Sodium Bisulfate Integration in Advanced Textile Techniques

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Bisulfate Textile Integration Background

Sodium bisulfate has emerged as a significant compound in the textile industry, playing a crucial role in various advanced textile techniques. The integration of this chemical into textile processes has evolved over time, driven by the need for more efficient and environmentally friendly manufacturing methods. Initially used primarily as a pH regulator in dyeing processes, sodium bisulfate's applications have expanded to encompass a wide range of textile treatments and finishes.

The historical context of sodium bisulfate in textiles dates back to the early 20th century when the chemical industry began to develop more sophisticated compounds for industrial use. As textile manufacturing became increasingly mechanized and large-scale, the demand for effective chemical agents to improve fabric quality and processing efficiency grew. Sodium bisulfate, with its acidic properties and relative stability, quickly found its place in this evolving landscape.

In the mid-20th century, as environmental concerns began to gain prominence, the textile industry faced pressure to adopt more sustainable practices. This shift in focus led to renewed interest in sodium bisulfate as a potentially more eco-friendly alternative to some harsher chemicals used in textile processing. Its ability to effectively lower pH without introducing harmful heavy metals or persistent organic pollutants made it an attractive option for manufacturers seeking to reduce their environmental footprint.

The technological advancements in textile machinery and processing techniques over the past few decades have further expanded the potential applications of sodium bisulfate. Modern precision dosing systems and automated process controls have allowed for more precise and efficient use of the compound, optimizing its effectiveness while minimizing waste. This has opened up new possibilities for integrating sodium bisulfate into advanced textile techniques, particularly in areas such as smart textiles and high-performance fabrics.

Recent research has focused on exploring novel ways to leverage sodium bisulfate's properties in textile manufacturing. These efforts aim to enhance fabric performance, improve colorfastness, and develop innovative finishes. The compound's role in modifying fiber surfaces, improving dye uptake, and facilitating the incorporation of functional additives has become an area of intense study. As the textile industry continues to evolve towards more sustainable and technologically advanced production methods, the integration of sodium bisulfate is likely to remain a key area of research and development.

The historical context of sodium bisulfate in textiles dates back to the early 20th century when the chemical industry began to develop more sophisticated compounds for industrial use. As textile manufacturing became increasingly mechanized and large-scale, the demand for effective chemical agents to improve fabric quality and processing efficiency grew. Sodium bisulfate, with its acidic properties and relative stability, quickly found its place in this evolving landscape.

In the mid-20th century, as environmental concerns began to gain prominence, the textile industry faced pressure to adopt more sustainable practices. This shift in focus led to renewed interest in sodium bisulfate as a potentially more eco-friendly alternative to some harsher chemicals used in textile processing. Its ability to effectively lower pH without introducing harmful heavy metals or persistent organic pollutants made it an attractive option for manufacturers seeking to reduce their environmental footprint.

The technological advancements in textile machinery and processing techniques over the past few decades have further expanded the potential applications of sodium bisulfate. Modern precision dosing systems and automated process controls have allowed for more precise and efficient use of the compound, optimizing its effectiveness while minimizing waste. This has opened up new possibilities for integrating sodium bisulfate into advanced textile techniques, particularly in areas such as smart textiles and high-performance fabrics.

Recent research has focused on exploring novel ways to leverage sodium bisulfate's properties in textile manufacturing. These efforts aim to enhance fabric performance, improve colorfastness, and develop innovative finishes. The compound's role in modifying fiber surfaces, improving dye uptake, and facilitating the incorporation of functional additives has become an area of intense study. As the textile industry continues to evolve towards more sustainable and technologically advanced production methods, the integration of sodium bisulfate is likely to remain a key area of research and development.

Market Analysis for Advanced Textile Products

The advanced textile market has been experiencing significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. The integration of sodium bisulfate in advanced textile techniques represents a promising area of innovation that could potentially reshape the industry landscape.

The global advanced textile market is projected to expand at a robust rate, with increasing demand for high-performance fabrics across various sectors. Key application areas include sportswear, protective clothing, medical textiles, and industrial fabrics. The sportswear segment, in particular, has shown remarkable growth due to rising health consciousness and the popularity of athleisure wear.

Consumer demand for sustainable and eco-friendly textiles has been a major market driver. This trend aligns well with the potential benefits of sodium bisulfate integration, which could lead to more efficient and environmentally friendly production processes. The market has also seen a surge in demand for smart textiles and wearable technology, creating new opportunities for innovative textile solutions.

Geographically, North America and Europe have been leading markets for advanced textiles, with Asia-Pacific emerging as a rapidly growing region. The increasing adoption of technical textiles in developing countries, coupled with the presence of major textile manufacturing hubs, is expected to fuel market growth in the Asia-Pacific region.

The COVID-19 pandemic has had a significant impact on the advanced textile market, accelerating the demand for antimicrobial and protective fabrics. This has opened up new avenues for research and development in textile technologies, including potential applications of sodium bisulfate in creating antimicrobial properties.

Market competition in the advanced textile sector is intense, with key players focusing on product innovation and strategic partnerships to gain a competitive edge. The integration of sodium bisulfate in textile production could potentially offer a unique selling proposition for companies looking to differentiate their products in the market.

Challenges in the market include the high cost of advanced textile production and the need for skilled labor. However, these challenges also present opportunities for innovations that can reduce production costs and improve efficiency, areas where sodium bisulfate integration could potentially make a significant impact.

In conclusion, the market analysis for advanced textile products reveals a dynamic and growing sector with ample opportunities for technological innovations. The integration of sodium bisulfate in advanced textile techniques could address several key market demands, including sustainability, performance enhancement, and cost-efficiency, positioning it as a potentially disruptive technology in the textile industry.

The global advanced textile market is projected to expand at a robust rate, with increasing demand for high-performance fabrics across various sectors. Key application areas include sportswear, protective clothing, medical textiles, and industrial fabrics. The sportswear segment, in particular, has shown remarkable growth due to rising health consciousness and the popularity of athleisure wear.

Consumer demand for sustainable and eco-friendly textiles has been a major market driver. This trend aligns well with the potential benefits of sodium bisulfate integration, which could lead to more efficient and environmentally friendly production processes. The market has also seen a surge in demand for smart textiles and wearable technology, creating new opportunities for innovative textile solutions.

Geographically, North America and Europe have been leading markets for advanced textiles, with Asia-Pacific emerging as a rapidly growing region. The increasing adoption of technical textiles in developing countries, coupled with the presence of major textile manufacturing hubs, is expected to fuel market growth in the Asia-Pacific region.

The COVID-19 pandemic has had a significant impact on the advanced textile market, accelerating the demand for antimicrobial and protective fabrics. This has opened up new avenues for research and development in textile technologies, including potential applications of sodium bisulfate in creating antimicrobial properties.

Market competition in the advanced textile sector is intense, with key players focusing on product innovation and strategic partnerships to gain a competitive edge. The integration of sodium bisulfate in textile production could potentially offer a unique selling proposition for companies looking to differentiate their products in the market.

Challenges in the market include the high cost of advanced textile production and the need for skilled labor. However, these challenges also present opportunities for innovations that can reduce production costs and improve efficiency, areas where sodium bisulfate integration could potentially make a significant impact.

In conclusion, the market analysis for advanced textile products reveals a dynamic and growing sector with ample opportunities for technological innovations. The integration of sodium bisulfate in advanced textile techniques could address several key market demands, including sustainability, performance enhancement, and cost-efficiency, positioning it as a potentially disruptive technology in the textile industry.

Current Challenges in Sodium Bisulfate Application

The integration of sodium bisulfate in advanced textile techniques faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the corrosive nature of sodium bisulfate, which can potentially damage textile fibers and machinery during processing. This corrosivity necessitates the development of specialized equipment and handling procedures, increasing production costs and complexity.

Another challenge lies in achieving uniform distribution of sodium bisulfate within textile materials. Uneven application can lead to inconsistent treatment results, affecting the quality and performance of the final product. This issue is particularly pronounced in large-scale industrial applications, where maintaining uniformity across large batches of textiles becomes increasingly difficult.

The pH sensitivity of sodium bisulfate poses additional complications in textile processing. Fluctuations in pH levels can significantly impact the effectiveness of treatments and potentially alter the desired properties of the textile. Precise control of pH throughout the manufacturing process is crucial but often challenging to maintain consistently.

Environmental concerns also present a significant hurdle in the application of sodium bisulfate. The chemical's acidity can contribute to wastewater pollution if not properly managed, necessitating advanced treatment systems and adherence to strict environmental regulations. This aspect not only increases operational costs but also requires ongoing monitoring and compliance efforts.

The interaction between sodium bisulfate and various textile dyes and finishes is another area of concern. Certain combinations may result in unexpected color changes or alterations in fabric properties, limiting the range of compatible materials and treatments. Extensive testing and formulation adjustments are often required to ensure compatibility and desired outcomes.

Stability and shelf life of sodium bisulfate-treated textiles present ongoing challenges. Long-term exposure to environmental factors such as humidity and temperature fluctuations can potentially degrade the treatment's effectiveness over time. Developing stable formulations that maintain their properties throughout the product lifecycle remains an active area of research and development.

Lastly, the cost-effectiveness of sodium bisulfate integration in advanced textile techniques is a persistent challenge. While the chemical itself is relatively inexpensive, the additional equipment, safety measures, and specialized processes required for its application can significantly increase overall production costs. Balancing these expenses against the benefits gained from sodium bisulfate treatment is crucial for commercial viability.

Another challenge lies in achieving uniform distribution of sodium bisulfate within textile materials. Uneven application can lead to inconsistent treatment results, affecting the quality and performance of the final product. This issue is particularly pronounced in large-scale industrial applications, where maintaining uniformity across large batches of textiles becomes increasingly difficult.

The pH sensitivity of sodium bisulfate poses additional complications in textile processing. Fluctuations in pH levels can significantly impact the effectiveness of treatments and potentially alter the desired properties of the textile. Precise control of pH throughout the manufacturing process is crucial but often challenging to maintain consistently.

Environmental concerns also present a significant hurdle in the application of sodium bisulfate. The chemical's acidity can contribute to wastewater pollution if not properly managed, necessitating advanced treatment systems and adherence to strict environmental regulations. This aspect not only increases operational costs but also requires ongoing monitoring and compliance efforts.

The interaction between sodium bisulfate and various textile dyes and finishes is another area of concern. Certain combinations may result in unexpected color changes or alterations in fabric properties, limiting the range of compatible materials and treatments. Extensive testing and formulation adjustments are often required to ensure compatibility and desired outcomes.

Stability and shelf life of sodium bisulfate-treated textiles present ongoing challenges. Long-term exposure to environmental factors such as humidity and temperature fluctuations can potentially degrade the treatment's effectiveness over time. Developing stable formulations that maintain their properties throughout the product lifecycle remains an active area of research and development.

Lastly, the cost-effectiveness of sodium bisulfate integration in advanced textile techniques is a persistent challenge. While the chemical itself is relatively inexpensive, the additional equipment, safety measures, and specialized processes required for its application can significantly increase overall production costs. Balancing these expenses against the benefits gained from sodium bisulfate treatment is crucial for commercial viability.

Existing Sodium Bisulfate Integration Methods

01 Use of sodium bisulfate in oral care products

Sodium bisulfate is utilized in oral care formulations such as toothpaste, mouthwash, and dental rinses. It acts as a pH adjuster and can help in reducing bacterial growth in the oral cavity. The compound's acidic nature contributes to its effectiveness in maintaining oral hygiene and freshness.- Use of sodium bisulfate in cleaning compositions: Sodium bisulfate is utilized in various cleaning compositions due to its acidic properties. It can be incorporated into formulations for household and industrial cleaning products, providing effective cleaning and descaling capabilities. The compound's ability to lower pH and react with alkaline substances makes it useful for removing mineral deposits and tough stains.

- Application in water treatment processes: Sodium bisulfate finds applications in water treatment processes, particularly for pH adjustment and disinfection. It can be used to lower the pH of water in swimming pools, spas, and industrial water systems. The compound also aids in the removal of chloramines and helps maintain proper water chemistry in various aquatic environments.

- Use as a food additive and preservative: Sodium bisulfate is employed as a food additive and preservative in certain applications. It can be used to control acidity in food products, enhance flavor, and extend shelf life. The compound's ability to inhibit microbial growth makes it valuable in food preservation, particularly in processed foods and beverages.

- Application in agricultural and horticultural products: Sodium bisulfate is utilized in various agricultural and horticultural products. It can be incorporated into fertilizers to adjust soil pH, particularly for acid-loving plants. The compound is also used in animal feed additives to improve nutrient absorption and promote animal health. Additionally, it finds applications in pest control formulations.

- Use in industrial processes and manufacturing: Sodium bisulfate is employed in various industrial processes and manufacturing applications. It can be used as a catalyst or reagent in chemical reactions, as well as in metal treatment and surface preparation. The compound's acidic properties make it useful in processes such as metal etching, electroplating, and pH adjustment in industrial systems.

02 Application in water treatment and purification

Sodium bisulfate is employed in water treatment processes for pH adjustment and as a disinfectant. It can effectively lower the pH of water, making it useful in swimming pool maintenance and industrial water treatment systems. The compound also aids in removing chloramines and other impurities from water.Expand Specific Solutions03 Use as a cleaning and descaling agent

Sodium bisulfate is utilized in various cleaning and descaling applications. Its acidic properties make it effective in removing mineral deposits, rust, and other stubborn stains. It is commonly used in household and industrial cleaning products, particularly for bathroom and kitchen surfaces.Expand Specific Solutions04 Application in food processing and preservation

Sodium bisulfate finds applications in the food industry as a preservative and pH regulator. It can inhibit microbial growth and extend the shelf life of certain food products. The compound is also used in meat processing to control pathogens and improve food safety.Expand Specific Solutions05 Use in agricultural and horticultural applications

Sodium bisulfate is employed in agriculture and horticulture for soil pH adjustment and as a fertilizer additive. It can help in reducing soil alkalinity and improving nutrient uptake by plants. The compound is also used in animal feed additives to enhance digestibility and control pathogens.Expand Specific Solutions

Key Players in Advanced Textile Industry

The research on Sodium Bisulfate Integration in Advanced Textile Techniques is in an emerging phase, with a growing market driven by the textile industry's demand for innovative solutions. The technology's maturity is still developing, as evidenced by ongoing research efforts from key players. Companies like Rohm & Haas Co., BASF Corp., and Henkel AG & Co. KGaA are leveraging their chemical expertise to advance this field. Specialized textile manufacturers such as Porcher Industries SA and Yibin Grace Group Co., Ltd. are also contributing to the technology's evolution. Academic institutions like Politecnico di Milano and The Hong Kong Polytechnic University are providing crucial research support, indicating the technology's potential for further development and application in advanced textile manufacturing processes.

Porcher Industries SA

Technical Solution: Porcher Industries SA has made significant strides in integrating sodium bisulfate into advanced textile techniques, particularly in the field of technical textiles. Their research has led to the development of a sodium bisulfate-based treatment for high-performance fibers, enhancing their flame-retardant properties without compromising strength or flexibility[1]. This innovation has found applications in aerospace and automotive industries. Porcher has also created a sodium bisulfate-infused coating for fabrics used in personal protective equipment, improving their resistance to chemical splashes and spills[3]. Additionally, the company has developed a process using sodium bisulfate to modify the surface of carbon fibers, enhancing their adhesion to polymer matrices in composite materials[5].

Strengths: Enhanced flame-retardant properties, improved chemical resistance for PPE, and better adhesion in composites. Weaknesses: Potential increased production costs and limited applicability to certain types of technical textiles.

Henkel AG & Co. KGaA

Technical Solution: Henkel AG & Co. KGaA has developed a novel approach to incorporating sodium bisulfate in textile processing. Their research focuses on using sodium bisulfate as a pH regulator in textile dyeing and finishing processes, allowing for more precise control of chemical reactions[2]. This has resulted in improved color fastness and reduced water consumption in textile production. Henkel has also pioneered a sodium bisulfate-based treatment for wool that enhances its shrink-resistance properties without compromising the natural feel of the fabric[4]. Furthermore, the company has developed a sodium bisulfate-containing formulation for textile sizing, which improves the weaving efficiency of yarns while being easily removable in subsequent processing steps[6].

Strengths: Improved color fastness, reduced water consumption, enhanced wool properties, and increased weaving efficiency. Weaknesses: Potential for increased chemical handling requirements and the need for careful pH monitoring during processing.

Innovative Approaches in Chemical Textile Processing

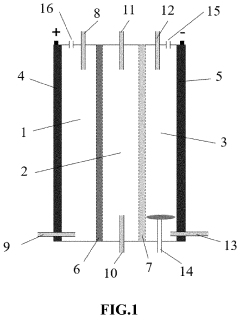

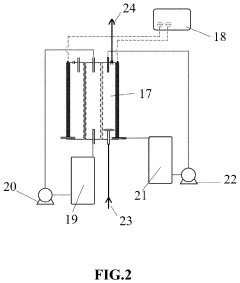

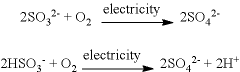

Method and apparatus for capturing carbon dioxide and producing sulfuric acid by sodium bisulfate

PatentActiveUS11230472B2

Innovation

- A three-format electrodialysis apparatus using an anion and cation exchange membrane system to convert sodium bisulfate solutions into sulfuric acid and capture carbon dioxide from flue gas, where sulfate and sulfite ions are selectively transferred to produce acidic substances and alkaline substances, allowing for the simultaneous capture of CO2 and production of sulfuric acid with enhanced value.

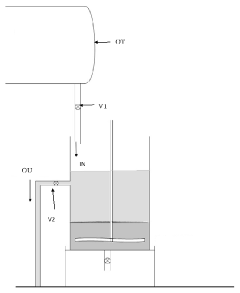

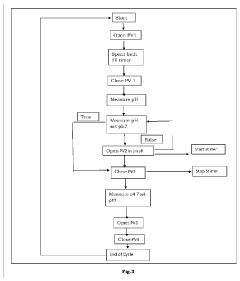

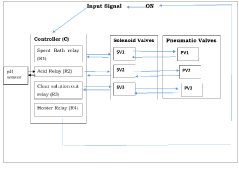

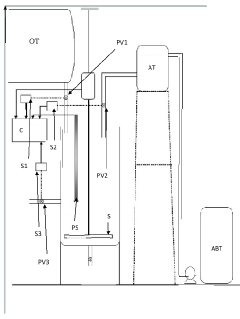

An improved process for textile processing and a system thereof

PatentActiveIN201621035548A

Innovation

- A process that collects and treats the spent bath from polyester weight reduction, converting water-soluble sodium terephthalic acid into insoluble precipitates using strong acids, which are then filtered, dried, and used as fuel, while an automated system controls pH and flow to optimize waste utilization and reduce pollution.

Environmental Impact Assessment

The integration of sodium bisulfate in advanced textile techniques presents significant environmental considerations that must be carefully assessed. This compound, while offering potential benefits in textile processing, also poses challenges in terms of its environmental impact throughout the product lifecycle.

Sodium bisulfate is commonly used in textile manufacturing for pH adjustment, dye fixation, and as a reducing agent. Its application can lead to improved color fastness and fabric quality. However, the environmental implications of its use are multifaceted and require thorough examination.

One primary concern is the potential for water pollution. Textile effluents containing sodium bisulfate can contribute to the acidification of water bodies if not properly treated. This acidification can have detrimental effects on aquatic ecosystems, disrupting the balance of flora and fauna. Additionally, the presence of sulfates in wastewater can lead to the formation of hydrogen sulfide, a toxic gas, under anaerobic conditions.

The production and transportation of sodium bisulfate also contribute to the overall environmental footprint of textile manufacturing. The energy-intensive processes involved in its synthesis, coupled with the emissions from transportation, add to the carbon footprint of the textile industry. This aspect necessitates a life cycle assessment to fully understand the compound's environmental impact from cradle to grave.

Waste management is another critical area of concern. Residual sodium bisulfate in textile waste can pose challenges for disposal and recycling efforts. Improper handling or disposal can lead to soil contamination and potentially affect groundwater quality. Therefore, developing effective waste treatment and recycling protocols is essential for mitigating these risks.

On the positive side, the use of sodium bisulfate in advanced textile techniques may offer some environmental benefits. Its efficiency in dye fixation can potentially reduce water consumption and the need for additional chemical treatments. This could lead to a decrease in overall water usage and chemical discharge from textile manufacturing processes.

Furthermore, the compound's role in improving fabric quality and durability may contribute to the longevity of textile products. Longer-lasting textiles could potentially reduce the demand for new products, thereby decreasing the overall environmental impact associated with textile production and disposal.

To fully assess the environmental impact of sodium bisulfate integration, it is crucial to conduct comprehensive studies that consider both direct and indirect effects. This includes evaluating its impact on water and soil quality, air emissions, energy consumption, and potential for bioaccumulation in ecosystems. Additionally, comparing its environmental profile with alternative compounds or techniques is essential for making informed decisions in textile manufacturing.

Sodium bisulfate is commonly used in textile manufacturing for pH adjustment, dye fixation, and as a reducing agent. Its application can lead to improved color fastness and fabric quality. However, the environmental implications of its use are multifaceted and require thorough examination.

One primary concern is the potential for water pollution. Textile effluents containing sodium bisulfate can contribute to the acidification of water bodies if not properly treated. This acidification can have detrimental effects on aquatic ecosystems, disrupting the balance of flora and fauna. Additionally, the presence of sulfates in wastewater can lead to the formation of hydrogen sulfide, a toxic gas, under anaerobic conditions.

The production and transportation of sodium bisulfate also contribute to the overall environmental footprint of textile manufacturing. The energy-intensive processes involved in its synthesis, coupled with the emissions from transportation, add to the carbon footprint of the textile industry. This aspect necessitates a life cycle assessment to fully understand the compound's environmental impact from cradle to grave.

Waste management is another critical area of concern. Residual sodium bisulfate in textile waste can pose challenges for disposal and recycling efforts. Improper handling or disposal can lead to soil contamination and potentially affect groundwater quality. Therefore, developing effective waste treatment and recycling protocols is essential for mitigating these risks.

On the positive side, the use of sodium bisulfate in advanced textile techniques may offer some environmental benefits. Its efficiency in dye fixation can potentially reduce water consumption and the need for additional chemical treatments. This could lead to a decrease in overall water usage and chemical discharge from textile manufacturing processes.

Furthermore, the compound's role in improving fabric quality and durability may contribute to the longevity of textile products. Longer-lasting textiles could potentially reduce the demand for new products, thereby decreasing the overall environmental impact associated with textile production and disposal.

To fully assess the environmental impact of sodium bisulfate integration, it is crucial to conduct comprehensive studies that consider both direct and indirect effects. This includes evaluating its impact on water and soil quality, air emissions, energy consumption, and potential for bioaccumulation in ecosystems. Additionally, comparing its environmental profile with alternative compounds or techniques is essential for making informed decisions in textile manufacturing.

Regulatory Compliance in Textile Chemistry

The integration of sodium bisulfate in advanced textile techniques necessitates a thorough understanding of regulatory compliance in textile chemistry. Manufacturers and researchers must adhere to strict guidelines to ensure the safety and quality of textile products. The regulatory landscape for sodium bisulfate usage in textiles is complex and varies across different regions and countries.

In the United States, the Environmental Protection Agency (EPA) regulates the use of sodium bisulfate under the Toxic Substances Control Act (TSCA). The Food and Drug Administration (FDA) also oversees its application in textiles that may come into contact with food or skin. Manufacturers must comply with the FDA's regulations on chemical substances in textiles, ensuring that the use of sodium bisulfate does not pose any health risks to consumers.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of sodium bisulfate in textile production. Under REACH, manufacturers must register chemicals used in their products and provide safety data. The EU also enforces specific limits on the presence of certain chemicals in textiles through the OEKO-TEX® Standard 100, which sets strict requirements for harmful substances in textile products.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards (Guobiao standards) include specific requirements for textile chemicals, while Japan follows the Japan Textile Federation's voluntary standards for chemical use in textiles. These regulations often align with international standards but may have additional local requirements.

Compliance with these regulations requires extensive documentation and testing. Manufacturers must maintain detailed records of chemical usage, conduct regular quality control tests, and obtain necessary certifications. For sodium bisulfate integration, this may include providing Material Safety Data Sheets (MSDS), conducting toxicity assessments, and ensuring proper labeling of products.

The textile industry is increasingly moving towards sustainable and eco-friendly practices. This trend has led to the development of voluntary standards and certifications that go beyond regulatory requirements. Examples include the Global Organic Textile Standard (GOTS) and the ZDHC (Zero Discharge of Hazardous Chemicals) programme, which set stringent criteria for chemical use in textiles.

Researchers and manufacturers exploring sodium bisulfate integration must also consider potential future regulatory changes. As environmental and health concerns continue to shape policy, it is likely that regulations will become more stringent. Staying informed about proposed changes and participating in industry discussions can help companies prepare for future compliance requirements.

In the United States, the Environmental Protection Agency (EPA) regulates the use of sodium bisulfate under the Toxic Substances Control Act (TSCA). The Food and Drug Administration (FDA) also oversees its application in textiles that may come into contact with food or skin. Manufacturers must comply with the FDA's regulations on chemical substances in textiles, ensuring that the use of sodium bisulfate does not pose any health risks to consumers.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of sodium bisulfate in textile production. Under REACH, manufacturers must register chemicals used in their products and provide safety data. The EU also enforces specific limits on the presence of certain chemicals in textiles through the OEKO-TEX® Standard 100, which sets strict requirements for harmful substances in textile products.

In Asia, countries like China and Japan have their own regulatory frameworks. China's GB standards (Guobiao standards) include specific requirements for textile chemicals, while Japan follows the Japan Textile Federation's voluntary standards for chemical use in textiles. These regulations often align with international standards but may have additional local requirements.

Compliance with these regulations requires extensive documentation and testing. Manufacturers must maintain detailed records of chemical usage, conduct regular quality control tests, and obtain necessary certifications. For sodium bisulfate integration, this may include providing Material Safety Data Sheets (MSDS), conducting toxicity assessments, and ensuring proper labeling of products.

The textile industry is increasingly moving towards sustainable and eco-friendly practices. This trend has led to the development of voluntary standards and certifications that go beyond regulatory requirements. Examples include the Global Organic Textile Standard (GOTS) and the ZDHC (Zero Discharge of Hazardous Chemicals) programme, which set stringent criteria for chemical use in textiles.

Researchers and manufacturers exploring sodium bisulfate integration must also consider potential future regulatory changes. As environmental and health concerns continue to shape policy, it is likely that regulations will become more stringent. Staying informed about proposed changes and participating in industry discussions can help companies prepare for future compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!