The role of mild hybrids in achieving sustainable logistics solutions

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Technology Evolution and Objectives

Mild hybrid technology has emerged as a crucial stepping stone in the evolution of sustainable transportation solutions, particularly in the logistics sector. This technology combines traditional internal combustion engines with small electric motors, offering a balance between improved fuel efficiency and reduced emissions without the complexity of full hybrid systems.

The development of mild hybrid technology can be traced back to the early 2000s, with initial implementations focusing on passenger vehicles. However, its potential for commercial and logistics applications became increasingly apparent as environmental regulations tightened and fuel costs rose. The primary objective of mild hybrid systems in logistics is to enhance the overall efficiency of vehicles while minimizing the impact on payload capacity and operational flexibility.

As the technology progressed, mild hybrid systems evolved from simple start-stop functionality to more sophisticated energy recovery and power assist features. This evolution has been driven by advancements in battery technology, power electronics, and control systems. The integration of 48-volt electrical systems has been a significant milestone, allowing for more powerful electric motors and expanded capabilities without the need for high-voltage infrastructure.

In the context of sustainable logistics solutions, mild hybrid technology aims to address several key objectives. Firstly, it seeks to reduce fuel consumption and CO2 emissions, which is critical for meeting increasingly stringent environmental regulations and corporate sustainability goals. Secondly, it aims to improve the overall efficiency of logistics operations by optimizing engine performance and reducing idle time.

Another important objective is to provide a cost-effective solution for fleet operators. Mild hybrid systems offer a more accessible entry point into electrification compared to full hybrid or battery-electric vehicles, requiring less initial investment and minimal changes to existing maintenance and operational practices. This makes them particularly attractive for logistics companies looking to gradually transition towards more sustainable practices.

Looking ahead, the evolution of mild hybrid technology in logistics is expected to focus on further integration with telematics and predictive systems. This will enable more intelligent energy management based on route characteristics, load conditions, and traffic patterns. Additionally, there is a growing trend towards the development of modular mild hybrid systems that can be retrofitted to existing vehicles, extending the benefits of this technology to a wider range of logistics fleets.

As the logistics industry continues to seek sustainable solutions, mild hybrid technology is positioned to play a pivotal role in bridging the gap between conventional powertrains and fully electric vehicles. Its ongoing evolution will likely see increased power output from electric components, improved energy recovery systems, and enhanced integration with other vehicle systems to maximize efficiency gains across various operational scenarios.

The development of mild hybrid technology can be traced back to the early 2000s, with initial implementations focusing on passenger vehicles. However, its potential for commercial and logistics applications became increasingly apparent as environmental regulations tightened and fuel costs rose. The primary objective of mild hybrid systems in logistics is to enhance the overall efficiency of vehicles while minimizing the impact on payload capacity and operational flexibility.

As the technology progressed, mild hybrid systems evolved from simple start-stop functionality to more sophisticated energy recovery and power assist features. This evolution has been driven by advancements in battery technology, power electronics, and control systems. The integration of 48-volt electrical systems has been a significant milestone, allowing for more powerful electric motors and expanded capabilities without the need for high-voltage infrastructure.

In the context of sustainable logistics solutions, mild hybrid technology aims to address several key objectives. Firstly, it seeks to reduce fuel consumption and CO2 emissions, which is critical for meeting increasingly stringent environmental regulations and corporate sustainability goals. Secondly, it aims to improve the overall efficiency of logistics operations by optimizing engine performance and reducing idle time.

Another important objective is to provide a cost-effective solution for fleet operators. Mild hybrid systems offer a more accessible entry point into electrification compared to full hybrid or battery-electric vehicles, requiring less initial investment and minimal changes to existing maintenance and operational practices. This makes them particularly attractive for logistics companies looking to gradually transition towards more sustainable practices.

Looking ahead, the evolution of mild hybrid technology in logistics is expected to focus on further integration with telematics and predictive systems. This will enable more intelligent energy management based on route characteristics, load conditions, and traffic patterns. Additionally, there is a growing trend towards the development of modular mild hybrid systems that can be retrofitted to existing vehicles, extending the benefits of this technology to a wider range of logistics fleets.

As the logistics industry continues to seek sustainable solutions, mild hybrid technology is positioned to play a pivotal role in bridging the gap between conventional powertrains and fully electric vehicles. Its ongoing evolution will likely see increased power output from electric components, improved energy recovery systems, and enhanced integration with other vehicle systems to maximize efficiency gains across various operational scenarios.

Market Demand for Sustainable Logistics Solutions

The demand for sustainable logistics solutions has been steadily increasing in recent years, driven by a combination of environmental concerns, regulatory pressures, and economic factors. As businesses and consumers become more aware of the environmental impact of traditional logistics operations, there is a growing market for technologies and practices that can reduce carbon emissions, improve energy efficiency, and minimize waste in the supply chain.

Mild hybrid technology has emerged as a promising solution in the sustainable logistics sector, particularly for commercial vehicles and delivery fleets. This technology offers a balance between improved fuel efficiency and reduced emissions without the complexity and cost associated with full hybrid or electric vehicles. The market for mild hybrid systems in logistics is expected to grow significantly over the next decade, as fleet operators seek cost-effective ways to meet increasingly stringent emissions regulations and corporate sustainability goals.

One of the key drivers of market demand for mild hybrid solutions in logistics is the potential for fuel cost savings. With fuel representing a significant portion of operating expenses for logistics companies, even modest improvements in fuel efficiency can translate into substantial cost reductions over the lifetime of a vehicle. Mild hybrid systems, which typically offer fuel savings of 10-15% compared to conventional vehicles, are particularly attractive to fleet operators looking to optimize their total cost of ownership.

Another factor contributing to the growing demand for mild hybrid technology in logistics is the increasing focus on urban air quality. Many cities around the world are implementing low emission zones and other restrictions on vehicle emissions, creating a need for cleaner transportation options in densely populated areas. Mild hybrid vehicles, with their reduced emissions and ability to operate in electric-only mode for short distances, are well-suited to meet these urban logistics challenges.

The market for sustainable logistics solutions is also being driven by consumer preferences and corporate sustainability initiatives. As more companies commit to reducing their carbon footprint and improving their environmental performance, there is a growing demand for logistics partners that can offer greener transportation options. Mild hybrid vehicles provide a visible and tangible demonstration of a company's commitment to sustainability, which can be a valuable differentiator in competitive markets.

Furthermore, the flexibility of mild hybrid technology makes it particularly appealing for logistics applications. Unlike full electric vehicles, which may face range limitations and charging infrastructure challenges, mild hybrids can operate effectively across a wide range of routes and duty cycles. This versatility allows logistics companies to adopt more sustainable practices without significant changes to their existing operations or infrastructure.

In conclusion, the market demand for sustainable logistics solutions, including mild hybrid technology, is robust and growing. As environmental concerns continue to shape consumer behavior and corporate strategies, the adoption of cleaner and more efficient transportation options is likely to accelerate. Mild hybrid systems offer a practical and cost-effective pathway for logistics companies to improve their environmental performance while maintaining operational efficiency.

Mild hybrid technology has emerged as a promising solution in the sustainable logistics sector, particularly for commercial vehicles and delivery fleets. This technology offers a balance between improved fuel efficiency and reduced emissions without the complexity and cost associated with full hybrid or electric vehicles. The market for mild hybrid systems in logistics is expected to grow significantly over the next decade, as fleet operators seek cost-effective ways to meet increasingly stringent emissions regulations and corporate sustainability goals.

One of the key drivers of market demand for mild hybrid solutions in logistics is the potential for fuel cost savings. With fuel representing a significant portion of operating expenses for logistics companies, even modest improvements in fuel efficiency can translate into substantial cost reductions over the lifetime of a vehicle. Mild hybrid systems, which typically offer fuel savings of 10-15% compared to conventional vehicles, are particularly attractive to fleet operators looking to optimize their total cost of ownership.

Another factor contributing to the growing demand for mild hybrid technology in logistics is the increasing focus on urban air quality. Many cities around the world are implementing low emission zones and other restrictions on vehicle emissions, creating a need for cleaner transportation options in densely populated areas. Mild hybrid vehicles, with their reduced emissions and ability to operate in electric-only mode for short distances, are well-suited to meet these urban logistics challenges.

The market for sustainable logistics solutions is also being driven by consumer preferences and corporate sustainability initiatives. As more companies commit to reducing their carbon footprint and improving their environmental performance, there is a growing demand for logistics partners that can offer greener transportation options. Mild hybrid vehicles provide a visible and tangible demonstration of a company's commitment to sustainability, which can be a valuable differentiator in competitive markets.

Furthermore, the flexibility of mild hybrid technology makes it particularly appealing for logistics applications. Unlike full electric vehicles, which may face range limitations and charging infrastructure challenges, mild hybrids can operate effectively across a wide range of routes and duty cycles. This versatility allows logistics companies to adopt more sustainable practices without significant changes to their existing operations or infrastructure.

In conclusion, the market demand for sustainable logistics solutions, including mild hybrid technology, is robust and growing. As environmental concerns continue to shape consumer behavior and corporate strategies, the adoption of cleaner and more efficient transportation options is likely to accelerate. Mild hybrid systems offer a practical and cost-effective pathway for logistics companies to improve their environmental performance while maintaining operational efficiency.

Current State and Challenges of Mild Hybrid Systems

Mild hybrid systems have gained significant traction in recent years as a transitional technology towards more sustainable transportation solutions. These systems combine a conventional internal combustion engine with a small electric motor and battery, offering improved fuel efficiency and reduced emissions without the complexity of full hybrid or electric vehicles.

Currently, mild hybrid technology is widely adopted in passenger vehicles, with many major automakers incorporating it into their product lines. However, its application in logistics and commercial vehicles is still in the early stages of development and implementation. The primary focus in this sector has been on improving fuel economy and reducing emissions in urban delivery scenarios, where frequent starts and stops occur.

One of the main challenges facing mild hybrid systems in logistics applications is the need for more robust and durable components capable of withstanding the demands of heavy-duty operations. The electric motors and batteries used in passenger vehicles may not be sufficient for the power requirements and duty cycles of commercial vehicles, necessitating the development of specialized components.

Another significant challenge is the integration of mild hybrid systems with existing logistics infrastructure and operations. Fleet managers must consider factors such as maintenance requirements, driver training, and potential changes to vehicle performance characteristics. Additionally, the initial cost of implementing mild hybrid technology across a fleet can be substantial, requiring careful cost-benefit analysis and long-term planning.

The regulatory landscape also presents both opportunities and challenges for mild hybrid systems in logistics. While increasingly stringent emissions standards are driving the adoption of cleaner technologies, the specific requirements and incentives for mild hybrids in commercial vehicles vary across regions and jurisdictions. This regulatory uncertainty can impact investment decisions and technology development strategies.

Furthermore, the rapid advancement of full electric and hydrogen fuel cell technologies poses a potential threat to the long-term viability of mild hybrid systems in logistics. As these alternative technologies mature and become more cost-effective, they may leapfrog mild hybrids in certain applications, particularly for long-haul transportation.

Despite these challenges, mild hybrid systems continue to evolve, with ongoing research focused on improving power density, energy recovery efficiency, and overall system integration. Innovations in areas such as 48-volt electrical systems and advanced power electronics are expanding the capabilities of mild hybrid technology, potentially opening up new applications in the logistics sector.

Currently, mild hybrid technology is widely adopted in passenger vehicles, with many major automakers incorporating it into their product lines. However, its application in logistics and commercial vehicles is still in the early stages of development and implementation. The primary focus in this sector has been on improving fuel economy and reducing emissions in urban delivery scenarios, where frequent starts and stops occur.

One of the main challenges facing mild hybrid systems in logistics applications is the need for more robust and durable components capable of withstanding the demands of heavy-duty operations. The electric motors and batteries used in passenger vehicles may not be sufficient for the power requirements and duty cycles of commercial vehicles, necessitating the development of specialized components.

Another significant challenge is the integration of mild hybrid systems with existing logistics infrastructure and operations. Fleet managers must consider factors such as maintenance requirements, driver training, and potential changes to vehicle performance characteristics. Additionally, the initial cost of implementing mild hybrid technology across a fleet can be substantial, requiring careful cost-benefit analysis and long-term planning.

The regulatory landscape also presents both opportunities and challenges for mild hybrid systems in logistics. While increasingly stringent emissions standards are driving the adoption of cleaner technologies, the specific requirements and incentives for mild hybrids in commercial vehicles vary across regions and jurisdictions. This regulatory uncertainty can impact investment decisions and technology development strategies.

Furthermore, the rapid advancement of full electric and hydrogen fuel cell technologies poses a potential threat to the long-term viability of mild hybrid systems in logistics. As these alternative technologies mature and become more cost-effective, they may leapfrog mild hybrids in certain applications, particularly for long-haul transportation.

Despite these challenges, mild hybrid systems continue to evolve, with ongoing research focused on improving power density, energy recovery efficiency, and overall system integration. Innovations in areas such as 48-volt electrical systems and advanced power electronics are expanding the capabilities of mild hybrid technology, potentially opening up new applications in the logistics sector.

Existing Mild Hybrid Solutions for Logistics

01 Hybrid powertrain systems

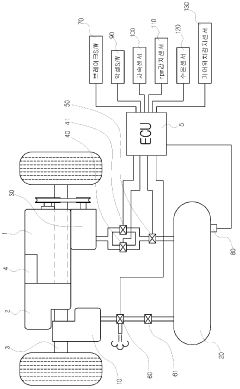

Mild hybrid systems integrate electric motors with conventional internal combustion engines to improve fuel efficiency and reduce emissions. These systems typically use a small electric motor to assist the engine during acceleration and recover energy during braking, without the capability for full electric-only operation.- Hybrid powertrain systems: Mild hybrid systems incorporate electric motors and combustion engines to improve fuel efficiency and reduce emissions. These systems typically use a small electric motor to assist the main engine during acceleration and allow for regenerative braking, capturing energy normally lost during deceleration.

- Energy storage and management: Mild hybrids utilize advanced energy storage systems, such as lithium-ion batteries or supercapacitors, to store and distribute electrical energy efficiently. Sophisticated energy management systems optimize the use of stored energy to maximize fuel economy and performance.

- Start-stop technology: Many mild hybrid systems incorporate start-stop technology, which automatically shuts off the engine when the vehicle is stationary and restarts it when the accelerator is pressed. This feature helps to reduce fuel consumption and emissions, particularly in urban driving conditions.

- Regenerative braking systems: Mild hybrids often employ regenerative braking systems that capture kinetic energy during deceleration and convert it into electrical energy. This recovered energy is then stored in the battery for later use, improving overall energy efficiency and reducing wear on traditional friction brakes.

- Integration with existing vehicle platforms: Mild hybrid technology is designed to be easily integrated into existing vehicle platforms, allowing manufacturers to improve fuel efficiency and reduce emissions without major redesigns. This approach often involves modifying the transmission, electrical system, and engine management to accommodate the hybrid components.

02 Energy storage and management

Mild hybrids employ advanced energy storage systems, such as lithium-ion batteries or supercapacitors, to store and deliver electrical energy efficiently. Sophisticated energy management systems optimize the use of stored energy to support vehicle operations and maximize fuel economy.Expand Specific Solutions03 Regenerative braking systems

Regenerative braking is a key feature in mild hybrid vehicles, allowing the electric motor to act as a generator during deceleration. This system captures kinetic energy that would otherwise be lost as heat during braking and converts it into electrical energy to recharge the battery.Expand Specific Solutions04 Start-stop technology

Mild hybrid systems often incorporate start-stop technology, which automatically shuts off the engine when the vehicle comes to a stop and restarts it when the accelerator is pressed. This feature helps reduce fuel consumption and emissions, particularly in urban driving conditions.Expand Specific Solutions05 Electric boost and torque assist

Mild hybrid powertrains provide electric boost and torque assist to the internal combustion engine during acceleration and high-load situations. This allows for the use of smaller, more efficient engines without compromising performance, leading to improved fuel economy and reduced emissions.Expand Specific Solutions

Key Players in Mild Hybrid Logistics Solutions

The mild hybrid technology market for sustainable logistics is in a growth phase, driven by increasing environmental regulations and the need for fuel efficiency. The market size is expanding rapidly, with major automotive players like AUDI AG, BMW, and FCA US LLC investing heavily in this technology. The technical maturity of mild hybrid systems is advancing, with companies such as Schaeffler Technologies AG & Co. KG and HELLA GmbH & Co. KGaA developing innovative solutions. Cummins, Inc. and Voith Patent GmbH are also contributing to the evolution of mild hybrid powertrains for commercial vehicles, indicating a competitive landscape with diverse players from both automotive and component manufacturing sectors.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed a range of mild hybrid solutions applicable to sustainable logistics. Their 48V hybrid module can be integrated into various vehicle types, including light commercial vehicles. The system features a compact electric motor that can be positioned between the engine and transmission, providing up to 20 kW of electric power and 200 Nm of torque[10]. Schaeffler's technology enables functions such as electric creep, sailing, and boost, contributing to fuel savings of up to 15% in urban driving scenarios[11]. Additionally, Schaeffler has developed a P0 belt-driven starter generator system that can be easily retrofitted to existing vehicle platforms, offering a cost-effective path to hybridization for logistics fleets. The company's mild hybrid solutions also incorporate advanced thermal management systems to optimize overall powertrain efficiency.

Strengths: Versatile integration options, significant fuel savings potential, and applicability to both new and existing vehicle platforms. Weaknesses: May require vehicle-specific adaptations and potential limitations in pure electric range compared to full hybrid systems.

Cummins, Inc.

Technical Solution: Cummins has developed a range of mild hybrid solutions for commercial vehicles, focusing on 48V systems. Their eAssist technology integrates a Belt-Driven Starter Generator (BSG) with a 48V battery, providing up to 30 kW of electrical power[1]. This system enables start-stop functionality, regenerative braking, and electric torque assist, reducing fuel consumption by up to 8% in urban delivery applications[2]. Cummins' mild hybrid technology also includes intelligent power management systems that optimize energy flow between the combustion engine and electric components, enhancing overall powertrain efficiency[3]. The company has successfully implemented these solutions in medium-duty trucks and buses, demonstrating their viability in real-world logistics operations.

Strengths: Proven fuel efficiency improvements, compatibility with existing powertrains, and scalability across various vehicle types. Weaknesses: Limited pure electric range compared to full hybrids, and potential complexity in integrating with diverse vehicle platforms.

Core Innovations in Mild Hybrid Technology

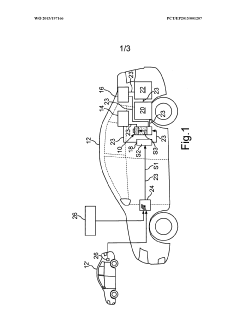

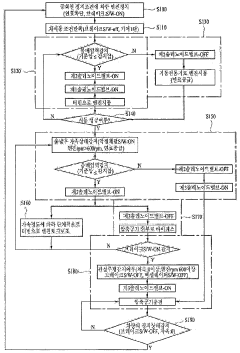

Predictively controlling the state of charge of an energy storage device of an electrically operated motor vehicle

PatentWO2015197166A1

Innovation

- A method that predicts energy requirements based on route data and traffic information to dynamically allocate energy reserves from chassis devices to comfort systems, ensuring sufficient energy for necessary components while minimizing unnecessary reserves, using a state of charge control device to optimize energy management.

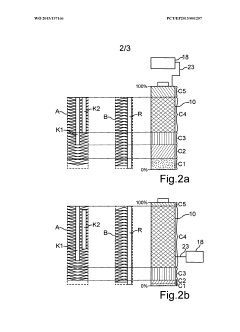

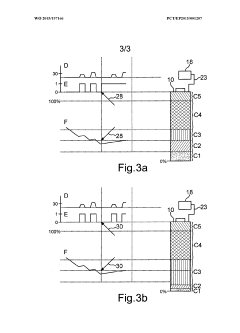

Mild hybrid system

PatentWO2011152619A2

Innovation

- A hybrid engine system utilizing a compressor, compressed air cylinder, turbine, and solenoid valves to control compressed air supply for smooth engine start and acceleration, reducing engine load and maintaining efficient operation without design changes to existing engines.

Environmental Impact Assessment

The environmental impact assessment of mild hybrid technology in sustainable logistics solutions reveals a complex interplay of benefits and challenges. Mild hybrid systems, which combine a conventional internal combustion engine with a small electric motor, offer significant potential for reducing greenhouse gas emissions and improving fuel efficiency in logistics operations.

These systems typically achieve a 10-15% reduction in CO2 emissions compared to conventional vehicles, contributing to lower overall carbon footprints for logistics fleets. The regenerative braking feature of mild hybrids captures energy normally lost during deceleration, further enhancing fuel economy and reducing emissions, particularly in urban delivery scenarios with frequent stops.

However, the environmental benefits of mild hybrids must be weighed against the increased complexity of vehicle production. The manufacturing process for hybrid components, especially batteries, involves energy-intensive processes and the use of rare earth metals. This can lead to higher initial environmental costs, which need to be offset by the vehicle's improved efficiency over its lifecycle.

Lifecycle assessments indicate that mild hybrids generally achieve a net positive environmental impact within 2-3 years of operation, depending on usage patterns and energy sources. In regions with cleaner electricity grids, the benefits accrue more rapidly, highlighting the importance of considering local energy contexts in environmental evaluations.

The adoption of mild hybrid technology in logistics fleets also presents opportunities for reducing local air pollution. Lower emissions of particulate matter and nitrogen oxides contribute to improved air quality in urban areas, where logistics operations often have significant impacts on public health.

Water consumption and waste generation in the production and end-of-life phases of mild hybrid vehicles remain areas of concern. While advancements in battery recycling technologies are promising, the current infrastructure for handling hybrid vehicle components at end-of-life is still developing, posing potential environmental risks if not properly managed.

Overall, the environmental impact assessment of mild hybrids in sustainable logistics solutions indicates a positive trend towards reduced emissions and improved energy efficiency. However, it also underscores the need for holistic approaches that consider the entire lifecycle of vehicles and the broader energy ecosystem in which they operate. As technology continues to evolve, ongoing assessments will be crucial to ensure that the environmental benefits of mild hybrids are maximized while minimizing potential negative impacts.

These systems typically achieve a 10-15% reduction in CO2 emissions compared to conventional vehicles, contributing to lower overall carbon footprints for logistics fleets. The regenerative braking feature of mild hybrids captures energy normally lost during deceleration, further enhancing fuel economy and reducing emissions, particularly in urban delivery scenarios with frequent stops.

However, the environmental benefits of mild hybrids must be weighed against the increased complexity of vehicle production. The manufacturing process for hybrid components, especially batteries, involves energy-intensive processes and the use of rare earth metals. This can lead to higher initial environmental costs, which need to be offset by the vehicle's improved efficiency over its lifecycle.

Lifecycle assessments indicate that mild hybrids generally achieve a net positive environmental impact within 2-3 years of operation, depending on usage patterns and energy sources. In regions with cleaner electricity grids, the benefits accrue more rapidly, highlighting the importance of considering local energy contexts in environmental evaluations.

The adoption of mild hybrid technology in logistics fleets also presents opportunities for reducing local air pollution. Lower emissions of particulate matter and nitrogen oxides contribute to improved air quality in urban areas, where logistics operations often have significant impacts on public health.

Water consumption and waste generation in the production and end-of-life phases of mild hybrid vehicles remain areas of concern. While advancements in battery recycling technologies are promising, the current infrastructure for handling hybrid vehicle components at end-of-life is still developing, posing potential environmental risks if not properly managed.

Overall, the environmental impact assessment of mild hybrids in sustainable logistics solutions indicates a positive trend towards reduced emissions and improved energy efficiency. However, it also underscores the need for holistic approaches that consider the entire lifecycle of vehicles and the broader energy ecosystem in which they operate. As technology continues to evolve, ongoing assessments will be crucial to ensure that the environmental benefits of mild hybrids are maximized while minimizing potential negative impacts.

Cost-Benefit Analysis of Mild Hybrid Implementation

The implementation of mild hybrid technology in logistics solutions requires a comprehensive cost-benefit analysis to determine its economic viability and long-term sustainability. This analysis must consider both the initial investment costs and the potential savings over the vehicle's lifecycle.

The primary cost factors associated with mild hybrid implementation include the additional components required for the hybrid system, such as the electric motor, battery pack, and power electronics. These components typically increase the upfront cost of the vehicle by 10-15% compared to conventional models. Additionally, there may be costs related to training maintenance personnel and upgrading service facilities to handle hybrid vehicles.

On the benefit side, mild hybrids offer significant fuel savings, typically ranging from 10-20% depending on the specific application and driving conditions. In logistics operations, where vehicles often operate in urban environments with frequent starts and stops, the regenerative braking system of mild hybrids can capture and reuse energy that would otherwise be lost, further improving fuel efficiency.

Reduced fuel consumption directly translates to lower operating costs, which can offset the higher initial investment over time. The payback period for mild hybrid technology in logistics applications generally ranges from 2 to 5 years, depending on factors such as annual mileage, fuel prices, and the specific hybrid system employed.

Beyond fuel savings, mild hybrids contribute to reduced maintenance costs due to less wear on brake systems and potentially extended oil change intervals. The start-stop functionality of mild hybrids also leads to decreased engine idling time, further reducing fuel consumption and emissions, particularly in urban delivery scenarios.

From an environmental perspective, the reduced fuel consumption of mild hybrids directly correlates to lower CO2 emissions, helping logistics companies meet increasingly stringent emissions regulations and corporate sustainability goals. This can result in indirect financial benefits through improved brand image, potential tax incentives, and avoidance of emissions-related penalties in certain jurisdictions.

When considering the total cost of ownership (TCO), mild hybrids often demonstrate a favorable position compared to conventional vehicles over a 5-7 year period, typical for many logistics fleet operations. However, the exact TCO advantage varies based on factors such as vehicle utilization, fuel prices, and local incentives for clean vehicle technologies.

In conclusion, while mild hybrid implementation does require a higher initial investment, the long-term benefits in terms of reduced operating costs, improved sustainability, and potential regulatory compliance make it an increasingly attractive option for logistics solutions. As technology continues to advance and production scales up, the cost-benefit ratio is expected to improve further, solidifying the role of mild hybrids in sustainable logistics operations.

The primary cost factors associated with mild hybrid implementation include the additional components required for the hybrid system, such as the electric motor, battery pack, and power electronics. These components typically increase the upfront cost of the vehicle by 10-15% compared to conventional models. Additionally, there may be costs related to training maintenance personnel and upgrading service facilities to handle hybrid vehicles.

On the benefit side, mild hybrids offer significant fuel savings, typically ranging from 10-20% depending on the specific application and driving conditions. In logistics operations, where vehicles often operate in urban environments with frequent starts and stops, the regenerative braking system of mild hybrids can capture and reuse energy that would otherwise be lost, further improving fuel efficiency.

Reduced fuel consumption directly translates to lower operating costs, which can offset the higher initial investment over time. The payback period for mild hybrid technology in logistics applications generally ranges from 2 to 5 years, depending on factors such as annual mileage, fuel prices, and the specific hybrid system employed.

Beyond fuel savings, mild hybrids contribute to reduced maintenance costs due to less wear on brake systems and potentially extended oil change intervals. The start-stop functionality of mild hybrids also leads to decreased engine idling time, further reducing fuel consumption and emissions, particularly in urban delivery scenarios.

From an environmental perspective, the reduced fuel consumption of mild hybrids directly correlates to lower CO2 emissions, helping logistics companies meet increasingly stringent emissions regulations and corporate sustainability goals. This can result in indirect financial benefits through improved brand image, potential tax incentives, and avoidance of emissions-related penalties in certain jurisdictions.

When considering the total cost of ownership (TCO), mild hybrids often demonstrate a favorable position compared to conventional vehicles over a 5-7 year period, typical for many logistics fleet operations. However, the exact TCO advantage varies based on factors such as vehicle utilization, fuel prices, and local incentives for clean vehicle technologies.

In conclusion, while mild hybrid implementation does require a higher initial investment, the long-term benefits in terms of reduced operating costs, improved sustainability, and potential regulatory compliance make it an increasingly attractive option for logistics solutions. As technology continues to advance and production scales up, the cost-benefit ratio is expected to improve further, solidifying the role of mild hybrids in sustainable logistics operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!