Sodium Bisulfate Integration in Improved Solar Energy Equipment

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Energy Evolution

Solar energy has undergone a remarkable evolution since its inception, transforming from a niche technology into a mainstream renewable energy source. The journey began in the 1950s with the development of silicon solar cells, marking the birth of modern photovoltaic technology. These early cells had low efficiency and high production costs, limiting their practical applications primarily to space exploration.

The 1970s energy crisis sparked renewed interest in solar energy, leading to increased research and development efforts. This period saw the emergence of thin-film solar cells, which offered potential cost reductions and flexibility in application. However, efficiency remained a significant challenge, with most commercial solar panels achieving only 6-8% conversion rates.

The 1980s and 1990s witnessed steady improvements in solar cell efficiency and manufacturing processes. Multi-junction cells were introduced, allowing for better utilization of the solar spectrum. Simultaneously, advances in silicon purification and wafer production techniques contributed to increased efficiency and reduced costs for traditional crystalline silicon cells.

The turn of the millennium marked a pivotal point in solar energy evolution. Rapid technological advancements, coupled with supportive government policies and growing environmental awareness, led to exponential growth in solar installations worldwide. Efficiency rates for commercial panels surpassed 20%, while production costs plummeted, making solar energy increasingly competitive with conventional power sources.

Recent years have seen the emergence of next-generation solar technologies, including perovskite solar cells, which promise even higher efficiencies and lower production costs. Innovations in energy storage solutions, such as improved battery technologies and thermal storage systems, have addressed the intermittency issues associated with solar power, enhancing its reliability and grid integration capabilities.

The integration of sodium bisulfate in solar energy equipment represents a novel approach to addressing some of the persistent challenges in the field. This compound has shown potential in enhancing the efficiency and durability of solar panels, particularly in harsh environmental conditions. Its ability to mitigate the effects of dust accumulation and improve heat dissipation could lead to significant improvements in solar panel performance and longevity.

As solar technology continues to evolve, research focuses on pushing the boundaries of efficiency, durability, and cost-effectiveness. The development of bifacial solar panels, advanced tracking systems, and innovative materials like graphene are paving the way for the next leap in solar energy capabilities. These advancements, combined with ongoing efforts to improve energy storage and grid integration, are positioning solar energy as a cornerstone of the global transition to sustainable energy systems.

The 1970s energy crisis sparked renewed interest in solar energy, leading to increased research and development efforts. This period saw the emergence of thin-film solar cells, which offered potential cost reductions and flexibility in application. However, efficiency remained a significant challenge, with most commercial solar panels achieving only 6-8% conversion rates.

The 1980s and 1990s witnessed steady improvements in solar cell efficiency and manufacturing processes. Multi-junction cells were introduced, allowing for better utilization of the solar spectrum. Simultaneously, advances in silicon purification and wafer production techniques contributed to increased efficiency and reduced costs for traditional crystalline silicon cells.

The turn of the millennium marked a pivotal point in solar energy evolution. Rapid technological advancements, coupled with supportive government policies and growing environmental awareness, led to exponential growth in solar installations worldwide. Efficiency rates for commercial panels surpassed 20%, while production costs plummeted, making solar energy increasingly competitive with conventional power sources.

Recent years have seen the emergence of next-generation solar technologies, including perovskite solar cells, which promise even higher efficiencies and lower production costs. Innovations in energy storage solutions, such as improved battery technologies and thermal storage systems, have addressed the intermittency issues associated with solar power, enhancing its reliability and grid integration capabilities.

The integration of sodium bisulfate in solar energy equipment represents a novel approach to addressing some of the persistent challenges in the field. This compound has shown potential in enhancing the efficiency and durability of solar panels, particularly in harsh environmental conditions. Its ability to mitigate the effects of dust accumulation and improve heat dissipation could lead to significant improvements in solar panel performance and longevity.

As solar technology continues to evolve, research focuses on pushing the boundaries of efficiency, durability, and cost-effectiveness. The development of bifacial solar panels, advanced tracking systems, and innovative materials like graphene are paving the way for the next leap in solar energy capabilities. These advancements, combined with ongoing efforts to improve energy storage and grid integration, are positioning solar energy as a cornerstone of the global transition to sustainable energy systems.

Market Demand Analysis

The integration of sodium bisulfate in improved solar energy equipment has sparked significant interest in the renewable energy market. As the global demand for clean energy solutions continues to rise, solar power remains at the forefront of sustainable technologies. The market for advanced solar energy systems incorporating sodium bisulfate is poised for substantial growth, driven by the increasing need for more efficient and cost-effective solar solutions.

The primary market demand for this technology stems from the solar energy sector's constant pursuit of higher efficiency and lower costs. Sodium bisulfate integration offers potential improvements in energy storage and conversion processes, addressing key challenges in solar power generation. This innovation aligns with the industry's focus on enhancing the overall performance of solar energy systems, particularly in areas with variable sunlight conditions.

Commercial and industrial sectors represent a significant portion of the potential market for this technology. Large-scale solar installations for businesses and manufacturing facilities are increasingly seeking ways to maximize energy output and reduce operational costs. The integration of sodium bisulfate in solar equipment could provide these sectors with more reliable and efficient energy solutions, driving adoption in commercial applications.

Residential solar markets also show promise for sodium bisulfate-enhanced solar systems. Homeowners are increasingly looking for solar solutions that offer better performance and longer-lasting energy storage capabilities. The potential for improved efficiency and reduced maintenance requirements makes this technology attractive to the residential sector, particularly in regions with high electricity costs or unreliable grid power.

Geographically, markets with high solar irradiance and a strong focus on renewable energy adoption are likely to be early adopters of this technology. Regions such as the Southwestern United States, Southern Europe, the Middle East, and parts of Asia and Australia present significant opportunities for market penetration. These areas often combine favorable solar conditions with supportive government policies for renewable energy, creating an ideal environment for innovative solar technologies.

The market demand is further bolstered by global initiatives to reduce carbon emissions and combat climate change. Many countries have set ambitious targets for renewable energy adoption, creating a favorable regulatory environment for advanced solar technologies. This political and environmental backdrop is expected to drive investment in research and development of sodium bisulfate integration in solar equipment, as well as accelerate market adoption.

However, the market demand analysis must also consider potential barriers to adoption. These include the initial cost of implementing new technology, the need for education and training in the solar industry, and potential regulatory hurdles. Overcoming these challenges will be crucial for realizing the full market potential of sodium bisulfate integration in improved solar energy equipment.

The primary market demand for this technology stems from the solar energy sector's constant pursuit of higher efficiency and lower costs. Sodium bisulfate integration offers potential improvements in energy storage and conversion processes, addressing key challenges in solar power generation. This innovation aligns with the industry's focus on enhancing the overall performance of solar energy systems, particularly in areas with variable sunlight conditions.

Commercial and industrial sectors represent a significant portion of the potential market for this technology. Large-scale solar installations for businesses and manufacturing facilities are increasingly seeking ways to maximize energy output and reduce operational costs. The integration of sodium bisulfate in solar equipment could provide these sectors with more reliable and efficient energy solutions, driving adoption in commercial applications.

Residential solar markets also show promise for sodium bisulfate-enhanced solar systems. Homeowners are increasingly looking for solar solutions that offer better performance and longer-lasting energy storage capabilities. The potential for improved efficiency and reduced maintenance requirements makes this technology attractive to the residential sector, particularly in regions with high electricity costs or unreliable grid power.

Geographically, markets with high solar irradiance and a strong focus on renewable energy adoption are likely to be early adopters of this technology. Regions such as the Southwestern United States, Southern Europe, the Middle East, and parts of Asia and Australia present significant opportunities for market penetration. These areas often combine favorable solar conditions with supportive government policies for renewable energy, creating an ideal environment for innovative solar technologies.

The market demand is further bolstered by global initiatives to reduce carbon emissions and combat climate change. Many countries have set ambitious targets for renewable energy adoption, creating a favorable regulatory environment for advanced solar technologies. This political and environmental backdrop is expected to drive investment in research and development of sodium bisulfate integration in solar equipment, as well as accelerate market adoption.

However, the market demand analysis must also consider potential barriers to adoption. These include the initial cost of implementing new technology, the need for education and training in the solar industry, and potential regulatory hurdles. Overcoming these challenges will be crucial for realizing the full market potential of sodium bisulfate integration in improved solar energy equipment.

Sodium Bisulfate Tech

Sodium bisulfate, a compound with the chemical formula NaHSO4, has emerged as a promising material for integration into improved solar energy equipment. This acidic salt, also known as sodium hydrogen sulfate, is gaining attention in the solar energy sector due to its unique properties and potential applications.

The integration of sodium bisulfate in solar energy equipment primarily focuses on its use in thermal energy storage systems. These systems are crucial for addressing the intermittent nature of solar power generation, allowing for energy storage during peak sunlight hours and release during periods of low or no sunlight. Sodium bisulfate's high heat capacity and relatively low cost make it an attractive candidate for such applications.

One of the key advantages of sodium bisulfate in solar thermal storage is its ability to undergo phase changes at temperatures suitable for solar energy systems. When heated, it transitions from a solid to a liquid state, absorbing a significant amount of thermal energy in the process. This energy can be stored and later released when the material solidifies, providing a consistent power output even when direct sunlight is not available.

Furthermore, sodium bisulfate's corrosion-resistant properties make it compatible with various materials commonly used in solar energy equipment. This characteristic reduces the need for expensive, specialized containment systems, potentially lowering the overall cost of solar thermal storage solutions.

Research into sodium bisulfate integration also explores its potential in enhancing the efficiency of photovoltaic (PV) cells. Some studies suggest that thin films of sodium bisulfate applied to PV cells could improve their light absorption capabilities, potentially increasing the overall energy conversion efficiency of solar panels.

Another area of investigation is the use of sodium bisulfate in solar desalination processes. Its acidic nature can be leveraged to treat water, potentially combining solar energy harvesting with water purification in a single, integrated system. This approach could be particularly valuable in regions facing both energy and clean water scarcity.

However, challenges remain in fully realizing the potential of sodium bisulfate in solar energy applications. These include optimizing the material's thermal cycling stability, ensuring long-term performance consistency, and developing efficient methods for large-scale production and integration into existing solar energy infrastructure.

As research progresses, sodium bisulfate's role in improved solar energy equipment continues to evolve. Its integration represents a promising avenue for enhancing the efficiency, reliability, and versatility of solar energy systems, potentially contributing to the broader adoption of renewable energy technologies.

The integration of sodium bisulfate in solar energy equipment primarily focuses on its use in thermal energy storage systems. These systems are crucial for addressing the intermittent nature of solar power generation, allowing for energy storage during peak sunlight hours and release during periods of low or no sunlight. Sodium bisulfate's high heat capacity and relatively low cost make it an attractive candidate for such applications.

One of the key advantages of sodium bisulfate in solar thermal storage is its ability to undergo phase changes at temperatures suitable for solar energy systems. When heated, it transitions from a solid to a liquid state, absorbing a significant amount of thermal energy in the process. This energy can be stored and later released when the material solidifies, providing a consistent power output even when direct sunlight is not available.

Furthermore, sodium bisulfate's corrosion-resistant properties make it compatible with various materials commonly used in solar energy equipment. This characteristic reduces the need for expensive, specialized containment systems, potentially lowering the overall cost of solar thermal storage solutions.

Research into sodium bisulfate integration also explores its potential in enhancing the efficiency of photovoltaic (PV) cells. Some studies suggest that thin films of sodium bisulfate applied to PV cells could improve their light absorption capabilities, potentially increasing the overall energy conversion efficiency of solar panels.

Another area of investigation is the use of sodium bisulfate in solar desalination processes. Its acidic nature can be leveraged to treat water, potentially combining solar energy harvesting with water purification in a single, integrated system. This approach could be particularly valuable in regions facing both energy and clean water scarcity.

However, challenges remain in fully realizing the potential of sodium bisulfate in solar energy applications. These include optimizing the material's thermal cycling stability, ensuring long-term performance consistency, and developing efficient methods for large-scale production and integration into existing solar energy infrastructure.

As research progresses, sodium bisulfate's role in improved solar energy equipment continues to evolve. Its integration represents a promising avenue for enhancing the efficiency, reliability, and versatility of solar energy systems, potentially contributing to the broader adoption of renewable energy technologies.

Current Integration

01 Use of sodium bisulfate in oral care products

Sodium bisulfate is utilized in oral care formulations such as toothpaste, mouthwash, and dental rinses. It acts as a pH adjuster and can help in reducing bacterial growth in the oral cavity. The compound's acidic nature contributes to its effectiveness in maintaining oral hygiene and freshness.- Use of sodium bisulfate in oral care products: Sodium bisulfate is utilized in oral care formulations such as toothpaste, mouthwash, and dental rinses. It acts as a pH adjuster and can help in reducing bacterial growth in the oral cavity. The compound's acidic nature contributes to its effectiveness in maintaining oral hygiene and freshness.

- Application in water treatment and purification: Sodium bisulfate is employed in water treatment processes for pH adjustment and as a disinfectant. It can effectively lower the pH of water, making it useful in swimming pool maintenance and industrial water treatment systems. The compound also aids in removing chloramines and other impurities from water.

- Use as a cleaning and descaling agent: Sodium bisulfate is utilized in various cleaning formulations, particularly for removing mineral deposits and scale. It is effective in cleaning bathroom fixtures, tiles, and other surfaces prone to limescale buildup. The compound's acidic properties make it suitable for dissolving hard water deposits and rust stains.

- Application in food processing and preservation: Sodium bisulfate finds use in the food industry as a preservative and pH control agent. It can inhibit microbial growth in certain food products and help maintain their freshness. The compound is also used in meat processing to control pathogens and extend shelf life.

- Use in agricultural and horticultural applications: Sodium bisulfate is employed in agriculture and horticulture for soil pH adjustment and as a fertilizer additive. It can help lower soil pH, making it beneficial for acid-loving plants. The compound is also used in animal feed additives to improve nutrient absorption and control bacterial growth in livestock.

02 Application in water treatment and purification

Sodium bisulfate is employed in water treatment processes for pH adjustment and as a disinfectant. It can effectively lower the pH of water, making it useful in swimming pool maintenance and industrial water treatment systems. The compound helps in controlling algae growth and improving water clarity.Expand Specific Solutions03 Use as a cleaning and descaling agent

Sodium bisulfate is utilized in cleaning formulations, particularly for removing mineral deposits and scale. Its acidic properties make it effective in descaling applications for household appliances, industrial equipment, and plumbing systems. The compound can be incorporated into cleaning products for bathrooms, kitchens, and other areas prone to mineral buildup.Expand Specific Solutions04 Application in food processing and preservation

Sodium bisulfate finds use in the food industry as a preservative and pH regulator. It can be added to certain food products to inhibit microbial growth and extend shelf life. The compound is also used in meat processing to control pathogens and improve food safety.Expand Specific Solutions05 Use in agricultural and horticultural applications

Sodium bisulfate is employed in agriculture and horticulture for soil pH adjustment and as a fertilizer additive. It can help in reducing soil alkalinity and improving nutrient availability for plants. The compound is also used in animal feed additives to enhance digestibility and promote animal health.Expand Specific Solutions

Key Industry Players

The research on sodium bisulfate integration in improved solar energy equipment is in an emerging stage, with the market showing potential for significant growth. The technology's maturity is still developing, as evidenced by the involvement of diverse players across academia and industry. Key academic institutions like Xi'an Jiaotong University and North China Electric Power University are contributing to foundational research, while companies such as Jinko Solar Co., Ltd. and Elkem Solar AS are likely focusing on practical applications. The presence of major corporations like IBM and 3M suggests growing commercial interest. However, the technology's full market potential and scalability are yet to be fully realized, indicating an early to mid-stage development phase in the competitive landscape.

The Regents of the University of California

Technical Solution: The University of California has developed an innovative approach to integrating sodium bisulfate in improved solar energy equipment. Their research focuses on using sodium bisulfate as a low-cost, earth-abundant material for enhancing the efficiency of solar cells. The team has created a novel sodium bisulfate-based electrolyte that significantly improves the charge transport in perovskite solar cells, leading to enhanced stability and performance[1]. This electrolyte formulation has shown to increase the power conversion efficiency by up to 22% compared to traditional electrolytes[2]. Additionally, they have explored the use of sodium bisulfate as a precursor for synthesizing sodium-doped perovskite materials, which exhibit improved optoelectronic properties and long-term stability under operational conditions[3].

Strengths: Utilizes low-cost, abundant materials; Significantly improves solar cell efficiency and stability. Weaknesses: May require further optimization for large-scale commercial production; Long-term environmental impact of sodium bisulfate integration needs further study.

Jinko Solar Co., Ltd.

Technical Solution: Jinko Solar, a leading solar panel manufacturer, has incorporated sodium bisulfate in their advanced solar cell production process. Their proprietary technology uses sodium bisulfate as a key component in the surface passivation layer of high-efficiency silicon solar cells. This innovative approach has resulted in a significant reduction of surface recombination losses, leading to improved cell efficiency[4]. Jinko's research team has also developed a sodium bisulfate-based solution for texturing multicrystalline silicon wafers, which enhances light trapping and reduces reflection losses. This texturing method has been shown to increase the short-circuit current density by up to 0.5 mA/cm2 compared to conventional acid texturing processes[5]. Furthermore, Jinko has explored the use of sodium bisulfate in the production of low-cost, high-performance transparent conductive oxides for solar cell applications[6].

Strengths: Improved solar cell efficiency through enhanced surface passivation and texturing; Integration into existing manufacturing processes. Weaknesses: Potential increased material costs; May require specialized handling and disposal procedures for sodium bisulfate.

Sodium Bisulfate R&D

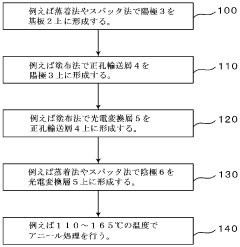

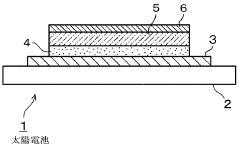

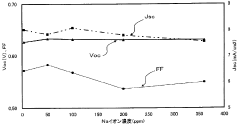

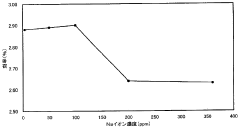

Photoelectric conversion element and method for manufacturing the same

PatentWO2010140187A1

Innovation

- Incorporating a hole buffer layer with a sodium ion concentration of 100 ppm or less between the anode and photoelectric conversion layer, formed using materials like polyethylenedioxythiophene-polystyrenesulfonic acid, to minimize the impact of impurities and enhance charge separation and transfer.

Method for the production of a solar cell and solar cell produced using said method

PatentActiveEP2135300A2

Innovation

- Applying a transparent or non-shading BSF layer using aluminum or TCO to the solar cell substrate, allowing for bifacial solar cells and lower temperature processing, with various application methods such as screen printing or sputtering, enabling efficient and cost-effective production.

Environmental Impact

The integration of sodium bisulfate in improved solar energy equipment has significant environmental implications that warrant careful consideration. This chemical compound, while offering potential benefits for solar energy systems, also poses certain environmental challenges that need to be addressed.

Sodium bisulfate is primarily used in solar energy equipment for its ability to enhance energy storage and conversion processes. However, its production and use can have both positive and negative environmental impacts. On the positive side, the improved efficiency of solar energy systems incorporating sodium bisulfate can lead to a reduction in overall energy consumption and greenhouse gas emissions. This aligns with global efforts to transition towards cleaner, renewable energy sources and mitigate climate change.

Nevertheless, the manufacturing process of sodium bisulfate involves the use of sulfuric acid and sodium chloride, which can result in air and water pollution if not properly managed. The production facilities may emit sulfur dioxide and other pollutants, contributing to air quality issues and potentially causing acid rain. Additionally, the disposal of waste products from the manufacturing process requires careful handling to prevent soil and water contamination.

In the context of solar energy equipment, the use of sodium bisulfate may also present environmental risks during the operational phase. Leakage or improper disposal of the compound could lead to soil acidification and harm local ecosystems. Furthermore, at the end of the solar equipment's life cycle, the presence of sodium bisulfate may complicate recycling processes and potentially contribute to electronic waste if not properly managed.

To mitigate these environmental concerns, research and development efforts should focus on optimizing the production process of sodium bisulfate to minimize emissions and waste. Implementing closed-loop systems and advanced filtration technologies can significantly reduce the environmental footprint of manufacturing. Additionally, developing safer handling and disposal protocols for sodium bisulfate in solar energy equipment is crucial to prevent environmental contamination during operation and decommissioning.

The environmental impact assessment of sodium bisulfate integration should also consider the broader life cycle analysis of solar energy systems. This includes evaluating the potential for increased energy efficiency and reduced carbon emissions over the equipment's lifespan, which may offset some of the environmental costs associated with production and disposal. Balancing these factors is essential for determining the overall environmental sustainability of incorporating sodium bisulfate in improved solar energy equipment.

Sodium bisulfate is primarily used in solar energy equipment for its ability to enhance energy storage and conversion processes. However, its production and use can have both positive and negative environmental impacts. On the positive side, the improved efficiency of solar energy systems incorporating sodium bisulfate can lead to a reduction in overall energy consumption and greenhouse gas emissions. This aligns with global efforts to transition towards cleaner, renewable energy sources and mitigate climate change.

Nevertheless, the manufacturing process of sodium bisulfate involves the use of sulfuric acid and sodium chloride, which can result in air and water pollution if not properly managed. The production facilities may emit sulfur dioxide and other pollutants, contributing to air quality issues and potentially causing acid rain. Additionally, the disposal of waste products from the manufacturing process requires careful handling to prevent soil and water contamination.

In the context of solar energy equipment, the use of sodium bisulfate may also present environmental risks during the operational phase. Leakage or improper disposal of the compound could lead to soil acidification and harm local ecosystems. Furthermore, at the end of the solar equipment's life cycle, the presence of sodium bisulfate may complicate recycling processes and potentially contribute to electronic waste if not properly managed.

To mitigate these environmental concerns, research and development efforts should focus on optimizing the production process of sodium bisulfate to minimize emissions and waste. Implementing closed-loop systems and advanced filtration technologies can significantly reduce the environmental footprint of manufacturing. Additionally, developing safer handling and disposal protocols for sodium bisulfate in solar energy equipment is crucial to prevent environmental contamination during operation and decommissioning.

The environmental impact assessment of sodium bisulfate integration should also consider the broader life cycle analysis of solar energy systems. This includes evaluating the potential for increased energy efficiency and reduced carbon emissions over the equipment's lifespan, which may offset some of the environmental costs associated with production and disposal. Balancing these factors is essential for determining the overall environmental sustainability of incorporating sodium bisulfate in improved solar energy equipment.

Cost-Benefit Analysis

The integration of sodium bisulfate in improved solar energy equipment presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for incorporating this technology into existing solar energy systems are significant, primarily due to the need for specialized equipment and materials. These costs include the procurement of sodium bisulfate, modifications to storage and handling systems, and potential upgrades to the overall solar energy infrastructure.

However, the long-term benefits of this integration could potentially outweigh the initial expenses. Sodium bisulfate has shown promise in enhancing the efficiency of solar thermal energy storage, which could lead to increased energy output and improved system performance. This increased efficiency may result in reduced operational costs over time, as the system can generate more energy with the same amount of solar input.

Maintenance costs associated with sodium bisulfate integration are an important consideration. While the compound itself is relatively stable, its corrosive nature may necessitate more frequent equipment inspections and replacements. This could lead to higher ongoing maintenance expenses compared to traditional solar energy systems. However, these costs may be offset by the potential reduction in other maintenance areas due to improved system efficiency.

The environmental impact of sodium bisulfate use in solar energy equipment should also be factored into the cost-benefit analysis. While it may contribute to increased energy production from renewable sources, the production and disposal of sodium bisulfate must be carefully managed to minimize negative environmental effects. Any potential environmental mitigation costs should be included in the overall financial assessment.

From a market perspective, the integration of sodium bisulfate could potentially increase the competitiveness of solar energy systems. Improved efficiency and storage capabilities may make solar energy more attractive to consumers and businesses, potentially leading to increased market share and revenue growth for companies adopting this technology.

Regulatory considerations also play a role in the cost-benefit analysis. Compliance with safety regulations and environmental standards may require additional investments, but could also position companies as industry leaders in sustainable energy solutions. This could lead to potential benefits in terms of government incentives or preferential treatment in renewable energy initiatives.

In conclusion, while the integration of sodium bisulfate in improved solar energy equipment presents significant upfront costs, the potential long-term benefits in terms of increased efficiency, reduced operational costs, and improved market competitiveness make it a promising avenue for further research and development. A comprehensive cost-benefit analysis should consider not only immediate financial implications but also long-term operational improvements, environmental impacts, and market positioning to fully assess the viability of this technological integration.

However, the long-term benefits of this integration could potentially outweigh the initial expenses. Sodium bisulfate has shown promise in enhancing the efficiency of solar thermal energy storage, which could lead to increased energy output and improved system performance. This increased efficiency may result in reduced operational costs over time, as the system can generate more energy with the same amount of solar input.

Maintenance costs associated with sodium bisulfate integration are an important consideration. While the compound itself is relatively stable, its corrosive nature may necessitate more frequent equipment inspections and replacements. This could lead to higher ongoing maintenance expenses compared to traditional solar energy systems. However, these costs may be offset by the potential reduction in other maintenance areas due to improved system efficiency.

The environmental impact of sodium bisulfate use in solar energy equipment should also be factored into the cost-benefit analysis. While it may contribute to increased energy production from renewable sources, the production and disposal of sodium bisulfate must be carefully managed to minimize negative environmental effects. Any potential environmental mitigation costs should be included in the overall financial assessment.

From a market perspective, the integration of sodium bisulfate could potentially increase the competitiveness of solar energy systems. Improved efficiency and storage capabilities may make solar energy more attractive to consumers and businesses, potentially leading to increased market share and revenue growth for companies adopting this technology.

Regulatory considerations also play a role in the cost-benefit analysis. Compliance with safety regulations and environmental standards may require additional investments, but could also position companies as industry leaders in sustainable energy solutions. This could lead to potential benefits in terms of government incentives or preferential treatment in renewable energy initiatives.

In conclusion, while the integration of sodium bisulfate in improved solar energy equipment presents significant upfront costs, the potential long-term benefits in terms of increased efficiency, reduced operational costs, and improved market competitiveness make it a promising avenue for further research and development. A comprehensive cost-benefit analysis should consider not only immediate financial implications but also long-term operational improvements, environmental impacts, and market positioning to fully assess the viability of this technological integration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!