Scalability of Manufacturing for Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Manufacturing Evolution and Objectives

Piezoelectric sensors have undergone significant evolution since their inception, driven by advancements in materials science, manufacturing techniques, and increasing demand across various industries. The journey began with the discovery of the piezoelectric effect in the late 19th century, leading to the development of early sensors primarily for military applications. As technology progressed, these sensors found their way into consumer electronics, automotive systems, and industrial monitoring equipment.

The manufacturing of piezoelectric sensors has seen a remarkable transformation over the years. Initially, production was limited to small-scale, labor-intensive processes. However, with the growing demand for these sensors in diverse applications, there has been a continuous push towards scalable manufacturing techniques. This evolution has been marked by the introduction of automated production lines, precision machining, and advanced deposition methods for piezoelectric materials.

One of the key objectives in the manufacturing evolution of piezoelectric sensors has been to enhance their performance while simultaneously reducing production costs. This has led to the development of new piezoelectric materials with improved properties, such as higher sensitivity and broader operating temperature ranges. Additionally, there has been a focus on miniaturization, enabling the integration of these sensors into increasingly compact devices.

Another critical goal in the manufacturing process has been to improve consistency and reliability. As piezoelectric sensors found applications in critical systems like aerospace and medical devices, ensuring uniform quality across large production volumes became paramount. This drove the adoption of advanced quality control measures and the implementation of stringent testing protocols throughout the manufacturing process.

The scalability of manufacturing for piezoelectric sensors remains a central objective in the industry. As the demand for these sensors continues to grow, particularly in emerging fields like Internet of Things (IoT) devices and wearable technology, manufacturers are exploring innovative production methods. These include the use of 3D printing technologies for rapid prototyping and customization, as well as the development of roll-to-roll manufacturing processes for flexible piezoelectric sensors.

Looking ahead, the objectives for piezoelectric sensor manufacturing are focused on further enhancing scalability while maintaining high quality and performance standards. This includes the exploration of new materials and composites that can be more easily mass-produced, as well as the development of more efficient and environmentally friendly manufacturing processes. The industry is also working towards greater integration of sensors with other electronic components, aiming to create more compact and multifunctional devices that can be produced at scale.

The manufacturing of piezoelectric sensors has seen a remarkable transformation over the years. Initially, production was limited to small-scale, labor-intensive processes. However, with the growing demand for these sensors in diverse applications, there has been a continuous push towards scalable manufacturing techniques. This evolution has been marked by the introduction of automated production lines, precision machining, and advanced deposition methods for piezoelectric materials.

One of the key objectives in the manufacturing evolution of piezoelectric sensors has been to enhance their performance while simultaneously reducing production costs. This has led to the development of new piezoelectric materials with improved properties, such as higher sensitivity and broader operating temperature ranges. Additionally, there has been a focus on miniaturization, enabling the integration of these sensors into increasingly compact devices.

Another critical goal in the manufacturing process has been to improve consistency and reliability. As piezoelectric sensors found applications in critical systems like aerospace and medical devices, ensuring uniform quality across large production volumes became paramount. This drove the adoption of advanced quality control measures and the implementation of stringent testing protocols throughout the manufacturing process.

The scalability of manufacturing for piezoelectric sensors remains a central objective in the industry. As the demand for these sensors continues to grow, particularly in emerging fields like Internet of Things (IoT) devices and wearable technology, manufacturers are exploring innovative production methods. These include the use of 3D printing technologies for rapid prototyping and customization, as well as the development of roll-to-roll manufacturing processes for flexible piezoelectric sensors.

Looking ahead, the objectives for piezoelectric sensor manufacturing are focused on further enhancing scalability while maintaining high quality and performance standards. This includes the exploration of new materials and composites that can be more easily mass-produced, as well as the development of more efficient and environmentally friendly manufacturing processes. The industry is also working towards greater integration of sensors with other electronic components, aiming to create more compact and multifunctional devices that can be produced at scale.

Market Demand Analysis for Piezoelectric Sensors

The global market for piezoelectric sensors has been experiencing robust growth, driven by increasing demand across various industries. The automotive sector stands out as a major consumer, utilizing these sensors in engine management systems, tire pressure monitoring, and advanced driver assistance systems (ADAS). The industrial sector also contributes significantly to market demand, employing piezoelectric sensors in process control, quality assurance, and predictive maintenance applications.

In recent years, the consumer electronics industry has emerged as a key growth driver for piezoelectric sensors. The proliferation of smartphones, wearables, and IoT devices has created new opportunities for sensor integration, particularly in touch-sensitive interfaces and energy harvesting applications. The healthcare sector is another rapidly expanding market, with piezoelectric sensors finding applications in medical imaging, diagnostic equipment, and patient monitoring devices.

The aerospace and defense industries continue to be substantial consumers of piezoelectric sensors, utilizing them in structural health monitoring, vibration control, and navigation systems. Additionally, the energy sector has shown increased interest in these sensors for applications in oil and gas exploration, wind turbine monitoring, and smart grid infrastructure.

Market analysts project the global piezoelectric sensors market to maintain a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the sensors' unique capabilities in pressure, force, and acceleration measurement, as well as their durability and reliability in harsh environments.

Geographically, North America and Europe currently dominate the market, owing to their advanced manufacturing capabilities and high adoption rates across industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and the expansion of consumer electronics manufacturing in countries like China, Japan, and South Korea.

The demand for miniaturization and improved sensitivity in sensor technology is a key trend shaping the market. Manufacturers are focusing on developing smaller, more efficient sensors to meet the requirements of compact electronic devices and space-constrained applications. Additionally, there is a growing emphasis on developing multi-functional sensors that can measure multiple parameters simultaneously, offering cost-effective solutions for various industries.

As the Internet of Things (IoT) and Industry 4.0 concepts gain traction, the demand for smart, connected sensors is expected to surge. This trend is likely to create new opportunities for piezoelectric sensor manufacturers, particularly in the development of wireless, low-power sensors capable of real-time data transmission and analysis.

In recent years, the consumer electronics industry has emerged as a key growth driver for piezoelectric sensors. The proliferation of smartphones, wearables, and IoT devices has created new opportunities for sensor integration, particularly in touch-sensitive interfaces and energy harvesting applications. The healthcare sector is another rapidly expanding market, with piezoelectric sensors finding applications in medical imaging, diagnostic equipment, and patient monitoring devices.

The aerospace and defense industries continue to be substantial consumers of piezoelectric sensors, utilizing them in structural health monitoring, vibration control, and navigation systems. Additionally, the energy sector has shown increased interest in these sensors for applications in oil and gas exploration, wind turbine monitoring, and smart grid infrastructure.

Market analysts project the global piezoelectric sensors market to maintain a compound annual growth rate (CAGR) of over 5% in the coming years. This growth is attributed to the sensors' unique capabilities in pressure, force, and acceleration measurement, as well as their durability and reliability in harsh environments.

Geographically, North America and Europe currently dominate the market, owing to their advanced manufacturing capabilities and high adoption rates across industries. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and the expansion of consumer electronics manufacturing in countries like China, Japan, and South Korea.

The demand for miniaturization and improved sensitivity in sensor technology is a key trend shaping the market. Manufacturers are focusing on developing smaller, more efficient sensors to meet the requirements of compact electronic devices and space-constrained applications. Additionally, there is a growing emphasis on developing multi-functional sensors that can measure multiple parameters simultaneously, offering cost-effective solutions for various industries.

As the Internet of Things (IoT) and Industry 4.0 concepts gain traction, the demand for smart, connected sensors is expected to surge. This trend is likely to create new opportunities for piezoelectric sensor manufacturers, particularly in the development of wireless, low-power sensors capable of real-time data transmission and analysis.

Current Challenges in Piezoelectric Sensor Production

The production of piezoelectric sensors faces several significant challenges that hinder the scalability of manufacturing processes. One of the primary issues is the complexity of material synthesis and preparation. Piezoelectric materials, such as lead zirconate titanate (PZT) or quartz, require precise control over composition, crystal structure, and purity. Achieving consistent material properties across large-scale production batches remains a formidable task, often resulting in yield inconsistencies and quality control issues.

Another major challenge lies in the miniaturization of sensor components. As demand grows for smaller, more sensitive sensors, manufacturers struggle to maintain performance while reducing size. This necessitates advanced microfabrication techniques, which are often costly and difficult to scale up. The integration of nanoscale materials and structures further complicates the manufacturing process, requiring specialized equipment and expertise that may not be readily available or easily scalable.

The assembly and packaging of piezoelectric sensors present additional hurdles. Many sensors require precise alignment and bonding of multiple layers, including the piezoelectric element, electrodes, and protective enclosures. Automating these delicate processes while maintaining high precision and reliability is a significant challenge. Moreover, ensuring hermetic sealing and environmental protection for sensors destined for harsh operating conditions adds another layer of complexity to the manufacturing process.

Quality control and testing pose substantial challenges in large-scale production. Piezoelectric sensors often require individual calibration and characterization, which can be time-consuming and resource-intensive. Developing efficient, automated testing procedures that can accurately assess sensor performance without bottlenecking production is a critical area of focus for manufacturers.

The supply chain for specialized materials and components used in piezoelectric sensors is another limiting factor. Many of these materials have limited sources or require long lead times, which can impact production schedules and scalability. Developing alternative materials or securing reliable supply chains is crucial for sustainable large-scale manufacturing.

Lastly, environmental and regulatory concerns present ongoing challenges. Many traditional piezoelectric materials contain lead, which is subject to increasing restrictions worldwide. Developing lead-free alternatives that match the performance of conventional materials while being amenable to large-scale production is an active area of research and development in the industry.

Another major challenge lies in the miniaturization of sensor components. As demand grows for smaller, more sensitive sensors, manufacturers struggle to maintain performance while reducing size. This necessitates advanced microfabrication techniques, which are often costly and difficult to scale up. The integration of nanoscale materials and structures further complicates the manufacturing process, requiring specialized equipment and expertise that may not be readily available or easily scalable.

The assembly and packaging of piezoelectric sensors present additional hurdles. Many sensors require precise alignment and bonding of multiple layers, including the piezoelectric element, electrodes, and protective enclosures. Automating these delicate processes while maintaining high precision and reliability is a significant challenge. Moreover, ensuring hermetic sealing and environmental protection for sensors destined for harsh operating conditions adds another layer of complexity to the manufacturing process.

Quality control and testing pose substantial challenges in large-scale production. Piezoelectric sensors often require individual calibration and characterization, which can be time-consuming and resource-intensive. Developing efficient, automated testing procedures that can accurately assess sensor performance without bottlenecking production is a critical area of focus for manufacturers.

The supply chain for specialized materials and components used in piezoelectric sensors is another limiting factor. Many of these materials have limited sources or require long lead times, which can impact production schedules and scalability. Developing alternative materials or securing reliable supply chains is crucial for sustainable large-scale manufacturing.

Lastly, environmental and regulatory concerns present ongoing challenges. Many traditional piezoelectric materials contain lead, which is subject to increasing restrictions worldwide. Developing lead-free alternatives that match the performance of conventional materials while being amenable to large-scale production is an active area of research and development in the industry.

Existing Scalable Manufacturing Solutions

01 Miniaturization and integration of piezoelectric sensors

Advancements in manufacturing techniques allow for the miniaturization and integration of piezoelectric sensors into various devices. This enables the development of smaller, more compact sensors that can be easily incorporated into a wide range of applications, improving scalability and versatility.- Miniaturization and integration of piezoelectric sensors: Advancements in manufacturing techniques allow for the miniaturization and integration of piezoelectric sensors into various devices. This enables the development of smaller, more compact sensors that can be easily incorporated into a wide range of applications, improving scalability and versatility.

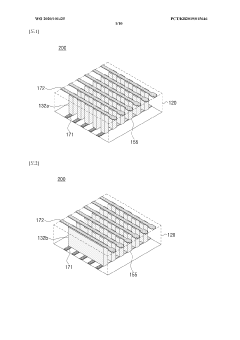

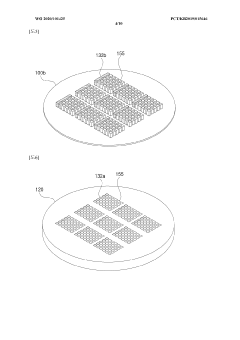

- Array-based piezoelectric sensor systems: Implementing piezoelectric sensors in array configurations enhances scalability by allowing for larger coverage areas and improved spatial resolution. These arrays can be designed to detect and measure various parameters across a wide surface area, making them suitable for applications requiring distributed sensing.

- Flexible and conformable piezoelectric sensors: Development of flexible and conformable piezoelectric sensors enables their application on curved or irregular surfaces. This flexibility improves scalability by allowing sensors to be integrated into a wider range of products and environments, including wearable devices and structural health monitoring systems.

- Multi-functional piezoelectric sensor systems: Creating multi-functional piezoelectric sensor systems that can measure multiple parameters simultaneously enhances scalability by reducing the number of separate sensors required. These integrated systems can combine various sensing capabilities, such as pressure, temperature, and vibration detection, in a single package.

- Wireless and self-powered piezoelectric sensor networks: Developing wireless and self-powered piezoelectric sensor networks improves scalability by eliminating the need for complex wiring and external power sources. These autonomous sensor systems can be easily deployed in large numbers and in hard-to-reach locations, enabling widespread monitoring and data collection.

02 Array-based piezoelectric sensor systems

Utilizing arrays of piezoelectric sensors enhances scalability by allowing for larger coverage areas and improved spatial resolution. These systems can be designed to detect and measure various parameters across a wide area, making them suitable for applications requiring distributed sensing capabilities.Expand Specific Solutions03 Flexible and stretchable piezoelectric sensors

Development of flexible and stretchable piezoelectric sensors enables their application on curved or dynamic surfaces. This innovation improves scalability by allowing sensors to conform to various shapes and sizes, expanding their use in wearable technology and structural health monitoring.Expand Specific Solutions04 Multi-functional piezoelectric sensor systems

Integration of multiple sensing capabilities within a single piezoelectric sensor system enhances scalability by reducing the number of separate sensors required. These multi-functional systems can simultaneously measure various parameters, such as pressure, temperature, and vibration, improving overall efficiency and reducing complexity.Expand Specific Solutions05 Wireless and self-powered piezoelectric sensor networks

Development of wireless and self-powered piezoelectric sensor networks improves scalability by eliminating the need for complex wiring and external power sources. These systems can harvest energy from their environment, enabling long-term, maintenance-free operation and facilitating deployment in large-scale or remote sensing applications.Expand Specific Solutions

Key Players in Piezoelectric Sensor Industry

The scalability of manufacturing for piezoelectric sensors is currently in a growth phase, with the market expanding rapidly due to increasing demand across various industries. The global piezoelectric sensors market is projected to reach significant size in the coming years, driven by applications in automotive, healthcare, and industrial sectors. Technologically, the field is advancing, with companies like Murata Manufacturing, Honeywell International, and Robert Bosch leading innovation. However, challenges remain in mass production techniques and material optimization. Emerging players such as Kistler Holding and CTS Denmark are also contributing to the competitive landscape, focusing on specialized applications and improved manufacturing processes to enhance scalability.

Kistler Holding AG

Technical Solution: Kistler has developed a scalable manufacturing process for high-performance piezoelectric sensors, particularly for industrial and research applications. Their approach focuses on precision engineering and customization capabilities. Kistler utilizes advanced crystal growing techniques to produce high-quality piezoelectric materials with consistent properties[11]. Their manufacturing process includes precision machining, automated assembly, and rigorous testing procedures to ensure sensor accuracy and reliability. Kistler has implemented modular production lines that can be adapted for different sensor types and sizes, enhancing manufacturing flexibility. They also employ advanced calibration techniques, including laser interferometry, to achieve high-precision sensor outputs[12].

Strengths: Expertise in high-performance sensor manufacturing, strong customization capabilities, advanced calibration techniques. Weaknesses: Potentially higher costs due to focus on precision and customization, which may limit mass-market applications.

Seiko Epson Corp.

Technical Solution: Seiko Epson has developed innovative manufacturing techniques for piezoelectric sensors, leveraging their expertise in precision manufacturing and MEMS technology. Their approach focuses on high-precision deposition of piezoelectric materials using advanced sputtering techniques[9]. Epson has implemented a unique "micropiezo" technology, allowing for the production of ultra-small, high-performance piezoelectric elements. Their manufacturing process includes automated assembly lines with high-precision robotic systems for consistent quality. Epson also utilizes their proprietary QMEMS (Quartz MEMS) technology, combining the advantages of quartz material with MEMS processing techniques for enhanced sensor performance and reliability[10].

Strengths: High-precision manufacturing capabilities, unique QMEMS technology, expertise in miniaturization. Weaknesses: Potentially limited to certain types of piezoelectric materials and sensor designs.

Innovative Approaches in Piezoelectric Sensor Fabrication

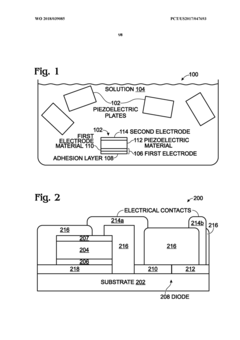

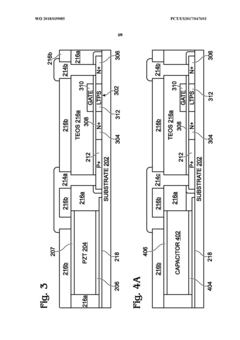

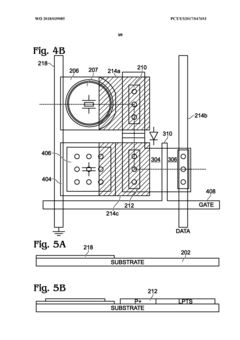

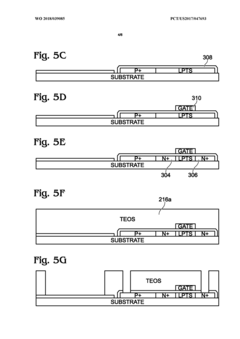

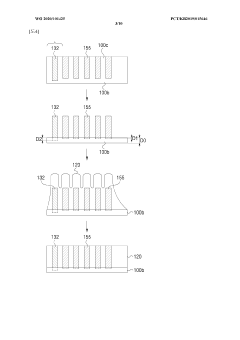

Fluidic assembly process using piezoelectric plates

PatentWO2018039085A1

Innovation

- A fluidic assembly process aligns and captures piezoelectric disks with top and bottom metal electrodes on a growth substrate, allowing high-density formation and subsequent harvesting onto substrates incompatible with high-temperature processing, ensuring complete processing before assembly and isolating microelectronics, enabling the formation of arrays for ultrasonic sensors and other applications.

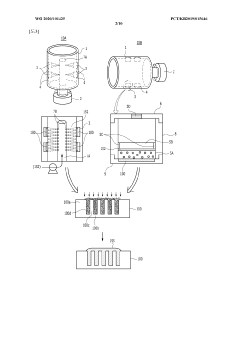

Centrifugal pattern filling apparatus, ultrasonic piezoelectric sensor manufacturing method using same, and ultrasonic piezoelectric sensor or ultrasonic recognition sensor manufactured using method

PatentWO2020101425A1

Innovation

- A centrifugal pattern filling device is used to simultaneously perform the spraying and pressurizing steps, utilizing centrifugal force to fill a slurry containing piezoelectric material into mold patterns within a sealed jig, thereby improving the filling density and reducing defects.

Supply Chain Optimization for Piezoelectric Sensors

Optimizing the supply chain for piezoelectric sensors is crucial for enhancing the scalability of manufacturing processes. A well-designed supply chain can significantly impact production efficiency, cost-effectiveness, and overall market competitiveness. To achieve this, manufacturers must focus on several key areas of improvement.

Firstly, strategic sourcing of raw materials is essential. Piezoelectric sensors require specific materials such as lead zirconate titanate (PZT) or quartz crystals. Establishing long-term relationships with reliable suppliers and diversifying the supplier base can ensure a steady supply of high-quality materials while mitigating risks associated with supply disruptions.

Inventory management plays a critical role in supply chain optimization. Implementing just-in-time (JIT) inventory systems can help reduce carrying costs and minimize waste. However, this approach must be balanced with maintaining sufficient safety stock to address potential supply chain disruptions or sudden increases in demand.

Streamlining the production process is another crucial aspect. Adopting lean manufacturing principles can help eliminate waste, reduce lead times, and improve overall efficiency. This may involve redesigning production layouts, implementing automated systems, and continuously improving processes through data analysis and feedback loops.

Logistics and distribution networks must be optimized to ensure timely delivery of finished products to customers. This may involve strategically locating distribution centers, partnering with reliable logistics providers, and leveraging advanced tracking and routing technologies to improve shipping efficiency and reduce costs.

Implementing robust quality control measures throughout the supply chain is vital for maintaining product consistency and reliability. This includes rigorous testing of raw materials, in-process quality checks, and final product inspections. Adopting advanced quality management systems and technologies can help identify and address issues early in the production process.

Collaboration and information sharing across the supply chain are essential for optimization. Implementing integrated supply chain management systems can improve visibility, facilitate better decision-making, and enable faster response to market changes. This may involve adopting cloud-based platforms that allow real-time data sharing among suppliers, manufacturers, and distributors.

Finally, embracing sustainability practices in the supply chain can lead to long-term benefits. This includes sourcing eco-friendly materials, optimizing transportation routes to reduce carbon emissions, and implementing recycling programs for waste materials. Such initiatives not only contribute to environmental conservation but can also lead to cost savings and improved brand reputation.

By focusing on these key areas, manufacturers can create a more resilient, efficient, and scalable supply chain for piezoelectric sensors, ultimately supporting the growth and competitiveness of their operations in the global market.

Firstly, strategic sourcing of raw materials is essential. Piezoelectric sensors require specific materials such as lead zirconate titanate (PZT) or quartz crystals. Establishing long-term relationships with reliable suppliers and diversifying the supplier base can ensure a steady supply of high-quality materials while mitigating risks associated with supply disruptions.

Inventory management plays a critical role in supply chain optimization. Implementing just-in-time (JIT) inventory systems can help reduce carrying costs and minimize waste. However, this approach must be balanced with maintaining sufficient safety stock to address potential supply chain disruptions or sudden increases in demand.

Streamlining the production process is another crucial aspect. Adopting lean manufacturing principles can help eliminate waste, reduce lead times, and improve overall efficiency. This may involve redesigning production layouts, implementing automated systems, and continuously improving processes through data analysis and feedback loops.

Logistics and distribution networks must be optimized to ensure timely delivery of finished products to customers. This may involve strategically locating distribution centers, partnering with reliable logistics providers, and leveraging advanced tracking and routing technologies to improve shipping efficiency and reduce costs.

Implementing robust quality control measures throughout the supply chain is vital for maintaining product consistency and reliability. This includes rigorous testing of raw materials, in-process quality checks, and final product inspections. Adopting advanced quality management systems and technologies can help identify and address issues early in the production process.

Collaboration and information sharing across the supply chain are essential for optimization. Implementing integrated supply chain management systems can improve visibility, facilitate better decision-making, and enable faster response to market changes. This may involve adopting cloud-based platforms that allow real-time data sharing among suppliers, manufacturers, and distributors.

Finally, embracing sustainability practices in the supply chain can lead to long-term benefits. This includes sourcing eco-friendly materials, optimizing transportation routes to reduce carbon emissions, and implementing recycling programs for waste materials. Such initiatives not only contribute to environmental conservation but can also lead to cost savings and improved brand reputation.

By focusing on these key areas, manufacturers can create a more resilient, efficient, and scalable supply chain for piezoelectric sensors, ultimately supporting the growth and competitiveness of their operations in the global market.

Environmental Impact of Piezoelectric Sensor Production

The production of piezoelectric sensors has significant environmental implications that must be carefully considered as manufacturing scales up. The primary materials used in these sensors, such as lead zirconate titanate (PZT), contain heavy metals that pose potential environmental risks if not properly managed throughout the production lifecycle.

Manufacturing processes for piezoelectric sensors involve several stages that can impact the environment. The synthesis of piezoelectric materials often requires high-temperature sintering, which consumes substantial energy and may result in greenhouse gas emissions. Additionally, the use of solvents and chemicals in the production process can lead to air and water pollution if not adequately controlled.

Waste management is a critical concern in piezoelectric sensor production. The generation of hazardous waste, particularly from lead-based materials, necessitates stringent handling and disposal protocols. As production scales up, the volume of waste increases proportionally, demanding more sophisticated waste treatment and recycling systems to mitigate environmental impact.

Water usage is another environmental factor to consider. The manufacturing process may require significant amounts of water for cleaning and cooling purposes. Implementing water recycling and treatment systems becomes increasingly important as production scales to ensure sustainable water management and reduce the strain on local water resources.

Energy consumption is a major contributor to the environmental footprint of piezoelectric sensor production. Large-scale manufacturing facilities require substantial power for operation, including energy-intensive processes like material synthesis and precision machining. Transitioning to renewable energy sources and improving energy efficiency in production lines can help mitigate this impact.

The supply chain for raw materials used in piezoelectric sensors also has environmental implications. Mining and processing of rare earth elements and other materials can lead to habitat disruption and soil contamination. As production scales up, responsible sourcing practices and the development of more sustainable material alternatives become crucial for minimizing environmental damage.

End-of-life considerations for piezoelectric sensors are increasingly important as production volumes grow. Developing effective recycling processes for these devices, particularly for recovering valuable and potentially harmful materials, is essential to reduce landfill waste and prevent environmental contamination.

To address these environmental challenges, manufacturers must adopt sustainable practices throughout the production process. This includes implementing cleaner production technologies, optimizing resource use, and investing in closed-loop systems for material recovery. Additionally, exploring alternative, more environmentally friendly piezoelectric materials could significantly reduce the overall environmental impact of sensor production as manufacturing scales up.

Manufacturing processes for piezoelectric sensors involve several stages that can impact the environment. The synthesis of piezoelectric materials often requires high-temperature sintering, which consumes substantial energy and may result in greenhouse gas emissions. Additionally, the use of solvents and chemicals in the production process can lead to air and water pollution if not adequately controlled.

Waste management is a critical concern in piezoelectric sensor production. The generation of hazardous waste, particularly from lead-based materials, necessitates stringent handling and disposal protocols. As production scales up, the volume of waste increases proportionally, demanding more sophisticated waste treatment and recycling systems to mitigate environmental impact.

Water usage is another environmental factor to consider. The manufacturing process may require significant amounts of water for cleaning and cooling purposes. Implementing water recycling and treatment systems becomes increasingly important as production scales to ensure sustainable water management and reduce the strain on local water resources.

Energy consumption is a major contributor to the environmental footprint of piezoelectric sensor production. Large-scale manufacturing facilities require substantial power for operation, including energy-intensive processes like material synthesis and precision machining. Transitioning to renewable energy sources and improving energy efficiency in production lines can help mitigate this impact.

The supply chain for raw materials used in piezoelectric sensors also has environmental implications. Mining and processing of rare earth elements and other materials can lead to habitat disruption and soil contamination. As production scales up, responsible sourcing practices and the development of more sustainable material alternatives become crucial for minimizing environmental damage.

End-of-life considerations for piezoelectric sensors are increasingly important as production volumes grow. Developing effective recycling processes for these devices, particularly for recovering valuable and potentially harmful materials, is essential to reduce landfill waste and prevent environmental contamination.

To address these environmental challenges, manufacturers must adopt sustainable practices throughout the production process. This includes implementing cleaner production technologies, optimizing resource use, and investing in closed-loop systems for material recovery. Additionally, exploring alternative, more environmentally friendly piezoelectric materials could significantly reduce the overall environmental impact of sensor production as manufacturing scales up.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!