Sodium Bisulfate in Biosafe Meat Packaging Solutions

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate in Meat Packaging: Background and Objectives

Sodium bisulfate has emerged as a promising solution in the realm of biosafe meat packaging, addressing critical challenges in food preservation and safety. The evolution of meat packaging technologies has been driven by the increasing demand for extended shelf life, improved food quality, and enhanced consumer safety. Sodium bisulfate, a compound with antimicrobial properties, has gained attention for its potential to revolutionize meat packaging practices.

The primary objective of researching sodium bisulfate in meat packaging is to develop innovative, sustainable, and effective solutions that can significantly reduce microbial growth and extend the shelf life of meat products. This aligns with the broader industry goals of minimizing food waste, ensuring food safety, and meeting the growing consumer demand for fresh, high-quality meat products with minimal preservatives.

Historically, meat packaging has progressed from simple wrapping methods to more sophisticated techniques involving modified atmosphere packaging (MAP) and active packaging systems. The introduction of sodium bisulfate represents a new frontier in this technological progression, offering a chemical approach to complement existing physical and biological preservation methods.

The exploration of sodium bisulfate in meat packaging is driven by several key factors. Firstly, there is an increasing consumer preference for "clean label" products with fewer synthetic additives. Sodium bisulfate, being a naturally occurring compound, aligns well with this trend. Secondly, the rise of antibiotic-resistant bacteria has necessitated the development of alternative antimicrobial strategies in food preservation.

Furthermore, the global meat industry faces significant challenges related to food safety and spoilage. Foodborne illnesses caused by pathogens such as Salmonella, E. coli, and Listeria continue to be a major concern. The potential of sodium bisulfate to inhibit the growth of these harmful microorganisms makes it a subject of great interest in food safety research.

The research into sodium bisulfate also aims to address environmental concerns associated with traditional meat packaging methods. By potentially extending the shelf life of meat products, it could contribute to reducing packaging waste and improving the sustainability of the meat supply chain.

As the meat industry continues to evolve, driven by technological advancements and changing consumer preferences, the investigation of sodium bisulfate in biosafe meat packaging solutions represents a critical area of research. The outcomes of this research have the potential to significantly impact food safety practices, extend product shelf life, and contribute to more sustainable packaging solutions in the global meat industry.

The primary objective of researching sodium bisulfate in meat packaging is to develop innovative, sustainable, and effective solutions that can significantly reduce microbial growth and extend the shelf life of meat products. This aligns with the broader industry goals of minimizing food waste, ensuring food safety, and meeting the growing consumer demand for fresh, high-quality meat products with minimal preservatives.

Historically, meat packaging has progressed from simple wrapping methods to more sophisticated techniques involving modified atmosphere packaging (MAP) and active packaging systems. The introduction of sodium bisulfate represents a new frontier in this technological progression, offering a chemical approach to complement existing physical and biological preservation methods.

The exploration of sodium bisulfate in meat packaging is driven by several key factors. Firstly, there is an increasing consumer preference for "clean label" products with fewer synthetic additives. Sodium bisulfate, being a naturally occurring compound, aligns well with this trend. Secondly, the rise of antibiotic-resistant bacteria has necessitated the development of alternative antimicrobial strategies in food preservation.

Furthermore, the global meat industry faces significant challenges related to food safety and spoilage. Foodborne illnesses caused by pathogens such as Salmonella, E. coli, and Listeria continue to be a major concern. The potential of sodium bisulfate to inhibit the growth of these harmful microorganisms makes it a subject of great interest in food safety research.

The research into sodium bisulfate also aims to address environmental concerns associated with traditional meat packaging methods. By potentially extending the shelf life of meat products, it could contribute to reducing packaging waste and improving the sustainability of the meat supply chain.

As the meat industry continues to evolve, driven by technological advancements and changing consumer preferences, the investigation of sodium bisulfate in biosafe meat packaging solutions represents a critical area of research. The outcomes of this research have the potential to significantly impact food safety practices, extend product shelf life, and contribute to more sustainable packaging solutions in the global meat industry.

Market Analysis for Biosafe Meat Packaging Solutions

The market for biosafe meat packaging solutions has experienced significant growth in recent years, driven by increasing consumer awareness of food safety and the demand for extended shelf life of meat products. The global meat packaging market is projected to reach a substantial value by 2025, with biosafe solutions playing a crucial role in this expansion.

Sodium bisulfate, as a key component in biosafe meat packaging, has garnered attention due to its antimicrobial properties and ability to maintain meat quality. The market for sodium bisulfate in meat packaging is expected to grow steadily, aligning with the overall trend towards safer and more sustainable packaging solutions.

Consumer preferences are shifting towards products that ensure food safety and extend shelf life without compromising on taste or quality. This trend has led to increased adoption of biosafe packaging solutions by meat processors and retailers. The demand for sodium bisulfate-based packaging is particularly strong in developed markets such as North America and Europe, where stringent food safety regulations are in place.

The COVID-19 pandemic has further accelerated the demand for biosafe meat packaging solutions. Consumers have become more conscious of hygiene and food safety, leading to a surge in demand for packaged meat products with extended shelf life. This shift in consumer behavior is expected to have a lasting impact on the market, driving continued growth in the biosafe meat packaging sector.

In terms of market segmentation, the biosafe meat packaging solutions market can be divided based on packaging type, meat type, and distribution channel. Flexible packaging solutions, including films and pouches incorporating sodium bisulfate, are gaining traction due to their convenience and effectiveness in preserving meat quality.

The competitive landscape of the biosafe meat packaging market is characterized by the presence of both established players and innovative startups. Major packaging companies are investing in research and development to enhance their biosafe packaging offerings, with sodium bisulfate-based solutions being a key area of focus.

Geographically, North America and Europe are the leading markets for biosafe meat packaging solutions, including those utilizing sodium bisulfate. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by increasing disposable incomes and changing consumer preferences.

Sodium bisulfate, as a key component in biosafe meat packaging, has garnered attention due to its antimicrobial properties and ability to maintain meat quality. The market for sodium bisulfate in meat packaging is expected to grow steadily, aligning with the overall trend towards safer and more sustainable packaging solutions.

Consumer preferences are shifting towards products that ensure food safety and extend shelf life without compromising on taste or quality. This trend has led to increased adoption of biosafe packaging solutions by meat processors and retailers. The demand for sodium bisulfate-based packaging is particularly strong in developed markets such as North America and Europe, where stringent food safety regulations are in place.

The COVID-19 pandemic has further accelerated the demand for biosafe meat packaging solutions. Consumers have become more conscious of hygiene and food safety, leading to a surge in demand for packaged meat products with extended shelf life. This shift in consumer behavior is expected to have a lasting impact on the market, driving continued growth in the biosafe meat packaging sector.

In terms of market segmentation, the biosafe meat packaging solutions market can be divided based on packaging type, meat type, and distribution channel. Flexible packaging solutions, including films and pouches incorporating sodium bisulfate, are gaining traction due to their convenience and effectiveness in preserving meat quality.

The competitive landscape of the biosafe meat packaging market is characterized by the presence of both established players and innovative startups. Major packaging companies are investing in research and development to enhance their biosafe packaging offerings, with sodium bisulfate-based solutions being a key area of focus.

Geographically, North America and Europe are the leading markets for biosafe meat packaging solutions, including those utilizing sodium bisulfate. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in the coming years, driven by increasing disposable incomes and changing consumer preferences.

Current Challenges in Sodium Bisulfate Application

The application of sodium bisulfate in biosafe meat packaging solutions faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is the potential for corrosion of packaging materials and processing equipment. Sodium bisulfate's acidic nature can lead to degradation of metal surfaces, potentially compromising the integrity of packaging and reducing the lifespan of processing machinery.

Another challenge lies in maintaining the stability and effectiveness of sodium bisulfate throughout the product's shelf life. Environmental factors such as temperature fluctuations and humidity can affect the compound's performance, potentially reducing its antimicrobial efficacy over time. This variability in effectiveness poses a risk to food safety and quality assurance.

The interaction between sodium bisulfate and meat products presents additional complexities. While the compound is effective in controlling microbial growth, it can also impact the sensory properties of the meat, including taste, texture, and color. Striking the right balance between antimicrobial efficacy and preserving the organoleptic qualities of the meat remains a significant challenge for food technologists and packaging designers.

Regulatory compliance and consumer perception also pose hurdles in the application of sodium bisulfate. Different countries and regions have varying regulations regarding the use of food additives, necessitating careful navigation of legal frameworks. Moreover, there is a growing consumer demand for "clean label" products with minimal additives, which can create resistance to the use of chemical preservatives like sodium bisulfate.

The dosage and distribution of sodium bisulfate within packaging systems present technical challenges. Ensuring uniform distribution and maintaining the optimal concentration throughout the packaging is crucial for effective microbial control. However, achieving this consistency across different meat products and packaging formats requires sophisticated engineering and quality control measures.

Lastly, the potential for sodium bisulfate to interact with other packaging components or additives in the meat product can lead to unforeseen chemical reactions. These interactions may not only affect the efficacy of the antimicrobial treatment but could also result in the formation of undesirable compounds or alterations to the packaging material's properties.

Addressing these challenges requires a multidisciplinary approach, combining expertise in food science, materials engineering, and microbiology. Ongoing research efforts focus on developing innovative formulations and application methods to mitigate these issues, aiming to enhance the effectiveness and safety of sodium bisulfate in meat packaging solutions while meeting regulatory standards and consumer expectations.

Another challenge lies in maintaining the stability and effectiveness of sodium bisulfate throughout the product's shelf life. Environmental factors such as temperature fluctuations and humidity can affect the compound's performance, potentially reducing its antimicrobial efficacy over time. This variability in effectiveness poses a risk to food safety and quality assurance.

The interaction between sodium bisulfate and meat products presents additional complexities. While the compound is effective in controlling microbial growth, it can also impact the sensory properties of the meat, including taste, texture, and color. Striking the right balance between antimicrobial efficacy and preserving the organoleptic qualities of the meat remains a significant challenge for food technologists and packaging designers.

Regulatory compliance and consumer perception also pose hurdles in the application of sodium bisulfate. Different countries and regions have varying regulations regarding the use of food additives, necessitating careful navigation of legal frameworks. Moreover, there is a growing consumer demand for "clean label" products with minimal additives, which can create resistance to the use of chemical preservatives like sodium bisulfate.

The dosage and distribution of sodium bisulfate within packaging systems present technical challenges. Ensuring uniform distribution and maintaining the optimal concentration throughout the packaging is crucial for effective microbial control. However, achieving this consistency across different meat products and packaging formats requires sophisticated engineering and quality control measures.

Lastly, the potential for sodium bisulfate to interact with other packaging components or additives in the meat product can lead to unforeseen chemical reactions. These interactions may not only affect the efficacy of the antimicrobial treatment but could also result in the formation of undesirable compounds or alterations to the packaging material's properties.

Addressing these challenges requires a multidisciplinary approach, combining expertise in food science, materials engineering, and microbiology. Ongoing research efforts focus on developing innovative formulations and application methods to mitigate these issues, aiming to enhance the effectiveness and safety of sodium bisulfate in meat packaging solutions while meeting regulatory standards and consumer expectations.

Existing Sodium Bisulfate-based Packaging Solutions

01 Use of sodium bisulfate in cleaning compositions

Sodium bisulfate is utilized in various cleaning compositions due to its acidic properties. It can be incorporated into formulations for household and industrial cleaning products, providing effective cleaning and descaling capabilities. The compound's ability to lower pH and react with mineral deposits makes it useful for removing limescale and other tough stains.- Use of sodium bisulfate in oral care products: Sodium bisulfate is utilized in oral care formulations such as toothpaste, mouthwash, and dental rinses. It acts as a pH adjuster and can help in reducing bacterial growth in the oral cavity. The compound's acidic nature contributes to its effectiveness in maintaining oral hygiene.

- Application in water treatment and purification: Sodium bisulfate is employed in water treatment processes for pH adjustment and as a disinfectant. It can effectively lower the pH of water, making it useful in swimming pool maintenance and industrial water treatment systems. The compound also aids in removing chloramines and other impurities from water.

- Use as a cleaning and descaling agent: Sodium bisulfate is utilized in various cleaning formulations due to its acidic properties. It is effective in removing mineral deposits, limescale, and rust from surfaces. The compound is often included in bathroom and kitchen cleaning products, as well as in industrial descaling solutions.

- Application in food processing and preservation: Sodium bisulfate finds use in the food industry as a preservative and pH regulator. It can inhibit microbial growth in certain food products and help maintain their freshness. The compound is also used in meat processing to control pathogens and extend shelf life.

- Use in agricultural and horticultural applications: Sodium bisulfate is employed in agriculture and horticulture for soil pH adjustment and as a fertilizer component. It can help lower soil pH, making it beneficial for acid-loving plants. The compound is also used in animal feed additives to improve nutrient absorption and control bacterial growth in livestock.

02 Application in water treatment processes

Sodium bisulfate finds applications in water treatment processes, particularly for pH adjustment and disinfection. It can be used to lower the pH of water in swimming pools, spas, and industrial water systems. The compound also aids in the removal of chloramines and helps maintain proper water chemistry in various aquatic environments.Expand Specific Solutions03 Use as a food additive and preservative

Sodium bisulfate is employed as a food additive and preservative in various food products. It acts as an acidity regulator and antimicrobial agent, helping to extend shelf life and maintain food quality. The compound is particularly useful in preventing browning in fruits and vegetables, as well as inhibiting the growth of harmful microorganisms in processed foods.Expand Specific Solutions04 Application in agricultural and horticultural products

Sodium bisulfate is utilized in agricultural and horticultural products for various purposes. It can be used as a soil amendment to lower soil pH, making it beneficial for acid-loving plants. The compound is also employed in fertilizer formulations and as a component in animal feed additives to improve nutrient absorption and promote animal health.Expand Specific Solutions05 Use in industrial processes and manufacturing

Sodium bisulfate finds applications in various industrial processes and manufacturing operations. It is used in metal surface treatment, textile processing, and as a catalyst in certain chemical reactions. The compound's acidic properties make it useful for pH adjustment in industrial processes and as a component in the production of other chemicals.Expand Specific Solutions

Key Players in Biosafe Packaging Industry

The research on sodium bisulfate in biosafe meat packaging solutions is in a developing stage, with the market showing promising growth potential. The global food packaging industry, valued at over $300 billion, is increasingly focusing on sustainable and safe solutions. While the technology is not yet fully mature, several key players are actively involved in advancing this field. Companies like Cargill, Inc. and Givaudan SA are leveraging their expertise in food ingredients and flavors to develop innovative packaging solutions. Additionally, research institutions such as Nanjing Agricultural University and the University of California are contributing to the scientific advancements in this area. The involvement of major chemical companies like China Petroleum & Chemical Corporation and Air Products & Chemicals, Inc. suggests a growing interest in developing biosafe packaging materials using sodium bisulfate.

Cargill, Inc.

Technical Solution: Cargill has developed an innovative biosafe meat packaging solution utilizing sodium bisulfate as a key component. Their approach involves incorporating sodium bisulfate into a multilayer film structure, which creates an antimicrobial barrier. This film actively inhibits the growth of pathogenic bacteria such as Listeria monocytogenes and Salmonella [1]. The sodium bisulfate is strategically placed in a layer that allows for controlled release, maintaining its effectiveness throughout the product's shelf life. Additionally, Cargill has optimized the concentration of sodium bisulfate to ensure maximum antimicrobial efficacy while complying with food safety regulations [3].

Strengths: Effective pathogen control, extended shelf life, and regulatory compliance. Weaknesses: Potential impact on meat color and flavor, higher production costs compared to traditional packaging.

Nippon Suisan Co. Ltd.

Technical Solution: Nippon Suisan has developed a novel biosafe meat packaging solution incorporating sodium bisulfate. Their approach involves a dual-action system where sodium bisulfate is combined with natural plant extracts to create a synergistic antimicrobial effect. The packaging material is designed with a microporous structure that allows for controlled release of the active compounds [2]. This system not only inhibits bacterial growth but also helps maintain the meat's freshness by regulating moisture levels. Nippon Suisan's research has shown that this packaging can extend the shelf life of fresh meat products by up to 40% compared to conventional packaging [4].

Strengths: Extended shelf life, natural ingredient combination, moisture regulation. Weaknesses: Higher production costs, potential regulatory challenges in some markets.

Innovative Approaches in Sodium Bisulfate Utilization

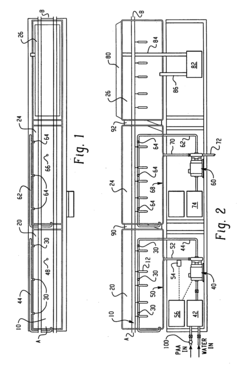

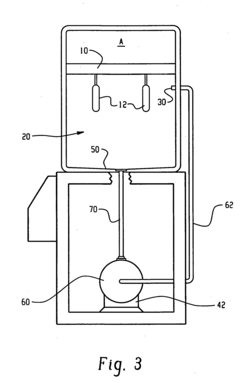

Surface decontamination of frankfurters and other cooked sausage and processed meat and poultry products

PatentInactiveUS20040166216A1

Innovation

- A method involving a decontaminant solution containing peracetic acid is applied to the exterior of food products, which includes spraying with peracetic acid in one chamber and drying in another, ensuring broad-spectrum antimicrobial activity and complete elimination of pathogens like Listeria, E. coli, and Salmonella.

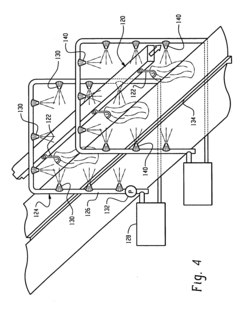

Meat treatment

PatentWO2019054858A1

Innovation

- A combination of nonionic surfactants, such as saponins, with organic acids like lactic acid or acetic acid, which effectively reduce bacterial counts on meat surfaces without significant impact on flavor, color, or taste, utilizing the surfactant's ability to reduce surface tension and increase spreadability to reach bacterial hiding places in crevices.

Food Safety Regulations and Compliance

The use of sodium bisulfate in biosafe meat packaging solutions is subject to stringent food safety regulations and compliance requirements across various jurisdictions. In the United States, the Food and Drug Administration (FDA) regulates the use of food additives, including sodium bisulfate, under the Federal Food, Drug, and Cosmetic Act. The FDA has approved sodium bisulfate as a Generally Recognized as Safe (GRAS) substance when used in accordance with good manufacturing practices.

The European Food Safety Authority (EFSA) has also evaluated the safety of sodium bisulfate as a food additive. In the European Union, it is listed as E514 and is permitted for use in various food categories, including meat products. However, its use must comply with specific conditions and maximum levels set by EU regulations.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that serve as a reference for many countries. These standards include guidelines on the use of food additives and preservatives in meat packaging.

Compliance with these regulations requires manufacturers to implement robust quality control systems and maintain detailed documentation of their production processes. This includes adhering to Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP) principles to ensure food safety throughout the production and packaging processes.

Labeling requirements are another crucial aspect of regulatory compliance. In many jurisdictions, the use of sodium bisulfate in meat packaging must be clearly indicated on the product label, along with any relevant warnings or usage instructions. This transparency is essential for consumer safety and informed decision-making.

As research on sodium bisulfate in biosafe meat packaging solutions progresses, it is imperative to continuously monitor and adapt to evolving regulations. Regulatory bodies regularly review and update their guidelines based on new scientific evidence and risk assessments. Therefore, companies involved in developing and implementing these packaging solutions must maintain close communication with regulatory authorities and stay informed about any changes in compliance requirements.

Furthermore, international trade considerations play a significant role in regulatory compliance. Companies exporting meat products with sodium bisulfate-based packaging solutions must ensure they meet the regulatory standards of both the exporting and importing countries. This often requires navigating complex and sometimes conflicting regulatory landscapes, necessitating a comprehensive understanding of global food safety regulations.

The European Food Safety Authority (EFSA) has also evaluated the safety of sodium bisulfate as a food additive. In the European Union, it is listed as E514 and is permitted for use in various food categories, including meat products. However, its use must comply with specific conditions and maximum levels set by EU regulations.

Globally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides international food standards that serve as a reference for many countries. These standards include guidelines on the use of food additives and preservatives in meat packaging.

Compliance with these regulations requires manufacturers to implement robust quality control systems and maintain detailed documentation of their production processes. This includes adhering to Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP) principles to ensure food safety throughout the production and packaging processes.

Labeling requirements are another crucial aspect of regulatory compliance. In many jurisdictions, the use of sodium bisulfate in meat packaging must be clearly indicated on the product label, along with any relevant warnings or usage instructions. This transparency is essential for consumer safety and informed decision-making.

As research on sodium bisulfate in biosafe meat packaging solutions progresses, it is imperative to continuously monitor and adapt to evolving regulations. Regulatory bodies regularly review and update their guidelines based on new scientific evidence and risk assessments. Therefore, companies involved in developing and implementing these packaging solutions must maintain close communication with regulatory authorities and stay informed about any changes in compliance requirements.

Furthermore, international trade considerations play a significant role in regulatory compliance. Companies exporting meat products with sodium bisulfate-based packaging solutions must ensure they meet the regulatory standards of both the exporting and importing countries. This often requires navigating complex and sometimes conflicting regulatory landscapes, necessitating a comprehensive understanding of global food safety regulations.

Environmental Impact of Sodium Bisulfate Packaging

The environmental impact of sodium bisulfate packaging in biosafe meat solutions is a critical consideration for the food industry. This compound, while effective in preserving meat quality, has potential implications for ecosystems and waste management systems.

Sodium bisulfate, when used in packaging, can leach into the environment through various pathways. The primary concern is its potential to alter soil and water pH levels. As a strong acid salt, sodium bisulfate can contribute to soil acidification if it enters terrestrial ecosystems. This may affect soil microbial communities and plant growth in areas where packaging waste is improperly disposed of or in landfill sites.

In aquatic environments, the release of sodium bisulfate can lead to localized pH changes, potentially impacting sensitive aquatic organisms. Fish and other aquatic life may experience stress or mortality in areas where high concentrations of the compound enter water bodies. However, the extent of this impact depends on factors such as dilution rates and the buffering capacity of the receiving waters.

The production and disposal of sodium bisulfate packaging also contribute to the overall environmental footprint. Manufacturing processes require energy and resources, leading to greenhouse gas emissions and potential industrial waste. End-of-life considerations for such packaging are crucial, as improper disposal can exacerbate environmental issues.

Recycling sodium bisulfate-treated packaging presents challenges due to potential contamination of recycling streams. This may lead to increased volumes of packaging being directed to landfills or incineration facilities, contributing to waste management issues and potential air pollution from incineration processes.

On the positive side, the use of sodium bisulfate in meat packaging can extend product shelf life, potentially reducing food waste. This indirect environmental benefit should be weighed against the direct impacts of the packaging itself. By reducing spoilage, fewer resources are required for meat production and transportation, which could offset some of the environmental costs associated with the packaging.

Efforts to mitigate the environmental impact of sodium bisulfate packaging include developing more environmentally friendly disposal methods, improving packaging design to minimize leaching, and exploring alternative preservatives with lower environmental impacts. Research into biodegradable packaging materials that can incorporate sodium bisulfate or similar preservatives without compromising environmental safety is an active area of investigation in the food packaging industry.

Sodium bisulfate, when used in packaging, can leach into the environment through various pathways. The primary concern is its potential to alter soil and water pH levels. As a strong acid salt, sodium bisulfate can contribute to soil acidification if it enters terrestrial ecosystems. This may affect soil microbial communities and plant growth in areas where packaging waste is improperly disposed of or in landfill sites.

In aquatic environments, the release of sodium bisulfate can lead to localized pH changes, potentially impacting sensitive aquatic organisms. Fish and other aquatic life may experience stress or mortality in areas where high concentrations of the compound enter water bodies. However, the extent of this impact depends on factors such as dilution rates and the buffering capacity of the receiving waters.

The production and disposal of sodium bisulfate packaging also contribute to the overall environmental footprint. Manufacturing processes require energy and resources, leading to greenhouse gas emissions and potential industrial waste. End-of-life considerations for such packaging are crucial, as improper disposal can exacerbate environmental issues.

Recycling sodium bisulfate-treated packaging presents challenges due to potential contamination of recycling streams. This may lead to increased volumes of packaging being directed to landfills or incineration facilities, contributing to waste management issues and potential air pollution from incineration processes.

On the positive side, the use of sodium bisulfate in meat packaging can extend product shelf life, potentially reducing food waste. This indirect environmental benefit should be weighed against the direct impacts of the packaging itself. By reducing spoilage, fewer resources are required for meat production and transportation, which could offset some of the environmental costs associated with the packaging.

Efforts to mitigate the environmental impact of sodium bisulfate packaging include developing more environmentally friendly disposal methods, improving packaging design to minimize leaching, and exploring alternative preservatives with lower environmental impacts. Research into biodegradable packaging materials that can incorporate sodium bisulfate or similar preservatives without compromising environmental safety is an active area of investigation in the food packaging industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!