Role of Solenoid Valves in Enhancing Food Safety in Processing Lines

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solenoid Valve Evolution in Food Processing

The evolution of solenoid valves in food processing has been marked by significant technological advancements and a growing emphasis on food safety. Initially introduced in the mid-20th century, solenoid valves quickly became integral components in food processing lines due to their ability to control fluid flow precisely and reliably.

In the 1960s and 1970s, early solenoid valve designs were primarily focused on basic on/off functionality. These valves were typically constructed with brass or stainless steel bodies and rubber seals. While effective for general fluid control, they lacked the sophistication required for the increasingly stringent food safety standards of the time.

The 1980s saw a shift towards more hygienic designs, with the introduction of food-grade materials and smoother internal surfaces. This period marked the beginning of solenoid valves specifically engineered for food and beverage applications. Manufacturers began to prioritize designs that minimized areas where bacteria could accumulate, addressing a critical food safety concern.

During the 1990s, the integration of electronic controls with solenoid valves revolutionized food processing operations. This advancement allowed for more precise control over fluid flow and pressure, enabling the development of more complex and efficient processing systems. The increased automation also reduced the risk of human error, further enhancing food safety.

The early 2000s brought about a focus on energy efficiency and miniaturization. Solenoid valve designs became more compact and consumed less power, allowing for their widespread use throughout food processing lines. This period also saw the introduction of multi-functional valves that could perform several tasks simultaneously, streamlining production processes.

In recent years, the evolution of solenoid valves has been driven by the demand for smart manufacturing and Industry 4.0 principles. Modern solenoid valves now incorporate sensors and communication capabilities, allowing for real-time monitoring and predictive maintenance. This connectivity has significantly improved food safety by enabling immediate detection and response to potential contamination risks.

The latest developments in solenoid valve technology for food processing include the use of advanced materials such as high-performance polymers, which offer superior chemical resistance and durability. Additionally, valve designs now feature improved cleanability, with some models offering clean-in-place (CIP) compatibility, further reducing the risk of bacterial contamination.

As food safety regulations continue to become more stringent, solenoid valve manufacturers are focusing on developing solutions that not only meet but exceed these standards. The ongoing evolution of these critical components promises to play a crucial role in shaping the future of safe and efficient food processing operations.

In the 1960s and 1970s, early solenoid valve designs were primarily focused on basic on/off functionality. These valves were typically constructed with brass or stainless steel bodies and rubber seals. While effective for general fluid control, they lacked the sophistication required for the increasingly stringent food safety standards of the time.

The 1980s saw a shift towards more hygienic designs, with the introduction of food-grade materials and smoother internal surfaces. This period marked the beginning of solenoid valves specifically engineered for food and beverage applications. Manufacturers began to prioritize designs that minimized areas where bacteria could accumulate, addressing a critical food safety concern.

During the 1990s, the integration of electronic controls with solenoid valves revolutionized food processing operations. This advancement allowed for more precise control over fluid flow and pressure, enabling the development of more complex and efficient processing systems. The increased automation also reduced the risk of human error, further enhancing food safety.

The early 2000s brought about a focus on energy efficiency and miniaturization. Solenoid valve designs became more compact and consumed less power, allowing for their widespread use throughout food processing lines. This period also saw the introduction of multi-functional valves that could perform several tasks simultaneously, streamlining production processes.

In recent years, the evolution of solenoid valves has been driven by the demand for smart manufacturing and Industry 4.0 principles. Modern solenoid valves now incorporate sensors and communication capabilities, allowing for real-time monitoring and predictive maintenance. This connectivity has significantly improved food safety by enabling immediate detection and response to potential contamination risks.

The latest developments in solenoid valve technology for food processing include the use of advanced materials such as high-performance polymers, which offer superior chemical resistance and durability. Additionally, valve designs now feature improved cleanability, with some models offering clean-in-place (CIP) compatibility, further reducing the risk of bacterial contamination.

As food safety regulations continue to become more stringent, solenoid valve manufacturers are focusing on developing solutions that not only meet but exceed these standards. The ongoing evolution of these critical components promises to play a crucial role in shaping the future of safe and efficient food processing operations.

Market Demand Analysis

The market demand for solenoid valves in food processing lines has been experiencing significant growth, driven by the increasing emphasis on food safety and the need for more efficient and automated production processes. As consumers become more conscious about food quality and safety, regulatory bodies worldwide have tightened their standards, compelling food manufacturers to adopt advanced technologies that ensure better control and monitoring of their production lines.

Solenoid valves play a crucial role in enhancing food safety by providing precise control over fluid flow in various stages of food processing. These valves are essential components in systems that regulate the flow of ingredients, cleaning solutions, and other fluids critical to maintaining hygiene standards. The ability of solenoid valves to operate quickly and accurately makes them indispensable in high-speed production environments, where even minor contamination risks can lead to significant product recalls and financial losses.

The global food and beverage processing equipment market, which includes solenoid valves, has been expanding steadily. This growth is particularly pronounced in regions with stringent food safety regulations, such as North America and Europe. Emerging economies in Asia-Pacific and Latin America are also showing increased demand as they upgrade their food processing infrastructure to meet international standards and cater to growing urban populations with higher food safety expectations.

One of the key drivers of market demand is the trend towards automation in food processing. Solenoid valves are integral to automated systems that reduce human intervention, thereby minimizing the risk of contamination and improving overall hygiene. This automation trend is expected to continue, further boosting the demand for sophisticated solenoid valve solutions.

The COVID-19 pandemic has also accelerated the adoption of automated solutions in food processing, as companies seek to reduce human contact with food products. This has created a surge in demand for technologies that can ensure food safety while maintaining production efficiency, positioning solenoid valves as critical components in this new landscape.

Moreover, the increasing complexity of food processing lines, with the introduction of new products and the need for flexible manufacturing, has led to a demand for more versatile and intelligent solenoid valve systems. Manufacturers are seeking valves that can be easily integrated into smart factory systems, offering features such as remote monitoring and predictive maintenance capabilities.

As sustainability becomes a growing concern in the food industry, there is also a rising demand for solenoid valves that can contribute to resource efficiency. Valves that help reduce water and energy consumption in cleaning and processing operations are gaining traction, aligning with the industry's move towards more environmentally friendly practices.

Solenoid valves play a crucial role in enhancing food safety by providing precise control over fluid flow in various stages of food processing. These valves are essential components in systems that regulate the flow of ingredients, cleaning solutions, and other fluids critical to maintaining hygiene standards. The ability of solenoid valves to operate quickly and accurately makes them indispensable in high-speed production environments, where even minor contamination risks can lead to significant product recalls and financial losses.

The global food and beverage processing equipment market, which includes solenoid valves, has been expanding steadily. This growth is particularly pronounced in regions with stringent food safety regulations, such as North America and Europe. Emerging economies in Asia-Pacific and Latin America are also showing increased demand as they upgrade their food processing infrastructure to meet international standards and cater to growing urban populations with higher food safety expectations.

One of the key drivers of market demand is the trend towards automation in food processing. Solenoid valves are integral to automated systems that reduce human intervention, thereby minimizing the risk of contamination and improving overall hygiene. This automation trend is expected to continue, further boosting the demand for sophisticated solenoid valve solutions.

The COVID-19 pandemic has also accelerated the adoption of automated solutions in food processing, as companies seek to reduce human contact with food products. This has created a surge in demand for technologies that can ensure food safety while maintaining production efficiency, positioning solenoid valves as critical components in this new landscape.

Moreover, the increasing complexity of food processing lines, with the introduction of new products and the need for flexible manufacturing, has led to a demand for more versatile and intelligent solenoid valve systems. Manufacturers are seeking valves that can be easily integrated into smart factory systems, offering features such as remote monitoring and predictive maintenance capabilities.

As sustainability becomes a growing concern in the food industry, there is also a rising demand for solenoid valves that can contribute to resource efficiency. Valves that help reduce water and energy consumption in cleaning and processing operations are gaining traction, aligning with the industry's move towards more environmentally friendly practices.

Current Challenges

The integration of solenoid valves in food processing lines has significantly improved food safety measures, yet several challenges persist in their implementation and operation. One of the primary concerns is the potential for contamination due to the complex design of solenoid valves. The intricate internal components and small crevices can harbor bacteria and other microorganisms, making thorough cleaning and sanitization a challenging task. This issue is particularly critical in wet processing environments where moisture can accumulate and promote microbial growth.

Another challenge lies in the reliability and durability of solenoid valves under harsh processing conditions. Food processing often involves extreme temperatures, corrosive chemicals, and high-pressure environments. These factors can lead to premature wear and tear of valve components, potentially compromising their performance and, consequently, food safety. The need for frequent maintenance and replacement not only increases operational costs but also introduces the risk of contamination during servicing.

The speed and precision of solenoid valve operation are crucial for maintaining consistent food safety standards. However, achieving the optimal balance between rapid response times and accurate control can be technically demanding. Slow or imprecise valve actuation may lead to inadequate process control, potentially resulting in under-processed or over-processed food products, both of which can pose safety risks.

Compatibility with various food products and processing methods presents another significant challenge. Different food types and production processes may require specific valve materials and designs to ensure food safety. For instance, certain food acids or high-temperature applications may necessitate specialized valve materials to prevent leaching or degradation, which can be costly and technically complex to implement across diverse production lines.

The integration of solenoid valves with existing food safety monitoring and control systems also poses challenges. Ensuring seamless communication and coordination between valve operations and other safety-critical processes, such as temperature control and product flow management, requires sophisticated automation and control systems. This integration is essential for maintaining a comprehensive food safety approach but can be technically complex and resource-intensive to implement effectively.

Lastly, the regulatory landscape surrounding food safety equipment, including solenoid valves, is continually evolving. Keeping up with changing standards and compliance requirements across different regions and markets can be challenging for manufacturers and food processors alike. This necessitates ongoing research, development, and adaptation of valve technologies to meet or exceed regulatory expectations while maintaining operational efficiency and cost-effectiveness.

Another challenge lies in the reliability and durability of solenoid valves under harsh processing conditions. Food processing often involves extreme temperatures, corrosive chemicals, and high-pressure environments. These factors can lead to premature wear and tear of valve components, potentially compromising their performance and, consequently, food safety. The need for frequent maintenance and replacement not only increases operational costs but also introduces the risk of contamination during servicing.

The speed and precision of solenoid valve operation are crucial for maintaining consistent food safety standards. However, achieving the optimal balance between rapid response times and accurate control can be technically demanding. Slow or imprecise valve actuation may lead to inadequate process control, potentially resulting in under-processed or over-processed food products, both of which can pose safety risks.

Compatibility with various food products and processing methods presents another significant challenge. Different food types and production processes may require specific valve materials and designs to ensure food safety. For instance, certain food acids or high-temperature applications may necessitate specialized valve materials to prevent leaching or degradation, which can be costly and technically complex to implement across diverse production lines.

The integration of solenoid valves with existing food safety monitoring and control systems also poses challenges. Ensuring seamless communication and coordination between valve operations and other safety-critical processes, such as temperature control and product flow management, requires sophisticated automation and control systems. This integration is essential for maintaining a comprehensive food safety approach but can be technically complex and resource-intensive to implement effectively.

Lastly, the regulatory landscape surrounding food safety equipment, including solenoid valves, is continually evolving. Keeping up with changing standards and compliance requirements across different regions and markets can be challenging for manufacturers and food processors alike. This necessitates ongoing research, development, and adaptation of valve technologies to meet or exceed regulatory expectations while maintaining operational efficiency and cost-effectiveness.

Existing Safety Solutions

01 Food-safe materials for solenoid valves

Solenoid valves used in food processing equipment must be constructed with food-safe materials to prevent contamination. This includes using stainless steel, food-grade plastics, and other materials that are resistant to corrosion and easy to clean. These materials ensure that the valves meet food safety regulations and standards.- Food-safe materials for solenoid valves: Solenoid valves used in food processing equipment must be constructed with food-safe materials to prevent contamination. This includes using stainless steel, food-grade plastics, and other materials that are resistant to corrosion and easy to clean. The design should also minimize areas where food particles can accumulate.

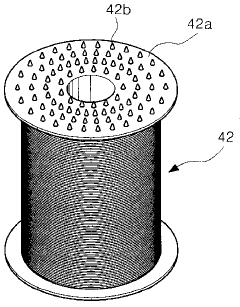

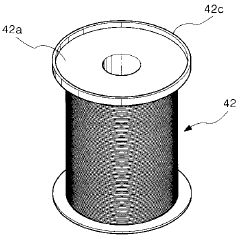

- Hygienic design and cleanability: Solenoid valves for food applications should have a hygienic design that allows for easy cleaning and sanitization. This includes smooth surfaces, minimal crevices, and self-draining configurations. The valves should be able to withstand high-temperature cleaning processes and chemical sanitizers without degradation.

- Leak-proof and contamination prevention: To ensure food safety, solenoid valves must be designed to prevent leaks and cross-contamination. This includes using high-quality seals, implementing fail-safe mechanisms, and ensuring proper valve closure. The valves should also be resistant to pressure fluctuations and maintain their integrity under various operating conditions.

- Compliance with food safety regulations: Solenoid valves used in food processing must comply with relevant food safety regulations and standards. This includes certifications such as FDA approval, NSF certification, or compliance with EU food contact materials regulations. The valves should be designed and manufactured in accordance with Good Manufacturing Practices (GMP) for food equipment.

- Monitoring and maintenance for food safety: Implementing proper monitoring and maintenance procedures is crucial for ensuring the ongoing food safety of solenoid valves. This includes regular inspections, cleaning schedules, and replacement of worn components. Advanced monitoring systems can be integrated to detect potential issues before they lead to contamination risks.

02 Hygienic design of solenoid valves

The design of solenoid valves for food applications focuses on hygienic principles to minimize the risk of bacterial growth and contamination. This includes smooth surfaces, minimal crevices, and easy-to-disassemble components for thorough cleaning and sanitization. The hygienic design ensures that the valves can be effectively cleaned and maintained in food processing environments.Expand Specific Solutions03 Sealing and leak prevention in food-grade solenoid valves

Effective sealing mechanisms are crucial for food-grade solenoid valves to prevent leaks and cross-contamination. This includes the use of specialized seals, gaskets, and diaphragms that are compatible with food products and cleaning agents. The sealing systems are designed to withstand frequent cleaning cycles and maintain their integrity over time.Expand Specific Solutions04 Cleaning and sanitization protocols for solenoid valves

Specific cleaning and sanitization protocols are developed for solenoid valves used in food processing. These protocols may include clean-in-place (CIP) systems, steam cleaning, or manual disassembly and cleaning procedures. The methods ensure that all surfaces of the valve that come into contact with food products are thoroughly cleaned and sanitized to maintain food safety standards.Expand Specific Solutions05 Monitoring and control systems for food-safe valve operation

Advanced monitoring and control systems are implemented to ensure the safe operation of solenoid valves in food processing. These systems may include sensors for detecting valve position, pressure, and flow, as well as automated control mechanisms to prevent contamination risks. The monitoring systems help maintain food safety by alerting operators to potential issues and ensuring proper valve function.Expand Specific Solutions

Key Industry Players

The solenoid valve market in food processing is experiencing steady growth, driven by increasing focus on food safety and automation. The industry is in a mature stage, with established players like Robert Bosch GmbH and Eaton Corp. leading technological advancements. Market size is expanding due to stringent regulations and the need for precise fluid control. Technological maturity varies, with companies like RPE Srl and ODE SRL specializing in innovative valve solutions for specific food processing applications. Emerging players such as Shanghai Juliang Solenoid Valve Manufacturing Co., Ltd are also contributing to market competitiveness, particularly in regional markets.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed advanced solenoid valve technology for food processing lines, focusing on hygienic design and precision control. Their solenoid valves feature stainless steel construction and FDA-approved materials to prevent contamination. The company's valves incorporate advanced sealing technology and self-draining designs to minimize bacterial growth and facilitate easy cleaning. Bosch's solenoid valves also utilize intelligent control systems that allow for precise regulation of flow rates and pressures, ensuring consistent product quality and reducing waste. The valves are designed to withstand high-temperature sterilization processes, enhancing food safety throughout the production line[1][3].

Strengths: Robust hygienic design, advanced control systems, and compatibility with sterilization processes. Weaknesses: Potentially higher cost compared to standard valves, may require specialized maintenance.

Eaton Corp.

Technical Solution: Eaton Corp. has developed a range of solenoid valves specifically designed for food and beverage processing applications. Their valves feature sanitary designs with smooth internal surfaces to prevent product buildup and contamination. Eaton's solenoid valves incorporate quick-disconnect fittings for easy cleaning and maintenance, reducing downtime in food processing lines. The company has also introduced smart valve technology that enables real-time monitoring of valve performance and early detection of potential issues, enhancing overall food safety. Eaton's valves are engineered to handle a wide range of temperatures and pressures, making them suitable for various food processing applications, from dairy to beverage production[2][4].

Strengths: Sanitary design, easy maintenance, smart monitoring capabilities. Weaknesses: May have a higher initial cost, potential complexity in integrating smart features with existing systems.

Innovative Valve Designs

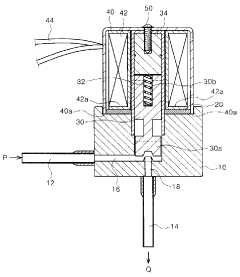

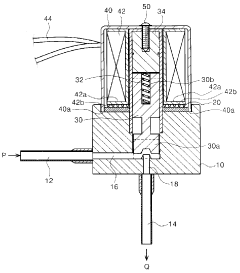

Solenoid valve for food storage

PatentInactiveKR1020020063748A

Innovation

- The solenoid valve design incorporates fixing protrusions on the lower plate of the coil or magnetic field forming plate, and a cover that does not directly contact the valve body, minimizing heat transfer to the refrigerant passage.

Solenoid valve

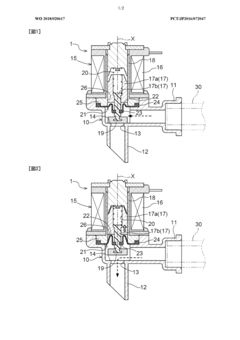

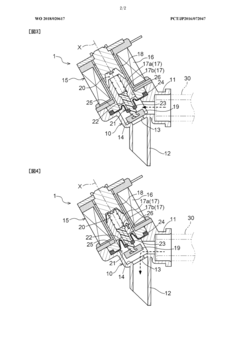

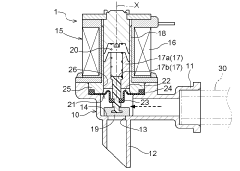

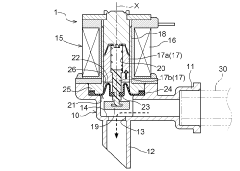

PatentWO2018020617A1

Innovation

- A solenoid valve design with a diaphragm that isolates the drive section from the valve box, allowing for separate construction of the valve body and diaphragm, enabling fluid isolation and reducing the complexity of sterilization, while using the fluid pressure to bias the valve body against the seat, allowing for a weaker spring and smaller coil, thus simplifying the mechanism and reducing costs.

Regulatory Compliance

Regulatory compliance plays a crucial role in the implementation of solenoid valves in food processing lines to enhance food safety. The food industry is subject to stringent regulations and standards set by various national and international bodies to ensure the safety and quality of food products. These regulations often encompass the design, materials, and operation of equipment used in food processing, including solenoid valves.

In the United States, the Food and Drug Administration (FDA) sets forth regulations under the Food Safety Modernization Act (FSMA) that directly impact the use of solenoid valves in food processing. These regulations require that all equipment, including valves, must be designed and constructed to be adequately cleanable and properly maintained. Solenoid valves used in food processing must comply with FDA's requirements for food contact materials, ensuring that they do not introduce harmful substances into the food products.

Similarly, the European Union has established regulations such as EC 1935/2004 and EC 2023/2006, which govern materials and articles intended to come into contact with food. These regulations mandate that solenoid valves used in food processing must not transfer their constituents to food in quantities that could endanger human health or bring about an unacceptable change in the composition of the food.

Compliance with hygienic design standards is another critical aspect of regulatory requirements for solenoid valves in food processing. Standards such as those set by the European Hygienic Engineering & Design Group (EHEDG) and 3-A Sanitary Standards provide guidelines for the design and construction of equipment used in food processing. These standards often require solenoid valves to be constructed from specific materials, have smooth surfaces, and be easily cleanable to prevent bacterial growth and contamination.

Furthermore, regulatory bodies often require documentation and certification to demonstrate compliance. This may include material certificates, declarations of conformity, and third-party certifications. Manufacturers of solenoid valves for food processing applications must maintain comprehensive documentation to prove their products meet all applicable regulatory requirements.

Regular inspections and audits are typically mandated to ensure ongoing compliance with food safety regulations. Food processing facilities must be prepared to demonstrate that their solenoid valves and other equipment meet all relevant standards during these inspections. This often necessitates implementing robust maintenance and cleaning procedures specific to solenoid valves to maintain their hygienic integrity throughout their operational life.

In the United States, the Food and Drug Administration (FDA) sets forth regulations under the Food Safety Modernization Act (FSMA) that directly impact the use of solenoid valves in food processing. These regulations require that all equipment, including valves, must be designed and constructed to be adequately cleanable and properly maintained. Solenoid valves used in food processing must comply with FDA's requirements for food contact materials, ensuring that they do not introduce harmful substances into the food products.

Similarly, the European Union has established regulations such as EC 1935/2004 and EC 2023/2006, which govern materials and articles intended to come into contact with food. These regulations mandate that solenoid valves used in food processing must not transfer their constituents to food in quantities that could endanger human health or bring about an unacceptable change in the composition of the food.

Compliance with hygienic design standards is another critical aspect of regulatory requirements for solenoid valves in food processing. Standards such as those set by the European Hygienic Engineering & Design Group (EHEDG) and 3-A Sanitary Standards provide guidelines for the design and construction of equipment used in food processing. These standards often require solenoid valves to be constructed from specific materials, have smooth surfaces, and be easily cleanable to prevent bacterial growth and contamination.

Furthermore, regulatory bodies often require documentation and certification to demonstrate compliance. This may include material certificates, declarations of conformity, and third-party certifications. Manufacturers of solenoid valves for food processing applications must maintain comprehensive documentation to prove their products meet all applicable regulatory requirements.

Regular inspections and audits are typically mandated to ensure ongoing compliance with food safety regulations. Food processing facilities must be prepared to demonstrate that their solenoid valves and other equipment meet all relevant standards during these inspections. This often necessitates implementing robust maintenance and cleaning procedures specific to solenoid valves to maintain their hygienic integrity throughout their operational life.

Environmental Impact

The implementation of solenoid valves in food processing lines not only enhances food safety but also contributes to environmental sustainability. These valves play a crucial role in reducing water and energy consumption, minimizing waste, and improving overall resource efficiency in food production facilities.

One of the primary environmental benefits of solenoid valves is their ability to precisely control fluid flow, which leads to significant water conservation. In food processing operations that require frequent cleaning and sanitization, solenoid valves enable precise timing and metering of water usage. This results in substantial reductions in water consumption compared to manual or less sophisticated control systems. Some estimates suggest that properly implemented solenoid valve systems can reduce water usage by up to 30% in certain food processing applications.

Energy efficiency is another key environmental advantage of solenoid valves. By providing accurate control over various processes, these valves help optimize energy usage throughout the production line. For instance, in thermal processing applications, solenoid valves can ensure that heating or cooling systems operate only when necessary, reducing overall energy consumption. This not only lowers the carbon footprint of food processing facilities but also contributes to cost savings for operators.

Solenoid valves also play a role in minimizing food waste, which is a significant environmental concern in the food industry. By enabling precise control over ingredient dispensing and product flow, these valves help reduce overproduction and product loss. This is particularly important in high-volume production environments where even small improvements in efficiency can lead to substantial reductions in waste generation.

Furthermore, the use of solenoid valves can contribute to the reduction of chemical usage in food processing. By allowing for more precise application of cleaning and sanitizing agents, these valves help minimize the amount of chemicals required while maintaining high hygiene standards. This not only reduces the environmental impact of chemical production and disposal but also decreases the potential for chemical residues in food products.

The durability and longevity of modern solenoid valves also contribute to their positive environmental impact. High-quality valves designed for food processing applications typically have longer operational lifespans compared to traditional mechanical valves. This reduces the frequency of replacements, thereby minimizing waste generation and the environmental footprint associated with manufacturing and disposing of valve components.

In conclusion, the integration of solenoid valves in food processing lines offers significant environmental benefits. From water and energy conservation to waste reduction and improved resource efficiency, these valves play a crucial role in enhancing the sustainability of food production processes. As the food industry continues to focus on environmental responsibility, the importance of technologies like solenoid valves in achieving sustainability goals is likely to grow.

One of the primary environmental benefits of solenoid valves is their ability to precisely control fluid flow, which leads to significant water conservation. In food processing operations that require frequent cleaning and sanitization, solenoid valves enable precise timing and metering of water usage. This results in substantial reductions in water consumption compared to manual or less sophisticated control systems. Some estimates suggest that properly implemented solenoid valve systems can reduce water usage by up to 30% in certain food processing applications.

Energy efficiency is another key environmental advantage of solenoid valves. By providing accurate control over various processes, these valves help optimize energy usage throughout the production line. For instance, in thermal processing applications, solenoid valves can ensure that heating or cooling systems operate only when necessary, reducing overall energy consumption. This not only lowers the carbon footprint of food processing facilities but also contributes to cost savings for operators.

Solenoid valves also play a role in minimizing food waste, which is a significant environmental concern in the food industry. By enabling precise control over ingredient dispensing and product flow, these valves help reduce overproduction and product loss. This is particularly important in high-volume production environments where even small improvements in efficiency can lead to substantial reductions in waste generation.

Furthermore, the use of solenoid valves can contribute to the reduction of chemical usage in food processing. By allowing for more precise application of cleaning and sanitizing agents, these valves help minimize the amount of chemicals required while maintaining high hygiene standards. This not only reduces the environmental impact of chemical production and disposal but also decreases the potential for chemical residues in food products.

The durability and longevity of modern solenoid valves also contribute to their positive environmental impact. High-quality valves designed for food processing applications typically have longer operational lifespans compared to traditional mechanical valves. This reduces the frequency of replacements, thereby minimizing waste generation and the environmental footprint associated with manufacturing and disposing of valve components.

In conclusion, the integration of solenoid valves in food processing lines offers significant environmental benefits. From water and energy conservation to waste reduction and improved resource efficiency, these valves play a crucial role in enhancing the sustainability of food production processes. As the food industry continues to focus on environmental responsibility, the importance of technologies like solenoid valves in achieving sustainability goals is likely to grow.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!