Sodium Bisulfate Benefits in Industrial Waste Reduction

JUL 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate Overview and Research Objectives

Sodium bisulfate, a versatile chemical compound with the formula NaHSO4, has gained significant attention in recent years for its potential in industrial waste reduction. This acidic salt, formed by the partial neutralization of sulfuric acid with sodium hydroxide or sodium chloride, exhibits unique properties that make it valuable in various industrial applications.

The evolution of sodium bisulfate usage in waste management can be traced back to its initial applications in water treatment and pH adjustment. Over time, researchers and industry professionals have recognized its potential for addressing more complex environmental challenges, particularly in the realm of industrial waste reduction.

The primary objective of this research is to explore and evaluate the benefits of sodium bisulfate in mitigating industrial waste, with a focus on its effectiveness, cost-efficiency, and environmental impact. This investigation aims to provide a comprehensive understanding of how sodium bisulfate can be leveraged to address the growing concerns surrounding industrial waste management and environmental sustainability.

One of the key areas of interest is the application of sodium bisulfate in the treatment of heavy metal-contaminated wastewater. Industrial processes often generate effluents containing high concentrations of toxic metals, posing significant environmental and health risks. Sodium bisulfate's ability to lower pH and facilitate metal precipitation offers a promising solution for removing these contaminants from industrial wastewater streams.

Another crucial aspect of this research is the exploration of sodium bisulfate's role in odor control within waste management facilities. The compound's acidic nature can effectively neutralize alkaline odors, making it a valuable tool in managing unpleasant emissions from landfills, composting operations, and wastewater treatment plants.

Furthermore, this study aims to investigate the potential of sodium bisulfate in enhancing the efficiency of waste-to-energy processes. By optimizing pH levels and reducing corrosion in incineration systems, sodium bisulfate may contribute to improved energy recovery from waste materials, aligning with global efforts to promote circular economy principles.

As environmental regulations become increasingly stringent, industries are under pressure to adopt more sustainable waste management practices. This research seeks to evaluate how sodium bisulfate can help businesses comply with these regulations while simultaneously reducing their environmental footprint and operational costs.

By examining the multifaceted applications of sodium bisulfate in industrial waste reduction, this study aims to provide valuable insights for policymakers, industry leaders, and environmental scientists. The findings are expected to contribute to the development of more effective and sustainable waste management strategies, ultimately supporting the global transition towards a cleaner and more resource-efficient industrial landscape.

The evolution of sodium bisulfate usage in waste management can be traced back to its initial applications in water treatment and pH adjustment. Over time, researchers and industry professionals have recognized its potential for addressing more complex environmental challenges, particularly in the realm of industrial waste reduction.

The primary objective of this research is to explore and evaluate the benefits of sodium bisulfate in mitigating industrial waste, with a focus on its effectiveness, cost-efficiency, and environmental impact. This investigation aims to provide a comprehensive understanding of how sodium bisulfate can be leveraged to address the growing concerns surrounding industrial waste management and environmental sustainability.

One of the key areas of interest is the application of sodium bisulfate in the treatment of heavy metal-contaminated wastewater. Industrial processes often generate effluents containing high concentrations of toxic metals, posing significant environmental and health risks. Sodium bisulfate's ability to lower pH and facilitate metal precipitation offers a promising solution for removing these contaminants from industrial wastewater streams.

Another crucial aspect of this research is the exploration of sodium bisulfate's role in odor control within waste management facilities. The compound's acidic nature can effectively neutralize alkaline odors, making it a valuable tool in managing unpleasant emissions from landfills, composting operations, and wastewater treatment plants.

Furthermore, this study aims to investigate the potential of sodium bisulfate in enhancing the efficiency of waste-to-energy processes. By optimizing pH levels and reducing corrosion in incineration systems, sodium bisulfate may contribute to improved energy recovery from waste materials, aligning with global efforts to promote circular economy principles.

As environmental regulations become increasingly stringent, industries are under pressure to adopt more sustainable waste management practices. This research seeks to evaluate how sodium bisulfate can help businesses comply with these regulations while simultaneously reducing their environmental footprint and operational costs.

By examining the multifaceted applications of sodium bisulfate in industrial waste reduction, this study aims to provide valuable insights for policymakers, industry leaders, and environmental scientists. The findings are expected to contribute to the development of more effective and sustainable waste management strategies, ultimately supporting the global transition towards a cleaner and more resource-efficient industrial landscape.

Industrial Waste Reduction Market Analysis

The industrial waste reduction market has been experiencing significant growth in recent years, driven by increasing environmental concerns, stringent regulations, and the rising costs associated with waste management. The global market for industrial waste management solutions is projected to reach substantial figures in the coming years, with a compound annual growth rate (CAGR) that reflects the urgency of addressing industrial waste issues.

In the context of sodium bisulfate's benefits in industrial waste reduction, the market analysis reveals several key trends and opportunities. Firstly, there is a growing demand for cost-effective and environmentally friendly solutions to treat and reduce industrial waste. Sodium bisulfate, with its versatile applications in waste treatment processes, is well-positioned to capitalize on this demand.

The chemical manufacturing sector, in particular, has shown a strong interest in sodium bisulfate for its ability to neutralize alkaline waste streams and reduce the environmental impact of industrial effluents. This sector's growth, coupled with increasing regulatory pressure to minimize harmful discharges, is expected to drive the adoption of sodium bisulfate-based solutions.

Moreover, the water treatment industry, which intersects with various industrial sectors, presents a significant market opportunity for sodium bisulfate. As industries strive to recycle and reuse water in their processes, the need for effective pH adjustment and contaminant removal becomes paramount. Sodium bisulfate's role in these applications is likely to expand, contributing to market growth.

The mining industry is another key sector where sodium bisulfate finds extensive use in waste reduction and environmental remediation. With the global mining industry facing stricter environmental regulations, the demand for efficient waste treatment solutions is on the rise. Sodium bisulfate's ability to treat metal-contaminated wastewater and aid in the recovery of valuable metals from waste streams positions it as a valuable tool in this sector.

Geographically, developed regions such as North America and Europe currently dominate the market for industrial waste reduction solutions, including those involving sodium bisulfate. However, rapid industrialization in emerging economies, particularly in Asia-Pacific and Latin America, is expected to create new growth opportunities. These regions are witnessing increased environmental awareness and implementing stricter waste management regulations, driving the demand for effective waste reduction technologies.

The market analysis also indicates a trend towards integrated waste management solutions that combine various technologies and chemicals to achieve optimal results. This trend presents both opportunities and challenges for sodium bisulfate applications, as it may need to be incorporated into more comprehensive waste reduction systems to maintain its market relevance.

In conclusion, the industrial waste reduction market analysis reveals a positive outlook for sodium bisulfate applications. The growing emphasis on sustainable industrial practices, coupled with the chemical's versatility and effectiveness in waste treatment processes, suggests a promising future for its use in industrial waste reduction strategies across multiple sectors and geographical regions.

In the context of sodium bisulfate's benefits in industrial waste reduction, the market analysis reveals several key trends and opportunities. Firstly, there is a growing demand for cost-effective and environmentally friendly solutions to treat and reduce industrial waste. Sodium bisulfate, with its versatile applications in waste treatment processes, is well-positioned to capitalize on this demand.

The chemical manufacturing sector, in particular, has shown a strong interest in sodium bisulfate for its ability to neutralize alkaline waste streams and reduce the environmental impact of industrial effluents. This sector's growth, coupled with increasing regulatory pressure to minimize harmful discharges, is expected to drive the adoption of sodium bisulfate-based solutions.

Moreover, the water treatment industry, which intersects with various industrial sectors, presents a significant market opportunity for sodium bisulfate. As industries strive to recycle and reuse water in their processes, the need for effective pH adjustment and contaminant removal becomes paramount. Sodium bisulfate's role in these applications is likely to expand, contributing to market growth.

The mining industry is another key sector where sodium bisulfate finds extensive use in waste reduction and environmental remediation. With the global mining industry facing stricter environmental regulations, the demand for efficient waste treatment solutions is on the rise. Sodium bisulfate's ability to treat metal-contaminated wastewater and aid in the recovery of valuable metals from waste streams positions it as a valuable tool in this sector.

Geographically, developed regions such as North America and Europe currently dominate the market for industrial waste reduction solutions, including those involving sodium bisulfate. However, rapid industrialization in emerging economies, particularly in Asia-Pacific and Latin America, is expected to create new growth opportunities. These regions are witnessing increased environmental awareness and implementing stricter waste management regulations, driving the demand for effective waste reduction technologies.

The market analysis also indicates a trend towards integrated waste management solutions that combine various technologies and chemicals to achieve optimal results. This trend presents both opportunities and challenges for sodium bisulfate applications, as it may need to be incorporated into more comprehensive waste reduction systems to maintain its market relevance.

In conclusion, the industrial waste reduction market analysis reveals a positive outlook for sodium bisulfate applications. The growing emphasis on sustainable industrial practices, coupled with the chemical's versatility and effectiveness in waste treatment processes, suggests a promising future for its use in industrial waste reduction strategies across multiple sectors and geographical regions.

Current Challenges in Industrial Waste Management

Industrial waste management faces numerous challenges in the current landscape, particularly in the context of sodium bisulfate's potential benefits for waste reduction. One of the primary issues is the sheer volume of waste generated by industrial processes, which continues to grow as global production increases. This puts immense pressure on existing waste management infrastructure and disposal facilities, often leading to environmental degradation and health hazards.

Another significant challenge is the complexity of waste streams in modern industrial settings. Many industries produce a diverse range of waste materials, including hazardous substances, which require specialized handling and treatment. This complexity makes it difficult to implement one-size-fits-all solutions and necessitates tailored approaches for different waste types.

The regulatory landscape surrounding industrial waste management is also becoming increasingly stringent. Governments worldwide are implementing stricter environmental regulations, forcing industries to adopt more sustainable practices. However, compliance with these regulations often requires substantial investments in new technologies and processes, which can be financially burdensome for many companies, especially small and medium-sized enterprises.

Furthermore, there is a growing emphasis on circular economy principles, which aim to minimize waste generation and maximize resource recovery. This shift requires a fundamental rethinking of industrial processes and waste management strategies. However, many industries struggle to transition from traditional linear models to more circular approaches due to technological, economic, and logistical barriers.

The lack of effective waste segregation at the source is another persistent challenge. Proper segregation is crucial for efficient recycling and resource recovery, but it often requires significant changes in operational practices and employee behavior. This can be particularly challenging in large industrial facilities with complex production processes.

Additionally, the management of hazardous waste remains a critical concern. Many industrial processes generate toxic or dangerous byproducts that pose significant risks to human health and the environment. Safe handling, transportation, and disposal of these materials require specialized facilities and expertise, which are not always readily available or affordable.

The global nature of industrial supply chains also complicates waste management efforts. Waste generated in one country may be transported across borders for treatment or disposal, raising issues of responsibility, traceability, and environmental justice. This international dimension adds layers of complexity to regulatory compliance and environmental protection efforts.

Another significant challenge is the complexity of waste streams in modern industrial settings. Many industries produce a diverse range of waste materials, including hazardous substances, which require specialized handling and treatment. This complexity makes it difficult to implement one-size-fits-all solutions and necessitates tailored approaches for different waste types.

The regulatory landscape surrounding industrial waste management is also becoming increasingly stringent. Governments worldwide are implementing stricter environmental regulations, forcing industries to adopt more sustainable practices. However, compliance with these regulations often requires substantial investments in new technologies and processes, which can be financially burdensome for many companies, especially small and medium-sized enterprises.

Furthermore, there is a growing emphasis on circular economy principles, which aim to minimize waste generation and maximize resource recovery. This shift requires a fundamental rethinking of industrial processes and waste management strategies. However, many industries struggle to transition from traditional linear models to more circular approaches due to technological, economic, and logistical barriers.

The lack of effective waste segregation at the source is another persistent challenge. Proper segregation is crucial for efficient recycling and resource recovery, but it often requires significant changes in operational practices and employee behavior. This can be particularly challenging in large industrial facilities with complex production processes.

Additionally, the management of hazardous waste remains a critical concern. Many industrial processes generate toxic or dangerous byproducts that pose significant risks to human health and the environment. Safe handling, transportation, and disposal of these materials require specialized facilities and expertise, which are not always readily available or affordable.

The global nature of industrial supply chains also complicates waste management efforts. Waste generated in one country may be transported across borders for treatment or disposal, raising issues of responsibility, traceability, and environmental justice. This international dimension adds layers of complexity to regulatory compliance and environmental protection efforts.

Existing Sodium Bisulfate Applications

01 Recycling and reuse of sodium bisulfate

Implementing recycling and reuse processes for sodium bisulfate can significantly reduce waste. This involves collecting and purifying the used sodium bisulfate, allowing it to be reintroduced into the production cycle. By reusing the chemical, the overall consumption and waste generation can be minimized.- Recycling and reuse of sodium bisulfate: Implementing recycling and reuse processes for sodium bisulfate can significantly reduce waste. This involves collecting and purifying the used sodium bisulfate, allowing it to be reintroduced into the production cycle. Such methods can include filtration, crystallization, or chemical treatment to remove impurities and restore the compound to a usable state.

- Conversion of sodium bisulfate to valuable products: Converting sodium bisulfate waste into valuable products can reduce overall waste and create additional revenue streams. This may involve chemical processes to transform sodium bisulfate into other useful compounds such as sodium sulfate, sulfuric acid, or other industrial chemicals. These conversion processes can be integrated into existing production lines to maximize efficiency.

- Optimization of production processes: Optimizing production processes that use or generate sodium bisulfate can lead to significant waste reduction. This may include improving reaction efficiency, implementing better process control systems, or using more precise measurement and dosing techniques. By minimizing excess reagent use and improving yield, the overall amount of sodium bisulfate waste can be reduced.

- Treatment and neutralization of sodium bisulfate waste: Developing effective treatment and neutralization methods for sodium bisulfate waste can reduce its environmental impact. This may involve using alkaline substances to neutralize the acidic nature of sodium bisulfate, or employing advanced treatment technologies such as membrane filtration or electrochemical processes to remove or convert the compound into less harmful substances.

- Alternative processes to reduce sodium bisulfate usage: Exploring alternative processes or materials that can reduce or eliminate the need for sodium bisulfate in various applications can lead to waste reduction. This may involve developing new catalysts, using different reagents, or redesigning processes to achieve the same results without relying on sodium bisulfate. Such innovations can significantly decrease the amount of waste generated in industrial operations.

02 Optimization of production processes

Improving the efficiency of production processes that involve sodium bisulfate can lead to waste reduction. This may include optimizing reaction conditions, improving catalyst performance, and implementing better process control systems. By enhancing the overall efficiency, less sodium bisulfate is wasted during production.Expand Specific Solutions03 Alternative chemical substitutions

Exploring and implementing alternative chemicals or processes that can replace sodium bisulfate in certain applications can contribute to waste reduction. This may involve using more environmentally friendly substances or developing new technologies that achieve the same results without generating sodium bisulfate waste.Expand Specific Solutions04 Waste treatment and neutralization

Developing effective waste treatment and neutralization methods for sodium bisulfate can help reduce its environmental impact. This may include chemical treatments to convert sodium bisulfate into less harmful compounds or implementing advanced filtration and separation techniques to remove it from waste streams.Expand Specific Solutions05 Improved storage and handling techniques

Implementing better storage and handling techniques for sodium bisulfate can prevent unnecessary waste generation. This includes using appropriate containers, maintaining proper storage conditions, and training personnel in safe handling practices. By reducing spills, leaks, and contamination, the overall waste output can be decreased.Expand Specific Solutions

Key Players in Sodium Bisulfate Industry

The research on sodium bisulfate benefits in industrial waste reduction is in a developing stage, with growing market potential due to increasing environmental regulations and sustainability initiatives. The global market for industrial waste management solutions is expanding, driven by the need for more efficient and eco-friendly processes. Key players in this field include research institutions like RIST and the Institute of Process Engineering, Chinese Academy of Sciences, as well as industry leaders such as Veolia Water Solutions & Technologies and Stora Enso Oyj. These organizations are at various stages of technological maturity, with some focusing on fundamental research while others are developing and implementing practical applications. The involvement of diverse entities, from universities to multinational corporations, indicates a competitive landscape with opportunities for innovation and market growth.

RIST (Research Institute of Industrial Science & Technology)

Technical Solution: RIST has developed an innovative approach to utilizing sodium bisulfate in the treatment of metal-containing industrial wastes. Their technology focuses on the selective recovery of valuable metals from complex waste streams using sodium bisulfate as a leaching agent. The process involves a multi-stage leaching system where sodium bisulfate is used to solubilize target metals under controlled pH and temperature conditions[7]. RIST has also integrated electrowinning and ion exchange technologies to further purify and concentrate the recovered metals. This approach has been successfully applied to various types of industrial wastes, including spent catalysts, electronic scrap, and metallurgical slags. The institute's research has shown metal recovery rates of up to 95% for certain elements, significantly reducing the volume of hazardous waste requiring disposal while creating value from waste materials[8].

Strengths: High metal recovery rates, applicable to various waste types, value creation from waste. Weaknesses: Process complexity, potential for generating secondary waste streams requiring treatment.

Institute of Process Engineering, Chinese Academy of Sciences

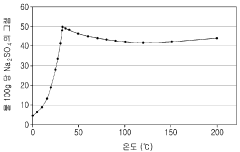

Technical Solution: The Institute of Process Engineering has conducted extensive research on utilizing sodium bisulfate for industrial waste reduction, particularly focusing on its application in flue gas desulfurization (FGD) processes. Their innovative approach involves using sodium bisulfate as a low-cost alternative to traditional alkaline absorbents in wet FGD systems[5]. The institute has developed a novel dual-alkali process where sodium bisulfate is used in the primary absorption step, followed by a calcium-based regeneration step. This method not only effectively removes sulfur dioxide from flue gases but also produces gypsum as a valuable by-product. The process has been optimized through computational fluid dynamics (CFD) modeling and pilot-scale testing, demonstrating SO2 removal efficiencies of over 95% while significantly reducing limestone consumption[6].

Strengths: Cost-effective alternative to traditional FGD methods, high SO2 removal efficiency, valuable by-product generation. Weaknesses: Complexity of the dual-alkali process, potential for equipment corrosion due to acidic conditions.

Innovative Uses of Sodium Bisulfate

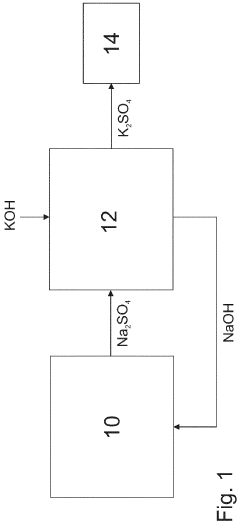

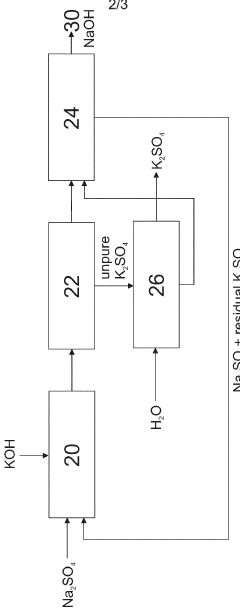

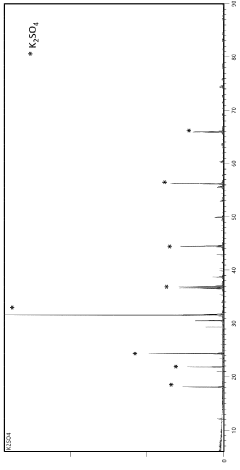

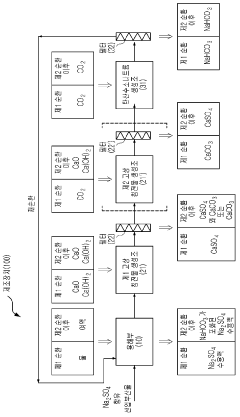

A method for treating waste sodium sulphate obtained from an industrial process of battery industry, use of waste sodium sulphate obtained from an industrial process of battery industry and an industrial processing plant of battery industry

PatentWO2024061893A1

Innovation

- A method involving the reaction of waste sodium sulphate with potassium hydroxide to produce potassium sulphate and sodium hydroxide, utilizing a zero-waste, low-temperature process that recovers both products, enabling their reuse in industrial processes and fertilizer production, thus reducing environmental impact and operational costs.

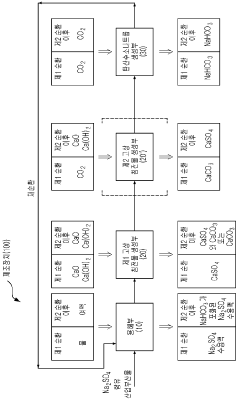

Apparatus for producing sodium bicarbonate from industrial by-products containing sodium sulfate

PatentWO2023121346A1

Innovation

- An apparatus that includes a dissolution unit, a first solid precipitate generation unit, and a sodium bicarbonate generation unit, where sodium bicarbonate is produced by dissolving carbon dioxide in the filtrate after recovering calcium sulfate, utilizing a calcium source to generate calcium sulfate and calcium carbonate, and recycling the filtrate to improve the efficiency and cost-effectiveness of the process.

Environmental Impact Assessment

The environmental impact assessment of sodium bisulfate in industrial waste reduction reveals both positive and negative effects on ecosystems and human health. On the positive side, sodium bisulfate's ability to neutralize alkaline waste streams helps prevent the release of harmful alkaline substances into water bodies. This pH adjustment is crucial for maintaining aquatic ecosystems and protecting marine life from the detrimental effects of high pH levels.

Furthermore, the use of sodium bisulfate in waste treatment processes can lead to a reduction in the overall volume of hazardous waste generated by industrial facilities. By effectively treating and neutralizing certain waste streams, it minimizes the need for more extensive and potentially environmentally damaging disposal methods. This contributes to a decrease in landfill usage and the associated risks of soil and groundwater contamination.

However, the environmental impact assessment also highlights potential concerns. The production and transportation of sodium bisulfate itself can contribute to carbon emissions and energy consumption. Additionally, improper handling or accidental releases of concentrated sodium bisulfate solutions can lead to localized soil acidification and potential harm to vegetation and soil microorganisms.

In terms of air quality, the use of sodium bisulfate in certain industrial processes may result in the formation of sulfur dioxide as a byproduct. While modern emission control technologies can mitigate this issue, it remains a consideration in the overall environmental impact assessment. Proper monitoring and control measures are essential to ensure compliance with air quality regulations.

The assessment also considers the long-term effects on water resources. While sodium bisulfate helps in treating wastewater, the increased salinity resulting from its use may impact freshwater ecosystems if not properly managed. This necessitates careful monitoring of effluent quality and potential impacts on receiving water bodies.

From a lifecycle perspective, the environmental impact assessment examines the sourcing of raw materials for sodium bisulfate production, as well as the energy requirements for its manufacture. Efforts to improve the sustainability of these processes, such as using renewable energy sources or optimizing production efficiency, can further enhance the overall environmental profile of sodium bisulfate use in industrial waste reduction.

In conclusion, the environmental impact assessment of sodium bisulfate in industrial waste reduction reveals a complex balance of benefits and potential risks. While it offers significant advantages in waste treatment and pH control, careful management and ongoing monitoring are essential to maximize its positive environmental contributions while minimizing any negative impacts.

Furthermore, the use of sodium bisulfate in waste treatment processes can lead to a reduction in the overall volume of hazardous waste generated by industrial facilities. By effectively treating and neutralizing certain waste streams, it minimizes the need for more extensive and potentially environmentally damaging disposal methods. This contributes to a decrease in landfill usage and the associated risks of soil and groundwater contamination.

However, the environmental impact assessment also highlights potential concerns. The production and transportation of sodium bisulfate itself can contribute to carbon emissions and energy consumption. Additionally, improper handling or accidental releases of concentrated sodium bisulfate solutions can lead to localized soil acidification and potential harm to vegetation and soil microorganisms.

In terms of air quality, the use of sodium bisulfate in certain industrial processes may result in the formation of sulfur dioxide as a byproduct. While modern emission control technologies can mitigate this issue, it remains a consideration in the overall environmental impact assessment. Proper monitoring and control measures are essential to ensure compliance with air quality regulations.

The assessment also considers the long-term effects on water resources. While sodium bisulfate helps in treating wastewater, the increased salinity resulting from its use may impact freshwater ecosystems if not properly managed. This necessitates careful monitoring of effluent quality and potential impacts on receiving water bodies.

From a lifecycle perspective, the environmental impact assessment examines the sourcing of raw materials for sodium bisulfate production, as well as the energy requirements for its manufacture. Efforts to improve the sustainability of these processes, such as using renewable energy sources or optimizing production efficiency, can further enhance the overall environmental profile of sodium bisulfate use in industrial waste reduction.

In conclusion, the environmental impact assessment of sodium bisulfate in industrial waste reduction reveals a complex balance of benefits and potential risks. While it offers significant advantages in waste treatment and pH control, careful management and ongoing monitoring are essential to maximize its positive environmental contributions while minimizing any negative impacts.

Cost-Benefit Analysis of Implementation

Implementing sodium bisulfate in industrial waste reduction processes requires a comprehensive cost-benefit analysis to determine its economic viability. The initial investment costs for incorporating sodium bisulfate into existing waste treatment systems can be significant, including equipment modifications, storage facilities, and safety measures. However, these upfront expenses should be weighed against the long-term benefits and potential cost savings.

One of the primary advantages of using sodium bisulfate is its effectiveness in pH adjustment and metal precipitation. This can lead to reduced chemical consumption in wastewater treatment processes, resulting in lower ongoing operational costs. Additionally, the improved efficiency in removing heavy metals and other contaminants can decrease the volume of sludge produced, thereby reducing disposal costs and environmental impact.

The implementation of sodium bisulfate can also contribute to compliance with increasingly stringent environmental regulations. By enhancing the quality of treated effluents, companies may avoid costly fines and penalties associated with non-compliance. This regulatory compliance benefit should be factored into the overall cost-benefit analysis, as it represents a significant risk mitigation strategy.

Energy savings is another potential benefit of sodium bisulfate implementation. Its use can optimize certain treatment processes, potentially reducing energy consumption in pumping, aeration, and other energy-intensive operations. These energy savings can translate into substantial cost reductions over time, particularly in large-scale industrial operations.

The analysis should also consider the potential for increased production efficiency. By improving waste treatment processes, companies may experience fewer production interruptions and reduced downtime for maintenance or regulatory issues. This increased operational efficiency can lead to higher productivity and, consequently, improved revenue streams.

However, it is crucial to account for potential drawbacks in the cost-benefit analysis. These may include increased corrosion of equipment due to the acidic nature of sodium bisulfate, necessitating more frequent maintenance or replacement of certain components. Additionally, there may be costs associated with employee training and safety measures to handle the chemical properly.

The environmental impact of sodium bisulfate use should also be evaluated. While it can improve waste treatment efficiency, its production and transportation have their own environmental footprints. A holistic analysis should consider these factors to ensure that the overall environmental benefit is positive.

In conclusion, a thorough cost-benefit analysis of implementing sodium bisulfate in industrial waste reduction should consider initial investments, operational cost savings, regulatory compliance benefits, energy efficiency improvements, productivity gains, and potential drawbacks. This comprehensive approach will provide a clear picture of the economic viability and long-term sustainability of adopting sodium bisulfate in industrial waste management processes.

One of the primary advantages of using sodium bisulfate is its effectiveness in pH adjustment and metal precipitation. This can lead to reduced chemical consumption in wastewater treatment processes, resulting in lower ongoing operational costs. Additionally, the improved efficiency in removing heavy metals and other contaminants can decrease the volume of sludge produced, thereby reducing disposal costs and environmental impact.

The implementation of sodium bisulfate can also contribute to compliance with increasingly stringent environmental regulations. By enhancing the quality of treated effluents, companies may avoid costly fines and penalties associated with non-compliance. This regulatory compliance benefit should be factored into the overall cost-benefit analysis, as it represents a significant risk mitigation strategy.

Energy savings is another potential benefit of sodium bisulfate implementation. Its use can optimize certain treatment processes, potentially reducing energy consumption in pumping, aeration, and other energy-intensive operations. These energy savings can translate into substantial cost reductions over time, particularly in large-scale industrial operations.

The analysis should also consider the potential for increased production efficiency. By improving waste treatment processes, companies may experience fewer production interruptions and reduced downtime for maintenance or regulatory issues. This increased operational efficiency can lead to higher productivity and, consequently, improved revenue streams.

However, it is crucial to account for potential drawbacks in the cost-benefit analysis. These may include increased corrosion of equipment due to the acidic nature of sodium bisulfate, necessitating more frequent maintenance or replacement of certain components. Additionally, there may be costs associated with employee training and safety measures to handle the chemical properly.

The environmental impact of sodium bisulfate use should also be evaluated. While it can improve waste treatment efficiency, its production and transportation have their own environmental footprints. A holistic analysis should consider these factors to ensure that the overall environmental benefit is positive.

In conclusion, a thorough cost-benefit analysis of implementing sodium bisulfate in industrial waste reduction should consider initial investments, operational cost savings, regulatory compliance benefits, energy efficiency improvements, productivity gains, and potential drawbacks. This comprehensive approach will provide a clear picture of the economic viability and long-term sustainability of adopting sodium bisulfate in industrial waste management processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!