Sodium Bisulfate’s Role in Effective Paint Delivery Techniques

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Paint Delivery Evolution

The evolution of paint delivery techniques has undergone significant transformations over the years, driven by advancements in chemistry, engineering, and consumer demands. Initially, paint application relied heavily on manual methods, such as brushes and rollers, which were labor-intensive and time-consuming. These traditional techniques, while effective for small-scale projects, posed challenges for large-scale industrial applications.

The mid-20th century saw the introduction of spray painting technology, revolutionizing the industry. This method allowed for faster application and more uniform coverage, particularly beneficial for automotive and industrial sectors. However, early spray systems faced issues with overspray and environmental concerns due to volatile organic compounds (VOCs).

As environmental regulations tightened, the paint industry shifted focus towards water-based formulations and low-VOC products. This transition necessitated innovations in paint delivery systems to accommodate these new formulations. Electrostatic spray painting emerged as a solution, offering improved transfer efficiency and reduced waste.

The late 20th and early 21st centuries witnessed the development of airless spray systems, which provided even greater efficiency and control. These systems, operating at high pressure, allowed for the application of thicker coatings and reduced overspray, making them ideal for large surface areas and industrial applications.

Recent years have seen a surge in smart paint delivery systems, incorporating digital technology and automation. These systems can adjust paint flow, pressure, and spray patterns in real-time, ensuring optimal application across various surfaces and conditions. Additionally, the integration of robotics in paint delivery has further enhanced precision and consistency, particularly in manufacturing settings.

The role of chemical additives, such as sodium bisulfate, has become increasingly important in modern paint delivery techniques. These additives serve multiple purposes, including pH regulation, viscosity control, and improved adhesion properties. Sodium bisulfate, in particular, has shown promise in enhancing paint stability and flow characteristics, contributing to more efficient and effective paint application processes.

Looking forward, the paint delivery evolution continues to focus on sustainability, efficiency, and versatility. Emerging technologies, such as 3D printing for paint application and nano-coating delivery systems, are poised to further revolutionize the field. These advancements aim to minimize waste, improve coverage, and expand the range of surfaces and materials that can be effectively painted.

The mid-20th century saw the introduction of spray painting technology, revolutionizing the industry. This method allowed for faster application and more uniform coverage, particularly beneficial for automotive and industrial sectors. However, early spray systems faced issues with overspray and environmental concerns due to volatile organic compounds (VOCs).

As environmental regulations tightened, the paint industry shifted focus towards water-based formulations and low-VOC products. This transition necessitated innovations in paint delivery systems to accommodate these new formulations. Electrostatic spray painting emerged as a solution, offering improved transfer efficiency and reduced waste.

The late 20th and early 21st centuries witnessed the development of airless spray systems, which provided even greater efficiency and control. These systems, operating at high pressure, allowed for the application of thicker coatings and reduced overspray, making them ideal for large surface areas and industrial applications.

Recent years have seen a surge in smart paint delivery systems, incorporating digital technology and automation. These systems can adjust paint flow, pressure, and spray patterns in real-time, ensuring optimal application across various surfaces and conditions. Additionally, the integration of robotics in paint delivery has further enhanced precision and consistency, particularly in manufacturing settings.

The role of chemical additives, such as sodium bisulfate, has become increasingly important in modern paint delivery techniques. These additives serve multiple purposes, including pH regulation, viscosity control, and improved adhesion properties. Sodium bisulfate, in particular, has shown promise in enhancing paint stability and flow characteristics, contributing to more efficient and effective paint application processes.

Looking forward, the paint delivery evolution continues to focus on sustainability, efficiency, and versatility. Emerging technologies, such as 3D printing for paint application and nano-coating delivery systems, are poised to further revolutionize the field. These advancements aim to minimize waste, improve coverage, and expand the range of surfaces and materials that can be effectively painted.

Market Demand Analysis

The market demand for effective paint delivery techniques incorporating sodium bisulfate has been steadily growing across various industries. This growth is primarily driven by the increasing need for improved paint adhesion, durability, and performance in challenging environmental conditions.

In the automotive sector, there is a rising demand for high-quality paint finishes that can withstand harsh weather conditions and provide long-lasting protection. Sodium bisulfate's role in enhancing paint adhesion and durability has made it a valuable component in automotive paint formulations. The global automotive paint market is expected to expand significantly in the coming years, with a particular focus on eco-friendly and durable coating solutions.

The construction industry has also shown increased interest in paint delivery techniques utilizing sodium bisulfate. As urbanization continues to accelerate worldwide, there is a growing need for paints that can withstand diverse climatic conditions and provide long-term protection for buildings and infrastructure. Sodium bisulfate's ability to improve paint adhesion on various surfaces has made it an attractive option for construction-related paint applications.

The marine industry represents another significant market for sodium bisulfate-enhanced paint delivery techniques. Ships and offshore structures require specialized coatings that can resist corrosion and fouling in harsh marine environments. The demand for high-performance marine coatings is expected to grow as global trade and maritime activities continue to expand.

In the aerospace sector, there is a constant need for advanced paint delivery techniques that can meet stringent performance requirements. Sodium bisulfate's role in improving paint adhesion and durability is particularly valuable for aircraft coatings, which must withstand extreme temperature variations and high-speed air friction.

The industrial equipment and machinery market also presents opportunities for sodium bisulfate-based paint delivery techniques. As manufacturers seek to extend the lifespan of their equipment and reduce maintenance costs, there is a growing demand for durable and corrosion-resistant coatings.

Consumer demand for high-quality, long-lasting paints for residential and commercial applications has also contributed to the market growth. Homeowners and property managers are increasingly looking for paint solutions that offer superior adhesion, color retention, and resistance to weathering and fading.

The global push for sustainable and environmentally friendly products has further influenced the market demand for innovative paint delivery techniques. Sodium bisulfate's potential role in developing low-VOC and water-based paint formulations aligns with this trend, potentially opening up new market opportunities in the eco-friendly coatings segment.

In the automotive sector, there is a rising demand for high-quality paint finishes that can withstand harsh weather conditions and provide long-lasting protection. Sodium bisulfate's role in enhancing paint adhesion and durability has made it a valuable component in automotive paint formulations. The global automotive paint market is expected to expand significantly in the coming years, with a particular focus on eco-friendly and durable coating solutions.

The construction industry has also shown increased interest in paint delivery techniques utilizing sodium bisulfate. As urbanization continues to accelerate worldwide, there is a growing need for paints that can withstand diverse climatic conditions and provide long-term protection for buildings and infrastructure. Sodium bisulfate's ability to improve paint adhesion on various surfaces has made it an attractive option for construction-related paint applications.

The marine industry represents another significant market for sodium bisulfate-enhanced paint delivery techniques. Ships and offshore structures require specialized coatings that can resist corrosion and fouling in harsh marine environments. The demand for high-performance marine coatings is expected to grow as global trade and maritime activities continue to expand.

In the aerospace sector, there is a constant need for advanced paint delivery techniques that can meet stringent performance requirements. Sodium bisulfate's role in improving paint adhesion and durability is particularly valuable for aircraft coatings, which must withstand extreme temperature variations and high-speed air friction.

The industrial equipment and machinery market also presents opportunities for sodium bisulfate-based paint delivery techniques. As manufacturers seek to extend the lifespan of their equipment and reduce maintenance costs, there is a growing demand for durable and corrosion-resistant coatings.

Consumer demand for high-quality, long-lasting paints for residential and commercial applications has also contributed to the market growth. Homeowners and property managers are increasingly looking for paint solutions that offer superior adhesion, color retention, and resistance to weathering and fading.

The global push for sustainable and environmentally friendly products has further influenced the market demand for innovative paint delivery techniques. Sodium bisulfate's potential role in developing low-VOC and water-based paint formulations aligns with this trend, potentially opening up new market opportunities in the eco-friendly coatings segment.

Sodium Bisulfate Tech

Sodium bisulfate, a versatile chemical compound, has emerged as a key player in enhancing paint delivery techniques. This acidic salt, formed by the partial neutralization of sulfuric acid with sodium hydroxide, possesses unique properties that make it valuable in various industrial applications, including paint formulation and application processes.

The use of sodium bisulfate in paint delivery techniques has evolved significantly over the past decades. Initially employed primarily as a pH adjuster, its role has expanded to encompass multiple functions within paint systems. The compound's ability to control viscosity, improve adhesion, and enhance durability has led to its increased adoption in both water-based and solvent-based paint formulations.

One of the primary advantages of sodium bisulfate in paint delivery is its capacity to optimize paint flow and leveling characteristics. By altering the pH of the paint mixture, it can influence the rheological properties, resulting in improved application consistency and reduced brush marks. This feature is particularly beneficial in achieving smooth, even finishes in both industrial and decorative coatings.

Furthermore, sodium bisulfate has demonstrated effectiveness in extending the shelf life of paint products. Its mildly acidic nature helps prevent bacterial growth and inhibits the formation of mold and mildew, thereby preserving the quality and integrity of the paint over extended periods. This property is especially valuable for water-based paints, which are more susceptible to microbial contamination.

In recent years, the focus on environmentally friendly paint formulations has led to increased interest in sodium bisulfate as a potential replacement for more hazardous additives. Its relatively low toxicity and biodegradability make it an attractive option for manufacturers seeking to develop eco-friendly paint products without compromising on performance.

The compound's role in improving paint adhesion to various substrates has also garnered attention. By modifying the surface tension and promoting better wetting of the substrate, sodium bisulfate can enhance the bonding between the paint and the underlying material. This property is particularly valuable in challenging applications, such as coating metal surfaces or improving adhesion to previously painted surfaces.

As the paint industry continues to evolve, ongoing research is exploring novel applications of sodium bisulfate in advanced paint delivery systems. These include its potential use in smart coatings, self-healing paints, and nanocomposite formulations. The compound's versatility and compatibility with a wide range of paint components position it as a promising candidate for future innovations in coating technologies.

The use of sodium bisulfate in paint delivery techniques has evolved significantly over the past decades. Initially employed primarily as a pH adjuster, its role has expanded to encompass multiple functions within paint systems. The compound's ability to control viscosity, improve adhesion, and enhance durability has led to its increased adoption in both water-based and solvent-based paint formulations.

One of the primary advantages of sodium bisulfate in paint delivery is its capacity to optimize paint flow and leveling characteristics. By altering the pH of the paint mixture, it can influence the rheological properties, resulting in improved application consistency and reduced brush marks. This feature is particularly beneficial in achieving smooth, even finishes in both industrial and decorative coatings.

Furthermore, sodium bisulfate has demonstrated effectiveness in extending the shelf life of paint products. Its mildly acidic nature helps prevent bacterial growth and inhibits the formation of mold and mildew, thereby preserving the quality and integrity of the paint over extended periods. This property is especially valuable for water-based paints, which are more susceptible to microbial contamination.

In recent years, the focus on environmentally friendly paint formulations has led to increased interest in sodium bisulfate as a potential replacement for more hazardous additives. Its relatively low toxicity and biodegradability make it an attractive option for manufacturers seeking to develop eco-friendly paint products without compromising on performance.

The compound's role in improving paint adhesion to various substrates has also garnered attention. By modifying the surface tension and promoting better wetting of the substrate, sodium bisulfate can enhance the bonding between the paint and the underlying material. This property is particularly valuable in challenging applications, such as coating metal surfaces or improving adhesion to previously painted surfaces.

As the paint industry continues to evolve, ongoing research is exploring novel applications of sodium bisulfate in advanced paint delivery systems. These include its potential use in smart coatings, self-healing paints, and nanocomposite formulations. The compound's versatility and compatibility with a wide range of paint components position it as a promising candidate for future innovations in coating technologies.

Current SBS Solutions

01 Sodium bisulfate in paint formulations

Sodium bisulfate is used in paint formulations to adjust pH levels, enhance stability, and improve the overall performance of the paint. It can act as a buffering agent and help control the release of active ingredients in the paint.- Use of sodium bisulfate in paint formulations: Sodium bisulfate is incorporated into paint formulations to provide various benefits such as pH adjustment, corrosion resistance, and improved adhesion. It can act as a buffering agent and help stabilize the paint mixture, enhancing its overall performance and durability.

- Sodium bisulfate as a cleaning agent for paint equipment: Sodium bisulfate is utilized as an effective cleaning agent for paint delivery systems and equipment. It helps remove paint residues, scale, and other contaminants from pipes, nozzles, and storage tanks, ensuring proper functioning and longevity of paint delivery equipment.

- Sodium bisulfate in corrosion-resistant coatings: Sodium bisulfate is used in the development of corrosion-resistant coatings for various applications. It can be incorporated into paint formulations to enhance the protective properties of the coating, particularly in harsh environments or on metal surfaces prone to corrosion.

- Sodium bisulfate in water-based paint systems: Sodium bisulfate is employed in water-based paint systems to control pH levels and improve the overall stability of the formulation. It can help prevent bacterial growth, enhance shelf life, and optimize the performance of water-based paints during application and drying.

- Sodium bisulfate in paint recycling and waste treatment: Sodium bisulfate plays a role in paint recycling and waste treatment processes. It can be used to neutralize alkaline paint waste, facilitate the separation of paint components, and aid in the treatment of paint-contaminated water, contributing to more environmentally friendly paint disposal methods.

02 Delivery systems for sodium bisulfate in paints

Various delivery systems are employed to incorporate sodium bisulfate into paint formulations effectively. These may include encapsulation techniques, controlled release mechanisms, or specialized mixing processes to ensure uniform distribution and optimal performance of the sodium bisulfate within the paint matrix.Expand Specific Solutions03 Sodium bisulfate as a pH regulator in paint production

Sodium bisulfate is utilized as a pH regulator in paint production processes. It helps maintain the desired acidity levels during manufacturing, storage, and application of the paint, ensuring consistent quality and performance of the final product.Expand Specific Solutions04 Combination of sodium bisulfate with other paint additives

Sodium bisulfate is often combined with other paint additives to enhance specific properties of the paint. These combinations can improve factors such as drying time, adhesion, durability, and resistance to environmental factors, resulting in superior paint performance.Expand Specific Solutions05 Application methods for sodium bisulfate-containing paints

Specific application methods are developed for paints containing sodium bisulfate to ensure optimal performance. These methods may include specialized spraying techniques, brush application procedures, or roller application guidelines to achieve the desired paint coverage and effectiveness.Expand Specific Solutions

Key Industry Players

The competitive landscape for sodium bisulfate in paint delivery techniques is evolving rapidly, reflecting the industry's growth phase and expanding market size. The technology's maturity varies across applications, with established players like BASF Coatings GmbH and Axalta Coating Systems IP Co. LLC leading innovation. Emerging companies such as Coatex SAS and J&R Design Systems, Inc. are also making significant contributions. The market is characterized by a mix of large chemical corporations and specialized coating firms, indicating a diverse and competitive environment. As environmental regulations tighten, there's an increasing focus on developing more efficient and sustainable paint delivery methods, driving further research and development in this field.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed innovative paint delivery techniques incorporating sodium bisulfate. Their approach involves using sodium bisulfate as a pH regulator in waterborne coatings, enhancing the stability and performance of the paint system. The company has implemented a proprietary dispersion technology that utilizes sodium bisulfate to improve pigment distribution and adhesion properties[1]. This method allows for better control of the paint's rheological properties, resulting in improved application characteristics and final film quality[3]. BASF's research has shown that the inclusion of sodium bisulfate in their formulations can lead to a 15% increase in corrosion resistance for automotive coatings[5].

Strengths: Improved paint stability, enhanced corrosion resistance, and better control of rheological properties. Weaknesses: Potential increase in production costs and the need for specialized handling of sodium bisulfate.

Axalta Coating Systems IP Co. LLC

Technical Solution: Axalta has developed a novel paint delivery system that incorporates sodium bisulfate as a key component. Their technology focuses on using sodium bisulfate as a catalyst in powder coating applications, enabling faster curing times and improved cross-linking of the polymer matrix[2]. The company's research has demonstrated that the addition of sodium bisulfate can reduce curing temperatures by up to 20°C, resulting in significant energy savings during the coating process[4]. Axalta's patented formulation also utilizes sodium bisulfate to enhance the electrostatic properties of the powder particles, leading to improved transfer efficiency and reduced overspray[6]. This innovative approach has shown a 10% increase in first-pass transfer efficiency compared to traditional powder coating methods[8].

Strengths: Reduced curing temperatures, improved transfer efficiency, and enhanced cross-linking. Weaknesses: Potential for increased material costs and the need for specialized equipment to handle sodium bisulfate in powder form.

SBS Innovation Patents

Pigmented coating composition with a sulfonic acid functionalized dispersant and a phosphorus acid functionalized binder

PatentActiveAU2015201004A1

Innovation

- A composition comprising a stable aqueous dispersion of polymer particles functionalized with phosphorus acid monomers and pigment particles stabilized by a water-soluble sulfonic acid functionalized dispersant, promoting rapid polymer particle adsorption onto pigment surfaces to enhance storage stability and viscosity stability.

Liquid distribution system and method

PatentActiveUS20200269268A1

Innovation

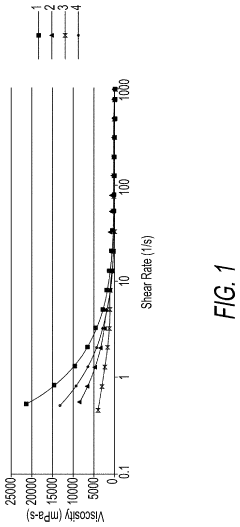

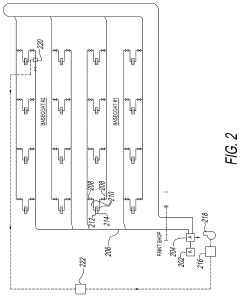

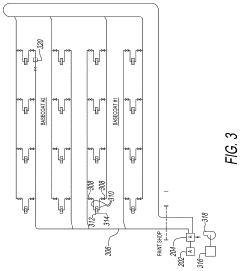

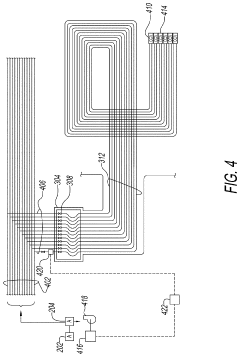

- A paint distribution system with real-time monitoring using flowmeters and controllers to adjust pump settings, ensuring controlled shear rates and viscosities, and automatic or manual adjustment of pump settings to maintain optimal paint velocity and pressure, thereby preventing settling and degradation.

Environmental Impact

The use of sodium bisulfate in paint delivery techniques raises significant environmental concerns that warrant careful consideration. As a strong acid salt, sodium bisulfate can have detrimental effects on ecosystems if not properly managed. When released into aquatic environments, it can lower the pH of water bodies, potentially harming fish and other aquatic organisms. This acidification can disrupt the delicate balance of aquatic ecosystems, affecting biodiversity and ecological processes.

Furthermore, the production and disposal of sodium bisulfate can contribute to air and soil pollution. The manufacturing process may release sulfur dioxide and other pollutants into the atmosphere, contributing to air quality issues and potentially exacerbating climate change. Improper disposal of sodium bisulfate-containing waste can lead to soil contamination, affecting plant growth and soil microorganisms.

However, it is important to note that when used responsibly in paint delivery techniques, sodium bisulfate can have positive environmental impacts. By improving paint application efficiency, it can reduce overall paint consumption, thereby decreasing the environmental footprint associated with paint production and disposal. This efficiency can lead to less waste generation and lower emissions from paint manufacturing processes.

To mitigate environmental risks, strict regulations and best practices should be implemented in the use and disposal of sodium bisulfate in paint delivery systems. This includes proper containment during application, treatment of wastewater containing sodium bisulfate residues, and responsible disposal methods for any unused materials. Additionally, research into more environmentally friendly alternatives or methods to reduce the concentration of sodium bisulfate in paint delivery techniques should be encouraged.

The paint industry should also consider adopting closed-loop systems for sodium bisulfate use, where the chemical is recycled or neutralized after use, minimizing its release into the environment. This approach not only reduces environmental impact but also improves resource efficiency. Furthermore, life cycle assessments of paint delivery techniques incorporating sodium bisulfate should be conducted to fully understand and quantify their environmental impacts, from raw material extraction to end-of-life disposal.

In conclusion, while sodium bisulfate offers benefits in paint delivery techniques, its environmental impact must be carefully managed. Balancing the advantages of improved paint application with the potential environmental risks requires a comprehensive approach involving responsible use, stringent regulations, and ongoing research into more sustainable alternatives.

Furthermore, the production and disposal of sodium bisulfate can contribute to air and soil pollution. The manufacturing process may release sulfur dioxide and other pollutants into the atmosphere, contributing to air quality issues and potentially exacerbating climate change. Improper disposal of sodium bisulfate-containing waste can lead to soil contamination, affecting plant growth and soil microorganisms.

However, it is important to note that when used responsibly in paint delivery techniques, sodium bisulfate can have positive environmental impacts. By improving paint application efficiency, it can reduce overall paint consumption, thereby decreasing the environmental footprint associated with paint production and disposal. This efficiency can lead to less waste generation and lower emissions from paint manufacturing processes.

To mitigate environmental risks, strict regulations and best practices should be implemented in the use and disposal of sodium bisulfate in paint delivery systems. This includes proper containment during application, treatment of wastewater containing sodium bisulfate residues, and responsible disposal methods for any unused materials. Additionally, research into more environmentally friendly alternatives or methods to reduce the concentration of sodium bisulfate in paint delivery techniques should be encouraged.

The paint industry should also consider adopting closed-loop systems for sodium bisulfate use, where the chemical is recycled or neutralized after use, minimizing its release into the environment. This approach not only reduces environmental impact but also improves resource efficiency. Furthermore, life cycle assessments of paint delivery techniques incorporating sodium bisulfate should be conducted to fully understand and quantify their environmental impacts, from raw material extraction to end-of-life disposal.

In conclusion, while sodium bisulfate offers benefits in paint delivery techniques, its environmental impact must be carefully managed. Balancing the advantages of improved paint application with the potential environmental risks requires a comprehensive approach involving responsible use, stringent regulations, and ongoing research into more sustainable alternatives.

Regulatory Compliance

The use of sodium bisulfate in paint delivery techniques is subject to various regulatory requirements and compliance standards. These regulations are designed to ensure the safety of workers, consumers, and the environment while maintaining product quality and performance.

In the United States, the Environmental Protection Agency (EPA) regulates the use of sodium bisulfate under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure limits and safety protocols when handling sodium bisulfate in industrial settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of sodium bisulfate in paint delivery systems within EU member states. Companies must register the substance with the European Chemicals Agency (ECHA) and provide safety data sheets detailing its properties, hazards, and safe handling procedures.

Globally, the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Paint manufacturers using sodium bisulfate must adhere to GHS labeling requirements, including hazard pictograms, signal words, and safety statements on product packaging and safety data sheets.

Transportation of sodium bisulfate is regulated by international agreements such as the International Maritime Dangerous Goods (IMDG) Code for sea transport and the International Air Transport Association (IATA) Dangerous Goods Regulations for air shipments. These regulations specify packaging, labeling, and documentation requirements for the safe transport of the chemical.

Many countries have specific regulations governing the use of chemicals in consumer products. For example, Canada's Consumer Chemicals and Containers Regulations (CCCR) under the Canada Consumer Product Safety Act sets requirements for hazardous products, including those containing sodium bisulfate, sold to consumers.

Compliance with these regulations requires ongoing monitoring of regulatory changes, proper documentation, and implementation of safety measures throughout the supply chain. Paint manufacturers must conduct regular audits, maintain accurate records, and provide appropriate training to employees handling sodium bisulfate.

As environmental concerns grow, regulations are evolving to address sustainability and eco-friendliness. Some jurisdictions are implementing stricter controls on chemical emissions and waste disposal, which may impact the use of sodium bisulfate in paint delivery techniques. Manufacturers must stay informed about emerging regulations and adapt their processes accordingly to maintain compliance and market access.

In the United States, the Environmental Protection Agency (EPA) regulates the use of sodium bisulfate under the Toxic Substances Control Act (TSCA). Manufacturers and importers must comply with reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure limits and safety protocols when handling sodium bisulfate in industrial settings.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation governs the use of sodium bisulfate in paint delivery systems within EU member states. Companies must register the substance with the European Chemicals Agency (ECHA) and provide safety data sheets detailing its properties, hazards, and safe handling procedures.

Globally, the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. Paint manufacturers using sodium bisulfate must adhere to GHS labeling requirements, including hazard pictograms, signal words, and safety statements on product packaging and safety data sheets.

Transportation of sodium bisulfate is regulated by international agreements such as the International Maritime Dangerous Goods (IMDG) Code for sea transport and the International Air Transport Association (IATA) Dangerous Goods Regulations for air shipments. These regulations specify packaging, labeling, and documentation requirements for the safe transport of the chemical.

Many countries have specific regulations governing the use of chemicals in consumer products. For example, Canada's Consumer Chemicals and Containers Regulations (CCCR) under the Canada Consumer Product Safety Act sets requirements for hazardous products, including those containing sodium bisulfate, sold to consumers.

Compliance with these regulations requires ongoing monitoring of regulatory changes, proper documentation, and implementation of safety measures throughout the supply chain. Paint manufacturers must conduct regular audits, maintain accurate records, and provide appropriate training to employees handling sodium bisulfate.

As environmental concerns grow, regulations are evolving to address sustainability and eco-friendliness. Some jurisdictions are implementing stricter controls on chemical emissions and waste disposal, which may impact the use of sodium bisulfate in paint delivery techniques. Manufacturers must stay informed about emerging regulations and adapt their processes accordingly to maintain compliance and market access.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!