growth. Additionally, the increasing focus on reducing cement's environmental impact may lead to further innovations in the use of sodium bisulfate and similar additives in cement production.

The cement industry's expansion, particularly in developing economies, has been a significant factor in the growing demand for sodium bisulfate. Countries like China, India, and Brazil have been at the forefront of this growth, with their rapid urbanization and infrastructure development projects fueling the need for cement and, consequently, cement additives like NaHSO4.

In terms of market size, the global sodium bisulfate market for cement production is estimated to be a substantial segment within the broader cement additives market. The cement additives market as a whole has been valued in the billions of dollars, with sodium bisulfate representing a significant portion of this value due to its versatile applications in cement manufacturing.

The market for NaHSO4 in cement production is characterized by a mix of large multinational chemical companies and regional suppliers. Key players in this market include companies with strong capabilities in sulfuric acid production, as sodium bisulfate is often a byproduct of this process. These companies have been focusing on expanding their production capacities to meet the growing demand from the cement industry.

Regional market dynamics play a crucial role in the sodium bisulfate market for cement production. While Asia-Pacific remains the largest market due to its booming construction sector, North America and Europe also represent significant markets, driven by the need for high-performance cement in infrastructure projects and the renovation of existing structures.

The market is also influenced by environmental regulations and sustainability trends in the cement industry. As cement manufacturers strive to reduce their carbon footprint and improve energy efficiency, the demand for additives like sodium bisulfate that can enhance cement performance and reduce clinker content has been increasing.

Looking ahead, the market for sodium bisulfate in cement production is expected to continue its growth trajectory. Factors such as ongoing urbanization in developing countries, the need for more durable and sustainable construction materials, and technological advancements in cement manufacturing are likely to drive this growth. Additionally, the increasing focus on reducing cement's environmental impact may lead to further innovations in the use of sodium bisulfate and similar additives in cement production.

NaHSO4 Application Challenges in Cement Manufacturing

The application of sodium bisulfate (NaHSO4) in cement manufacturing presents several significant challenges that require careful consideration and innovative solutions. One of the primary issues is the corrosive nature of NaHSO4, which can lead to accelerated wear and tear on equipment and infrastructure within cement plants. This corrosivity is particularly problematic in areas with high humidity or where the compound comes into direct contact with metal surfaces, potentially causing damage to conveyor systems, storage silos, and processing machinery.

Another challenge lies in the precise dosing and distribution of NaHSO4 throughout the cement production process. Achieving uniform dispersion is crucial for optimal performance, yet the hygroscopic properties of sodium bisulfate can lead to clumping and uneven distribution. This inconsistency can result in variations in cement quality and performance, potentially affecting the final product's strength and durability.

The reactivity of NaHSO4 with other components in the cement mix also poses a challenge. While its ability to react with alkalis is beneficial for reducing efflorescence, it can also interfere with other desired chemical reactions in the cement-making process. Balancing these interactions to achieve the desired outcomes without compromising other aspects of cement quality requires precise control and extensive knowledge of cement chemistry.

Environmental concerns present another set of challenges in the application of sodium bisulfate. The compound's acidity can potentially impact local ecosystems if not properly managed, particularly in cases of accidental spills or improper disposal. Additionally, the production and transportation of NaHSO4 contribute to the overall carbon footprint of cement manufacturing, an industry already under scrutiny for its environmental impact.

Worker safety is a critical consideration when handling NaHSO4 in cement plants. The compound's acidic nature necessitates stringent safety protocols, including proper personal protective equipment (PPE) and specialized handling procedures. Ensuring compliance with these safety measures across all shifts and operations can be challenging, particularly in large-scale production environments.

Lastly, the economic aspects of incorporating NaHSO4 into cement production present their own set of challenges. While the compound offers benefits in terms of cement quality and performance, its cost and the additional equipment or process modifications required for its effective use must be carefully weighed against the potential improvements in the final product. Fluctuations in the price and availability of sodium bisulfate can also impact the consistency and profitability of its application in cement manufacturing.

Another challenge lies in the precise dosing and distribution of NaHSO4 throughout the cement production process. Achieving uniform dispersion is crucial for optimal performance, yet the hygroscopic properties of sodium bisulfate can lead to clumping and uneven distribution. This inconsistency can result in variations in cement quality and performance, potentially affecting the final product's strength and durability.

The reactivity of NaHSO4 with other components in the cement mix also poses a challenge. While its ability to react with alkalis is beneficial for reducing efflorescence, it can also interfere with other desired chemical reactions in the cement-making process. Balancing these interactions to achieve the desired outcomes without compromising other aspects of cement quality requires precise control and extensive knowledge of cement chemistry.

Environmental concerns present another set of challenges in the application of sodium bisulfate. The compound's acidity can potentially impact local ecosystems if not properly managed, particularly in cases of accidental spills or improper disposal. Additionally, the production and transportation of NaHSO4 contribute to the overall carbon footprint of cement manufacturing, an industry already under scrutiny for its environmental impact.

Worker safety is a critical consideration when handling NaHSO4 in cement plants. The compound's acidic nature necessitates stringent safety protocols, including proper personal protective equipment (PPE) and specialized handling procedures. Ensuring compliance with these safety measures across all shifts and operations can be challenging, particularly in large-scale production environments.

Lastly, the economic aspects of incorporating NaHSO4 into cement production present their own set of challenges. While the compound offers benefits in terms of cement quality and performance, its cost and the additional equipment or process modifications required for its effective use must be carefully weighed against the potential improvements in the final product. Fluctuations in the price and availability of sodium bisulfate can also impact the consistency and profitability of its application in cement manufacturing.

Current NaHSO4 Integration Methods in Cement

01 Production and purification of sodium bisulfate

Various methods for producing and purifying sodium bisulfate are described. These processes involve reactions between sulfuric acid and sodium chloride or sodium sulfate, followed by crystallization and separation techniques to obtain high-purity sodium bisulfate. The methods aim to improve yield and product quality while reducing production costs.- Production and purification of sodium bisulfate: Various methods for producing and purifying sodium bisulfate are described. These processes involve reactions between sulfuric acid and sodium chloride or sodium sulfate, followed by crystallization and separation techniques to obtain high-purity sodium bisulfate. The methods aim to improve yield, reduce impurities, and optimize production efficiency.

- Applications in water treatment and pH control: Sodium bisulfate is widely used in water treatment processes and pH control applications. It is effective in adjusting pH levels in swimming pools, industrial wastewater, and other aqueous systems. The compound's ability to lower pH and its relatively safe handling characteristics make it a preferred choice in various water treatment scenarios.

- Use in food processing and preservation: Sodium bisulfate finds applications in food processing and preservation. It is used as an acidulant and preservative in various food products. The compound helps in controlling microbial growth, enhancing flavor, and extending shelf life. Its use in meat processing, beverage production, and as a cleaning agent in food processing facilities is notable.

- Environmental and agricultural applications: Sodium bisulfate is utilized in environmental and agricultural contexts. It is employed in soil treatment to adjust soil pH, particularly in acidic soils. The compound also finds use in composting processes, helping to control odors and accelerate decomposition. Additionally, it is used in certain fertilizer formulations and for treating animal waste in agricultural settings.

- Industrial and chemical manufacturing processes: Sodium bisulfate plays a role in various industrial and chemical manufacturing processes. It is used as a raw material or intermediate in the production of other chemicals, including dyes, pharmaceuticals, and specialty chemicals. The compound's acidic properties make it useful in metal surface treatment, cleaning formulations, and as a catalyst in certain chemical reactions.

02 Applications in water treatment and pH control

Sodium bisulfate is widely used in water treatment processes for pH adjustment and as a disinfectant. It is effective in controlling alkalinity in swimming pools, spas, and industrial water systems. The compound's ability to lower pH makes it valuable in various applications where acidic conditions are required.Expand Specific Solutions03 Use in food processing and preservation

Sodium bisulfate finds applications in food processing as a preservative and pH regulator. It is used to extend shelf life, prevent microbial growth, and maintain the quality of various food products. The compound's effectiveness in controlling acidity makes it valuable in the food industry for ensuring product safety and stability.Expand Specific Solutions04 Environmental and waste management applications

Sodium bisulfate is utilized in environmental and waste management processes. It is effective in treating and neutralizing alkaline waste streams, controlling odors in sewage systems, and as a component in soil remediation techniques. The compound's acidic properties make it useful for various environmental applications.Expand Specific Solutions05 Industrial and chemical manufacturing processes

Sodium bisulfate plays a role in various industrial and chemical manufacturing processes. It is used as a raw material or intermediate in the production of other chemicals, as a catalyst in certain reactions, and as a cleaning agent in industrial applications. The compound's versatility makes it valuable in multiple industrial sectors.Expand Specific Solutions

Key Players in NaHSO4 and Cement Production

The sodium bisulfate dynamics in cement industry improvements present a competitive landscape in a mature but evolving sector. The market is characterized by established players like China Petroleum & Chemical Corp., Taiheiyo Cement Corp., and Cement Australia Pty Ltd., alongside emerging companies such as Negative Emissions Materials, Inc. The industry is in a growth phase, driven by increasing infrastructure development and environmental concerns. The global cement market size is substantial, expected to reach over $400 billion by 2030. Technologically, advancements focus on reducing environmental impact and improving efficiency, with companies like China Building Materials Academy Co. Ltd. and Southeast University leading research efforts in sustainable cement production and sodium bisulfate applications.

China Building Materials Academy Co. Ltd.

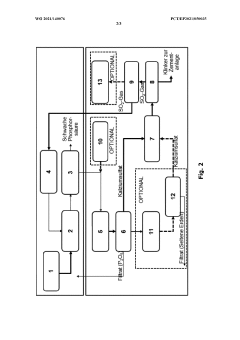

Technical Solution: China Building Materials Academy Co. Ltd. has developed an innovative approach to manage sodium bisulfate dynamics in cement production. Their method involves a two-stage process: first, they use a pre-treatment system to neutralize the sodium bisulfate before it enters the kiln, reducing its corrosive effects. This is achieved by introducing alkaline materials such as limestone or fly ash at controlled rates[1]. Second, they employ advanced sensors and real-time monitoring systems to continuously track sodium levels throughout the production process, allowing for immediate adjustments to maintain optimal chemical balance[3]. The company has also pioneered the use of alternative raw materials with lower sodium content, effectively reducing the overall sodium bisulfate formation in the cement production cycle[5].

Strengths: Comprehensive approach addressing both prevention and management of sodium bisulfate; real-time monitoring capabilities. Weaknesses: May require significant initial investment for implementation; effectiveness could vary depending on specific cement plant configurations.

Taiheiyo Cement Corp.

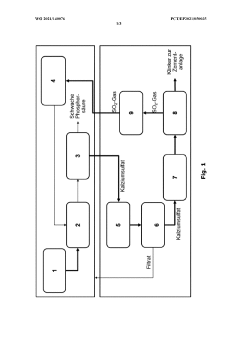

Technical Solution: Taiheiyo Cement Corp. has developed a novel "Sodium Bypass System" to address sodium bisulfate dynamics in cement production. This system utilizes a specialized extraction process at the preheater tower to remove excess sodium compounds before they can form sodium bisulfate in the kiln[2]. The extracted material is then treated separately, allowing for potential recovery of valuable components. Additionally, Taiheiyo has implemented advanced computational fluid dynamics (CFD) modeling to optimize kiln conditions, reducing the likelihood of sodium bisulfate formation[4]. Their approach also includes the use of specially formulated additives that bind with sodium ions, preventing them from reacting with sulfur compounds[6].

Strengths: Innovative extraction system combined with predictive modeling; potential for resource recovery. Weaknesses: May require significant modifications to existing plant infrastructure; effectiveness could be impacted by variations in raw material composition.

Innovative NaHSO4 Technologies for Cement

Integrated method for producing sulphur dioxide quality suitable for a sulphuric acid process from calcium sulphate/phosphogypsum from phosphoric acid production

PatentWO2021140076A1

Innovation

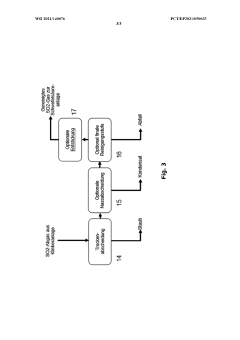

- An integrated process that treats calcium sulphate with an acid to create a purified suspension, which is then used to produce cement clinker and sulfur dioxide, with the latter being purified and reused in sulfuric acid production, thereby optimizing process parameters and reducing environmental impact.

Production system of sodium bisulfate

PatentActiveCN209583653U

Innovation

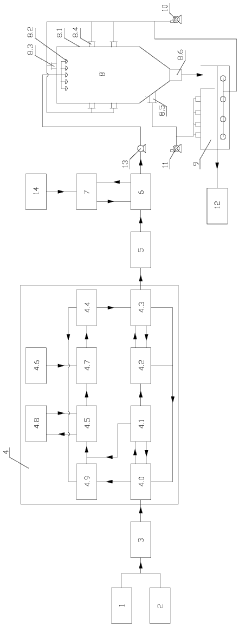

- A production system including dilute sulfuric acid storage tank, sodium sulfate storage tank, stirring tank, evaporation concentration system, crystallization device, melting kettle, granulation tower, vibrating fluidized bed and other equipment is designed. By converting the crystallized sodium bisulfate into The particles are heated and melted in the melting kettle, and further react to generate sodium bisulfate, which is cooled through a granulation tower and a vibrating fluidized bed to form dry sodium bisulfate particles.

Environmental Impact of NaHSO4 in Cement Production

The environmental impact of sodium bisulfate (NaHSO4) in cement production is a critical aspect that requires thorough examination. This compound, while essential for certain processes in cement manufacturing, can have significant implications for the surrounding ecosystem and human health if not properly managed.

NaHSO4 is primarily used in cement production as a grinding aid and performance enhancer. It helps to reduce the energy required for cement grinding and improves the overall quality of the final product. However, its acidic nature and potential for releasing sulfur dioxide (SO2) during high-temperature processes pose environmental concerns.

One of the main environmental issues associated with NaHSO4 in cement production is air pollution. When exposed to high temperatures in cement kilns, NaHSO4 can decompose, releasing SO2 into the atmosphere. SO2 is a major contributor to acid rain and can have detrimental effects on plant life, aquatic ecosystems, and human respiratory health. The emission of SO2 also contributes to the formation of fine particulate matter (PM2.5), which is known to cause various respiratory and cardiovascular problems.

Water pollution is another significant concern. If not properly contained, NaHSO4 can leach into groundwater or surface water bodies, altering their pH levels and potentially harming aquatic life. The acidification of water sources can lead to the mobilization of heavy metals, further exacerbating the environmental impact.

Soil contamination is also a potential risk associated with the use of NaHSO4 in cement production. Improper storage or disposal of this compound can lead to soil acidification, affecting plant growth and soil microbial communities. This, in turn, can disrupt local ecosystems and potentially impact agricultural productivity in surrounding areas.

The production and transportation of NaHSO4 itself also contribute to the overall environmental footprint of cement manufacturing. The energy-intensive processes involved in its synthesis and the emissions associated with its transportation add to the carbon footprint of the cement industry, which is already a significant contributor to global CO2 emissions.

To mitigate these environmental impacts, cement manufacturers are increasingly adopting more sustainable practices. These include implementing advanced air pollution control technologies, such as scrubbers and electrostatic precipitators, to reduce SO2 emissions. Some companies are also exploring alternative grinding aids and performance enhancers that have a lower environmental impact than NaHSO4.

Furthermore, proper handling, storage, and disposal protocols for NaHSO4 are crucial in minimizing its environmental impact. This includes using sealed containers, implementing spill prevention measures, and ensuring proper wastewater treatment before discharge.

NaHSO4 is primarily used in cement production as a grinding aid and performance enhancer. It helps to reduce the energy required for cement grinding and improves the overall quality of the final product. However, its acidic nature and potential for releasing sulfur dioxide (SO2) during high-temperature processes pose environmental concerns.

One of the main environmental issues associated with NaHSO4 in cement production is air pollution. When exposed to high temperatures in cement kilns, NaHSO4 can decompose, releasing SO2 into the atmosphere. SO2 is a major contributor to acid rain and can have detrimental effects on plant life, aquatic ecosystems, and human respiratory health. The emission of SO2 also contributes to the formation of fine particulate matter (PM2.5), which is known to cause various respiratory and cardiovascular problems.

Water pollution is another significant concern. If not properly contained, NaHSO4 can leach into groundwater or surface water bodies, altering their pH levels and potentially harming aquatic life. The acidification of water sources can lead to the mobilization of heavy metals, further exacerbating the environmental impact.

Soil contamination is also a potential risk associated with the use of NaHSO4 in cement production. Improper storage or disposal of this compound can lead to soil acidification, affecting plant growth and soil microbial communities. This, in turn, can disrupt local ecosystems and potentially impact agricultural productivity in surrounding areas.

The production and transportation of NaHSO4 itself also contribute to the overall environmental footprint of cement manufacturing. The energy-intensive processes involved in its synthesis and the emissions associated with its transportation add to the carbon footprint of the cement industry, which is already a significant contributor to global CO2 emissions.

To mitigate these environmental impacts, cement manufacturers are increasingly adopting more sustainable practices. These include implementing advanced air pollution control technologies, such as scrubbers and electrostatic precipitators, to reduce SO2 emissions. Some companies are also exploring alternative grinding aids and performance enhancers that have a lower environmental impact than NaHSO4.

Furthermore, proper handling, storage, and disposal protocols for NaHSO4 are crucial in minimizing its environmental impact. This includes using sealed containers, implementing spill prevention measures, and ensuring proper wastewater treatment before discharge.

Economic Feasibility of NaHSO4 Adoption in Cement

The economic feasibility of adopting sodium bisulfate (NaHSO4) in the cement industry is a critical consideration for manufacturers looking to optimize their production processes and reduce costs. This analysis examines the financial implications of implementing NaHSO4 in cement manufacturing, taking into account various economic factors and potential benefits.

One of the primary advantages of using NaHSO4 in cement production is its ability to act as a set retarder, which can lead to significant cost savings in terms of energy consumption and equipment wear. By slowing down the setting time of cement, manufacturers can reduce the need for rapid cooling processes, thereby decreasing energy expenditure and associated costs. This energy efficiency improvement can result in substantial long-term savings, particularly for large-scale cement production facilities.

Furthermore, the adoption of NaHSO4 can potentially reduce the overall raw material costs in cement manufacturing. As a byproduct of various industrial processes, NaHSO4 is often available at competitive prices compared to traditional set retarders. This cost advantage can contribute to improved profit margins for cement producers, especially in markets where raw material expenses represent a significant portion of production costs.

The implementation of NaHSO4 in cement production may also lead to enhanced product quality and consistency. By providing better control over the setting time, manufacturers can achieve more uniform cement properties, potentially reducing waste and improving overall product performance. This quality improvement can translate into increased market competitiveness and customer satisfaction, potentially leading to higher sales volumes and revenue growth.

However, the economic feasibility of NaHSO4 adoption also depends on several factors that may vary across different cement production facilities. Initial investment costs for equipment modifications or additions to accommodate NaHSO4 usage must be carefully evaluated against projected long-term savings. Additionally, the availability and transportation costs of NaHSO4 in different geographical regions can significantly impact its economic viability.

Regulatory considerations and environmental compliance requirements may also influence the economic feasibility of NaHSO4 adoption. While the use of NaHSO4 can potentially reduce the environmental footprint of cement production through improved energy efficiency, manufacturers must ensure compliance with local and international environmental standards. The costs associated with meeting these regulatory requirements should be factored into the overall economic assessment.

In conclusion, the economic feasibility of NaHSO4 adoption in the cement industry appears promising, with potential benefits in energy savings, raw material costs, and product quality. However, a comprehensive cost-benefit analysis, taking into account facility-specific factors and market conditions, is essential for cement manufacturers to make informed decisions regarding the implementation of this technology.

One of the primary advantages of using NaHSO4 in cement production is its ability to act as a set retarder, which can lead to significant cost savings in terms of energy consumption and equipment wear. By slowing down the setting time of cement, manufacturers can reduce the need for rapid cooling processes, thereby decreasing energy expenditure and associated costs. This energy efficiency improvement can result in substantial long-term savings, particularly for large-scale cement production facilities.

Furthermore, the adoption of NaHSO4 can potentially reduce the overall raw material costs in cement manufacturing. As a byproduct of various industrial processes, NaHSO4 is often available at competitive prices compared to traditional set retarders. This cost advantage can contribute to improved profit margins for cement producers, especially in markets where raw material expenses represent a significant portion of production costs.

The implementation of NaHSO4 in cement production may also lead to enhanced product quality and consistency. By providing better control over the setting time, manufacturers can achieve more uniform cement properties, potentially reducing waste and improving overall product performance. This quality improvement can translate into increased market competitiveness and customer satisfaction, potentially leading to higher sales volumes and revenue growth.

However, the economic feasibility of NaHSO4 adoption also depends on several factors that may vary across different cement production facilities. Initial investment costs for equipment modifications or additions to accommodate NaHSO4 usage must be carefully evaluated against projected long-term savings. Additionally, the availability and transportation costs of NaHSO4 in different geographical regions can significantly impact its economic viability.

Regulatory considerations and environmental compliance requirements may also influence the economic feasibility of NaHSO4 adoption. While the use of NaHSO4 can potentially reduce the environmental footprint of cement production through improved energy efficiency, manufacturers must ensure compliance with local and international environmental standards. The costs associated with meeting these regulatory requirements should be factored into the overall economic assessment.

In conclusion, the economic feasibility of NaHSO4 adoption in the cement industry appears promising, with potential benefits in energy savings, raw material costs, and product quality. However, a comprehensive cost-benefit analysis, taking into account facility-specific factors and market conditions, is essential for cement manufacturers to make informed decisions regarding the implementation of this technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!