Solenoid Valve Use in Controlling Liquid Metal Flows

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal Flow Control Background and Objectives

Liquid metal flow control has emerged as a critical area of research and development in recent years, driven by the unique properties of liquid metals and their potential applications across various industries. The evolution of this technology can be traced back to the early 20th century, with significant advancements occurring in the past few decades. Liquid metals, such as gallium and its alloys, possess remarkable characteristics including high electrical and thermal conductivity, low melting points, and the ability to maintain liquid state at room temperature.

The primary objective of liquid metal flow control research is to develop precise and efficient methods for manipulating these materials in various systems and devices. This encompasses a wide range of applications, from microfluidics and soft robotics to thermal management and flexible electronics. As the field progresses, researchers aim to overcome challenges related to oxidation, wettability, and precise control mechanisms.

One of the key technological trends in liquid metal flow control is the integration of solenoid valves. These electromagnetic devices offer a promising solution for achieving accurate and responsive control over liquid metal movements. Solenoid valves provide the ability to rapidly switch and regulate flow, making them ideal for applications requiring dynamic and precise manipulation of liquid metals.

The development of liquid metal flow control technology is driven by several factors, including the growing demand for flexible and reconfigurable electronic systems, advancements in soft robotics, and the need for innovative thermal management solutions in various industries. As research in this field continues to evolve, it is expected to enable new possibilities in areas such as adaptive antennas, self-healing circuits, and shape-morphing structures.

The objectives of current research on solenoid valve use in controlling liquid metal flows are multifaceted. Firstly, there is a focus on improving the precision and responsiveness of flow control mechanisms, allowing for more intricate and complex liquid metal manipulations. Secondly, researchers aim to enhance the compatibility between solenoid valves and various liquid metal compositions, addressing issues related to corrosion and long-term reliability. Additionally, there is a push towards miniaturization and integration, enabling the development of compact and efficient liquid metal-based devices and systems.

As the field progresses, it is anticipated that liquid metal flow control technology will play a crucial role in shaping the future of adaptive and reconfigurable systems across multiple industries. The ongoing research and development efforts are expected to lead to breakthroughs in areas such as soft robotics, wearable electronics, and advanced manufacturing processes, ultimately revolutionizing the way we interact with and utilize liquid metals in various applications.

The primary objective of liquid metal flow control research is to develop precise and efficient methods for manipulating these materials in various systems and devices. This encompasses a wide range of applications, from microfluidics and soft robotics to thermal management and flexible electronics. As the field progresses, researchers aim to overcome challenges related to oxidation, wettability, and precise control mechanisms.

One of the key technological trends in liquid metal flow control is the integration of solenoid valves. These electromagnetic devices offer a promising solution for achieving accurate and responsive control over liquid metal movements. Solenoid valves provide the ability to rapidly switch and regulate flow, making them ideal for applications requiring dynamic and precise manipulation of liquid metals.

The development of liquid metal flow control technology is driven by several factors, including the growing demand for flexible and reconfigurable electronic systems, advancements in soft robotics, and the need for innovative thermal management solutions in various industries. As research in this field continues to evolve, it is expected to enable new possibilities in areas such as adaptive antennas, self-healing circuits, and shape-morphing structures.

The objectives of current research on solenoid valve use in controlling liquid metal flows are multifaceted. Firstly, there is a focus on improving the precision and responsiveness of flow control mechanisms, allowing for more intricate and complex liquid metal manipulations. Secondly, researchers aim to enhance the compatibility between solenoid valves and various liquid metal compositions, addressing issues related to corrosion and long-term reliability. Additionally, there is a push towards miniaturization and integration, enabling the development of compact and efficient liquid metal-based devices and systems.

As the field progresses, it is anticipated that liquid metal flow control technology will play a crucial role in shaping the future of adaptive and reconfigurable systems across multiple industries. The ongoing research and development efforts are expected to lead to breakthroughs in areas such as soft robotics, wearable electronics, and advanced manufacturing processes, ultimately revolutionizing the way we interact with and utilize liquid metals in various applications.

Market Analysis for Liquid Metal Flow Applications

The market for liquid metal flow applications is experiencing significant growth, driven by advancements in various industries such as electronics, energy, and advanced manufacturing. The unique properties of liquid metals, including high thermal and electrical conductivity, low melting points, and excellent fluidity, make them attractive for a wide range of applications.

In the electronics sector, liquid metal flows are gaining traction in thermal management solutions for high-performance computing systems and data centers. As the demand for more powerful and compact electronic devices continues to rise, the need for efficient cooling solutions becomes paramount. Liquid metal cooling systems offer superior heat dissipation capabilities compared to traditional air or water-based cooling methods, potentially revolutionizing thermal management in the electronics industry.

The energy sector is another key market for liquid metal flow applications. Concentrated solar power plants are exploring the use of liquid metals as heat transfer fluids, offering improved efficiency and lower operating costs compared to conventional molten salt systems. Additionally, nuclear energy research is investigating liquid metal coolants for next-generation reactors, promising enhanced safety and performance.

Advanced manufacturing processes are also benefiting from liquid metal flow technologies. 3D printing with liquid metals is emerging as a promising technique for creating complex metal structures with unique properties. This technology has potential applications in aerospace, automotive, and medical industries, where customized metal components with specific characteristics are in high demand.

The market for liquid metal flow applications is further bolstered by the growing interest in flexible and stretchable electronics. Liquid metal-based circuits and interconnects offer the potential for creating highly deformable electronic devices, opening up new possibilities in wearable technology, soft robotics, and biomedical implants.

While the market shows great promise, it is important to note that challenges remain in terms of material compatibility, long-term stability, and scalability of liquid metal flow systems. Overcoming these hurdles will be crucial for widespread adoption across industries.

As research and development in this field continue to progress, the market for liquid metal flow applications is expected to expand significantly in the coming years. The ability to precisely control liquid metal flows using technologies such as solenoid valves will play a critical role in unlocking the full potential of these applications across various industries.

In the electronics sector, liquid metal flows are gaining traction in thermal management solutions for high-performance computing systems and data centers. As the demand for more powerful and compact electronic devices continues to rise, the need for efficient cooling solutions becomes paramount. Liquid metal cooling systems offer superior heat dissipation capabilities compared to traditional air or water-based cooling methods, potentially revolutionizing thermal management in the electronics industry.

The energy sector is another key market for liquid metal flow applications. Concentrated solar power plants are exploring the use of liquid metals as heat transfer fluids, offering improved efficiency and lower operating costs compared to conventional molten salt systems. Additionally, nuclear energy research is investigating liquid metal coolants for next-generation reactors, promising enhanced safety and performance.

Advanced manufacturing processes are also benefiting from liquid metal flow technologies. 3D printing with liquid metals is emerging as a promising technique for creating complex metal structures with unique properties. This technology has potential applications in aerospace, automotive, and medical industries, where customized metal components with specific characteristics are in high demand.

The market for liquid metal flow applications is further bolstered by the growing interest in flexible and stretchable electronics. Liquid metal-based circuits and interconnects offer the potential for creating highly deformable electronic devices, opening up new possibilities in wearable technology, soft robotics, and biomedical implants.

While the market shows great promise, it is important to note that challenges remain in terms of material compatibility, long-term stability, and scalability of liquid metal flow systems. Overcoming these hurdles will be crucial for widespread adoption across industries.

As research and development in this field continue to progress, the market for liquid metal flow applications is expected to expand significantly in the coming years. The ability to precisely control liquid metal flows using technologies such as solenoid valves will play a critical role in unlocking the full potential of these applications across various industries.

Solenoid Valve Technology: Current State and Challenges

Solenoid valves have become a critical component in controlling liquid metal flows, with their current state and challenges reflecting the broader advancements and limitations in fluid control technology. These electromagnetic devices have seen significant improvements in recent years, particularly in their response time, precision, and durability when handling high-temperature liquid metals.

The current state of solenoid valve technology for liquid metal control is characterized by the development of specialized materials and designs. Advanced alloys and ceramics are being utilized to withstand the corrosive nature and high temperatures of liquid metals, such as gallium, indium, and their alloys. Manufacturers have made strides in creating valve seals and actuators that can maintain integrity under extreme conditions, often employing multi-layer coatings to prevent degradation.

Miniaturization has been a key focus, with researchers developing micro-solenoid valves capable of precise control over small volumes of liquid metal. This has opened up new possibilities in fields such as microfluidics and flexible electronics. Additionally, the integration of smart control systems has enhanced the responsiveness and adaptability of solenoid valves, allowing for real-time adjustments based on flow conditions.

Despite these advancements, several challenges persist in the application of solenoid valves for liquid metal control. One of the primary issues is the long-term reliability of valve components when exposed to liquid metals, especially at elevated temperatures. The potential for metal solidification within the valve mechanism remains a concern, necessitating the development of more robust heating and cooling systems to maintain optimal flow conditions.

Another significant challenge lies in achieving consistent performance across a wide range of liquid metal compositions and operating temperatures. The varying viscosities and surface tensions of different liquid metal alloys require valves with adaptable characteristics, which is technically demanding to implement without compromising overall system efficiency.

The power consumption of solenoid valves in liquid metal applications is also an area of ongoing research. High-temperature operations often require more energy to maintain proper valve function, leading to increased operational costs and potential heat management issues in compact systems.

Lastly, the scalability of current solenoid valve technology for larger industrial applications involving liquid metals remains limited. While progress has been made in small-scale and laboratory settings, translating this success to high-volume, continuous flow systems presents engineering challenges that are yet to be fully resolved.

The current state of solenoid valve technology for liquid metal control is characterized by the development of specialized materials and designs. Advanced alloys and ceramics are being utilized to withstand the corrosive nature and high temperatures of liquid metals, such as gallium, indium, and their alloys. Manufacturers have made strides in creating valve seals and actuators that can maintain integrity under extreme conditions, often employing multi-layer coatings to prevent degradation.

Miniaturization has been a key focus, with researchers developing micro-solenoid valves capable of precise control over small volumes of liquid metal. This has opened up new possibilities in fields such as microfluidics and flexible electronics. Additionally, the integration of smart control systems has enhanced the responsiveness and adaptability of solenoid valves, allowing for real-time adjustments based on flow conditions.

Despite these advancements, several challenges persist in the application of solenoid valves for liquid metal control. One of the primary issues is the long-term reliability of valve components when exposed to liquid metals, especially at elevated temperatures. The potential for metal solidification within the valve mechanism remains a concern, necessitating the development of more robust heating and cooling systems to maintain optimal flow conditions.

Another significant challenge lies in achieving consistent performance across a wide range of liquid metal compositions and operating temperatures. The varying viscosities and surface tensions of different liquid metal alloys require valves with adaptable characteristics, which is technically demanding to implement without compromising overall system efficiency.

The power consumption of solenoid valves in liquid metal applications is also an area of ongoing research. High-temperature operations often require more energy to maintain proper valve function, leading to increased operational costs and potential heat management issues in compact systems.

Lastly, the scalability of current solenoid valve technology for larger industrial applications involving liquid metals remains limited. While progress has been made in small-scale and laboratory settings, translating this success to high-volume, continuous flow systems presents engineering challenges that are yet to be fully resolved.

Existing Solenoid Valve Solutions for Liquid Metal Control

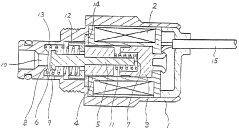

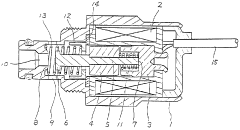

01 Solenoid valve design for precise flow control

Solenoid valves can be designed with specific features to enhance flow control precision. This may include adjustable orifices, balanced poppet designs, or multi-stage configurations. These design elements allow for more accurate regulation of fluid flow rates and pressures in various applications.- Solenoid valve design for precise flow control: Solenoid valves are designed with specific features to achieve precise flow control. These designs may include adjustable orifices, multiple stages, or specialized internal components that allow for fine-tuning of fluid flow. The valve's structure and operation mechanism are optimized to provide accurate and responsive control over the flow rate.

- Electronic control systems for solenoid valves: Advanced electronic control systems are implemented to enhance the performance of solenoid valves in flow control applications. These systems may include microprocessors, sensors, and feedback mechanisms to continuously monitor and adjust valve operation. The electronic controls enable precise regulation of flow rates, pressure, and timing, improving overall system efficiency and responsiveness.

- Solenoid valve configurations for specific flow control applications: Various solenoid valve configurations are developed to address specific flow control requirements in different industries. These may include multi-port valves, proportional valves, or specialized designs for high-pressure or corrosive environments. The valve configurations are tailored to meet the unique demands of applications such as hydraulic systems, pneumatic controls, or fluid dispensing.

- Integration of flow sensors with solenoid valves: Flow sensors are integrated with solenoid valves to create closed-loop control systems for enhanced flow regulation. These integrated systems provide real-time flow measurement and feedback, allowing for automatic adjustments to maintain desired flow rates. The combination of flow sensing and valve actuation improves accuracy and responsiveness in flow control applications.

- Energy-efficient solenoid valve designs for flow control: Innovative solenoid valve designs focus on improving energy efficiency in flow control applications. These designs may incorporate low-power actuators, optimized magnetic circuits, or energy recovery mechanisms. The energy-efficient valves reduce power consumption while maintaining precise flow control capabilities, making them suitable for battery-powered or energy-conscious systems.

02 Electronic control systems for solenoid valves

Integration of electronic control systems with solenoid valves enables advanced flow control capabilities. These systems may incorporate microprocessors, sensors, and feedback mechanisms to continuously monitor and adjust valve operation. This results in improved responsiveness and precision in flow regulation.Expand Specific Solutions03 Proportional solenoid valves for variable flow control

Proportional solenoid valves offer continuous variable flow control by modulating the valve opening in response to input signals. These valves use specialized actuators and control circuitry to achieve precise positioning of the valve element, allowing for smooth and accurate flow adjustment across a wide range of operating conditions.Expand Specific Solutions04 Solenoid valve flow characteristics optimization

Optimization of solenoid valve flow characteristics involves careful design of internal geometries, such as valve seats, flow paths, and armature shapes. These optimizations aim to reduce turbulence, minimize pressure drops, and improve overall flow efficiency. Advanced modeling and simulation techniques may be used to achieve desired flow profiles.Expand Specific Solutions05 Adaptive solenoid valve control algorithms

Implementation of adaptive control algorithms enhances solenoid valve performance in dynamic operating conditions. These algorithms can compensate for variations in system parameters, environmental factors, and wear over time. Machine learning techniques may be employed to continuously improve flow control accuracy and responsiveness based on operational data.Expand Specific Solutions

Key Players in Solenoid Valve and Liquid Metal Industries

The research on solenoid valve use in controlling liquid metal flows is in an emerging stage, with a growing market driven by advancements in advanced manufacturing and materials science. The technology's maturity is still developing, with key players like Eaton Corp., Robert Bosch GmbH, and BorgWarner, Inc. leading innovation. These companies are leveraging their expertise in automotive and industrial applications to explore liquid metal flow control. The market size is expanding as industries recognize the potential of liquid metal technologies, particularly in areas like thermal management and flexible electronics. However, challenges in material compatibility and high-temperature operation remain, indicating room for further technological progress.

Eaton Corp.

Technical Solution: Eaton Corp. has developed advanced solenoid valve technology for controlling liquid metal flows in industrial applications. Their system utilizes high-temperature resistant materials and precision control mechanisms to handle the unique properties of liquid metals. The valves incorporate specialized coatings to prevent corrosion and ensure long-term reliability when exposed to reactive liquid metals[1]. Eaton's design also features rapid response times and precise flow control, achieved through optimized electromagnetic actuators and flow path geometries[2]. The company has integrated smart diagnostics and predictive maintenance capabilities into their valve systems, allowing for real-time monitoring of valve performance and early detection of potential issues[3].

Strengths: Robust design for harsh environments, precise control, and smart diagnostics. Weaknesses: Potentially higher cost due to specialized materials and complexity.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has innovated in the field of liquid metal flow control with their advanced solenoid valve technology. Their approach focuses on miniaturization and integration, developing compact valve systems suitable for microfluidic applications involving liquid metals[4]. Bosch's valves utilize a combination of electromagnetic actuation and piezoelectric elements for ultra-precise control at the microscale. The company has also developed specialized sealing technologies to prevent leakage of liquid metals, which can be highly corrosive[5]. Bosch's system incorporates advanced control algorithms that adapt to changes in liquid metal viscosity and temperature, ensuring consistent performance across various operating conditions[6].

Strengths: Miniaturization capabilities, precise microfluidic control, and adaptive algorithms. Weaknesses: May be limited to smaller-scale applications compared to industrial-sized systems.

Core Innovations in Liquid Metal Flow Control

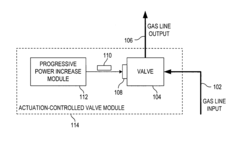

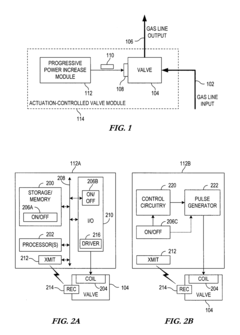

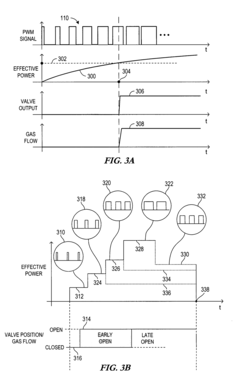

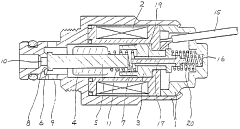

System, apparatus and method for controlling valves

PatentActiveUS7950622B2

Innovation

- A system and method that progressively increase the power signal to the valve control input, starting below the actuation threshold and gradually increasing until the valve is actuated, reducing the force required to open or close the valve, thus minimizing strain on mechanical components.

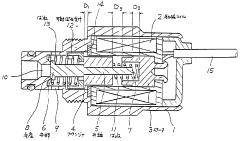

Solenoid valve for flow rate regulating

PatentInactiveJP1988076971A

Innovation

- The design incorporates multiple springs with initial loads set to zero, allowing for gentle axial movement of the valve shaft, where the electromagnetic force controls the valve opening and closing, ensuring consistent flow rates by adjusting the spring loads in response to current changes, thereby maintaining stable fluid flow characteristics.

Material Compatibility and Corrosion Resistance

The use of solenoid valves in controlling liquid metal flows presents significant challenges in terms of material compatibility and corrosion resistance. Liquid metals, such as mercury, gallium, and various alloys, are highly reactive and can cause severe corrosion in many conventional valve materials. This necessitates careful selection of materials that can withstand the aggressive nature of liquid metals while maintaining the valve's functionality and longevity.

Stainless steel, particularly grades 316 and 316L, has been widely used in solenoid valve construction for liquid metal applications due to its excellent corrosion resistance. However, even these alloys can experience degradation over time when exposed to certain liquid metals, especially at elevated temperatures. To address this issue, researchers have explored the use of refractory metals like tungsten, molybdenum, and tantalum, which exhibit superior resistance to liquid metal corrosion.

Ceramic materials have also gained attention for their potential in liquid metal valve applications. Materials such as silicon carbide, alumina, and zirconia offer exceptional chemical inertness and can withstand high temperatures. However, their brittle nature and challenges in manufacturing complex valve components have limited their widespread adoption.

Coatings and surface treatments have emerged as promising solutions to enhance the corrosion resistance of valve materials. Techniques such as nitriding, carburizing, and the application of ceramic coatings have shown potential in extending the lifespan of solenoid valves exposed to liquid metals. These treatments create a protective layer that acts as a barrier between the base material and the corrosive liquid metal.

The choice of sealing materials is equally critical in ensuring the longevity and reliability of solenoid valves in liquid metal applications. Traditional elastomers often degrade rapidly when exposed to liquid metals, leading to leakage and valve failure. Advanced fluoropolymers, such as PTFE and its derivatives, have demonstrated improved resistance to liquid metal attack and are increasingly being used in valve seals and gaskets.

Researchers are also investigating novel composite materials that combine the strength and durability of metals with the chemical resistance of ceramics. These materials aim to provide a balance between mechanical properties and corrosion resistance, potentially offering superior performance in liquid metal valve applications.

As the demand for efficient and reliable liquid metal flow control continues to grow in industries such as nuclear power, metallurgy, and advanced manufacturing, ongoing research in material science and engineering will play a crucial role in developing next-generation solenoid valves capable of withstanding the harsh conditions imposed by liquid metals.

Stainless steel, particularly grades 316 and 316L, has been widely used in solenoid valve construction for liquid metal applications due to its excellent corrosion resistance. However, even these alloys can experience degradation over time when exposed to certain liquid metals, especially at elevated temperatures. To address this issue, researchers have explored the use of refractory metals like tungsten, molybdenum, and tantalum, which exhibit superior resistance to liquid metal corrosion.

Ceramic materials have also gained attention for their potential in liquid metal valve applications. Materials such as silicon carbide, alumina, and zirconia offer exceptional chemical inertness and can withstand high temperatures. However, their brittle nature and challenges in manufacturing complex valve components have limited their widespread adoption.

Coatings and surface treatments have emerged as promising solutions to enhance the corrosion resistance of valve materials. Techniques such as nitriding, carburizing, and the application of ceramic coatings have shown potential in extending the lifespan of solenoid valves exposed to liquid metals. These treatments create a protective layer that acts as a barrier between the base material and the corrosive liquid metal.

The choice of sealing materials is equally critical in ensuring the longevity and reliability of solenoid valves in liquid metal applications. Traditional elastomers often degrade rapidly when exposed to liquid metals, leading to leakage and valve failure. Advanced fluoropolymers, such as PTFE and its derivatives, have demonstrated improved resistance to liquid metal attack and are increasingly being used in valve seals and gaskets.

Researchers are also investigating novel composite materials that combine the strength and durability of metals with the chemical resistance of ceramics. These materials aim to provide a balance between mechanical properties and corrosion resistance, potentially offering superior performance in liquid metal valve applications.

As the demand for efficient and reliable liquid metal flow control continues to grow in industries such as nuclear power, metallurgy, and advanced manufacturing, ongoing research in material science and engineering will play a crucial role in developing next-generation solenoid valves capable of withstanding the harsh conditions imposed by liquid metals.

Safety and Environmental Considerations

The use of solenoid valves in controlling liquid metal flows presents unique safety and environmental considerations that must be carefully addressed. Liquid metals, such as mercury, gallium, or alloys like Galinstan, possess distinct properties that require specialized handling and containment measures.

From a safety perspective, the primary concern is the potential for leaks or spills of liquid metal. Many liquid metals are toxic if ingested or inhaled, and some can be absorbed through the skin. To mitigate these risks, robust containment systems and fail-safe mechanisms must be integrated into the solenoid valve design. This includes the use of corrosion-resistant materials, redundant sealing systems, and leak detection sensors.

Thermal management is another critical safety aspect. Liquid metals often have high thermal conductivity and can reach elevated temperatures during operation. The solenoid valve system must incorporate adequate thermal insulation and cooling mechanisms to prevent overheating and potential burns to operators or damage to surrounding equipment.

Environmental considerations are equally important when working with liquid metals. Proper disposal and recycling protocols must be established to prevent contamination of soil and water resources. This is particularly crucial for mercury-based systems, given the severe environmental impact of mercury pollution.

The choice of liquid metal also influences environmental impact. While mercury has been traditionally used in some applications, its use is being phased out due to its toxicity. Alternative liquid metals like gallium-based alloys offer lower environmental risks but may still require careful handling and disposal procedures.

Electromagnetic shielding is another consideration, as the operation of solenoid valves generates electromagnetic fields. These fields could potentially interfere with sensitive electronic equipment in the vicinity. Proper shielding and grounding techniques must be employed to minimize electromagnetic interference.

In the event of system failure or emergency shutdown, containment of the liquid metal is paramount. Fail-safe designs that default to a closed position and secondary containment systems should be incorporated to prevent uncontrolled release of the liquid metal.

Long-term storage and transportation of liquid metal systems also require careful planning. Appropriate packaging, labeling, and handling procedures must be developed to ensure safe transport and storage, complying with relevant regulations and standards.

Regular maintenance and inspection protocols are essential to ensure the ongoing safety and environmental compliance of solenoid valve systems used with liquid metals. This includes periodic checks for wear, corrosion, and potential leaks, as well as calibration of control systems to maintain precise flow control.

From a safety perspective, the primary concern is the potential for leaks or spills of liquid metal. Many liquid metals are toxic if ingested or inhaled, and some can be absorbed through the skin. To mitigate these risks, robust containment systems and fail-safe mechanisms must be integrated into the solenoid valve design. This includes the use of corrosion-resistant materials, redundant sealing systems, and leak detection sensors.

Thermal management is another critical safety aspect. Liquid metals often have high thermal conductivity and can reach elevated temperatures during operation. The solenoid valve system must incorporate adequate thermal insulation and cooling mechanisms to prevent overheating and potential burns to operators or damage to surrounding equipment.

Environmental considerations are equally important when working with liquid metals. Proper disposal and recycling protocols must be established to prevent contamination of soil and water resources. This is particularly crucial for mercury-based systems, given the severe environmental impact of mercury pollution.

The choice of liquid metal also influences environmental impact. While mercury has been traditionally used in some applications, its use is being phased out due to its toxicity. Alternative liquid metals like gallium-based alloys offer lower environmental risks but may still require careful handling and disposal procedures.

Electromagnetic shielding is another consideration, as the operation of solenoid valves generates electromagnetic fields. These fields could potentially interfere with sensitive electronic equipment in the vicinity. Proper shielding and grounding techniques must be employed to minimize electromagnetic interference.

In the event of system failure or emergency shutdown, containment of the liquid metal is paramount. Fail-safe designs that default to a closed position and secondary containment systems should be incorporated to prevent uncontrolled release of the liquid metal.

Long-term storage and transportation of liquid metal systems also require careful planning. Appropriate packaging, labeling, and handling procedures must be developed to ensure safe transport and storage, complying with relevant regulations and standards.

Regular maintenance and inspection protocols are essential to ensure the ongoing safety and environmental compliance of solenoid valve systems used with liquid metals. This includes periodic checks for wear, corrosion, and potential leaks, as well as calibration of control systems to maintain precise flow control.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!