Sodium Bisulfate’s Benefits in Dye Industry Improvements

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate in Dyes

Sodium bisulfate, a versatile chemical compound, has gained significant attention in the dye industry due to its multifaceted benefits. This acidic salt, also known as sodium hydrogen sulfate, plays a crucial role in various dyeing processes, contributing to improved color fastness, enhanced dye penetration, and overall efficiency in textile coloration.

In the realm of textile dyeing, sodium bisulfate serves as an effective pH regulator. Its ability to lower the pH of dyebaths is particularly valuable when working with acid dyes, which require acidic conditions for optimal performance. By creating the ideal pH environment, sodium bisulfate facilitates better dye uptake and more uniform color distribution across fibers.

One of the primary advantages of using sodium bisulfate in dye formulations is its contribution to color fastness. The compound helps to fix dyes more securely to fabric fibers, resulting in colors that are more resistant to fading, washing, and general wear. This enhanced durability is especially beneficial for textiles that undergo frequent laundering or exposure to harsh environmental conditions.

Sodium bisulfate also acts as a reducing agent in certain dyeing processes. This property is particularly useful in vat dyeing, where it aids in the reduction of vat dyes, allowing them to penetrate fibers more effectively. Once the dye is absorbed, oxidation occurs, locking the color in place and producing vibrant, long-lasting results.

In addition to its direct role in dyeing, sodium bisulfate serves as a cleaning agent for dyeing equipment. Its acidic nature helps to remove mineral deposits and scale buildup, ensuring that dyeing machinery remains in optimal condition. This maintenance aspect contributes to the overall efficiency and longevity of dyeing operations.

The compound's versatility extends to its use as a neutralizing agent in post-dyeing treatments. After alkaline dyeing processes, sodium bisulfate can be employed to neutralize excess alkali, bringing the pH of the fabric back to a neutral or slightly acidic state. This step is crucial for preventing damage to fibers and ensuring the stability of the dyed product.

Furthermore, sodium bisulfate has shown promise in eco-friendly dyeing initiatives. Its ability to improve dye fixation rates can lead to reduced water consumption and decreased levels of unfixed dyes in wastewater. This aligns with the growing industry focus on sustainable and environmentally responsible dyeing practices.

As the textile industry continues to evolve, the role of sodium bisulfate in dye formulations and processes is likely to expand. Ongoing research is exploring its potential in new dyeing technologies, such as low-temperature dyeing methods and advanced fiber treatments, further cementing its position as a valuable component in the dye industry's toolkit.

In the realm of textile dyeing, sodium bisulfate serves as an effective pH regulator. Its ability to lower the pH of dyebaths is particularly valuable when working with acid dyes, which require acidic conditions for optimal performance. By creating the ideal pH environment, sodium bisulfate facilitates better dye uptake and more uniform color distribution across fibers.

One of the primary advantages of using sodium bisulfate in dye formulations is its contribution to color fastness. The compound helps to fix dyes more securely to fabric fibers, resulting in colors that are more resistant to fading, washing, and general wear. This enhanced durability is especially beneficial for textiles that undergo frequent laundering or exposure to harsh environmental conditions.

Sodium bisulfate also acts as a reducing agent in certain dyeing processes. This property is particularly useful in vat dyeing, where it aids in the reduction of vat dyes, allowing them to penetrate fibers more effectively. Once the dye is absorbed, oxidation occurs, locking the color in place and producing vibrant, long-lasting results.

In addition to its direct role in dyeing, sodium bisulfate serves as a cleaning agent for dyeing equipment. Its acidic nature helps to remove mineral deposits and scale buildup, ensuring that dyeing machinery remains in optimal condition. This maintenance aspect contributes to the overall efficiency and longevity of dyeing operations.

The compound's versatility extends to its use as a neutralizing agent in post-dyeing treatments. After alkaline dyeing processes, sodium bisulfate can be employed to neutralize excess alkali, bringing the pH of the fabric back to a neutral or slightly acidic state. This step is crucial for preventing damage to fibers and ensuring the stability of the dyed product.

Furthermore, sodium bisulfate has shown promise in eco-friendly dyeing initiatives. Its ability to improve dye fixation rates can lead to reduced water consumption and decreased levels of unfixed dyes in wastewater. This aligns with the growing industry focus on sustainable and environmentally responsible dyeing practices.

As the textile industry continues to evolve, the role of sodium bisulfate in dye formulations and processes is likely to expand. Ongoing research is exploring its potential in new dyeing technologies, such as low-temperature dyeing methods and advanced fiber treatments, further cementing its position as a valuable component in the dye industry's toolkit.

Dye Industry Demand

The dye industry has experienced significant growth and transformation in recent years, driven by increasing demand across various sectors. The global dye market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) that reflects the industry's robust expansion. This growth is primarily fueled by the rising consumption of dyes in textile, leather, paper, and plastic industries.

In the textile sector, which remains the largest consumer of dyes, there is a growing demand for high-quality, eco-friendly dyes that offer superior color fastness and durability. This trend is partly driven by consumer preferences for sustainable and long-lasting products, as well as stringent environmental regulations in many countries. The fashion industry, in particular, has been a key driver of innovation in textile dyes, constantly seeking new colors and effects to meet changing consumer tastes.

The leather industry also contributes significantly to the demand for dyes, with a focus on achieving rich, consistent colors that can withstand various treatments and environmental conditions. Similarly, the paper industry requires dyes that can provide vibrant colors while maintaining the paper's structural integrity and meeting environmental standards.

In recent years, there has been a notable shift towards water-based dyes and those with reduced environmental impact. This trend is particularly evident in developed markets where environmental concerns and regulatory pressures are more pronounced. Manufacturers are increasingly investing in research and development to create dyes that minimize water consumption, reduce chemical waste, and lower energy requirements during the dyeing process.

The plastic industry's demand for dyes has also been on the rise, driven by the growing use of colored plastics in various applications, from consumer goods to automotive parts. This sector requires dyes that can withstand high processing temperatures and maintain color stability over extended periods.

Geographically, Asia-Pacific remains the largest market for dyes, with China and India being major producers and consumers. The region's dominance is attributed to its large textile and leather industries, as well as the presence of numerous dye manufacturers. However, there is growing demand from emerging markets in Africa and Latin America, presenting new opportunities for industry expansion.

The industry faces challenges related to raw material price volatility and increasing environmental regulations. These factors are driving innovation in dye formulations and application processes. There is a growing emphasis on developing dyes that require less water and energy during application, aligning with global sustainability goals.

In conclusion, the dye industry's demand is characterized by a complex interplay of factors including technological advancements, environmental considerations, and shifting consumer preferences. The industry's future growth will likely be shaped by innovations that address these multifaceted demands while improving efficiency and sustainability in dye production and application processes.

In the textile sector, which remains the largest consumer of dyes, there is a growing demand for high-quality, eco-friendly dyes that offer superior color fastness and durability. This trend is partly driven by consumer preferences for sustainable and long-lasting products, as well as stringent environmental regulations in many countries. The fashion industry, in particular, has been a key driver of innovation in textile dyes, constantly seeking new colors and effects to meet changing consumer tastes.

The leather industry also contributes significantly to the demand for dyes, with a focus on achieving rich, consistent colors that can withstand various treatments and environmental conditions. Similarly, the paper industry requires dyes that can provide vibrant colors while maintaining the paper's structural integrity and meeting environmental standards.

In recent years, there has been a notable shift towards water-based dyes and those with reduced environmental impact. This trend is particularly evident in developed markets where environmental concerns and regulatory pressures are more pronounced. Manufacturers are increasingly investing in research and development to create dyes that minimize water consumption, reduce chemical waste, and lower energy requirements during the dyeing process.

The plastic industry's demand for dyes has also been on the rise, driven by the growing use of colored plastics in various applications, from consumer goods to automotive parts. This sector requires dyes that can withstand high processing temperatures and maintain color stability over extended periods.

Geographically, Asia-Pacific remains the largest market for dyes, with China and India being major producers and consumers. The region's dominance is attributed to its large textile and leather industries, as well as the presence of numerous dye manufacturers. However, there is growing demand from emerging markets in Africa and Latin America, presenting new opportunities for industry expansion.

The industry faces challenges related to raw material price volatility and increasing environmental regulations. These factors are driving innovation in dye formulations and application processes. There is a growing emphasis on developing dyes that require less water and energy during application, aligning with global sustainability goals.

In conclusion, the dye industry's demand is characterized by a complex interplay of factors including technological advancements, environmental considerations, and shifting consumer preferences. The industry's future growth will likely be shaped by innovations that address these multifaceted demands while improving efficiency and sustainability in dye production and application processes.

Current Challenges

The dye industry faces several significant challenges in its current state, particularly concerning the use of sodium bisulfate and its potential benefits. One of the primary issues is the environmental impact of traditional dyeing processes. These processes often involve the use of harsh chemicals and generate substantial amounts of wastewater, which can be harmful to ecosystems if not properly treated. The industry is under increasing pressure to adopt more sustainable practices and reduce its ecological footprint.

Another challenge is the high energy consumption associated with conventional dyeing methods. Many dyeing processes require elevated temperatures and extended processing times, leading to significant energy expenditure and increased production costs. This not only affects the industry's profitability but also contributes to its overall carbon footprint.

The inconsistency in dye quality and color fastness remains a persistent problem. Achieving uniform and long-lasting colors across different fabrics and materials is crucial for meeting consumer expectations and maintaining product quality. However, current dyeing techniques often struggle to deliver consistent results, leading to variations in color intensity and durability.

Water scarcity is becoming an increasingly critical issue for the dye industry. Traditional dyeing processes are water-intensive, consuming large volumes of freshwater resources. In regions where water is scarce, this poses a significant challenge to production capacity and sustainability.

The industry also grapples with the challenge of chemical safety and worker health. Many conventional dyes and auxiliaries used in the dyeing process can be toxic or potentially harmful to workers if not handled properly. Ensuring workplace safety while maintaining production efficiency is a delicate balance that the industry must strike.

Furthermore, there is a growing demand for more versatile dyeing processes that can accommodate a wider range of materials and fibers. As new synthetic and blended fabrics enter the market, existing dyeing technologies may struggle to provide optimal results across all material types.

Regulatory compliance presents another significant challenge. Environmental regulations are becoming increasingly stringent, requiring dye manufacturers and users to adapt their processes and products to meet new standards. This often necessitates substantial investments in research, development, and new equipment.

Lastly, the industry faces the challenge of innovation inertia. Many established companies are reluctant to invest in new technologies or processes due to the high costs and perceived risks associated with change. This resistance to innovation can hinder the adoption of potentially beneficial solutions, such as those involving sodium bisulfate, which could address some of the aforementioned challenges.

Another challenge is the high energy consumption associated with conventional dyeing methods. Many dyeing processes require elevated temperatures and extended processing times, leading to significant energy expenditure and increased production costs. This not only affects the industry's profitability but also contributes to its overall carbon footprint.

The inconsistency in dye quality and color fastness remains a persistent problem. Achieving uniform and long-lasting colors across different fabrics and materials is crucial for meeting consumer expectations and maintaining product quality. However, current dyeing techniques often struggle to deliver consistent results, leading to variations in color intensity and durability.

Water scarcity is becoming an increasingly critical issue for the dye industry. Traditional dyeing processes are water-intensive, consuming large volumes of freshwater resources. In regions where water is scarce, this poses a significant challenge to production capacity and sustainability.

The industry also grapples with the challenge of chemical safety and worker health. Many conventional dyes and auxiliaries used in the dyeing process can be toxic or potentially harmful to workers if not handled properly. Ensuring workplace safety while maintaining production efficiency is a delicate balance that the industry must strike.

Furthermore, there is a growing demand for more versatile dyeing processes that can accommodate a wider range of materials and fibers. As new synthetic and blended fabrics enter the market, existing dyeing technologies may struggle to provide optimal results across all material types.

Regulatory compliance presents another significant challenge. Environmental regulations are becoming increasingly stringent, requiring dye manufacturers and users to adapt their processes and products to meet new standards. This often necessitates substantial investments in research, development, and new equipment.

Lastly, the industry faces the challenge of innovation inertia. Many established companies are reluctant to invest in new technologies or processes due to the high costs and perceived risks associated with change. This resistance to innovation can hinder the adoption of potentially beneficial solutions, such as those involving sodium bisulfate, which could address some of the aforementioned challenges.

Sodium Bisulfate Uses

01 pH adjustment and acidity control

Sodium bisulfate is widely used as a pH adjuster and acidity control agent in various industries. It effectively lowers pH levels in solutions, making it valuable in water treatment, food processing, and industrial applications where precise pH control is crucial.- pH adjustment and acidity control: Sodium bisulfate is widely used as a pH adjuster and acidity control agent in various applications. It effectively lowers pH levels in solutions, making it useful in water treatment, food processing, and industrial cleaning. Its ability to control acidity helps in preserving products and maintaining desired chemical properties.

- Cleaning and disinfection: Sodium bisulfate serves as an effective cleaning and disinfecting agent. It is used in household and industrial cleaning products, swimming pool treatments, and sanitizers. Its acidic properties help in removing mineral deposits, scale, and stains, while also providing antimicrobial effects.

- Food preservation and processing: In the food industry, sodium bisulfate is utilized as a preservative and processing aid. It helps prevent microbial growth, maintains color, and extends shelf life of various food products. It is also used in meat processing to improve texture and flavor, and in baking as a leavening agent.

- Water treatment and purification: Sodium bisulfate is beneficial in water treatment processes. It is used to adjust pH levels in swimming pools, aquariums, and industrial water systems. It also aids in removing chlorine from water, making it useful in dechlorination applications and improving water quality.

- Agricultural and horticultural applications: In agriculture and horticulture, sodium bisulfate offers various benefits. It is used to acidify soil, improve nutrient uptake in plants, and as a component in fertilizers. It also serves as a feed additive in animal nutrition to enhance digestion and prevent certain diseases.

02 Cleaning and disinfection

The compound exhibits strong cleaning and disinfecting properties, making it useful in household and industrial cleaning products. It can effectively remove mineral deposits, scale, and stains while also providing antimicrobial action, contributing to improved hygiene and sanitation.Expand Specific Solutions03 Water treatment applications

Sodium bisulfate is beneficial in water treatment processes, including swimming pool maintenance and wastewater treatment. It helps balance water chemistry, control alkalinity, and can act as a flocculant to improve water clarity and quality.Expand Specific Solutions04 Food industry applications

In the food industry, sodium bisulfate serves as a preservative, flavor enhancer, and leavening agent. It can extend shelf life, improve texture, and contribute to the overall quality and safety of various food products.Expand Specific Solutions05 Industrial and agricultural uses

Sodium bisulfate finds applications in various industrial processes and agriculture. It can be used in metal treatment, as a catalyst in chemical reactions, and as a soil amendment to adjust soil pH for optimal plant growth.Expand Specific Solutions

Key Industry Players

The research on sodium bisulfate's benefits in dye industry improvements is currently in a growth phase, with increasing market size and technological advancements. The global market for sodium bisulfate in the dye industry is expanding, driven by the growing demand for efficient and eco-friendly dyeing processes. Companies like BASF Corp., Kemira Oyj, and Procter & Gamble Co. are at the forefront of developing innovative applications, indicating a moderate to high level of technological maturity. However, there is still room for further research and development, particularly in enhancing sustainability and cost-effectiveness, as evidenced by ongoing studies at institutions like the University of Leeds and the Industrial Technology Research Institute.

Kemira Oyj

Technical Solution: Kemira Oyj has made significant strides in utilizing sodium bisulfate for dye industry improvements. Their research has led to the development of a novel pH control system that uses sodium bisulfate to maintain optimal acidity levels during the dyeing process[2]. This system allows for more precise color matching and improved dye penetration, particularly in challenging fabrics. Kemira has also explored the use of sodium bisulfate in wastewater treatment processes specific to the textile industry, developing methods to neutralize alkaline effluents and remove excess dyes from wastewater streams[4]. Furthermore, the company has invested in creating specialized sodium bisulfate blends that enhance the performance of reactive dyes, leading to brighter colors and reduced dye runoff during washing[6].

Strengths: Strong focus on process optimization and environmental solutions, innovative pH control systems. Weaknesses: May face challenges in markets where traditional dyeing methods are deeply entrenched.

BASF Corp.

Technical Solution: BASF Corp. has developed an innovative approach to utilizing sodium bisulfate in the dye industry. Their research focuses on enhancing the stability and color fastness of dyes through a proprietary process that incorporates sodium bisulfate as a key component. This process involves the creation of a specialized dye fixative that combines sodium bisulfate with other synergistic chemicals to form a complex that bonds more effectively with fabric fibers[1]. The company has also explored the use of sodium bisulfate in pre-treatment processes to improve dye uptake and reduce water consumption in textile dyeing[3]. Additionally, BASF has invested in developing eco-friendly dye formulations that leverage sodium bisulfate's properties to minimize environmental impact while maintaining high-quality color results[5].

Strengths: Advanced research capabilities, comprehensive approach to dye improvement, focus on sustainability. Weaknesses: Potential higher costs associated with proprietary processes, may require specialized equipment for implementation.

Innovative Applications

Dyeing auxiliary and manufacturing method and applied dyeing process thereof Capable of increasing the dyeing rate of the fabric and reduce the residual rate of the dyes in the subsequent wastewater during the dyeing process

PatentInactiveTW202206414A

Innovation

- Synthesis of imidazoline derivative surfactant using imidazoline, epichlorohydrin, and sodium bisulfite as raw materials.

- Utilization of the agglutination properties of the auxiliary to capture dyes from wastewater and bring them into the cellulose fabric.

- Simultaneous increase in fabric dyeing rate and reduction of dye residual rate in wastewater.

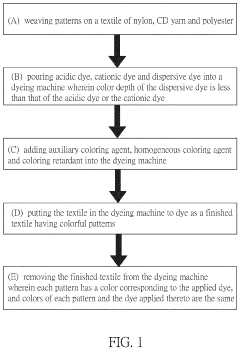

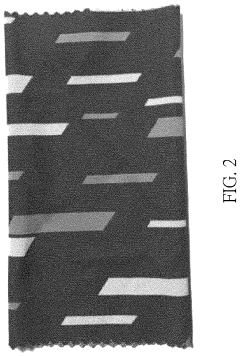

Process of Dyeing Patterns of Textile

PatentInactiveUS20200102698A1

Innovation

- A process involving the use of nylon, cationic polyester yarn, and polyester textiles, with specific dyes (acidic, cationic, and dispersive dyes) and auxiliary agents (acetic acid solution and sodium sulfate) in a dyeing machine, allowing for rapid dyeing and improved color uniformity, enabling quick identification and reduced storage and modification costs.

Environmental Impact

The use of sodium bisulfate in the dye industry has significant environmental implications that warrant careful consideration. As a strong acid salt, sodium bisulfate can potentially impact water quality and aquatic ecosystems if not properly managed. When discharged into water bodies, it can lower the pH, leading to acidification that may harm aquatic life and disrupt ecological balance. However, the controlled use of sodium bisulfate in dye processes can also offer environmental benefits.

One of the primary environmental advantages of sodium bisulfate in the dye industry is its potential to reduce water consumption. By enhancing dye fixation and improving color fastness, it allows for more efficient dyeing processes that require less water for rinsing and washing. This water conservation aspect is particularly crucial in regions facing water scarcity issues and aligns with global efforts to reduce industrial water footprints.

Furthermore, sodium bisulfate can contribute to the reduction of chemical waste in dye effluents. Its ability to neutralize alkaline wastewater helps in maintaining optimal pH levels, which is essential for effective wastewater treatment. This can lead to decreased use of additional chemicals for pH adjustment in effluent treatment plants, thereby reducing the overall chemical load in industrial discharges.

The compound also plays a role in improving the biodegradability of certain dyes. By modifying the chemical structure of dye molecules, sodium bisulfate can make them more susceptible to breakdown by natural processes or in wastewater treatment facilities. This enhanced biodegradability can result in reduced persistence of dye compounds in the environment, mitigating long-term ecological impacts.

However, the environmental benefits of sodium bisulfate must be balanced against potential risks. Improper handling or accidental spills can lead to soil acidification and damage to vegetation. Therefore, stringent safety protocols and proper storage facilities are essential to prevent environmental contamination. Additionally, the production of sodium bisulfate itself has an environmental footprint that should be considered in lifecycle assessments of dye industry practices.

In the context of circular economy principles, the use of sodium bisulfate in the dye industry presents opportunities for resource recovery. The compound can be regenerated from certain waste streams, offering potential for closed-loop systems that minimize resource consumption and waste generation. This aligns with broader sustainability goals and can contribute to reducing the overall environmental impact of dye manufacturing processes.

As environmental regulations become increasingly stringent, the role of sodium bisulfate in meeting compliance standards becomes more prominent. Its use can help dye manufacturers achieve lower levels of pollutants in their effluents, potentially reducing the need for extensive end-of-pipe treatment solutions. This proactive approach to pollution prevention can lead to cost savings and improved environmental performance across the industry.

One of the primary environmental advantages of sodium bisulfate in the dye industry is its potential to reduce water consumption. By enhancing dye fixation and improving color fastness, it allows for more efficient dyeing processes that require less water for rinsing and washing. This water conservation aspect is particularly crucial in regions facing water scarcity issues and aligns with global efforts to reduce industrial water footprints.

Furthermore, sodium bisulfate can contribute to the reduction of chemical waste in dye effluents. Its ability to neutralize alkaline wastewater helps in maintaining optimal pH levels, which is essential for effective wastewater treatment. This can lead to decreased use of additional chemicals for pH adjustment in effluent treatment plants, thereby reducing the overall chemical load in industrial discharges.

The compound also plays a role in improving the biodegradability of certain dyes. By modifying the chemical structure of dye molecules, sodium bisulfate can make them more susceptible to breakdown by natural processes or in wastewater treatment facilities. This enhanced biodegradability can result in reduced persistence of dye compounds in the environment, mitigating long-term ecological impacts.

However, the environmental benefits of sodium bisulfate must be balanced against potential risks. Improper handling or accidental spills can lead to soil acidification and damage to vegetation. Therefore, stringent safety protocols and proper storage facilities are essential to prevent environmental contamination. Additionally, the production of sodium bisulfate itself has an environmental footprint that should be considered in lifecycle assessments of dye industry practices.

In the context of circular economy principles, the use of sodium bisulfate in the dye industry presents opportunities for resource recovery. The compound can be regenerated from certain waste streams, offering potential for closed-loop systems that minimize resource consumption and waste generation. This aligns with broader sustainability goals and can contribute to reducing the overall environmental impact of dye manufacturing processes.

As environmental regulations become increasingly stringent, the role of sodium bisulfate in meeting compliance standards becomes more prominent. Its use can help dye manufacturers achieve lower levels of pollutants in their effluents, potentially reducing the need for extensive end-of-pipe treatment solutions. This proactive approach to pollution prevention can lead to cost savings and improved environmental performance across the industry.

Regulatory Compliance

The use of sodium bisulfate in the dye industry is subject to various regulatory frameworks that govern its production, handling, and application. In the United States, the Environmental Protection Agency (EPA) regulates sodium bisulfate under the Toxic Substances Control Act (TSCA), which requires manufacturers and importers to report chemical data and potential risks. The Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure limits and safety protocols for handling sodium bisulfate.

In the European Union, sodium bisulfate falls under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework ensures that chemical substances are registered and their potential impacts on human health and the environment are assessed. Manufacturers and importers must provide detailed information on the properties, uses, and safe handling of sodium bisulfate to the European Chemicals Agency (ECHA).

The dye industry must also comply with specific regulations related to textile and chemical production. For instance, the EU's REACH regulation includes restrictions on certain hazardous substances in textile and leather articles. Companies using sodium bisulfate in dye production must ensure that their final products meet these standards.

In addition to chemical regulations, the dye industry must adhere to environmental regulations concerning wastewater discharge and air emissions. The use of sodium bisulfate in dye production processes may generate acidic wastewater, which must be treated to meet local and national environmental standards before discharge. In the United States, the Clean Water Act and Clean Air Act set guidelines for industrial effluents and emissions, respectively.

Globally, the Stockholm Convention on Persistent Organic Pollutants (POPs) aims to eliminate or restrict the production and use of certain hazardous chemicals. While sodium bisulfate itself is not listed as a POP, the dye industry must ensure that its use does not contribute to the formation or release of any regulated substances.

To maintain regulatory compliance, companies in the dye industry must implement robust chemical management systems, conduct regular risk assessments, and stay informed about evolving regulations. This includes maintaining detailed records of chemical usage, implementing proper labeling and safety data sheets, and providing adequate training for employees handling sodium bisulfate and other chemicals.

As sustainability becomes increasingly important, the dye industry faces growing pressure to adopt more environmentally friendly practices. This may lead to the development of new regulations or voluntary industry standards that encourage the use of less harmful alternatives or more efficient production processes. Companies investing in research on sodium bisulfate's benefits in dye industry improvements should consider these potential future regulatory developments in their long-term strategies.

In the European Union, sodium bisulfate falls under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework ensures that chemical substances are registered and their potential impacts on human health and the environment are assessed. Manufacturers and importers must provide detailed information on the properties, uses, and safe handling of sodium bisulfate to the European Chemicals Agency (ECHA).

The dye industry must also comply with specific regulations related to textile and chemical production. For instance, the EU's REACH regulation includes restrictions on certain hazardous substances in textile and leather articles. Companies using sodium bisulfate in dye production must ensure that their final products meet these standards.

In addition to chemical regulations, the dye industry must adhere to environmental regulations concerning wastewater discharge and air emissions. The use of sodium bisulfate in dye production processes may generate acidic wastewater, which must be treated to meet local and national environmental standards before discharge. In the United States, the Clean Water Act and Clean Air Act set guidelines for industrial effluents and emissions, respectively.

Globally, the Stockholm Convention on Persistent Organic Pollutants (POPs) aims to eliminate or restrict the production and use of certain hazardous chemicals. While sodium bisulfate itself is not listed as a POP, the dye industry must ensure that its use does not contribute to the formation or release of any regulated substances.

To maintain regulatory compliance, companies in the dye industry must implement robust chemical management systems, conduct regular risk assessments, and stay informed about evolving regulations. This includes maintaining detailed records of chemical usage, implementing proper labeling and safety data sheets, and providing adequate training for employees handling sodium bisulfate and other chemicals.

As sustainability becomes increasingly important, the dye industry faces growing pressure to adopt more environmentally friendly practices. This may lead to the development of new regulations or voluntary industry standards that encourage the use of less harmful alternatives or more efficient production processes. Companies investing in research on sodium bisulfate's benefits in dye industry improvements should consider these potential future regulatory developments in their long-term strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!