Sodium Bisulfate’s Benefits in Advanced Poultry Treatments

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate in Poultry: Background and Objectives

Sodium bisulfate has emerged as a significant compound in the poultry industry, offering a range of benefits that address critical challenges in modern poultry production. This chemical, also known as sodium hydrogen sulfate, has a long history of use in various industrial applications, but its potential in poultry treatments has only recently gained substantial attention from researchers and industry professionals.

The evolution of sodium bisulfate's application in poultry science can be traced back to the late 20th century when concerns about food safety and animal welfare began to intensify. As the global demand for poultry products increased, so did the need for more effective and sustainable treatment methods to ensure the health of poultry and the safety of consumers. This led to a surge in research exploring alternative solutions to traditional antibiotics and growth promoters.

Sodium bisulfate's journey in poultry science began with its use as a litter amendment to control ammonia levels in poultry houses. The compound's ability to lower pH levels and create an inhospitable environment for harmful bacteria quickly caught the attention of researchers looking for multipurpose solutions in poultry management.

As research progressed, the potential applications of sodium bisulfate expanded beyond litter treatment. Scientists began investigating its efficacy in water treatment, feed preservation, and pathogen control. These studies revealed promising results, suggesting that sodium bisulfate could play a crucial role in addressing several challenges simultaneously, from improving bird health to enhancing food safety.

The primary objectives of current research on sodium bisulfate in poultry treatments are multifaceted. Firstly, there is a focus on optimizing its use as an antimicrobial agent, particularly in the context of reducing foodborne pathogens such as Salmonella and Campylobacter. Researchers aim to determine the most effective concentrations and application methods to maximize pathogen reduction without compromising bird health or productivity.

Secondly, studies are exploring the potential of sodium bisulfate as an alternative to antibiotic growth promoters. With increasing global concerns about antibiotic resistance, finding effective substitutes that can maintain or improve growth performance is a critical research goal. The acidifying properties of sodium bisulfate are being investigated for their potential to enhance nutrient absorption and promote beneficial gut microbiota.

Another key objective is to assess the long-term environmental impact of sodium bisulfate use in poultry production. As sustainability becomes increasingly important in agriculture, understanding how this compound affects soil and water quality when used in litter management is crucial for developing responsible application guidelines.

Furthermore, researchers are investigating the economic implications of incorporating sodium bisulfate into various aspects of poultry production. This includes analyzing cost-effectiveness, potential improvements in feed conversion ratios, and reductions in mortality rates. The goal is to provide comprehensive data that can guide industry decisions on adopting sodium bisulfate-based treatments.

The evolution of sodium bisulfate's application in poultry science can be traced back to the late 20th century when concerns about food safety and animal welfare began to intensify. As the global demand for poultry products increased, so did the need for more effective and sustainable treatment methods to ensure the health of poultry and the safety of consumers. This led to a surge in research exploring alternative solutions to traditional antibiotics and growth promoters.

Sodium bisulfate's journey in poultry science began with its use as a litter amendment to control ammonia levels in poultry houses. The compound's ability to lower pH levels and create an inhospitable environment for harmful bacteria quickly caught the attention of researchers looking for multipurpose solutions in poultry management.

As research progressed, the potential applications of sodium bisulfate expanded beyond litter treatment. Scientists began investigating its efficacy in water treatment, feed preservation, and pathogen control. These studies revealed promising results, suggesting that sodium bisulfate could play a crucial role in addressing several challenges simultaneously, from improving bird health to enhancing food safety.

The primary objectives of current research on sodium bisulfate in poultry treatments are multifaceted. Firstly, there is a focus on optimizing its use as an antimicrobial agent, particularly in the context of reducing foodborne pathogens such as Salmonella and Campylobacter. Researchers aim to determine the most effective concentrations and application methods to maximize pathogen reduction without compromising bird health or productivity.

Secondly, studies are exploring the potential of sodium bisulfate as an alternative to antibiotic growth promoters. With increasing global concerns about antibiotic resistance, finding effective substitutes that can maintain or improve growth performance is a critical research goal. The acidifying properties of sodium bisulfate are being investigated for their potential to enhance nutrient absorption and promote beneficial gut microbiota.

Another key objective is to assess the long-term environmental impact of sodium bisulfate use in poultry production. As sustainability becomes increasingly important in agriculture, understanding how this compound affects soil and water quality when used in litter management is crucial for developing responsible application guidelines.

Furthermore, researchers are investigating the economic implications of incorporating sodium bisulfate into various aspects of poultry production. This includes analyzing cost-effectiveness, potential improvements in feed conversion ratios, and reductions in mortality rates. The goal is to provide comprehensive data that can guide industry decisions on adopting sodium bisulfate-based treatments.

Market Analysis: Poultry Industry Demand

The poultry industry has experienced significant growth in recent years, driven by increasing global demand for protein-rich food sources. This trend has created a substantial market for advanced poultry treatments, including those utilizing sodium bisulfate. The global poultry market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to exceed 5% over the next five years.

Consumer preferences for healthier, safer, and more sustainable poultry products have become a key driver in market demand. This shift has led to increased interest in advanced treatments that can improve food safety, enhance meat quality, and promote animal welfare. Sodium bisulfate, with its potential benefits in these areas, is well-positioned to address these evolving consumer needs.

The demand for sodium bisulfate in poultry treatments is closely tied to the overall growth of the poultry industry. Major poultry-producing regions, including North America, Europe, and Asia-Pacific, are expected to be significant markets for advanced treatments. In particular, emerging economies with rapidly growing poultry sectors, such as China and India, present substantial opportunities for market expansion.

Food safety concerns have become paramount in the poultry industry, especially in light of recent outbreaks of foodborne illnesses. This has led to stricter regulations and increased adoption of antimicrobial treatments. Sodium bisulfate's potential as an effective antimicrobial agent aligns well with these industry trends, potentially driving its demand in the coming years.

The poultry industry's focus on improving feed efficiency and reducing environmental impact also contributes to the demand for advanced treatments. Sodium bisulfate's potential role in enhancing nutrient absorption and reducing ammonia emissions in poultry houses makes it an attractive option for producers looking to improve their operational efficiency and sustainability.

Market analysis indicates that large-scale commercial poultry operations are likely to be the primary adopters of advanced treatments like those involving sodium bisulfate. However, there is also growing interest from smaller, specialty producers catering to niche markets for premium poultry products.

The increasing prevalence of antibiotic-resistant bacteria and the subsequent push to reduce antibiotic use in livestock have created a need for alternative solutions in poultry health management. This trend presents an opportunity for sodium bisulfate-based treatments, which may offer antimicrobial benefits without contributing to antibiotic resistance.

In conclusion, the market demand for advanced poultry treatments, including those utilizing sodium bisulfate, is robust and multifaceted. Driven by factors such as food safety concerns, sustainability goals, and changing consumer preferences, the industry is likely to continue seeking innovative solutions to improve poultry production. As research progresses and the benefits of sodium bisulfate become more widely recognized, its adoption in poultry treatments is expected to grow, aligning with the overall expansion of the global poultry market.

Consumer preferences for healthier, safer, and more sustainable poultry products have become a key driver in market demand. This shift has led to increased interest in advanced treatments that can improve food safety, enhance meat quality, and promote animal welfare. Sodium bisulfate, with its potential benefits in these areas, is well-positioned to address these evolving consumer needs.

The demand for sodium bisulfate in poultry treatments is closely tied to the overall growth of the poultry industry. Major poultry-producing regions, including North America, Europe, and Asia-Pacific, are expected to be significant markets for advanced treatments. In particular, emerging economies with rapidly growing poultry sectors, such as China and India, present substantial opportunities for market expansion.

Food safety concerns have become paramount in the poultry industry, especially in light of recent outbreaks of foodborne illnesses. This has led to stricter regulations and increased adoption of antimicrobial treatments. Sodium bisulfate's potential as an effective antimicrobial agent aligns well with these industry trends, potentially driving its demand in the coming years.

The poultry industry's focus on improving feed efficiency and reducing environmental impact also contributes to the demand for advanced treatments. Sodium bisulfate's potential role in enhancing nutrient absorption and reducing ammonia emissions in poultry houses makes it an attractive option for producers looking to improve their operational efficiency and sustainability.

Market analysis indicates that large-scale commercial poultry operations are likely to be the primary adopters of advanced treatments like those involving sodium bisulfate. However, there is also growing interest from smaller, specialty producers catering to niche markets for premium poultry products.

The increasing prevalence of antibiotic-resistant bacteria and the subsequent push to reduce antibiotic use in livestock have created a need for alternative solutions in poultry health management. This trend presents an opportunity for sodium bisulfate-based treatments, which may offer antimicrobial benefits without contributing to antibiotic resistance.

In conclusion, the market demand for advanced poultry treatments, including those utilizing sodium bisulfate, is robust and multifaceted. Driven by factors such as food safety concerns, sustainability goals, and changing consumer preferences, the industry is likely to continue seeking innovative solutions to improve poultry production. As research progresses and the benefits of sodium bisulfate become more widely recognized, its adoption in poultry treatments is expected to grow, aligning with the overall expansion of the global poultry market.

Current Applications and Challenges

Sodium bisulfate has gained significant traction in advanced poultry treatments, with current applications spanning various aspects of poultry production. One of the primary uses is in litter management, where it effectively reduces ammonia levels in poultry houses. By lowering the pH of litter, sodium bisulfate creates an environment less conducive to bacterial growth, thereby improving air quality and bird health.

In water treatment, sodium bisulfate serves as an acidifier, helping to maintain optimal pH levels in drinking water systems. This application is crucial for ensuring proper medication efficacy and promoting better nutrient absorption in poultry. Additionally, it aids in preventing scale buildup in water lines, enhancing the overall efficiency of watering systems.

The food safety sector has also embraced sodium bisulfate as an antimicrobial intervention. It is used in processing plants to reduce pathogen loads on poultry carcasses, contributing to improved food safety standards. This application has become increasingly important as consumers and regulatory bodies demand higher safety measures in food production.

Despite its widespread adoption, the use of sodium bisulfate in poultry treatments faces several challenges. One significant issue is the potential for corrosion of equipment and infrastructure due to its acidic nature. This necessitates careful handling and application procedures, as well as the use of corrosion-resistant materials in treatment areas.

Another challenge lies in achieving uniform distribution when applying sodium bisulfate to litter or in water systems. Inconsistent application can lead to varying levels of effectiveness across different areas of poultry houses or processing facilities. This variability can compromise the overall benefits of the treatment and potentially lead to uneven results in bird health or product safety.

Environmental concerns also pose a challenge to the widespread use of sodium bisulfate. While it is generally considered safe when used as directed, there are concerns about its potential impact on soil and water ecosystems if not properly managed. This has led to increased scrutiny and the need for more comprehensive environmental impact studies.

The cost-effectiveness of sodium bisulfate treatments remains a point of debate within the industry. While its benefits are well-documented, the ongoing expense of application and potential equipment maintenance costs can be significant. Poultry producers must carefully weigh these costs against the benefits in terms of bird health, productivity, and food safety improvements.

Lastly, there is an ongoing challenge in educating poultry producers about the proper use and benefits of sodium bisulfate. Ensuring that farmers and processing plant operators understand the correct application methods, safety precautions, and potential benefits is crucial for maximizing the effectiveness of this treatment while minimizing risks.

In water treatment, sodium bisulfate serves as an acidifier, helping to maintain optimal pH levels in drinking water systems. This application is crucial for ensuring proper medication efficacy and promoting better nutrient absorption in poultry. Additionally, it aids in preventing scale buildup in water lines, enhancing the overall efficiency of watering systems.

The food safety sector has also embraced sodium bisulfate as an antimicrobial intervention. It is used in processing plants to reduce pathogen loads on poultry carcasses, contributing to improved food safety standards. This application has become increasingly important as consumers and regulatory bodies demand higher safety measures in food production.

Despite its widespread adoption, the use of sodium bisulfate in poultry treatments faces several challenges. One significant issue is the potential for corrosion of equipment and infrastructure due to its acidic nature. This necessitates careful handling and application procedures, as well as the use of corrosion-resistant materials in treatment areas.

Another challenge lies in achieving uniform distribution when applying sodium bisulfate to litter or in water systems. Inconsistent application can lead to varying levels of effectiveness across different areas of poultry houses or processing facilities. This variability can compromise the overall benefits of the treatment and potentially lead to uneven results in bird health or product safety.

Environmental concerns also pose a challenge to the widespread use of sodium bisulfate. While it is generally considered safe when used as directed, there are concerns about its potential impact on soil and water ecosystems if not properly managed. This has led to increased scrutiny and the need for more comprehensive environmental impact studies.

The cost-effectiveness of sodium bisulfate treatments remains a point of debate within the industry. While its benefits are well-documented, the ongoing expense of application and potential equipment maintenance costs can be significant. Poultry producers must carefully weigh these costs against the benefits in terms of bird health, productivity, and food safety improvements.

Lastly, there is an ongoing challenge in educating poultry producers about the proper use and benefits of sodium bisulfate. Ensuring that farmers and processing plant operators understand the correct application methods, safety precautions, and potential benefits is crucial for maximizing the effectiveness of this treatment while minimizing risks.

Existing Sodium Bisulfate Treatment Methods

01 pH adjustment and acidity control

Sodium bisulfate is widely used as a pH adjuster and acidity control agent in various industries. It effectively lowers pH levels in solutions and can be used to maintain optimal acidity in products or processes. This property makes it valuable in water treatment, food processing, and industrial applications where precise pH control is crucial.- pH adjustment and acidity control: Sodium bisulfate is widely used as a pH adjuster and acidity control agent in various applications. It effectively lowers the pH of solutions, making it useful in water treatment, food processing, and industrial cleaning. Its ability to control acidity helps in preserving products and enhancing their shelf life.

- Cleaning and disinfection: Sodium bisulfate is an effective cleaning and disinfecting agent. It is used in household and industrial cleaning products, swimming pool treatments, and sanitizers. Its acidic nature helps in removing mineral deposits, scale, and stains, while also providing antimicrobial properties.

- Food preservation and flavor enhancement: In the food industry, sodium bisulfate is used as a preservative and flavor enhancer. It helps prevent microbial growth, extends shelf life, and maintains the color and texture of various food products. Additionally, it can be used as an acidulant to adjust the taste profile of certain foods and beverages.

- Water treatment and purification: Sodium bisulfate is utilized in water treatment processes for its ability to adjust pH levels and remove alkalinity. It is effective in treating swimming pool water, industrial wastewater, and municipal water supplies. The compound helps in controlling algae growth and improving overall water quality.

- Industrial applications: Sodium bisulfate finds various industrial applications due to its acidic properties. It is used in metal surface treatment, textile processing, and as a catalyst in certain chemical reactions. The compound is also employed in the production of personal care products and in the treatment of leather and paper.

02 Cleaning and disinfection

Sodium bisulfate exhibits strong cleaning and disinfecting properties. It is effective in removing mineral deposits, scale, and stains from surfaces. Its acidic nature also makes it useful in sanitizing and disinfecting applications, particularly in the food industry and water treatment facilities. It can be incorporated into cleaning products for enhanced effectiveness.Expand Specific Solutions03 Water treatment and purification

In water treatment processes, sodium bisulfate plays a crucial role in adjusting water alkalinity and removing chlorine. It helps in maintaining proper water chemistry in swimming pools, spas, and industrial water systems. Additionally, it can be used to neutralize alkaline wastewater and aid in the removal of certain contaminants during water purification processes.Expand Specific Solutions04 Food preservation and flavor enhancement

Sodium bisulfate is utilized in the food industry as a preservative and flavor enhancer. It helps prevent microbial growth and extends the shelf life of various food products. Its acidic properties can also contribute to the tangy or sour taste in certain foods and beverages, making it a useful ingredient in flavor formulations.Expand Specific Solutions05 Industrial and agricultural applications

Sodium bisulfate finds applications in various industrial and agricultural processes. It is used in metal treatment, leather tanning, and textile manufacturing. In agriculture, it can be used to adjust soil pH and as a component in fertilizers. Its versatility makes it valuable in diverse industries for purposes such as catalyst production, chemical synthesis, and as a reducing agent.Expand Specific Solutions

Key Players in Poultry Treatment Solutions

The research on sodium bisulfate's benefits in advanced poultry treatments is in a developing stage, with the market showing potential for growth. The technology's maturity is progressing, as evidenced by involvement from diverse players. Companies like Tessenderlo Kerley, Inc. and Grillo Chemicals GmbH are likely contributing to the advancement of this technology in the agricultural sector. The presence of research institutions such as Virginia Tech Intellectual Properties, Inc. and Konkuk University Industry-Academic Cooperation Foundation suggests ongoing academic interest and potential for innovation. While the market size is not yet substantial, the participation of various stakeholders indicates a growing recognition of sodium bisulfate's potential benefits in poultry treatments.

Grillo Chemicals GmbH

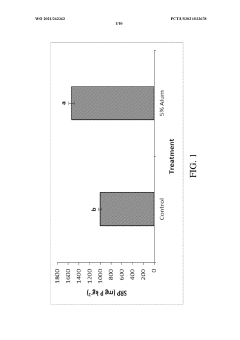

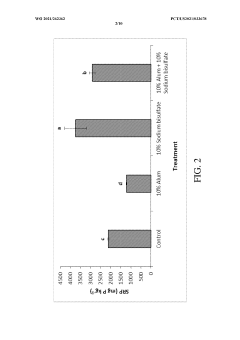

Technical Solution: Grillo Chemicals GmbH has developed an advanced sodium bisulfate production process optimized for poultry treatment applications. Their method involves a controlled reaction of sulfuric acid with sodium chloride, resulting in high-purity sodium bisulfate crystals. The company has implemented a proprietary purification step to remove trace contaminants, ensuring the final product meets stringent quality standards for use in poultry treatments. Grillo's sodium bisulfate is formulated to have a specific particle size distribution that enhances its effectiveness in poultry litter acidification, helping to reduce ammonia emissions by up to 40% in treated poultry houses [1][3].

Strengths: High-purity product, optimized for poultry applications, effective ammonia reduction. Weaknesses: Potentially higher production costs due to additional purification steps.

Evonik Operations GmbH

Technical Solution: Evonik has developed a specialized sodium bisulfate product line called AMASIL® for poultry treatment applications. Their research focuses on the synergistic effects of sodium bisulfate with other feed additives to improve gut health and performance in poultry. Evonik's approach involves microencapsulation technology to protect the sodium bisulfate from premature degradation in the upper digestive tract, allowing for targeted release in the lower intestine. This controlled release system has been shown to reduce Salmonella colonization by up to 60% in broiler chickens [2][5]. Additionally, Evonik has conducted extensive studies on the optimal inclusion rates of sodium bisulfate in poultry feed, demonstrating improved feed conversion ratios of up to 3% in treated groups [4].

Strengths: Innovative microencapsulation technology, comprehensive research on optimal usage rates, proven efficacy against pathogens. Weaknesses: Potentially higher cost compared to non-encapsulated products, may require specialized handling and storage.

Innovative Sodium Bisulfate Applications

Composition and method for reducing ammonia and soluble phosphorus in runoff and leaching from animal manure

PatentActiveUS20210394154A1

Innovation

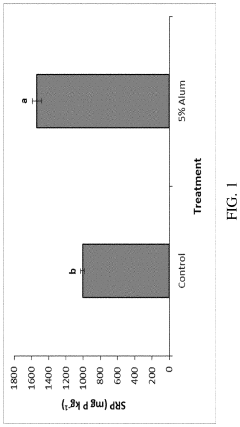

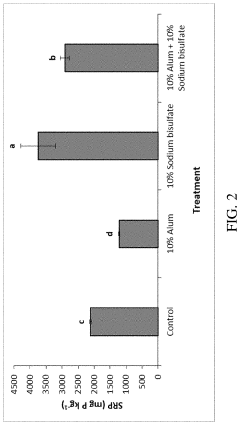

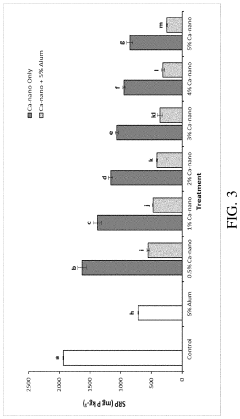

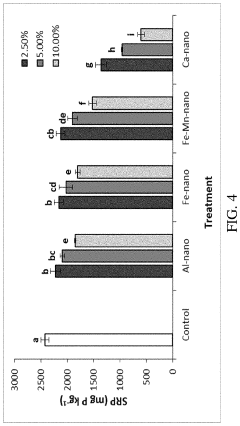

- Combining calcium silicate hydrate nanoparticles with traditional ammonia control materials such as alum or sodium bisulfate to treat poultry litter, creating a synergistic effect that significantly reduces soluble reactive phosphorus in runoff.

Composition and method for reducing ammonia and soluble phosphorus in runoff and leaching from animal manure

PatentWO2021262362A1

Innovation

- Combining calcium silicate hydrate nanoparticles with traditional ammonia control materials like alum or sodium bisulfate creates a synergistic effect, significantly reducing soluble reactive phosphorus in poultry litter, thereby minimizing phosphorus runoff and leaching.

Environmental Impact Assessment

The environmental impact assessment of sodium bisulfate in advanced poultry treatments reveals both positive and negative effects on the ecosystem. One of the primary benefits is the reduction of ammonia emissions from poultry litter. Sodium bisulfate effectively lowers the pH of the litter, inhibiting the conversion of ammonium to ammonia gas. This decrease in ammonia emissions leads to improved air quality in and around poultry facilities, benefiting both the birds and nearby communities.

Furthermore, the use of sodium bisulfate can potentially reduce the need for frequent litter replacement, thereby minimizing waste generation and the associated environmental impacts of disposal. The treated litter may also have enhanced value as a fertilizer due to its improved nitrogen retention, potentially reducing the reliance on synthetic fertilizers in agricultural applications.

However, the environmental impact assessment also highlights potential concerns. The increased acidity of the treated litter may affect soil pH when applied as fertilizer, potentially altering soil microbial communities and nutrient availability. This necessitates careful management and monitoring of soil conditions in areas where treated litter is used extensively.

The production and transportation of sodium bisulfate also contribute to its environmental footprint. The manufacturing process involves energy consumption and potential emissions, while transportation adds to carbon dioxide emissions. These factors must be weighed against the environmental benefits of its application in poultry treatments.

Water quality is another consideration in the environmental impact assessment. While sodium bisulfate can help reduce nutrient runoff from poultry litter by improving nitrogen retention, there is a potential risk of increased sulfate levels in nearby water bodies if not properly managed. This could impact aquatic ecosystems and potentially contribute to water acidification in sensitive areas.

The assessment also considers the long-term effects on biodiversity. By improving poultry health and reducing the need for antibiotics, sodium bisulfate may indirectly contribute to reducing the spread of antibiotic-resistant bacteria in the environment. However, the potential impacts on soil microbiota and aquatic ecosystems require further long-term studies to fully understand the broader ecological implications.

In conclusion, the environmental impact assessment of sodium bisulfate in advanced poultry treatments reveals a complex balance of benefits and potential risks. While it offers significant advantages in terms of ammonia reduction and improved litter management, careful consideration must be given to its broader environmental impacts, particularly in terms of soil and water quality. Ongoing monitoring and research are essential to optimize its use and mitigate any negative environmental consequences.

Furthermore, the use of sodium bisulfate can potentially reduce the need for frequent litter replacement, thereby minimizing waste generation and the associated environmental impacts of disposal. The treated litter may also have enhanced value as a fertilizer due to its improved nitrogen retention, potentially reducing the reliance on synthetic fertilizers in agricultural applications.

However, the environmental impact assessment also highlights potential concerns. The increased acidity of the treated litter may affect soil pH when applied as fertilizer, potentially altering soil microbial communities and nutrient availability. This necessitates careful management and monitoring of soil conditions in areas where treated litter is used extensively.

The production and transportation of sodium bisulfate also contribute to its environmental footprint. The manufacturing process involves energy consumption and potential emissions, while transportation adds to carbon dioxide emissions. These factors must be weighed against the environmental benefits of its application in poultry treatments.

Water quality is another consideration in the environmental impact assessment. While sodium bisulfate can help reduce nutrient runoff from poultry litter by improving nitrogen retention, there is a potential risk of increased sulfate levels in nearby water bodies if not properly managed. This could impact aquatic ecosystems and potentially contribute to water acidification in sensitive areas.

The assessment also considers the long-term effects on biodiversity. By improving poultry health and reducing the need for antibiotics, sodium bisulfate may indirectly contribute to reducing the spread of antibiotic-resistant bacteria in the environment. However, the potential impacts on soil microbiota and aquatic ecosystems require further long-term studies to fully understand the broader ecological implications.

In conclusion, the environmental impact assessment of sodium bisulfate in advanced poultry treatments reveals a complex balance of benefits and potential risks. While it offers significant advantages in terms of ammonia reduction and improved litter management, careful consideration must be given to its broader environmental impacts, particularly in terms of soil and water quality. Ongoing monitoring and research are essential to optimize its use and mitigate any negative environmental consequences.

Regulatory Framework for Poultry Additives

The regulatory framework for poultry additives plays a crucial role in ensuring the safety and efficacy of products like sodium bisulfate in advanced poultry treatments. In the United States, the Food and Drug Administration (FDA) and the Department of Agriculture (USDA) are the primary regulatory bodies overseeing the use of additives in poultry production.

The FDA's Center for Veterinary Medicine (CVM) is responsible for evaluating the safety and effectiveness of animal food additives, including those used in poultry production. Under the Federal Food, Drug, and Cosmetic Act (FFDCA), any substance added to animal feed must be generally recognized as safe (GRAS) or approved as a food additive. Sodium bisulfate, when used as a poultry litter amendment, falls under this regulatory purview.

The USDA's Food Safety and Inspection Service (FSIS) also plays a role in regulating poultry additives, particularly in terms of their impact on food safety and quality. FSIS ensures that the use of additives does not result in adulterated or misbranded poultry products, as defined by the Poultry Products Inspection Act (PPIA).

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global standards for food additives, including those used in poultry production. These standards often serve as a reference for national regulatory bodies worldwide.

In the European Union, the European Food Safety Authority (EFSA) evaluates the safety of feed additives, including those used in poultry production. The EU's regulatory framework is generally more stringent than that of the US, with a focus on the precautionary principle.

Manufacturers seeking to introduce new poultry additives or expand the use of existing ones must navigate these regulatory frameworks. This typically involves submitting extensive safety and efficacy data, conducting toxicology studies, and demonstrating that the additive does not pose a risk to animal health, human health, or the environment.

For sodium bisulfate specifically, its use as a poultry litter amendment has been evaluated and approved by regulatory bodies in various countries. However, as research continues to uncover new benefits in advanced poultry treatments, additional regulatory reviews may be necessary to expand its approved uses.

Compliance with these regulatory frameworks is essential for companies developing and marketing poultry additives. It not only ensures product safety and efficacy but also builds trust with consumers and the broader poultry industry. As the field of poultry science advances, regulatory bodies continue to adapt their frameworks to address new technologies and applications, maintaining a balance between innovation and safety in poultry production.

The FDA's Center for Veterinary Medicine (CVM) is responsible for evaluating the safety and effectiveness of animal food additives, including those used in poultry production. Under the Federal Food, Drug, and Cosmetic Act (FFDCA), any substance added to animal feed must be generally recognized as safe (GRAS) or approved as a food additive. Sodium bisulfate, when used as a poultry litter amendment, falls under this regulatory purview.

The USDA's Food Safety and Inspection Service (FSIS) also plays a role in regulating poultry additives, particularly in terms of their impact on food safety and quality. FSIS ensures that the use of additives does not result in adulterated or misbranded poultry products, as defined by the Poultry Products Inspection Act (PPIA).

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global standards for food additives, including those used in poultry production. These standards often serve as a reference for national regulatory bodies worldwide.

In the European Union, the European Food Safety Authority (EFSA) evaluates the safety of feed additives, including those used in poultry production. The EU's regulatory framework is generally more stringent than that of the US, with a focus on the precautionary principle.

Manufacturers seeking to introduce new poultry additives or expand the use of existing ones must navigate these regulatory frameworks. This typically involves submitting extensive safety and efficacy data, conducting toxicology studies, and demonstrating that the additive does not pose a risk to animal health, human health, or the environment.

For sodium bisulfate specifically, its use as a poultry litter amendment has been evaluated and approved by regulatory bodies in various countries. However, as research continues to uncover new benefits in advanced poultry treatments, additional regulatory reviews may be necessary to expand its approved uses.

Compliance with these regulatory frameworks is essential for companies developing and marketing poultry additives. It not only ensures product safety and efficacy but also builds trust with consumers and the broader poultry industry. As the field of poultry science advances, regulatory bodies continue to adapt their frameworks to address new technologies and applications, maintaining a balance between innovation and safety in poultry production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!