Sodium Bisulfate Utilization in Industry Water Preservation

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate Background and Objectives

Sodium bisulfate, a versatile chemical compound, has gained significant attention in recent years for its potential applications in industrial water preservation. This acidic salt, also known as sodium hydrogen sulfate, has a rich history dating back to its discovery in the early 19th century. Initially utilized in various industrial processes, its role in water treatment and preservation has become increasingly prominent over the past few decades.

The evolution of sodium bisulfate's use in water preservation can be traced through several key milestones. In the 1970s, researchers began exploring its potential as a pH adjuster in water treatment systems. By the 1990s, its effectiveness in controlling microbial growth in industrial water systems was well-established, leading to its widespread adoption in cooling towers and process water applications.

As environmental concerns grew in the 21st century, the focus shifted towards developing more sustainable and eco-friendly water preservation methods. This trend has propelled sodium bisulfate to the forefront of research, as it offers a balance between effectiveness and environmental impact. Its ability to lower pH levels without introducing harmful chlorine compounds has made it an attractive alternative to traditional water treatment chemicals.

The primary objective of current research on sodium bisulfate utilization in industrial water preservation is to optimize its application for maximum efficiency and minimal environmental impact. This includes investigating its synergistic effects with other water treatment chemicals, developing novel formulations for specific industrial applications, and exploring its potential in emerging water preservation technologies.

Another crucial aim is to understand and mitigate any potential long-term effects of sodium bisulfate use on industrial equipment and ecosystems. Researchers are working on developing comprehensive guidelines for its safe and effective application across various industries, from food processing to power generation.

Furthermore, there is a growing interest in exploring the circular economy potential of sodium bisulfate. This involves researching methods to recover and recycle the compound from treated water, thereby reducing waste and improving the overall sustainability of industrial water preservation processes.

As global water scarcity concerns intensify, the importance of efficient water preservation techniques cannot be overstated. The ongoing research on sodium bisulfate utilization is expected to play a crucial role in addressing these challenges, potentially revolutionizing industrial water management practices in the coming years.

The evolution of sodium bisulfate's use in water preservation can be traced through several key milestones. In the 1970s, researchers began exploring its potential as a pH adjuster in water treatment systems. By the 1990s, its effectiveness in controlling microbial growth in industrial water systems was well-established, leading to its widespread adoption in cooling towers and process water applications.

As environmental concerns grew in the 21st century, the focus shifted towards developing more sustainable and eco-friendly water preservation methods. This trend has propelled sodium bisulfate to the forefront of research, as it offers a balance between effectiveness and environmental impact. Its ability to lower pH levels without introducing harmful chlorine compounds has made it an attractive alternative to traditional water treatment chemicals.

The primary objective of current research on sodium bisulfate utilization in industrial water preservation is to optimize its application for maximum efficiency and minimal environmental impact. This includes investigating its synergistic effects with other water treatment chemicals, developing novel formulations for specific industrial applications, and exploring its potential in emerging water preservation technologies.

Another crucial aim is to understand and mitigate any potential long-term effects of sodium bisulfate use on industrial equipment and ecosystems. Researchers are working on developing comprehensive guidelines for its safe and effective application across various industries, from food processing to power generation.

Furthermore, there is a growing interest in exploring the circular economy potential of sodium bisulfate. This involves researching methods to recover and recycle the compound from treated water, thereby reducing waste and improving the overall sustainability of industrial water preservation processes.

As global water scarcity concerns intensify, the importance of efficient water preservation techniques cannot be overstated. The ongoing research on sodium bisulfate utilization is expected to play a crucial role in addressing these challenges, potentially revolutionizing industrial water management practices in the coming years.

Market Analysis for Water Preservation Solutions

The water preservation solutions market has witnessed significant growth in recent years, driven by increasing water scarcity concerns and stringent environmental regulations. The global market for industrial water treatment chemicals is projected to reach $36.5 billion by 2025, with a compound annual growth rate of 5.2% from 2020 to 2025. This growth is primarily attributed to the rising demand for clean water in various industries, including power generation, oil and gas, mining, and manufacturing.

Sodium bisulfate, a key component in water preservation solutions, has gained traction due to its effectiveness in pH adjustment and scale control. The market for sodium bisulfate in water treatment applications is expected to grow at a CAGR of 4.8% from 2021 to 2026. This growth is fueled by the increasing adoption of sodium bisulfate in industrial water treatment processes, particularly in regions facing water stress and stringent environmental regulations.

The Asia-Pacific region is anticipated to be the fastest-growing market for water preservation solutions, driven by rapid industrialization, urbanization, and increasing water pollution concerns. China and India are expected to be the major contributors to this growth, with their governments implementing strict water quality standards and promoting sustainable water management practices.

In North America and Europe, the market for water preservation solutions is mature but continues to grow steadily. The focus in these regions is shifting towards advanced technologies and sustainable solutions, creating opportunities for innovative products and services. The United States, in particular, is witnessing a surge in demand for water preservation solutions due to aging water infrastructure and increasing water stress in certain regions.

The industrial sector remains the largest end-user of water preservation solutions, accounting for approximately 60% of the market share. Power generation, chemical processing, and food and beverage industries are the primary consumers of water treatment chemicals and technologies. The municipal water treatment sector is also experiencing growth, driven by urbanization and the need for improved water quality in developing countries.

Key market trends include the increasing adoption of membrane-based water treatment technologies, the rise of digital water management solutions, and the growing emphasis on sustainable and eco-friendly water treatment chemicals. These trends are reshaping the competitive landscape, with companies investing in research and development to develop innovative and environmentally friendly water preservation solutions.

The market is characterized by the presence of both global players and regional suppliers. Major companies in the water preservation solutions market include Ecolab Inc., Suez Water Technologies & Solutions, Kemira Oyj, and Solenis LLC. These companies are focusing on strategic partnerships, mergers and acquisitions, and product innovations to strengthen their market position and expand their product portfolios.

Sodium bisulfate, a key component in water preservation solutions, has gained traction due to its effectiveness in pH adjustment and scale control. The market for sodium bisulfate in water treatment applications is expected to grow at a CAGR of 4.8% from 2021 to 2026. This growth is fueled by the increasing adoption of sodium bisulfate in industrial water treatment processes, particularly in regions facing water stress and stringent environmental regulations.

The Asia-Pacific region is anticipated to be the fastest-growing market for water preservation solutions, driven by rapid industrialization, urbanization, and increasing water pollution concerns. China and India are expected to be the major contributors to this growth, with their governments implementing strict water quality standards and promoting sustainable water management practices.

In North America and Europe, the market for water preservation solutions is mature but continues to grow steadily. The focus in these regions is shifting towards advanced technologies and sustainable solutions, creating opportunities for innovative products and services. The United States, in particular, is witnessing a surge in demand for water preservation solutions due to aging water infrastructure and increasing water stress in certain regions.

The industrial sector remains the largest end-user of water preservation solutions, accounting for approximately 60% of the market share. Power generation, chemical processing, and food and beverage industries are the primary consumers of water treatment chemicals and technologies. The municipal water treatment sector is also experiencing growth, driven by urbanization and the need for improved water quality in developing countries.

Key market trends include the increasing adoption of membrane-based water treatment technologies, the rise of digital water management solutions, and the growing emphasis on sustainable and eco-friendly water treatment chemicals. These trends are reshaping the competitive landscape, with companies investing in research and development to develop innovative and environmentally friendly water preservation solutions.

The market is characterized by the presence of both global players and regional suppliers. Major companies in the water preservation solutions market include Ecolab Inc., Suez Water Technologies & Solutions, Kemira Oyj, and Solenis LLC. These companies are focusing on strategic partnerships, mergers and acquisitions, and product innovations to strengthen their market position and expand their product portfolios.

Current Challenges in Industrial Water Conservation

Industrial water conservation faces numerous challenges in the current landscape, particularly in the context of sodium bisulfate utilization. One of the primary issues is the increasing water scarcity worldwide, which puts pressure on industries to reduce their water consumption and improve efficiency. This scarcity is exacerbated by climate change, population growth, and urbanization, making it crucial for industries to adopt innovative water conservation techniques.

Another significant challenge is the stringent environmental regulations imposed on industrial wastewater discharge. Many countries have implemented strict guidelines for water quality and treatment, forcing industries to invest in advanced water treatment technologies. This regulatory pressure, while necessary for environmental protection, often results in increased operational costs for businesses.

The presence of contaminants in industrial wastewater poses a substantial challenge to water conservation efforts. Sodium bisulfate, while useful in certain applications, can contribute to water pollution if not properly managed. Industries must develop effective methods to remove or neutralize this compound and other pollutants before water can be reused or safely discharged, adding complexity to the conservation process.

Energy consumption in water treatment and conservation processes is another critical challenge. Many water treatment technologies, including those involving sodium bisulfate, require significant energy inputs. This not only increases operational costs but also contributes to the overall carbon footprint of industrial operations, creating a conflict between water conservation goals and energy efficiency objectives.

The lack of widespread adoption of water-efficient technologies and practices across industries remains a persistent challenge. Many businesses still rely on outdated water management systems, either due to financial constraints or a lack of awareness about more efficient alternatives. This slow adoption rate hinders progress in industrial water conservation efforts.

Infrastructure limitations also present a significant hurdle. Aging water systems in many industrial facilities lead to leaks, inefficiencies, and water loss. Upgrading these systems requires substantial investment, which many companies are reluctant to undertake, especially in economically challenging times.

Finally, there is a growing need for better data management and monitoring systems in industrial water conservation. Many facilities lack real-time water usage data, making it difficult to identify areas of waste or opportunities for improvement. Implementing comprehensive water monitoring systems is crucial for effective conservation but often requires significant technological and financial resources.

Another significant challenge is the stringent environmental regulations imposed on industrial wastewater discharge. Many countries have implemented strict guidelines for water quality and treatment, forcing industries to invest in advanced water treatment technologies. This regulatory pressure, while necessary for environmental protection, often results in increased operational costs for businesses.

The presence of contaminants in industrial wastewater poses a substantial challenge to water conservation efforts. Sodium bisulfate, while useful in certain applications, can contribute to water pollution if not properly managed. Industries must develop effective methods to remove or neutralize this compound and other pollutants before water can be reused or safely discharged, adding complexity to the conservation process.

Energy consumption in water treatment and conservation processes is another critical challenge. Many water treatment technologies, including those involving sodium bisulfate, require significant energy inputs. This not only increases operational costs but also contributes to the overall carbon footprint of industrial operations, creating a conflict between water conservation goals and energy efficiency objectives.

The lack of widespread adoption of water-efficient technologies and practices across industries remains a persistent challenge. Many businesses still rely on outdated water management systems, either due to financial constraints or a lack of awareness about more efficient alternatives. This slow adoption rate hinders progress in industrial water conservation efforts.

Infrastructure limitations also present a significant hurdle. Aging water systems in many industrial facilities lead to leaks, inefficiencies, and water loss. Upgrading these systems requires substantial investment, which many companies are reluctant to undertake, especially in economically challenging times.

Finally, there is a growing need for better data management and monitoring systems in industrial water conservation. Many facilities lack real-time water usage data, making it difficult to identify areas of waste or opportunities for improvement. Implementing comprehensive water monitoring systems is crucial for effective conservation but often requires significant technological and financial resources.

Existing Sodium Bisulfate Applications

01 Use of sodium bisulfate for water treatment

Sodium bisulfate is utilized in water treatment processes to adjust pH levels and control microbial growth. It acts as an acidifying agent and can help in the preservation of water by creating an environment less favorable for bacterial proliferation. This compound is effective in various water systems, including swimming pools, industrial water treatment, and potable water applications.- Use of sodium bisulfate for water treatment: Sodium bisulfate is utilized in water treatment processes to adjust pH levels and control microbial growth. It acts as an effective acidifying agent and can help in the preservation of water quality in various applications, including swimming pools, industrial water systems, and drinking water treatment.

- Sodium bisulfate in food preservation: Sodium bisulfate is employed as a food preservative due to its ability to inhibit microbial growth and maintain product freshness. It is particularly useful in extending the shelf life of various food products by lowering pH levels and creating an environment unfavorable for bacterial proliferation.

- Application in personal care products: Sodium bisulfate finds applications in personal care products as a pH adjuster and preservative. It helps maintain the stability and efficacy of formulations such as shampoos, body washes, and other cosmetic products by preventing microbial contamination and ensuring optimal pH levels.

- Industrial wastewater treatment: Sodium bisulfate is utilized in industrial wastewater treatment processes to neutralize alkaline effluents and remove contaminants. It aids in the precipitation of heavy metals, reduction of chemical oxygen demand, and overall improvement of water quality before discharge or recycling.

- Combination with other preservatives: Sodium bisulfate is often used in combination with other preservatives to enhance water preservation efficacy. These synergistic formulations can provide broader spectrum antimicrobial activity, improved stability, and longer-lasting protection against various microorganisms in water systems.

02 Combination with other preservatives

Sodium bisulfate can be combined with other preservatives to enhance its water preservation capabilities. These combinations may include other acids, biocides, or oxidizing agents. The synergistic effects of these combinations can provide broader spectrum antimicrobial activity and improved stability in various water systems.Expand Specific Solutions03 Application in food and beverage preservation

Sodium bisulfate is used in the food and beverage industry for water preservation and as a preservative itself. It helps maintain the quality and safety of products by inhibiting microbial growth and controlling pH levels. This application extends the shelf life of various food and beverage items while ensuring water quality in processing.Expand Specific Solutions04 Use in industrial and agricultural water systems

Sodium bisulfate plays a crucial role in preserving water quality in industrial and agricultural settings. It is used to treat irrigation water, prevent scale formation in industrial water systems, and control algae growth in large water bodies. The compound's ability to adjust pH and inhibit microbial growth makes it valuable in these applications.Expand Specific Solutions05 Formulation and delivery methods

Various formulation and delivery methods have been developed for the effective use of sodium bisulfate in water preservation. These include slow-release tablets, liquid concentrates, and powder forms. The different formulations allow for precise dosing and controlled release of the compound, ensuring optimal water preservation in diverse applications and environments.Expand Specific Solutions

Key Players in Water Treatment Industry

The research on sodium bisulfate utilization in industry water preservation is in a developing stage, with growing market potential due to increasing water scarcity concerns. The technology's maturity is moderate, with ongoing advancements. Key players like China Petroleum & Chemical Corp., Toray Industries, and Saudi Arabian Oil Co. are investing in research and development to improve efficiency and applications. Universities such as Central South University and Tianjin University are contributing to academic research. The competitive landscape is diverse, including chemical companies, research institutions, and environmental technology firms, indicating a multifaceted approach to addressing water preservation challenges using sodium bisulfate.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach for sodium bisulfate utilization in industrial water preservation. Their method involves using sodium bisulfate as a pH adjuster and scale inhibitor in cooling water systems. The process includes adding sodium bisulfate to the circulating water, which helps maintain optimal pH levels (typically between 7.0-8.5) and prevents scale formation on heat exchange surfaces[1]. This technique has shown to reduce water consumption by up to 20% in their refinery operations[2]. Additionally, Sinopec has implemented a sodium bisulfate recovery system that captures and recycles the chemical from wastewater streams, further enhancing sustainability and reducing operational costs[3]. The company has also explored the use of sodium bisulfate in conjunction with other water treatment chemicals to create synergistic effects, improving overall water quality and reducing the need for frequent blowdowns in cooling towers[4].

Strengths: Cost-effective solution for pH control and scale inhibition; Reduces water consumption; Enables chemical recycling. Weaknesses: May require careful monitoring to prevent over-acidification; Potential for increased corrosion in some systems if not properly managed.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a novel membrane-based technology for sodium bisulfate utilization in industrial water preservation. Their approach combines reverse osmosis (RO) membranes with specialized ion exchange resins to effectively remove and recover sodium bisulfate from industrial wastewater[1]. The process involves a two-stage treatment: first, the wastewater passes through an RO system to concentrate the sodium bisulfate; then, the concentrate is fed into an ion exchange column for further purification and recovery[2]. This method has demonstrated a recovery rate of up to 95% of sodium bisulfate from wastewater streams[3]. Toray has also developed a proprietary membrane coating that enhances resistance to acidic conditions, extending the lifespan of the RO membranes when treating sodium bisulfate-rich waters[4]. The recovered sodium bisulfate can be reused in various industrial processes, creating a closed-loop system that significantly reduces water consumption and chemical waste[5].

Strengths: High recovery rate of sodium bisulfate; Creates a closed-loop system; Reduces water and chemical consumption. Weaknesses: High initial capital investment; Requires specialized expertise for operation and maintenance.

Innovative Uses of Sodium Bisulfate

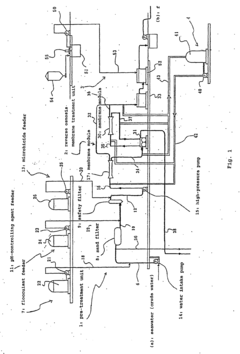

Water treatment device with chemical washing device of filtration membrane and chemical washing method

PatentInactiveJP2012245520A

Innovation

- Using a flexible plastic sheet container for sodium bisulfite storage, sealed to prevent air contact and equipped with a suction port, along with temperature and concentration control, to minimize sulfurous acid gas generation and sulfate crystallization, and an automatic switching system for chemical replenishment.

Method for inhibiting growth of bacteria or sterilizing around separating membrane

PatentInactiveEP1031372B1

Innovation

- A method involving acid treatment of crude water to a pH of 2.7 to 4, with intermittent acid addition to inhibit microorganism growth, using sulfuric acid to control pH and disinfect membranes, reducing the need for high concentrations of expensive sodium bisulfite.

Environmental Impact Assessment

The utilization of sodium bisulfate in industrial water preservation has significant environmental implications that require careful assessment. This chemical compound, while effective in water treatment processes, can potentially impact various environmental aspects if not managed properly.

One of the primary environmental concerns is the effect on aquatic ecosystems. When sodium bisulfate is used in water treatment, it can alter the pH levels of the treated water. If not properly neutralized before discharge, this acidic effluent may harm aquatic life in receiving water bodies. Fish, amphibians, and other aquatic organisms are particularly sensitive to changes in water acidity, which can disrupt their reproductive cycles and overall health.

Soil quality is another area of potential impact. In cases where treated water is used for irrigation or accidentally leaks into the soil, the increased acidity can affect soil chemistry. This may lead to changes in nutrient availability for plants and soil microorganisms, potentially impacting agricultural productivity and local ecosystems.

Air quality considerations are also relevant, particularly in industrial settings where sodium bisulfate is handled in large quantities. While not highly volatile, improper handling or accidental releases could lead to localized air quality issues, potentially causing respiratory irritation for workers or nearby communities.

The production and transportation of sodium bisulfate also contribute to its overall environmental footprint. Manufacturing processes may involve energy-intensive steps and potential emissions, while transportation adds to carbon footprint and risk of accidental spills during transit.

However, it's important to note that the use of sodium bisulfate in water preservation can also yield positive environmental outcomes. By effectively treating industrial wastewater, it helps prevent the release of harmful contaminants into the environment. This can lead to improved water quality in rivers, lakes, and coastal areas, benefiting both ecosystems and human communities that rely on these water resources.

Waste management is a crucial aspect of environmental impact assessment for sodium bisulfate utilization. Proper disposal methods must be implemented to prevent environmental contamination. This includes neutralization of acidic waste streams and appropriate handling of any byproducts or residues from the treatment process.

Long-term ecological effects should also be considered in the assessment. While immediate impacts may be manageable, cumulative effects of prolonged use in a specific area could potentially alter local ecosystems over time. Monitoring programs should be established to track any gradual changes in water quality, soil composition, or biodiversity in areas where sodium bisulfate is regularly used for industrial water preservation.

One of the primary environmental concerns is the effect on aquatic ecosystems. When sodium bisulfate is used in water treatment, it can alter the pH levels of the treated water. If not properly neutralized before discharge, this acidic effluent may harm aquatic life in receiving water bodies. Fish, amphibians, and other aquatic organisms are particularly sensitive to changes in water acidity, which can disrupt their reproductive cycles and overall health.

Soil quality is another area of potential impact. In cases where treated water is used for irrigation or accidentally leaks into the soil, the increased acidity can affect soil chemistry. This may lead to changes in nutrient availability for plants and soil microorganisms, potentially impacting agricultural productivity and local ecosystems.

Air quality considerations are also relevant, particularly in industrial settings where sodium bisulfate is handled in large quantities. While not highly volatile, improper handling or accidental releases could lead to localized air quality issues, potentially causing respiratory irritation for workers or nearby communities.

The production and transportation of sodium bisulfate also contribute to its overall environmental footprint. Manufacturing processes may involve energy-intensive steps and potential emissions, while transportation adds to carbon footprint and risk of accidental spills during transit.

However, it's important to note that the use of sodium bisulfate in water preservation can also yield positive environmental outcomes. By effectively treating industrial wastewater, it helps prevent the release of harmful contaminants into the environment. This can lead to improved water quality in rivers, lakes, and coastal areas, benefiting both ecosystems and human communities that rely on these water resources.

Waste management is a crucial aspect of environmental impact assessment for sodium bisulfate utilization. Proper disposal methods must be implemented to prevent environmental contamination. This includes neutralization of acidic waste streams and appropriate handling of any byproducts or residues from the treatment process.

Long-term ecological effects should also be considered in the assessment. While immediate impacts may be manageable, cumulative effects of prolonged use in a specific area could potentially alter local ecosystems over time. Monitoring programs should be established to track any gradual changes in water quality, soil composition, or biodiversity in areas where sodium bisulfate is regularly used for industrial water preservation.

Regulatory Framework for Industrial Water Use

The regulatory framework for industrial water use plays a crucial role in the utilization of sodium bisulfate for water preservation in industrial settings. Governments worldwide have implemented various regulations and policies to ensure sustainable water management practices and minimize environmental impacts.

In many countries, industrial water use is subject to strict permitting processes. These permits often require companies to demonstrate their commitment to water conservation and efficient use of resources. The use of sodium bisulfate in water treatment processes may be subject to specific regulations due to its potential environmental impacts and safety considerations.

Environmental protection agencies typically set discharge limits for industrial effluents, including parameters such as pH, total dissolved solids, and specific chemical concentrations. The use of sodium bisulfate in water treatment must comply with these limits to ensure that treated water meets the required standards before being discharged into the environment.

Water quality standards for industrial processes are another key aspect of the regulatory framework. These standards may dictate the acceptable levels of various contaminants in water used for different industrial applications. The use of sodium bisulfate for water treatment must align with these standards to ensure the treated water is suitable for its intended use.

Many jurisdictions have implemented water conservation regulations that require industries to adopt best practices for water management. This may include mandates for water recycling, reuse, and the implementation of water-efficient technologies. The use of sodium bisulfate in water treatment processes may be evaluated within this context to determine its effectiveness in supporting water conservation efforts.

Occupational health and safety regulations also play a significant role in the use of sodium bisulfate in industrial settings. These regulations typically outline requirements for safe handling, storage, and disposal of chemicals used in water treatment processes. Companies must ensure compliance with these regulations to protect worker safety and minimize the risk of accidents or exposure.

In recent years, there has been a growing emphasis on circular economy principles in industrial water management. Regulations are increasingly encouraging the recovery and reuse of valuable resources from wastewater streams. The use of sodium bisulfate in water treatment processes may need to be evaluated in terms of its compatibility with resource recovery efforts and its potential impact on the circular economy approach.

International agreements and treaties related to water management and pollution control may also influence the regulatory framework for industrial water use. These agreements often set targets for reducing water pollution and improving water quality across borders, which can impact national regulations and industry practices.

As concerns about water scarcity and environmental sustainability continue to grow, it is likely that the regulatory framework for industrial water use will become increasingly stringent. Industries utilizing sodium bisulfate for water preservation must stay informed about evolving regulations and adapt their practices accordingly to ensure compliance and sustainable water management.

In many countries, industrial water use is subject to strict permitting processes. These permits often require companies to demonstrate their commitment to water conservation and efficient use of resources. The use of sodium bisulfate in water treatment processes may be subject to specific regulations due to its potential environmental impacts and safety considerations.

Environmental protection agencies typically set discharge limits for industrial effluents, including parameters such as pH, total dissolved solids, and specific chemical concentrations. The use of sodium bisulfate in water treatment must comply with these limits to ensure that treated water meets the required standards before being discharged into the environment.

Water quality standards for industrial processes are another key aspect of the regulatory framework. These standards may dictate the acceptable levels of various contaminants in water used for different industrial applications. The use of sodium bisulfate for water treatment must align with these standards to ensure the treated water is suitable for its intended use.

Many jurisdictions have implemented water conservation regulations that require industries to adopt best practices for water management. This may include mandates for water recycling, reuse, and the implementation of water-efficient technologies. The use of sodium bisulfate in water treatment processes may be evaluated within this context to determine its effectiveness in supporting water conservation efforts.

Occupational health and safety regulations also play a significant role in the use of sodium bisulfate in industrial settings. These regulations typically outline requirements for safe handling, storage, and disposal of chemicals used in water treatment processes. Companies must ensure compliance with these regulations to protect worker safety and minimize the risk of accidents or exposure.

In recent years, there has been a growing emphasis on circular economy principles in industrial water management. Regulations are increasingly encouraging the recovery and reuse of valuable resources from wastewater streams. The use of sodium bisulfate in water treatment processes may need to be evaluated in terms of its compatibility with resource recovery efforts and its potential impact on the circular economy approach.

International agreements and treaties related to water management and pollution control may also influence the regulatory framework for industrial water use. These agreements often set targets for reducing water pollution and improving water quality across borders, which can impact national regulations and industry practices.

As concerns about water scarcity and environmental sustainability continue to grow, it is likely that the regulatory framework for industrial water use will become increasingly stringent. Industries utilizing sodium bisulfate for water preservation must stay informed about evolving regulations and adapt their practices accordingly to ensure compliance and sustainable water management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!