Solenoid Valve Case Study in Aerospace Composite Machining

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Solenoid Valve Evolution and Objectives

Solenoid valves have played a crucial role in aerospace applications since the early days of aviation. The evolution of these components has been closely tied to the advancement of aerospace technology, particularly in the realm of composite machining. Initially, solenoid valves in aerospace were primarily used for simple on-off control of fluid systems. However, as aircraft designs became more complex and demanding, the requirements for these valves expanded significantly.

In the 1950s and 1960s, with the advent of jet propulsion and the increasing use of hydraulic systems in aircraft, solenoid valves underwent substantial improvements in terms of reliability, precision, and response time. The introduction of miniaturized solenoid valves in the 1970s marked a significant milestone, allowing for more compact and lightweight designs crucial for aerospace applications.

The 1980s and 1990s saw the integration of electronic controls and feedback systems into solenoid valves, enhancing their performance and enabling more sophisticated fluid control in aerospace systems. This period also witnessed the development of materials and manufacturing techniques specifically tailored for aerospace environments, improving the valves' resistance to extreme temperatures, pressures, and vibrations.

As composite materials gained prominence in aerospace manufacturing, the role of solenoid valves in composite machining processes became increasingly important. The precision control offered by advanced solenoid valves proved essential in managing the complex fluid dynamics involved in cutting, cooling, and cleaning operations during composite machining.

The primary objectives in the ongoing evolution of aerospace solenoid valves focus on several key areas. Firstly, there is a continuous drive towards miniaturization and weight reduction without compromising performance or reliability. This aligns with the aerospace industry's overarching goal of improving fuel efficiency and reducing overall aircraft weight.

Secondly, enhancing the durability and lifespan of solenoid valves in the harsh conditions of aerospace applications remains a critical objective. This includes developing valves that can withstand extreme temperature fluctuations, high-pressure differentials, and exposure to various chemicals and fluids used in composite machining processes.

Another significant objective is the improvement of response times and precision control. As aerospace systems become more sophisticated, the demand for solenoid valves capable of rapid, accurate, and repeatable operations increases. This is particularly crucial in composite machining applications where precise fluid control can significantly impact the quality and efficiency of the manufacturing process.

Furthermore, the integration of smart technologies and IoT capabilities into solenoid valves is an emerging objective. This aims to enable real-time monitoring, predictive maintenance, and enhanced system integration, contributing to overall operational efficiency and safety in aerospace applications.

In the 1950s and 1960s, with the advent of jet propulsion and the increasing use of hydraulic systems in aircraft, solenoid valves underwent substantial improvements in terms of reliability, precision, and response time. The introduction of miniaturized solenoid valves in the 1970s marked a significant milestone, allowing for more compact and lightweight designs crucial for aerospace applications.

The 1980s and 1990s saw the integration of electronic controls and feedback systems into solenoid valves, enhancing their performance and enabling more sophisticated fluid control in aerospace systems. This period also witnessed the development of materials and manufacturing techniques specifically tailored for aerospace environments, improving the valves' resistance to extreme temperatures, pressures, and vibrations.

As composite materials gained prominence in aerospace manufacturing, the role of solenoid valves in composite machining processes became increasingly important. The precision control offered by advanced solenoid valves proved essential in managing the complex fluid dynamics involved in cutting, cooling, and cleaning operations during composite machining.

The primary objectives in the ongoing evolution of aerospace solenoid valves focus on several key areas. Firstly, there is a continuous drive towards miniaturization and weight reduction without compromising performance or reliability. This aligns with the aerospace industry's overarching goal of improving fuel efficiency and reducing overall aircraft weight.

Secondly, enhancing the durability and lifespan of solenoid valves in the harsh conditions of aerospace applications remains a critical objective. This includes developing valves that can withstand extreme temperature fluctuations, high-pressure differentials, and exposure to various chemicals and fluids used in composite machining processes.

Another significant objective is the improvement of response times and precision control. As aerospace systems become more sophisticated, the demand for solenoid valves capable of rapid, accurate, and repeatable operations increases. This is particularly crucial in composite machining applications where precise fluid control can significantly impact the quality and efficiency of the manufacturing process.

Furthermore, the integration of smart technologies and IoT capabilities into solenoid valves is an emerging objective. This aims to enable real-time monitoring, predictive maintenance, and enhanced system integration, contributing to overall operational efficiency and safety in aerospace applications.

Market Analysis for Aerospace Composite Machining

The aerospace composite machining market has experienced significant growth in recent years, driven by the increasing demand for lightweight and high-performance materials in aircraft manufacturing. This market segment is closely tied to the broader aerospace industry, which has shown steady expansion despite occasional fluctuations due to economic cycles and global events.

The global aerospace composites market was valued at approximately $29 billion in 2020 and is projected to reach $53 billion by 2027, growing at a CAGR of around 9% during this period. This growth is primarily attributed to the rising adoption of composite materials in commercial and military aircraft, as well as in space applications. The use of composites offers numerous advantages, including weight reduction, improved fuel efficiency, and enhanced structural integrity.

Within the aerospace composite machining sector, key market drivers include the increasing production rates of commercial aircraft, the growing demand for fuel-efficient planes, and the expansion of the aerospace industry in emerging economies. Major aircraft manufacturers such as Boeing and Airbus have been incorporating a higher percentage of composite materials in their latest models, further stimulating market growth.

The market for solenoid valves in aerospace composite machining represents a niche but critical segment. These valves play a crucial role in controlling fluid flow and pressure in various aircraft systems, including hydraulic, pneumatic, and fuel systems. The demand for precision-engineered solenoid valves that can withstand the harsh operating conditions of aerospace applications is on the rise.

Geographically, North America dominates the aerospace composite machining market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to the presence of major aircraft manufacturers and a robust aerospace industry. However, emerging markets in China and India are expected to witness rapid growth in the coming years, driven by increasing domestic aircraft production and government initiatives to boost the aerospace sector.

The market landscape is characterized by intense competition among key players, including Hexcel Corporation, Solvay S.A., Toray Industries, and Spirit AeroSystems. These companies are investing heavily in research and development to innovate new composite materials and machining technologies, aiming to gain a competitive edge in the market.

The global aerospace composites market was valued at approximately $29 billion in 2020 and is projected to reach $53 billion by 2027, growing at a CAGR of around 9% during this period. This growth is primarily attributed to the rising adoption of composite materials in commercial and military aircraft, as well as in space applications. The use of composites offers numerous advantages, including weight reduction, improved fuel efficiency, and enhanced structural integrity.

Within the aerospace composite machining sector, key market drivers include the increasing production rates of commercial aircraft, the growing demand for fuel-efficient planes, and the expansion of the aerospace industry in emerging economies. Major aircraft manufacturers such as Boeing and Airbus have been incorporating a higher percentage of composite materials in their latest models, further stimulating market growth.

The market for solenoid valves in aerospace composite machining represents a niche but critical segment. These valves play a crucial role in controlling fluid flow and pressure in various aircraft systems, including hydraulic, pneumatic, and fuel systems. The demand for precision-engineered solenoid valves that can withstand the harsh operating conditions of aerospace applications is on the rise.

Geographically, North America dominates the aerospace composite machining market, followed by Europe and Asia-Pacific. The United States, in particular, holds a significant market share due to the presence of major aircraft manufacturers and a robust aerospace industry. However, emerging markets in China and India are expected to witness rapid growth in the coming years, driven by increasing domestic aircraft production and government initiatives to boost the aerospace sector.

The market landscape is characterized by intense competition among key players, including Hexcel Corporation, Solvay S.A., Toray Industries, and Spirit AeroSystems. These companies are investing heavily in research and development to innovate new composite materials and machining technologies, aiming to gain a competitive edge in the market.

Solenoid Valve Challenges in Composite Machining

Solenoid valves play a crucial role in aerospace composite machining, but they face several significant challenges in this demanding application. The primary issue stems from the unique properties of composite materials, which differ substantially from traditional metals. Composites, such as carbon fiber reinforced polymers (CFRP), are known for their high strength-to-weight ratio and corrosion resistance, making them ideal for aerospace applications. However, these same properties present difficulties for solenoid valve operation and durability.

One of the main challenges is the abrasive nature of composite dust generated during machining processes. This fine, highly abrasive particulate matter can infiltrate valve components, causing accelerated wear and potential failure. The hardness of composite fibers, particularly carbon fibers, can lead to scoring and erosion of valve seats, seals, and other internal components, compromising the valve's ability to maintain proper sealing and control.

Temperature management is another significant concern. Composite machining often involves high-speed cutting, which generates substantial heat. Solenoid valves must maintain consistent performance across a wide temperature range, from the heat generated during machining to the extreme cold experienced at high altitudes. This thermal cycling can lead to material fatigue and potential failure of valve components, especially those made from materials with different thermal expansion coefficients.

The chemical compatibility of valve materials with composite resins and coolants used in machining processes presents another challenge. Some resins and coolants can be corrosive or cause swelling in certain elastomers used in valve seals, leading to leakage or valve malfunction. Selecting materials that can withstand these chemical exposures while maintaining their mechanical properties is crucial for long-term reliability.

Precision control is paramount in aerospace composite machining, requiring solenoid valves to operate with high accuracy and repeatability. However, the accumulation of composite dust and debris can interfere with valve actuation, potentially leading to inconsistent performance or stuck valves. This challenge is exacerbated by the need for miniaturization in aerospace applications, where space and weight constraints limit the size of valves and their protective enclosures.

Lastly, the high-frequency cycling typical in aerospace machining applications puts significant stress on solenoid valve components. Rapid opening and closing cycles can lead to fatigue in springs, armatures, and other moving parts. This fatigue is compounded by the presence of abrasive particles, potentially leading to premature failure if not properly addressed in the valve design and material selection.

One of the main challenges is the abrasive nature of composite dust generated during machining processes. This fine, highly abrasive particulate matter can infiltrate valve components, causing accelerated wear and potential failure. The hardness of composite fibers, particularly carbon fibers, can lead to scoring and erosion of valve seats, seals, and other internal components, compromising the valve's ability to maintain proper sealing and control.

Temperature management is another significant concern. Composite machining often involves high-speed cutting, which generates substantial heat. Solenoid valves must maintain consistent performance across a wide temperature range, from the heat generated during machining to the extreme cold experienced at high altitudes. This thermal cycling can lead to material fatigue and potential failure of valve components, especially those made from materials with different thermal expansion coefficients.

The chemical compatibility of valve materials with composite resins and coolants used in machining processes presents another challenge. Some resins and coolants can be corrosive or cause swelling in certain elastomers used in valve seals, leading to leakage or valve malfunction. Selecting materials that can withstand these chemical exposures while maintaining their mechanical properties is crucial for long-term reliability.

Precision control is paramount in aerospace composite machining, requiring solenoid valves to operate with high accuracy and repeatability. However, the accumulation of composite dust and debris can interfere with valve actuation, potentially leading to inconsistent performance or stuck valves. This challenge is exacerbated by the need for miniaturization in aerospace applications, where space and weight constraints limit the size of valves and their protective enclosures.

Lastly, the high-frequency cycling typical in aerospace machining applications puts significant stress on solenoid valve components. Rapid opening and closing cycles can lead to fatigue in springs, armatures, and other moving parts. This fatigue is compounded by the presence of abrasive particles, potentially leading to premature failure if not properly addressed in the valve design and material selection.

Current Solenoid Solutions for Composite Machining

01 Solenoid valve design improvements

Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced sealing technologies. Such enhancements result in better flow control, reduced leakage, and increased durability of the valve.- Solenoid valve design improvements: Various design improvements have been made to solenoid valves to enhance their performance and reliability. These include optimizing the valve body structure, improving the plunger mechanism, and incorporating advanced sealing technologies. Such enhancements result in better flow control, reduced leakage, and increased durability of the valve.

- Energy-efficient solenoid valves: Developments in energy-efficient solenoid valves focus on reducing power consumption while maintaining optimal performance. This is achieved through the use of advanced materials, improved coil designs, and innovative control mechanisms. These energy-saving features make the valves more environmentally friendly and cost-effective for long-term operation.

- Smart solenoid valve systems: Integration of smart technologies into solenoid valve systems enables advanced control and monitoring capabilities. These systems may incorporate sensors, microprocessors, and communication interfaces for real-time data analysis and remote operation. Smart solenoid valves offer improved precision, adaptability, and predictive maintenance features.

- Miniaturization of solenoid valves: Efforts to miniaturize solenoid valves have resulted in compact designs suitable for space-constrained applications. These miniature valves maintain high performance while reducing overall size and weight. Advancements in manufacturing techniques and materials contribute to the development of these smaller, yet efficient solenoid valves.

- Specialized solenoid valves for specific industries: Customized solenoid valves have been developed to meet the unique requirements of various industries such as automotive, medical, and aerospace. These specialized valves incorporate features tailored to specific applications, including high-pressure capabilities, corrosion resistance, and compatibility with different fluids or gases.

02 Energy-efficient solenoid valves

Developments in energy-efficient solenoid valves focus on reducing power consumption while maintaining optimal performance. This includes the use of low-power coils, improved magnetic circuit designs, and innovative control strategies. These advancements result in valves that require less energy to operate, making them more environmentally friendly and cost-effective.Expand Specific Solutions03 Smart solenoid valves with integrated sensors

Integration of sensors and smart technologies into solenoid valves enables real-time monitoring and control of valve operations. These smart valves can provide data on flow rates, pressure, temperature, and valve position. This integration allows for predictive maintenance, improved process control, and enhanced overall system efficiency.Expand Specific Solutions04 Miniaturization of solenoid valves

Efforts to miniaturize solenoid valves have resulted in compact designs suitable for space-constrained applications. These miniature valves maintain high performance while reducing overall size and weight. Advancements in materials and manufacturing techniques have enabled the production of smaller, yet robust solenoid valves for various industries.Expand Specific Solutions05 Solenoid valve materials and coatings

Innovations in materials and coatings for solenoid valves have led to improved corrosion resistance, wear resistance, and overall longevity. Advanced materials such as high-performance polymers and ceramics are being used for valve components. Additionally, specialized coatings are applied to enhance the valve's resistance to harsh environments and chemicals.Expand Specific Solutions

Key Aerospace Solenoid Valve Manufacturers

The aerospace composite machining industry, particularly in the context of solenoid valve case studies, is in a mature growth phase with a steadily expanding market size. The technology has reached a high level of maturity, with established players like Robert Bosch GmbH, Eaton Corp., and Emerson Electric Co. leading the field. These companies have extensive experience in developing precision control systems for aerospace applications. Emerging players such as Suzhou Hangfa Aviation Parts Co., Ltd. and Xian Aerospace Engine Corp are also making significant contributions, particularly in the Asian market. The competitive landscape is characterized by a focus on innovation, reliability, and efficiency, with companies investing heavily in R&D to maintain their market positions.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced solenoid valve technology for aerospace composite machining, focusing on precision control and durability. Their system utilizes high-frequency pulse width modulation (PWM) to achieve precise fluid flow control, essential for the delicate nature of composite materials[1]. The valves incorporate wear-resistant materials and coatings to withstand the harsh environment of aerospace manufacturing. Bosch's solenoid valves feature integrated sensors for real-time monitoring of valve position and flow rate, enabling adaptive control systems that optimize machining processes[3]. The company has also implemented advanced sealing technologies to prevent leakage and contamination, crucial for maintaining the integrity of composite structures[5].

Strengths: Precision control, durability in harsh environments, and integrated sensing capabilities. Weaknesses: Potentially higher cost due to advanced features, and may require specialized maintenance.

Suzhou Hangfa Aviation Parts Co., Ltd.

Technical Solution: Suzhou Hangfa specializes in solenoid valves for aerospace applications, including composite machining. Their valves feature a compact design optimized for weight reduction, crucial in aerospace applications[2]. The company employs advanced magnetic circuit designs to enhance response times and reduce power consumption. Hangfa's valves utilize aerospace-grade materials that meet stringent industry standards for corrosion resistance and temperature tolerance[4]. They have developed a proprietary sealing technology that ensures zero-leakage performance even under extreme pressure differentials. Hangfa's solenoid valves incorporate fail-safe mechanisms and redundancy features to enhance reliability in critical aerospace systems[6].

Strengths: Lightweight design, aerospace-specific materials, and high reliability. Weaknesses: Limited global presence may affect support and availability in some regions.

Innovative Solenoid Designs for Aerospace Applications

Solenoid assembly with high-flux c-frame and method of making same

PatentInactiveEP1107266A3

Innovation

- A C-shaped pole frame or flux collector is formed from a single sheet stock, with ends curled over coil bobbin extensions to secure the bobbin and coil, providing increased flux transfer and a robust assembly with reduced manufacturing costs.

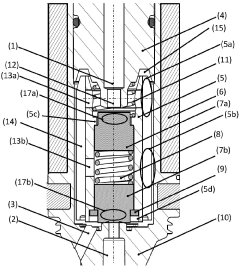

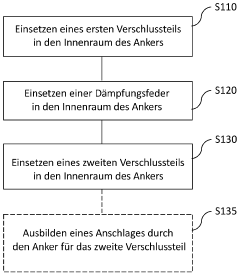

Solenoid valve with improved damping and method for producing the same

PatentPendingDE102022110448A1

Innovation

- A solenoid valve design featuring a first and second closure part with a damping spring between them, which cushions the closing of connections, and an anchor with through openings for pressure equalization, allowing for simple production and reliable operation through double damping.

Material Compatibility and Durability Considerations

In the context of solenoid valve applications in aerospace composite machining, material compatibility and durability are critical considerations that significantly impact the performance and longevity of the system. The harsh operating conditions in aerospace environments, combined with the unique properties of composite materials, necessitate careful selection of valve components and materials.

Solenoid valves in aerospace applications are exposed to a wide range of temperatures, pressures, and chemical environments. The materials used in these valves must maintain their structural integrity and functional properties across these diverse conditions. For instance, the valve body and internal components must resist corrosion, wear, and degradation when in contact with various fluids, including hydraulic oils, fuels, and coolants commonly used in aerospace systems.

Composite materials, such as carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), present unique challenges for solenoid valve design. These materials have different thermal expansion coefficients and chemical resistances compared to traditional metallic aerospace components. As a result, the interface between the valve and the composite structure requires special attention to prevent issues such as galvanic corrosion, thermal stress, or chemical incompatibility.

The selection of seal materials is particularly crucial in solenoid valve design for aerospace composite machining. Elastomers used for seals must maintain their elasticity and sealing properties across a wide temperature range while resisting chemical attack from process fluids and aerospace chemicals. Fluoroelastomers, such as Viton, and perfluoroelastomers like Kalrez, are often preferred for their excellent chemical resistance and temperature stability.

Durability considerations extend beyond material selection to the design of the valve itself. The cycling frequency of solenoid valves in aerospace applications can be extremely high, necessitating robust designs that can withstand millions of actuations without failure. This includes considerations for wear-resistant coatings on moving parts, optimized magnetic circuit designs to reduce heat generation, and fail-safe mechanisms to ensure system safety in case of valve malfunction.

Furthermore, the integration of solenoid valves with composite structures requires careful consideration of mounting and fastening methods. Traditional fastening techniques may not be suitable for composite materials, necessitating the development of specialized mounting solutions that distribute loads evenly and prevent damage to the composite structure.

In conclusion, the material compatibility and durability considerations for solenoid valves in aerospace composite machining encompass a wide range of factors, from chemical resistance and thermal stability to wear resistance and structural integrity. Addressing these considerations is essential for ensuring the reliability, safety, and longevity of aerospace systems incorporating composite materials and solenoid valve technology.

Solenoid valves in aerospace applications are exposed to a wide range of temperatures, pressures, and chemical environments. The materials used in these valves must maintain their structural integrity and functional properties across these diverse conditions. For instance, the valve body and internal components must resist corrosion, wear, and degradation when in contact with various fluids, including hydraulic oils, fuels, and coolants commonly used in aerospace systems.

Composite materials, such as carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), present unique challenges for solenoid valve design. These materials have different thermal expansion coefficients and chemical resistances compared to traditional metallic aerospace components. As a result, the interface between the valve and the composite structure requires special attention to prevent issues such as galvanic corrosion, thermal stress, or chemical incompatibility.

The selection of seal materials is particularly crucial in solenoid valve design for aerospace composite machining. Elastomers used for seals must maintain their elasticity and sealing properties across a wide temperature range while resisting chemical attack from process fluids and aerospace chemicals. Fluoroelastomers, such as Viton, and perfluoroelastomers like Kalrez, are often preferred for their excellent chemical resistance and temperature stability.

Durability considerations extend beyond material selection to the design of the valve itself. The cycling frequency of solenoid valves in aerospace applications can be extremely high, necessitating robust designs that can withstand millions of actuations without failure. This includes considerations for wear-resistant coatings on moving parts, optimized magnetic circuit designs to reduce heat generation, and fail-safe mechanisms to ensure system safety in case of valve malfunction.

Furthermore, the integration of solenoid valves with composite structures requires careful consideration of mounting and fastening methods. Traditional fastening techniques may not be suitable for composite materials, necessitating the development of specialized mounting solutions that distribute loads evenly and prevent damage to the composite structure.

In conclusion, the material compatibility and durability considerations for solenoid valves in aerospace composite machining encompass a wide range of factors, from chemical resistance and thermal stability to wear resistance and structural integrity. Addressing these considerations is essential for ensuring the reliability, safety, and longevity of aerospace systems incorporating composite materials and solenoid valve technology.

Aerospace Industry Standards and Certifications

The aerospace industry operates under stringent regulations and quality standards to ensure the safety and reliability of aircraft and spacecraft. For solenoid valves used in composite machining processes, adherence to these standards is crucial. The primary regulatory bodies governing aerospace manufacturing include the Federal Aviation Administration (FAA) in the United States, the European Union Aviation Safety Agency (EASA) in Europe, and the International Civil Aviation Organization (ICAO) globally.

One of the most critical certifications for aerospace components is the AS9100 standard, which is based on ISO 9001 but includes additional requirements specific to the aerospace industry. Solenoid valves used in composite machining must be manufactured and tested in compliance with AS9100 to ensure they meet the rigorous quality and safety standards required for aerospace applications.

In addition to AS9100, solenoid valves must also comply with specific performance standards such as MIL-STD-810, which outlines environmental test methods for aerospace equipment. This standard ensures that components can withstand the extreme conditions encountered during flight, including temperature variations, vibration, and pressure changes.

The RTCA DO-160 standard is another crucial certification for aerospace electronic equipment, including solenoid valves with electronic controls. This standard provides guidelines for environmental conditions and test procedures for airborne equipment, ensuring that components can function reliably in various operational scenarios.

For composite machining applications, solenoid valves must also meet the requirements of SAE AMS2750, which specifies pyrometry requirements for thermal processing equipment used in aerospace manufacturing. This standard is particularly relevant for temperature-controlled processes in composite curing and machining.

Electromagnetic compatibility (EMC) is a critical consideration in aerospace applications. Solenoid valves must comply with MIL-STD-461, which sets requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This ensures that the valves do not interfere with other electronic systems on the aircraft.

Furthermore, materials used in solenoid valves for aerospace applications must meet specific standards such as AMS-QQ-N-290 for corrosion-resistant steel and AMS-QQ-A-250/4 for aluminum alloys. These standards ensure that the materials used can withstand the harsh environments encountered in aerospace applications.

Compliance with these standards and certifications is not a one-time process but requires ongoing monitoring and periodic recertification. Manufacturers of solenoid valves for aerospace composite machining must maintain robust quality management systems and documentation to demonstrate continuous compliance with these rigorous industry standards.

One of the most critical certifications for aerospace components is the AS9100 standard, which is based on ISO 9001 but includes additional requirements specific to the aerospace industry. Solenoid valves used in composite machining must be manufactured and tested in compliance with AS9100 to ensure they meet the rigorous quality and safety standards required for aerospace applications.

In addition to AS9100, solenoid valves must also comply with specific performance standards such as MIL-STD-810, which outlines environmental test methods for aerospace equipment. This standard ensures that components can withstand the extreme conditions encountered during flight, including temperature variations, vibration, and pressure changes.

The RTCA DO-160 standard is another crucial certification for aerospace electronic equipment, including solenoid valves with electronic controls. This standard provides guidelines for environmental conditions and test procedures for airborne equipment, ensuring that components can function reliably in various operational scenarios.

For composite machining applications, solenoid valves must also meet the requirements of SAE AMS2750, which specifies pyrometry requirements for thermal processing equipment used in aerospace manufacturing. This standard is particularly relevant for temperature-controlled processes in composite curing and machining.

Electromagnetic compatibility (EMC) is a critical consideration in aerospace applications. Solenoid valves must comply with MIL-STD-461, which sets requirements for the control of electromagnetic interference characteristics of subsystems and equipment. This ensures that the valves do not interfere with other electronic systems on the aircraft.

Furthermore, materials used in solenoid valves for aerospace applications must meet specific standards such as AMS-QQ-N-290 for corrosion-resistant steel and AMS-QQ-A-250/4 for aluminum alloys. These standards ensure that the materials used can withstand the harsh environments encountered in aerospace applications.

Compliance with these standards and certifications is not a one-time process but requires ongoing monitoring and periodic recertification. Manufacturers of solenoid valves for aerospace composite machining must maintain robust quality management systems and documentation to demonstrate continuous compliance with these rigorous industry standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!