Solenoid Valve Control Systems in Advanced Gas Sensor Applications

JUL 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Control Background and Objectives

Solenoid valve control systems have played a crucial role in the development and advancement of gas sensor applications. These systems have evolved significantly over the past few decades, driven by the increasing demand for precise and reliable gas detection across various industries. The primary objective of solenoid valve control in gas sensor applications is to regulate gas flow accurately, ensuring optimal sensor performance and measurement accuracy.

The evolution of solenoid valve control systems can be traced back to the early days of industrial automation. Initially, these systems were primarily mechanical, with limited control capabilities. As technology progressed, the integration of electronic components and microcontrollers revolutionized solenoid valve control, enabling more sophisticated and responsive systems. This technological advancement has been particularly beneficial for gas sensor applications, where precise control of gas flow is critical for accurate measurements.

In recent years, the focus has shifted towards developing advanced solenoid valve control systems that can meet the demanding requirements of modern gas sensing technologies. These systems aim to achieve faster response times, improved reliability, and enhanced energy efficiency. The integration of smart technologies, such as IoT connectivity and machine learning algorithms, has further expanded the capabilities of solenoid valve control systems in gas sensor applications.

One of the key objectives in the field of solenoid valve control for gas sensors is to minimize response time and improve overall system performance. This is particularly important in applications where rapid detection of gas concentrations is critical, such as in industrial safety systems or environmental monitoring. Researchers and engineers are continuously working on developing innovative control algorithms and hardware designs to achieve these goals.

Another important objective is to enhance the adaptability and versatility of solenoid valve control systems. As gas sensor applications become more diverse and complex, there is a growing need for control systems that can operate effectively across a wide range of environmental conditions and gas types. This includes the ability to handle different pressure ranges, flow rates, and gas compositions without compromising accuracy or reliability.

Energy efficiency and sustainability have also emerged as significant objectives in the development of solenoid valve control systems for gas sensors. With increasing emphasis on reducing energy consumption and environmental impact, researchers are exploring ways to optimize power usage in these systems without sacrificing performance. This includes the development of low-power control circuits and energy-harvesting technologies to extend the operational life of battery-powered gas sensing devices.

As we look towards the future, the objectives for solenoid valve control in advanced gas sensor applications continue to evolve. There is a growing focus on developing more compact and integrated solutions that can be easily deployed in various settings, from industrial environments to portable devices. Additionally, the integration of advanced diagnostic and predictive maintenance capabilities is becoming increasingly important to ensure long-term reliability and reduce downtime in critical gas sensing applications.

The evolution of solenoid valve control systems can be traced back to the early days of industrial automation. Initially, these systems were primarily mechanical, with limited control capabilities. As technology progressed, the integration of electronic components and microcontrollers revolutionized solenoid valve control, enabling more sophisticated and responsive systems. This technological advancement has been particularly beneficial for gas sensor applications, where precise control of gas flow is critical for accurate measurements.

In recent years, the focus has shifted towards developing advanced solenoid valve control systems that can meet the demanding requirements of modern gas sensing technologies. These systems aim to achieve faster response times, improved reliability, and enhanced energy efficiency. The integration of smart technologies, such as IoT connectivity and machine learning algorithms, has further expanded the capabilities of solenoid valve control systems in gas sensor applications.

One of the key objectives in the field of solenoid valve control for gas sensors is to minimize response time and improve overall system performance. This is particularly important in applications where rapid detection of gas concentrations is critical, such as in industrial safety systems or environmental monitoring. Researchers and engineers are continuously working on developing innovative control algorithms and hardware designs to achieve these goals.

Another important objective is to enhance the adaptability and versatility of solenoid valve control systems. As gas sensor applications become more diverse and complex, there is a growing need for control systems that can operate effectively across a wide range of environmental conditions and gas types. This includes the ability to handle different pressure ranges, flow rates, and gas compositions without compromising accuracy or reliability.

Energy efficiency and sustainability have also emerged as significant objectives in the development of solenoid valve control systems for gas sensors. With increasing emphasis on reducing energy consumption and environmental impact, researchers are exploring ways to optimize power usage in these systems without sacrificing performance. This includes the development of low-power control circuits and energy-harvesting technologies to extend the operational life of battery-powered gas sensing devices.

As we look towards the future, the objectives for solenoid valve control in advanced gas sensor applications continue to evolve. There is a growing focus on developing more compact and integrated solutions that can be easily deployed in various settings, from industrial environments to portable devices. Additionally, the integration of advanced diagnostic and predictive maintenance capabilities is becoming increasingly important to ensure long-term reliability and reduce downtime in critical gas sensing applications.

Gas Sensor Market Demand Analysis

The global gas sensor market has been experiencing significant growth, driven by increasing awareness of environmental safety, stringent government regulations, and the rising demand for air quality monitoring in both industrial and residential sectors. Advanced gas sensor applications, particularly those utilizing solenoid valve control systems, are at the forefront of this market expansion.

In the industrial sector, there is a growing need for precise and reliable gas detection systems to ensure workplace safety and compliance with environmental regulations. Industries such as oil and gas, chemical manufacturing, and mining are major contributors to this demand. These sectors require advanced gas sensors with solenoid valve control systems to detect and manage potentially hazardous gas leaks, monitor air quality in confined spaces, and maintain optimal process conditions.

The automotive industry is another key driver of gas sensor market growth. With the increasing focus on reducing vehicle emissions and improving fuel efficiency, there is a rising demand for advanced gas sensors in engine management systems. Solenoid valve control systems play a crucial role in these applications, enabling precise control of fuel injection and exhaust gas recirculation.

In the residential and commercial building sector, the demand for gas sensors is being fueled by the growing emphasis on indoor air quality and smart home technologies. Advanced gas sensors with solenoid valve control systems are being integrated into HVAC systems and smart home devices to monitor and regulate indoor air quality, detect potential gas leaks, and optimize energy consumption.

The healthcare sector is emerging as a significant market for advanced gas sensors. Applications include breath analysis for disease diagnosis, monitoring anesthetic gases in operating rooms, and ensuring air quality in hospitals and laboratories. Solenoid valve control systems in these applications enable precise gas sampling and analysis, contributing to improved diagnostic accuracy and patient safety.

Environmental monitoring is another area driving market demand. Government agencies and environmental organizations are increasingly deploying advanced gas sensor networks to monitor air quality in urban areas, industrial zones, and natural environments. These systems often incorporate solenoid valve control mechanisms for automated and precise gas sampling and analysis.

The market for portable and wearable gas sensors is also expanding rapidly. These devices, often equipped with miniaturized solenoid valve systems, are finding applications in personal safety equipment for workers in hazardous environments, as well as in consumer products for health and wellness monitoring.

As the Internet of Things (IoT) and Industry 4.0 concepts continue to evolve, there is a growing trend towards connected and intelligent gas sensing systems. This is creating new opportunities for advanced gas sensors with integrated solenoid valve control systems that can provide real-time data, remote monitoring capabilities, and predictive maintenance features.

In the industrial sector, there is a growing need for precise and reliable gas detection systems to ensure workplace safety and compliance with environmental regulations. Industries such as oil and gas, chemical manufacturing, and mining are major contributors to this demand. These sectors require advanced gas sensors with solenoid valve control systems to detect and manage potentially hazardous gas leaks, monitor air quality in confined spaces, and maintain optimal process conditions.

The automotive industry is another key driver of gas sensor market growth. With the increasing focus on reducing vehicle emissions and improving fuel efficiency, there is a rising demand for advanced gas sensors in engine management systems. Solenoid valve control systems play a crucial role in these applications, enabling precise control of fuel injection and exhaust gas recirculation.

In the residential and commercial building sector, the demand for gas sensors is being fueled by the growing emphasis on indoor air quality and smart home technologies. Advanced gas sensors with solenoid valve control systems are being integrated into HVAC systems and smart home devices to monitor and regulate indoor air quality, detect potential gas leaks, and optimize energy consumption.

The healthcare sector is emerging as a significant market for advanced gas sensors. Applications include breath analysis for disease diagnosis, monitoring anesthetic gases in operating rooms, and ensuring air quality in hospitals and laboratories. Solenoid valve control systems in these applications enable precise gas sampling and analysis, contributing to improved diagnostic accuracy and patient safety.

Environmental monitoring is another area driving market demand. Government agencies and environmental organizations are increasingly deploying advanced gas sensor networks to monitor air quality in urban areas, industrial zones, and natural environments. These systems often incorporate solenoid valve control mechanisms for automated and precise gas sampling and analysis.

The market for portable and wearable gas sensors is also expanding rapidly. These devices, often equipped with miniaturized solenoid valve systems, are finding applications in personal safety equipment for workers in hazardous environments, as well as in consumer products for health and wellness monitoring.

As the Internet of Things (IoT) and Industry 4.0 concepts continue to evolve, there is a growing trend towards connected and intelligent gas sensing systems. This is creating new opportunities for advanced gas sensors with integrated solenoid valve control systems that can provide real-time data, remote monitoring capabilities, and predictive maintenance features.

Current Challenges in Solenoid Valve Control

Solenoid valve control systems in advanced gas sensor applications face several significant challenges that hinder their optimal performance and reliability. One of the primary issues is the precision and speed of valve actuation. As gas sensors become more sophisticated, requiring rapid and accurate gas flow control, traditional solenoid valve systems often struggle to meet these demanding requirements. The response time of conventional solenoids may not be sufficient for high-frequency gas sampling or quick gas mixture adjustments, leading to potential inaccuracies in sensor readings.

Another critical challenge lies in the power consumption and heat generation of solenoid valves. In many advanced gas sensing applications, particularly in portable or battery-operated devices, energy efficiency is paramount. Conventional solenoid valves tend to consume substantial power during operation, which not only reduces battery life but also generates excess heat. This heat can interfere with sensitive gas sensors, potentially skewing measurements or reducing overall system reliability.

Miniaturization presents yet another hurdle for solenoid valve control systems. As gas sensors and their associated equipment become more compact, there is a growing demand for smaller, lighter valve systems. However, reducing the size of solenoid valves while maintaining their performance characteristics proves to be a complex engineering task. Smaller valves may suffer from reduced flow rates, increased susceptibility to clogging, or diminished durability, all of which can compromise the effectiveness of gas sensing applications.

The issue of valve wear and maintenance also poses significant challenges. Solenoid valves in gas sensor systems often operate under demanding conditions, including exposure to various gases, high cycling rates, and potentially corrosive environments. Over time, this can lead to wear on valve components, affecting their sealing properties and overall performance. The need for regular maintenance and replacement of valve parts can increase the operational costs and downtime of gas sensing equipment.

Furthermore, the integration of solenoid valve control systems with advanced digital interfaces and smart sensing technologies presents its own set of challenges. Many modern gas sensing applications require seamless communication between valve controllers and data acquisition systems. Developing robust, responsive control algorithms that can adapt to varying gas flow requirements while maintaining system stability is a complex task. Additionally, ensuring compatibility with various communication protocols and sensor feedback mechanisms adds another layer of complexity to the design of effective solenoid valve control systems.

Lastly, environmental factors such as temperature fluctuations, vibrations, and electromagnetic interference can significantly impact the performance of solenoid valve control systems in gas sensing applications. Designing valve systems that can maintain consistent operation across a wide range of environmental conditions, while still meeting the precision requirements of advanced gas sensors, remains a considerable engineering challenge.

Another critical challenge lies in the power consumption and heat generation of solenoid valves. In many advanced gas sensing applications, particularly in portable or battery-operated devices, energy efficiency is paramount. Conventional solenoid valves tend to consume substantial power during operation, which not only reduces battery life but also generates excess heat. This heat can interfere with sensitive gas sensors, potentially skewing measurements or reducing overall system reliability.

Miniaturization presents yet another hurdle for solenoid valve control systems. As gas sensors and their associated equipment become more compact, there is a growing demand for smaller, lighter valve systems. However, reducing the size of solenoid valves while maintaining their performance characteristics proves to be a complex engineering task. Smaller valves may suffer from reduced flow rates, increased susceptibility to clogging, or diminished durability, all of which can compromise the effectiveness of gas sensing applications.

The issue of valve wear and maintenance also poses significant challenges. Solenoid valves in gas sensor systems often operate under demanding conditions, including exposure to various gases, high cycling rates, and potentially corrosive environments. Over time, this can lead to wear on valve components, affecting their sealing properties and overall performance. The need for regular maintenance and replacement of valve parts can increase the operational costs and downtime of gas sensing equipment.

Furthermore, the integration of solenoid valve control systems with advanced digital interfaces and smart sensing technologies presents its own set of challenges. Many modern gas sensing applications require seamless communication between valve controllers and data acquisition systems. Developing robust, responsive control algorithms that can adapt to varying gas flow requirements while maintaining system stability is a complex task. Additionally, ensuring compatibility with various communication protocols and sensor feedback mechanisms adds another layer of complexity to the design of effective solenoid valve control systems.

Lastly, environmental factors such as temperature fluctuations, vibrations, and electromagnetic interference can significantly impact the performance of solenoid valve control systems in gas sensing applications. Designing valve systems that can maintain consistent operation across a wide range of environmental conditions, while still meeting the precision requirements of advanced gas sensors, remains a considerable engineering challenge.

Existing Solenoid Valve Control Solutions

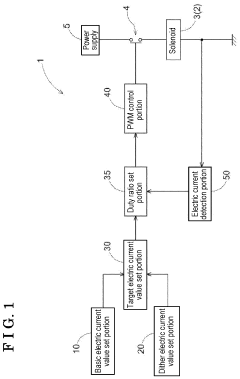

01 Electronic control systems for solenoid valves

Advanced electronic control systems are used to manage solenoid valve operations. These systems often incorporate microprocessors or programmable logic controllers (PLCs) to provide precise timing, sequencing, and modulation of valve actuation. They can offer features such as pulse width modulation (PWM) for fine control of fluid flow, diagnostics for valve health monitoring, and integration with broader automation systems.- Electronic control systems for solenoid valves: Advanced electronic control systems are used to regulate solenoid valve operations. These systems often incorporate microcontrollers or programmable logic controllers (PLCs) to provide precise timing, sequencing, and modulation of valve actuation. They can offer features such as pulse width modulation (PWM) for fine control of fluid flow, diagnostics for valve health monitoring, and integration with broader automation systems.

- Hydraulic and pneumatic solenoid valve control: Specialized control systems are designed for hydraulic and pneumatic applications using solenoid valves. These systems often include pressure sensors, flow meters, and feedback mechanisms to ensure accurate control of fluid power systems. They may incorporate proportional control techniques to achieve variable flow rates and pressures, enhancing system efficiency and performance in industrial and mobile equipment.

- Fail-safe and redundancy in solenoid valve control: Control systems for critical applications incorporate fail-safe mechanisms and redundancy to ensure reliable operation of solenoid valves. These may include dual-channel architectures, watchdog timers, and self-diagnostic routines. In the event of a system failure, the control system can automatically switch to a backup mode or safely shut down the valve to prevent hazardous conditions.

- Energy-efficient solenoid valve control strategies: Innovative control strategies are developed to minimize energy consumption in solenoid valve systems. These may include adaptive control algorithms that optimize valve timing and reduce hold-in current, as well as energy harvesting techniques to power low-energy valve actuators. Such systems can significantly reduce power requirements in battery-operated or energy-constrained applications.

- Network-integrated solenoid valve control systems: Modern solenoid valve control systems are designed to integrate with industrial networks and IoT platforms. These systems enable remote monitoring, control, and configuration of valve operations through protocols such as Modbus, PROFINET, or OPC UA. They facilitate predictive maintenance, real-time process optimization, and seamless integration with higher-level control and management systems in smart manufacturing environments.

02 Hydraulic and pneumatic solenoid valve control

Specialized control systems are designed for hydraulic and pneumatic applications using solenoid valves. These systems often include pressure sensors, flow regulators, and feedback mechanisms to ensure accurate control of fluid or gas flow. They may incorporate proportional control techniques to achieve variable flow rates and pressures, enhancing system efficiency and responsiveness in applications such as industrial machinery and automotive systems.Expand Specific Solutions03 Fail-safe and redundancy in solenoid valve control

Control systems for critical applications incorporate fail-safe mechanisms and redundancy to ensure reliable operation of solenoid valves. These may include dual-channel control circuits, watchdog timers, and self-diagnostic features. In the event of a system failure, the control system can automatically switch to a backup mode or safely shut down the valve to prevent hazardous conditions.Expand Specific Solutions04 Energy-efficient solenoid valve control

Modern control systems focus on optimizing energy consumption in solenoid valve operation. Techniques such as power-saving modes, adaptive control algorithms, and energy harvesting are employed to reduce power requirements. These systems may use intelligent switching strategies to minimize hold-in current and heat generation, extending valve life and improving overall system efficiency.Expand Specific Solutions05 Networked and IoT-enabled solenoid valve control

Advanced control systems integrate solenoid valves into networked and Internet of Things (IoT) environments. These systems enable remote monitoring, control, and data logging of valve operations. They often utilize industrial communication protocols for seamless integration with SCADA systems and cloud-based platforms, allowing for predictive maintenance, real-time adjustments, and data-driven optimization of valve performance across multiple locations.Expand Specific Solutions

Key Players in Gas Sensor Industry

The research on solenoid valve control systems in advanced gas sensor applications is in a growth phase, with increasing market size driven by demand for precise gas detection across industries. The global market for gas sensors is projected to reach $1.5 billion by 2025, with a CAGR of 7.8%. Technologically, the field is advancing rapidly, with companies like Eaton Corp., Robert Bosch GmbH, and Air Liquide SA leading innovation. These firms are developing more sophisticated, miniaturized, and energy-efficient solenoid valve control systems, integrating IoT and AI capabilities for enhanced performance and reliability in gas sensing applications. The competitive landscape is characterized by a mix of established industrial giants and specialized sensor technology firms, fostering a dynamic environment for technological advancements.

Eaton Corp.

Technical Solution: Eaton has developed innovative solenoid valve control systems for gas sensor applications, with a focus on energy efficiency and reliability. Their technology utilizes low-power solenoids coupled with advanced power management circuits to reduce overall energy consumption. Eaton's system incorporates a unique "soft-switching" technique that minimizes electromagnetic interference and extends valve life [8]. The company has also implemented a digital twin approach for their valve control systems, allowing for real-time monitoring and predictive maintenance [10]. Eaton's solution includes a proprietary valve position sensing technology that provides high-resolution feedback, enabling more precise control in gas sensing applications [12].

Strengths: Energy-efficient design, reduced electromagnetic interference, digital twin capabilities for monitoring. Weaknesses: May have limited customization options for specialized applications, potential dependency on proprietary components.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valve control systems for gas sensor applications, focusing on precision and reliability. Their technology utilizes a combination of high-performance microcontrollers and custom-designed solenoid drivers to achieve accurate gas flow control. The system incorporates adaptive control algorithms that compensate for environmental variations and valve wear, ensuring consistent performance over time [1]. Bosch's solution also features integrated diagnostics and predictive maintenance capabilities, which can detect potential issues before they lead to system failures [3]. The company has implemented this technology in various applications, including automotive emission control systems and industrial gas analyzers, demonstrating its versatility and scalability [5].

Strengths: High precision control, adaptive algorithms for consistent performance, integrated diagnostics. Weaknesses: Potentially higher cost due to advanced features, may require specialized maintenance.

Core Innovations in Valve Control Systems

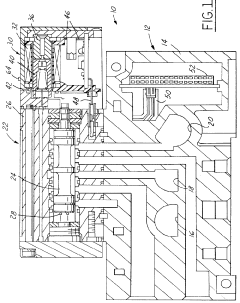

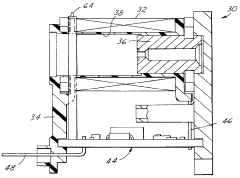

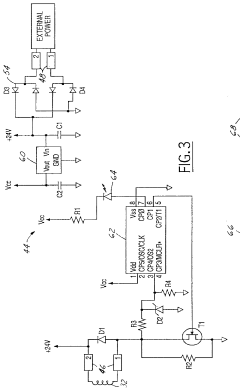

Solenoid valve control system

PatentInactiveUS6164323A

Innovation

- A solenoid valve assembly with embedded microprocessor-based control circuitry and a unitary molded or potted assembly, featuring a microprocessor that monitors solenoid coil conditions, reduces power consumption and operating temperature by applying power at a reduced duty cycle, and includes an LED indicator for coil failures, integrating the solenoid and control circuitry as a single, sealed unit.

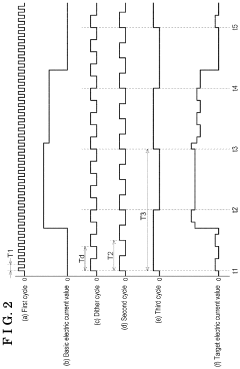

Solenoid valve control apparatus and control method of solenoid valve

PatentInactiveUS20200133312A1

Innovation

- A solenoid valve control apparatus that sets a basic electric current value, a dither electric current value, and a target electric current value, with a duty ratio set based on actual current values, allowing for PWM control with reduced calculation frequency and maintaining effective dithering without the need for high-performance calculation.

Environmental Impact of Gas Sensors

The environmental impact of gas sensors, particularly those utilizing solenoid valve control systems, is a critical consideration in their development and deployment. These advanced sensing technologies play a crucial role in monitoring and controlling various gases, which can have significant implications for environmental protection and sustainability.

Solenoid valve-controlled gas sensors contribute to environmental conservation by enabling precise detection and measurement of harmful gases. This capability is essential for early warning systems in industrial settings, where toxic or greenhouse gas emissions can be quickly identified and mitigated. By facilitating rapid response to gas leaks or excessive emissions, these sensors help prevent potential environmental disasters and reduce the overall carbon footprint of industrial operations.

The use of solenoid valve control systems in gas sensors also promotes energy efficiency. These systems allow for more accurate and responsive gas flow control, which can lead to optimized combustion processes in various applications. This optimization results in reduced fuel consumption and lower emissions of pollutants such as carbon dioxide, nitrogen oxides, and particulate matter.

In the context of air quality monitoring, advanced gas sensors equipped with solenoid valve controls provide real-time data on atmospheric pollutants. This information is crucial for environmental agencies and policymakers to implement effective measures for improving air quality in urban areas. The high precision and reliability of these sensors enable more accurate modeling of air pollution patterns, leading to better-informed decisions on emission control strategies.

However, the environmental impact of gas sensors extends beyond their operational benefits. The manufacturing process of these devices, including the production of solenoid valves and electronic components, can have negative environmental consequences. The extraction of raw materials, energy consumption during production, and potential electronic waste at the end of the sensor's lifecycle are important factors to consider.

To address these concerns, manufacturers are increasingly focusing on sustainable production methods and materials for gas sensors and their components. This includes the use of recycled materials, energy-efficient manufacturing processes, and designing for recyclability. Additionally, efforts are being made to extend the lifespan of gas sensors and their control systems, reducing the frequency of replacement and associated waste.

The integration of solenoid valve control systems in gas sensors also contributes to the development of smart cities and intelligent environmental monitoring networks. These advanced sensors can be interconnected, forming a comprehensive system for tracking and analyzing environmental data across large areas. This networked approach enhances our understanding of environmental dynamics and supports more effective conservation strategies.

Solenoid valve-controlled gas sensors contribute to environmental conservation by enabling precise detection and measurement of harmful gases. This capability is essential for early warning systems in industrial settings, where toxic or greenhouse gas emissions can be quickly identified and mitigated. By facilitating rapid response to gas leaks or excessive emissions, these sensors help prevent potential environmental disasters and reduce the overall carbon footprint of industrial operations.

The use of solenoid valve control systems in gas sensors also promotes energy efficiency. These systems allow for more accurate and responsive gas flow control, which can lead to optimized combustion processes in various applications. This optimization results in reduced fuel consumption and lower emissions of pollutants such as carbon dioxide, nitrogen oxides, and particulate matter.

In the context of air quality monitoring, advanced gas sensors equipped with solenoid valve controls provide real-time data on atmospheric pollutants. This information is crucial for environmental agencies and policymakers to implement effective measures for improving air quality in urban areas. The high precision and reliability of these sensors enable more accurate modeling of air pollution patterns, leading to better-informed decisions on emission control strategies.

However, the environmental impact of gas sensors extends beyond their operational benefits. The manufacturing process of these devices, including the production of solenoid valves and electronic components, can have negative environmental consequences. The extraction of raw materials, energy consumption during production, and potential electronic waste at the end of the sensor's lifecycle are important factors to consider.

To address these concerns, manufacturers are increasingly focusing on sustainable production methods and materials for gas sensors and their components. This includes the use of recycled materials, energy-efficient manufacturing processes, and designing for recyclability. Additionally, efforts are being made to extend the lifespan of gas sensors and their control systems, reducing the frequency of replacement and associated waste.

The integration of solenoid valve control systems in gas sensors also contributes to the development of smart cities and intelligent environmental monitoring networks. These advanced sensors can be interconnected, forming a comprehensive system for tracking and analyzing environmental data across large areas. This networked approach enhances our understanding of environmental dynamics and supports more effective conservation strategies.

Regulatory Framework for Gas Sensing Technologies

The regulatory framework for gas sensing technologies plays a crucial role in ensuring the safety, reliability, and effectiveness of advanced gas sensor applications, including those utilizing solenoid valve control systems. This framework encompasses a complex network of standards, guidelines, and regulations set forth by various national and international bodies.

At the forefront of these regulatory efforts are organizations such as the International Organization for Standardization (ISO), which has developed several standards relevant to gas detection and measurement. These include ISO 26142 for hydrogen detection apparatus and ISO 7240-8 for point-type fire detectors using carbon monoxide sensors. These standards provide manufacturers and end-users with clear specifications for performance, testing, and calibration of gas sensing devices.

In the United States, the Occupational Safety and Health Administration (OSHA) has established regulations for gas detection in workplace environments. OSHA's standards outline the permissible exposure limits (PELs) for various gases and vapors, as well as requirements for monitoring and alarm systems. The National Institute for Occupational Safety and Health (NIOSH) complements OSHA's efforts by conducting research and providing recommendations for gas detection practices.

The European Union has implemented the ATEX Directive (2014/34/EU) for equipment and protective systems intended for use in potentially explosive atmospheres. This directive is particularly relevant for gas sensors and associated control systems used in hazardous environments. Additionally, the EU's Measuring Instruments Directive (MID) 2014/32/EU sets requirements for gas meters and other measuring devices used in commercial transactions.

Specific to solenoid valve control systems in gas sensing applications, regulatory bodies often focus on the reliability and fail-safe operation of these components. The IEC 60079 series of standards, for instance, provides guidelines for electrical equipment in explosive atmospheres, which is applicable to solenoid valves used in gas detection systems.

Environmental protection agencies also contribute to the regulatory landscape. The U.S. Environmental Protection Agency (EPA) has established regulations for continuous emission monitoring systems (CEMS) under the Clean Air Act, which often incorporate advanced gas sensing technologies.

As the field of gas sensing continues to evolve, regulatory frameworks are adapting to address emerging technologies and applications. For instance, the development of miniaturized and integrated gas sensor systems has prompted discussions on new standards for wearable and portable gas detectors. Similarly, the increasing use of wireless communication in gas sensing networks has led to considerations of cybersecurity regulations to protect these critical systems from potential threats.

At the forefront of these regulatory efforts are organizations such as the International Organization for Standardization (ISO), which has developed several standards relevant to gas detection and measurement. These include ISO 26142 for hydrogen detection apparatus and ISO 7240-8 for point-type fire detectors using carbon monoxide sensors. These standards provide manufacturers and end-users with clear specifications for performance, testing, and calibration of gas sensing devices.

In the United States, the Occupational Safety and Health Administration (OSHA) has established regulations for gas detection in workplace environments. OSHA's standards outline the permissible exposure limits (PELs) for various gases and vapors, as well as requirements for monitoring and alarm systems. The National Institute for Occupational Safety and Health (NIOSH) complements OSHA's efforts by conducting research and providing recommendations for gas detection practices.

The European Union has implemented the ATEX Directive (2014/34/EU) for equipment and protective systems intended for use in potentially explosive atmospheres. This directive is particularly relevant for gas sensors and associated control systems used in hazardous environments. Additionally, the EU's Measuring Instruments Directive (MID) 2014/32/EU sets requirements for gas meters and other measuring devices used in commercial transactions.

Specific to solenoid valve control systems in gas sensing applications, regulatory bodies often focus on the reliability and fail-safe operation of these components. The IEC 60079 series of standards, for instance, provides guidelines for electrical equipment in explosive atmospheres, which is applicable to solenoid valves used in gas detection systems.

Environmental protection agencies also contribute to the regulatory landscape. The U.S. Environmental Protection Agency (EPA) has established regulations for continuous emission monitoring systems (CEMS) under the Clean Air Act, which often incorporate advanced gas sensing technologies.

As the field of gas sensing continues to evolve, regulatory frameworks are adapting to address emerging technologies and applications. For instance, the development of miniaturized and integrated gas sensor systems has prompted discussions on new standards for wearable and portable gas detectors. Similarly, the increasing use of wireless communication in gas sensing networks has led to considerations of cybersecurity regulations to protect these critical systems from potential threats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!