The optimization of mild hybrid systems for urban landscaping machinery

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Landscaping Tech Evolution

The evolution of mild hybrid systems for urban landscaping machinery has been marked by significant technological advancements and a growing emphasis on sustainability. Initially, these systems were primarily focused on reducing fuel consumption and emissions in larger vehicles. However, as environmental concerns and urban regulations became more stringent, the technology began to find its way into smaller, specialized equipment used in landscaping.

The early stages of mild hybrid integration in landscaping machinery were characterized by simple start-stop systems, which automatically shut off the engine when the equipment was idle. This basic functionality provided modest fuel savings and reduced emissions, particularly in urban environments where equipment often experiences frequent periods of inactivity.

As the technology progressed, more sophisticated energy recovery systems were introduced. These systems captured energy during braking or deceleration and stored it in small battery packs. This recovered energy could then be used to assist the engine during acceleration or to power auxiliary systems, further improving fuel efficiency and reducing the overall environmental impact of the machinery.

The next significant milestone in the evolution of mild hybrid systems for landscaping equipment was the introduction of electric-assisted propulsion. This advancement allowed for short periods of all-electric operation, particularly useful for low-speed maneuvering or when working in noise-sensitive areas. The integration of electric motors also enabled more precise control over equipment functions, leading to improved performance and operator comfort.

Recent developments have focused on optimizing the balance between the internal combustion engine and electric components. Advanced power management systems have been developed to seamlessly switch between power sources, maximizing efficiency based on the specific task and operating conditions. This has led to the creation of "smart" landscaping equipment that can adapt its power usage in real-time to minimize fuel consumption and emissions.

The latest trend in mild hybrid landscaping technology is the integration of connectivity and data analytics. Modern systems now incorporate sensors and telematics to collect operational data, allowing for predictive maintenance and optimized usage patterns. This not only improves the longevity and reliability of the equipment but also provides valuable insights for further refinement of the hybrid systems.

Looking ahead, the evolution of mild hybrid systems in urban landscaping machinery is likely to continue towards increased electrification and automation. Future iterations may see the development of modular power systems that can be easily upgraded or swapped, allowing landscaping businesses to adapt their equipment to changing environmental regulations and technological advancements without the need for complete fleet replacement.

The early stages of mild hybrid integration in landscaping machinery were characterized by simple start-stop systems, which automatically shut off the engine when the equipment was idle. This basic functionality provided modest fuel savings and reduced emissions, particularly in urban environments where equipment often experiences frequent periods of inactivity.

As the technology progressed, more sophisticated energy recovery systems were introduced. These systems captured energy during braking or deceleration and stored it in small battery packs. This recovered energy could then be used to assist the engine during acceleration or to power auxiliary systems, further improving fuel efficiency and reducing the overall environmental impact of the machinery.

The next significant milestone in the evolution of mild hybrid systems for landscaping equipment was the introduction of electric-assisted propulsion. This advancement allowed for short periods of all-electric operation, particularly useful for low-speed maneuvering or when working in noise-sensitive areas. The integration of electric motors also enabled more precise control over equipment functions, leading to improved performance and operator comfort.

Recent developments have focused on optimizing the balance between the internal combustion engine and electric components. Advanced power management systems have been developed to seamlessly switch between power sources, maximizing efficiency based on the specific task and operating conditions. This has led to the creation of "smart" landscaping equipment that can adapt its power usage in real-time to minimize fuel consumption and emissions.

The latest trend in mild hybrid landscaping technology is the integration of connectivity and data analytics. Modern systems now incorporate sensors and telematics to collect operational data, allowing for predictive maintenance and optimized usage patterns. This not only improves the longevity and reliability of the equipment but also provides valuable insights for further refinement of the hybrid systems.

Looking ahead, the evolution of mild hybrid systems in urban landscaping machinery is likely to continue towards increased electrification and automation. Future iterations may see the development of modular power systems that can be easily upgraded or swapped, allowing landscaping businesses to adapt their equipment to changing environmental regulations and technological advancements without the need for complete fleet replacement.

Urban Green Space Market Analysis

The urban green space market has experienced significant growth in recent years, driven by increasing urbanization and a growing awareness of the importance of green spaces in urban environments. This market encompasses various elements, including parks, gardens, green corridors, and urban forests, which collectively contribute to the quality of life in cities and towns.

The global urban green space market is projected to expand at a steady rate, with a particular focus on sustainable and eco-friendly landscaping solutions. This growth is fueled by government initiatives to promote green infrastructure, rising environmental concerns, and the need for improved air quality in urban areas. Additionally, the COVID-19 pandemic has further highlighted the importance of accessible green spaces for public health and well-being, leading to increased investments in urban landscaping projects.

In the context of urban landscaping machinery, there is a growing demand for equipment that can efficiently maintain and manage green spaces while minimizing environmental impact. This has led to a shift towards more sustainable and technologically advanced machinery, including those incorporating mild hybrid systems. The market for such equipment is expected to grow as cities and municipalities seek to reduce their carbon footprint and operational costs associated with landscape maintenance.

The adoption of mild hybrid systems in urban landscaping machinery aligns with the broader trend of electrification in the automotive and equipment industries. These systems offer improved fuel efficiency, reduced emissions, and lower noise levels compared to traditional combustion engine-powered equipment. As a result, they are becoming increasingly attractive for use in urban environments where noise and air pollution regulations are becoming more stringent.

Key market drivers for mild hybrid urban landscaping machinery include stricter environmental regulations, rising fuel costs, and growing public demand for sustainable urban development. Municipal governments and private landscaping companies are increasingly looking for equipment that can meet these challenges while maintaining high performance and reliability.

However, the market also faces certain challenges. The initial cost of mild hybrid equipment is generally higher than traditional machinery, which can be a barrier to adoption, especially for smaller landscaping businesses or municipalities with limited budgets. Additionally, there may be concerns about the long-term reliability and maintenance requirements of these new systems, particularly in the early stages of market adoption.

Despite these challenges, the overall outlook for mild hybrid systems in urban landscaping machinery remains positive. As technology advances and economies of scale are realized, the cost-benefit ratio is expected to improve, making these systems more accessible to a wider range of users. This trend is likely to accelerate as cities worldwide continue to prioritize sustainable urban development and green space management.

The global urban green space market is projected to expand at a steady rate, with a particular focus on sustainable and eco-friendly landscaping solutions. This growth is fueled by government initiatives to promote green infrastructure, rising environmental concerns, and the need for improved air quality in urban areas. Additionally, the COVID-19 pandemic has further highlighted the importance of accessible green spaces for public health and well-being, leading to increased investments in urban landscaping projects.

In the context of urban landscaping machinery, there is a growing demand for equipment that can efficiently maintain and manage green spaces while minimizing environmental impact. This has led to a shift towards more sustainable and technologically advanced machinery, including those incorporating mild hybrid systems. The market for such equipment is expected to grow as cities and municipalities seek to reduce their carbon footprint and operational costs associated with landscape maintenance.

The adoption of mild hybrid systems in urban landscaping machinery aligns with the broader trend of electrification in the automotive and equipment industries. These systems offer improved fuel efficiency, reduced emissions, and lower noise levels compared to traditional combustion engine-powered equipment. As a result, they are becoming increasingly attractive for use in urban environments where noise and air pollution regulations are becoming more stringent.

Key market drivers for mild hybrid urban landscaping machinery include stricter environmental regulations, rising fuel costs, and growing public demand for sustainable urban development. Municipal governments and private landscaping companies are increasingly looking for equipment that can meet these challenges while maintaining high performance and reliability.

However, the market also faces certain challenges. The initial cost of mild hybrid equipment is generally higher than traditional machinery, which can be a barrier to adoption, especially for smaller landscaping businesses or municipalities with limited budgets. Additionally, there may be concerns about the long-term reliability and maintenance requirements of these new systems, particularly in the early stages of market adoption.

Despite these challenges, the overall outlook for mild hybrid systems in urban landscaping machinery remains positive. As technology advances and economies of scale are realized, the cost-benefit ratio is expected to improve, making these systems more accessible to a wider range of users. This trend is likely to accelerate as cities worldwide continue to prioritize sustainable urban development and green space management.

Hybrid System Challenges in Landscaping

The integration of mild hybrid systems into urban landscaping machinery presents several unique challenges that require innovative solutions. One of the primary obstacles is the need for compact and lightweight hybrid powertrains that can fit within the space constraints of landscaping equipment without compromising maneuverability or increasing overall weight significantly. This is particularly crucial for handheld tools and smaller machines where every additional pound can impact operator fatigue and productivity.

Another significant challenge lies in the power management and energy distribution between the internal combustion engine and the electric motor. Landscaping tasks often involve intermittent high-power demands, such as when cutting through thick vegetation or operating multiple tools simultaneously. Developing a hybrid system that can seamlessly transition between power sources and provide instant torque when needed is essential for maintaining performance levels comparable to traditional gas-powered equipment.

The durability and reliability of hybrid systems in harsh outdoor environments pose additional hurdles. Landscaping machinery is exposed to dust, debris, moisture, and extreme temperatures, which can affect the longevity and performance of electrical components. Engineers must design robust enclosures and cooling systems to protect sensitive hybrid elements while ensuring easy maintenance access for landscaping professionals who may not be familiar with hybrid technology.

Battery technology presents its own set of challenges in the context of landscaping applications. The ideal battery solution must offer high energy density to provide sufficient runtime, rapid charging capabilities to minimize downtime, and the ability to withstand frequent charge-discharge cycles without significant degradation. Additionally, the battery system must be designed to handle the vibrations and impacts common in landscaping operations.

Noise reduction is another critical aspect that hybrid systems must address in urban landscaping. While electric operation can significantly reduce noise levels, the transition between electric and combustion power must be carefully managed to maintain a consistent and acceptable noise profile, especially in noise-sensitive urban areas.

Lastly, the cost-effectiveness of hybrid systems in landscaping machinery remains a significant challenge. The initial investment in hybrid technology must be balanced against long-term operational savings and environmental benefits. Manufacturers need to develop strategies to reduce production costs and demonstrate clear value propositions to landscaping professionals and municipal buyers who may be hesitant to adopt new technologies.

Another significant challenge lies in the power management and energy distribution between the internal combustion engine and the electric motor. Landscaping tasks often involve intermittent high-power demands, such as when cutting through thick vegetation or operating multiple tools simultaneously. Developing a hybrid system that can seamlessly transition between power sources and provide instant torque when needed is essential for maintaining performance levels comparable to traditional gas-powered equipment.

The durability and reliability of hybrid systems in harsh outdoor environments pose additional hurdles. Landscaping machinery is exposed to dust, debris, moisture, and extreme temperatures, which can affect the longevity and performance of electrical components. Engineers must design robust enclosures and cooling systems to protect sensitive hybrid elements while ensuring easy maintenance access for landscaping professionals who may not be familiar with hybrid technology.

Battery technology presents its own set of challenges in the context of landscaping applications. The ideal battery solution must offer high energy density to provide sufficient runtime, rapid charging capabilities to minimize downtime, and the ability to withstand frequent charge-discharge cycles without significant degradation. Additionally, the battery system must be designed to handle the vibrations and impacts common in landscaping operations.

Noise reduction is another critical aspect that hybrid systems must address in urban landscaping. While electric operation can significantly reduce noise levels, the transition between electric and combustion power must be carefully managed to maintain a consistent and acceptable noise profile, especially in noise-sensitive urban areas.

Lastly, the cost-effectiveness of hybrid systems in landscaping machinery remains a significant challenge. The initial investment in hybrid technology must be balanced against long-term operational savings and environmental benefits. Manufacturers need to develop strategies to reduce production costs and demonstrate clear value propositions to landscaping professionals and municipal buyers who may be hesitant to adopt new technologies.

Current Mild Hybrid Solutions

01 Energy management optimization

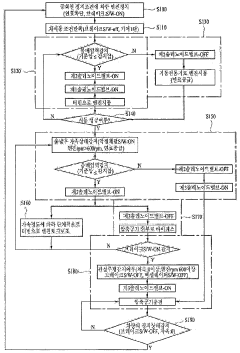

Optimization of energy management systems in mild hybrid vehicles to improve fuel efficiency and reduce emissions. This involves advanced control strategies for power distribution between the internal combustion engine and electric motor, as well as optimizing regenerative braking and battery charging processes.- Energy management optimization: Optimization of energy management systems in mild hybrid vehicles to improve fuel efficiency and reduce emissions. This involves advanced control strategies for power distribution between the internal combustion engine and electric motor, as well as optimizing battery charging and discharging cycles.

- Powertrain configuration improvements: Enhancements to the powertrain configuration of mild hybrid systems, including optimized integration of electric motors, improved transmission designs, and more efficient coupling mechanisms between the internal combustion engine and electric components.

- Battery technology advancements: Developments in battery technology for mild hybrid systems, focusing on improving energy density, charge/discharge efficiency, and overall lifespan. This includes the use of advanced materials and innovative cell designs to enhance the performance of the hybrid system.

- Regenerative braking optimization: Improvements in regenerative braking systems for mild hybrids, maximizing energy recovery during deceleration and braking events. This involves advanced control algorithms and hardware enhancements to increase the efficiency of energy recuperation.

- Intelligent control systems: Development of advanced control systems utilizing artificial intelligence and machine learning algorithms to optimize the performance of mild hybrid systems. These intelligent systems can adapt to driving conditions, predict energy demands, and optimize power distribution in real-time.

02 Powertrain configuration improvements

Enhancements to the powertrain configuration of mild hybrid systems, including optimized integration of electric motors, improved transmission designs, and more efficient coupling mechanisms between the internal combustion engine and electric drive components.Expand Specific Solutions03 Battery and electrical system optimization

Advancements in battery technology and electrical systems for mild hybrid vehicles, focusing on improving energy storage capacity, charge/discharge efficiency, and overall system reliability. This includes optimizing battery management systems and enhancing power electronics.Expand Specific Solutions04 Control strategy and software improvements

Development of sophisticated control strategies and software algorithms to optimize the performance of mild hybrid systems. This includes predictive energy management, adaptive control systems, and machine learning techniques to enhance overall system efficiency and driving experience.Expand Specific Solutions05 Integration with advanced driver assistance systems

Optimization of mild hybrid systems through integration with advanced driver assistance systems (ADAS) and connected vehicle technologies. This approach leverages real-time data and predictive algorithms to optimize energy management and vehicle performance based on driving conditions and route information.Expand Specific Solutions

Key Players in Hybrid Landscaping

The optimization of mild hybrid systems for urban landscaping machinery is in an early development stage, with a growing market driven by increasing urbanization and environmental concerns. The technology's maturity varies among key players, with automotive giants like Audi AG, Hyundai Motor Co., and Kia Corp. leading in hybrid system development. Construction equipment manufacturers such as Caterpillar, Inc., Hitachi Construction Machinery Co., and Volvo Construction Equipment AB are adapting these technologies for landscaping applications. Specialized companies like Pubang Landscape Architecture Co., Ltd. and Wuhan Rongmu Environmental Engineering Co., Ltd. are likely focusing on integrating mild hybrid systems into specific urban landscaping equipment, leveraging their industry expertise to address unique challenges in this niche market.

Caterpillar, Inc.

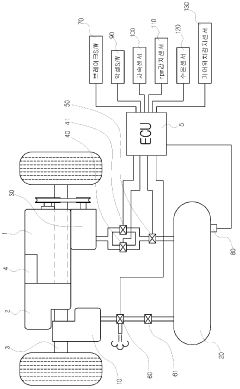

Technical Solution: Caterpillar has developed a mild hybrid system for urban landscaping machinery that integrates an electric motor-generator with a conventional internal combustion engine. This system utilizes regenerative braking to capture energy during deceleration and store it in a compact battery pack. The stored energy is then used to assist the engine during acceleration and high-load operations, reducing fuel consumption by up to 25% in urban environments[1]. The system also incorporates start-stop technology, automatically shutting off the engine when the machine is idle and restarting it instantly when needed. Caterpillar's mild hybrid system features advanced power management algorithms that optimize the balance between electric and combustion power based on real-time operating conditions and load requirements[3].

Strengths: Significant fuel savings, reduced emissions, improved performance in urban settings. Weaknesses: Higher initial cost, complexity of system integration, potential reliability concerns in harsh environments.

Honda Motor Co., Ltd.

Technical Solution: Honda has adapted its i-MMD (Intelligent Multi-Mode Drive) hybrid system for use in urban landscaping machinery. This system employs two electric motors: one for propulsion and another as a generator. The internal combustion engine primarily acts as a generator, with direct drive engagement at higher speeds for improved efficiency. Honda's mild hybrid system for landscaping equipment features a compact, high-output lithium-ion battery and an intelligent power control unit that optimizes power distribution between electric and combustion sources based on load and operating conditions[7]. The system also incorporates regenerative braking and an electric-only mode for low-noise operation in sensitive urban areas, achieving up to 30% reduction in fuel consumption[8].

Strengths: Versatile operating modes, high efficiency in various load conditions, low-noise operation capability. Weaknesses: Complexity of dual-motor system, potentially higher manufacturing costs.

Core Innovations in Hybrid Systems

Mild hybrid system

PatentWO2011152619A2

Innovation

- A hybrid engine system utilizing a compressor, compressed air cylinder, turbine, and solenoid valves to control compressed air supply for smooth engine start and acceleration, reducing engine load and maintaining efficient operation without design changes to existing engines.

Mild hybrid system and method for controlling the same

PatentActiveUS9428063B2

Innovation

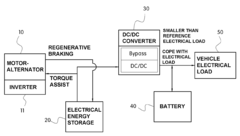

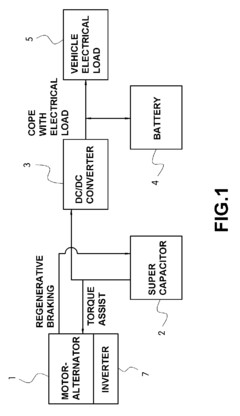

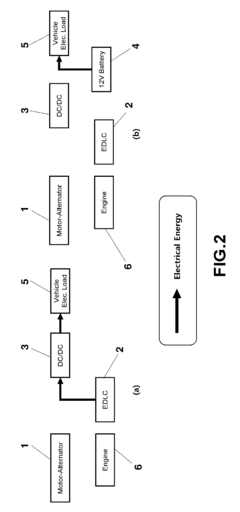

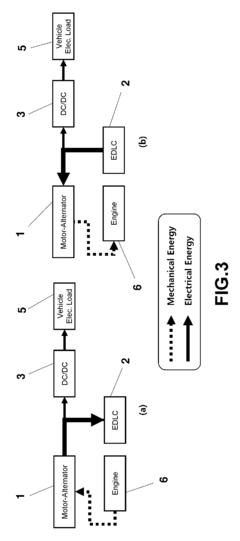

- A mild hybrid system utilizing a unidirectional DC/DC buck converter with a bypass function to manage electrical energy flow, allowing for bidirectional electricity flow in bypass states and eliminating the need for a bidirectional converter.

Environmental Impact Assessment

The environmental impact assessment of mild hybrid systems for urban landscaping machinery is a crucial aspect of their optimization. These systems, which combine conventional internal combustion engines with electric propulsion, offer significant potential for reducing the environmental footprint of landscaping operations in urban areas.

One of the primary environmental benefits of mild hybrid systems is the reduction in fuel consumption and, consequently, greenhouse gas emissions. By utilizing electric power during low-load operations and regenerative braking, these systems can achieve fuel savings of up to 20% compared to conventional machinery. This translates to a substantial decrease in carbon dioxide emissions, contributing to improved air quality in urban environments.

Noise pollution is another critical environmental concern addressed by mild hybrid systems. Urban landscaping activities often generate significant noise, causing disturbance to residents and wildlife. Hybrid systems allow for quieter operation during low-power tasks, as the electric motor can handle these functions without engaging the combustion engine. This reduction in noise levels is particularly beneficial in noise-sensitive areas such as parks, residential neighborhoods, and near hospitals or schools.

The use of mild hybrid systems also contributes to reduced local air pollution. By optimizing engine operation and reducing idling time, these systems minimize the emission of particulate matter, nitrogen oxides, and other harmful pollutants. This is especially important in urban areas where air quality is often a significant concern and can have direct impacts on public health.

Furthermore, the integration of mild hybrid technology in landscaping machinery can lead to improved resource efficiency. The optimized power management allows for more precise control of equipment, potentially reducing water usage in irrigation systems and minimizing the overuse of fertilizers and pesticides. This not only conserves resources but also reduces the risk of soil and water contamination.

The environmental benefits extend to the lifecycle of the equipment as well. Mild hybrid systems can potentially extend the operational life of machinery by reducing wear on engine components. This longevity translates to less frequent replacement of equipment, thereby reducing the environmental impact associated with manufacturing and disposal of landscaping machinery.

However, it is important to consider the potential environmental trade-offs. The production of batteries and electronic components for hybrid systems may have its own environmental impacts, including resource extraction and energy-intensive manufacturing processes. A comprehensive lifecycle assessment is necessary to fully understand the net environmental benefit of these systems compared to conventional alternatives.

One of the primary environmental benefits of mild hybrid systems is the reduction in fuel consumption and, consequently, greenhouse gas emissions. By utilizing electric power during low-load operations and regenerative braking, these systems can achieve fuel savings of up to 20% compared to conventional machinery. This translates to a substantial decrease in carbon dioxide emissions, contributing to improved air quality in urban environments.

Noise pollution is another critical environmental concern addressed by mild hybrid systems. Urban landscaping activities often generate significant noise, causing disturbance to residents and wildlife. Hybrid systems allow for quieter operation during low-power tasks, as the electric motor can handle these functions without engaging the combustion engine. This reduction in noise levels is particularly beneficial in noise-sensitive areas such as parks, residential neighborhoods, and near hospitals or schools.

The use of mild hybrid systems also contributes to reduced local air pollution. By optimizing engine operation and reducing idling time, these systems minimize the emission of particulate matter, nitrogen oxides, and other harmful pollutants. This is especially important in urban areas where air quality is often a significant concern and can have direct impacts on public health.

Furthermore, the integration of mild hybrid technology in landscaping machinery can lead to improved resource efficiency. The optimized power management allows for more precise control of equipment, potentially reducing water usage in irrigation systems and minimizing the overuse of fertilizers and pesticides. This not only conserves resources but also reduces the risk of soil and water contamination.

The environmental benefits extend to the lifecycle of the equipment as well. Mild hybrid systems can potentially extend the operational life of machinery by reducing wear on engine components. This longevity translates to less frequent replacement of equipment, thereby reducing the environmental impact associated with manufacturing and disposal of landscaping machinery.

However, it is important to consider the potential environmental trade-offs. The production of batteries and electronic components for hybrid systems may have its own environmental impacts, including resource extraction and energy-intensive manufacturing processes. A comprehensive lifecycle assessment is necessary to fully understand the net environmental benefit of these systems compared to conventional alternatives.

Noise Reduction Technologies

Noise reduction technologies play a crucial role in optimizing mild hybrid systems for urban landscaping machinery. As these machines operate in densely populated areas, minimizing noise pollution is essential for environmental compliance and public acceptance. Advanced noise reduction techniques focus on both mechanical and electrical components of hybrid systems.

One primary approach involves the use of acoustic enclosures and sound-absorbing materials. These enclosures are designed to contain and absorb noise generated by the engine and other mechanical components. High-performance materials such as polyurethane foam, fiberglass, and recycled textile fibers are employed to create effective sound barriers without significantly increasing the machine's weight.

Active noise control systems represent another innovative solution. These systems use electronic sound waves to counteract unwanted noise, effectively canceling out specific frequencies. In mild hybrid systems, active noise control can be particularly effective in mitigating low-frequency sounds produced by the internal combustion engine during operation.

Vibration damping technologies are also integral to noise reduction efforts. By isolating the engine and other vibrating components from the machine's frame, these systems significantly reduce structure-borne noise. Advanced rubber mounts, hydraulic engine mounts, and tuned mass dampers are commonly used to achieve this isolation.

Electric motor design plays a crucial role in noise reduction for mild hybrid systems. The latest brushless DC motors and switched reluctance motors offer quieter operation compared to traditional brushed motors. Additionally, advanced motor control algorithms can optimize the motor's operation to minimize noise output across various speed ranges.

Exhaust system modifications contribute significantly to noise reduction. Resonators and mufflers specifically designed for hybrid systems can effectively attenuate exhaust noise without compromising engine performance. Some advanced designs incorporate active exhaust valves that can adjust the exhaust flow and noise levels based on operating conditions.

Software-based noise reduction strategies are becoming increasingly important. These include intelligent engine management systems that optimize the balance between the electric motor and internal combustion engine to minimize overall noise output. Such systems can dynamically adjust the power distribution based on the machine's operating mode and environmental conditions.

Lastly, aerodynamic improvements to the machine's design can help reduce wind noise during operation. This includes streamlining the body shape and optimizing air intake and cooling systems to minimize turbulence-induced noise.

One primary approach involves the use of acoustic enclosures and sound-absorbing materials. These enclosures are designed to contain and absorb noise generated by the engine and other mechanical components. High-performance materials such as polyurethane foam, fiberglass, and recycled textile fibers are employed to create effective sound barriers without significantly increasing the machine's weight.

Active noise control systems represent another innovative solution. These systems use electronic sound waves to counteract unwanted noise, effectively canceling out specific frequencies. In mild hybrid systems, active noise control can be particularly effective in mitigating low-frequency sounds produced by the internal combustion engine during operation.

Vibration damping technologies are also integral to noise reduction efforts. By isolating the engine and other vibrating components from the machine's frame, these systems significantly reduce structure-borne noise. Advanced rubber mounts, hydraulic engine mounts, and tuned mass dampers are commonly used to achieve this isolation.

Electric motor design plays a crucial role in noise reduction for mild hybrid systems. The latest brushless DC motors and switched reluctance motors offer quieter operation compared to traditional brushed motors. Additionally, advanced motor control algorithms can optimize the motor's operation to minimize noise output across various speed ranges.

Exhaust system modifications contribute significantly to noise reduction. Resonators and mufflers specifically designed for hybrid systems can effectively attenuate exhaust noise without compromising engine performance. Some advanced designs incorporate active exhaust valves that can adjust the exhaust flow and noise levels based on operating conditions.

Software-based noise reduction strategies are becoming increasingly important. These include intelligent engine management systems that optimize the balance between the electric motor and internal combustion engine to minimize overall noise output. Such systems can dynamically adjust the power distribution based on the machine's operating mode and environmental conditions.

Lastly, aerodynamic improvements to the machine's design can help reduce wind noise during operation. This includes streamlining the body shape and optimizing air intake and cooling systems to minimize turbulence-induced noise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!