Thermal management challenges in mild hybrid systems during extended operations

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Evolution and Objectives

Thermal management in mild hybrid systems has evolved significantly over the past decades, driven by the increasing complexity and power density of automotive powertrains. The integration of electric components with traditional internal combustion engines has introduced new challenges in heat dissipation and temperature control. This evolution has been marked by a shift from simple, passive cooling systems to more sophisticated, active thermal management solutions.

In the early stages of hybrid vehicle development, thermal management primarily focused on maintaining optimal operating temperatures for the internal combustion engine. As hybrid systems became more prevalent, the scope expanded to include cooling of electric motors, power electronics, and battery packs. This expansion necessitated the development of more complex cooling circuits and the integration of multiple heat exchangers.

The objectives of thermal management in mild hybrid systems have become increasingly multifaceted. The primary goal remains to maintain all components within their optimal temperature ranges to ensure efficiency, performance, and longevity. However, this must now be achieved while minimizing energy consumption, reducing system weight, and optimizing packaging within the limited space of a vehicle.

A key objective is to manage the thermal loads during extended operations, particularly in challenging environments or during high-performance driving scenarios. This includes preventing overheating of electric components, which can lead to reduced efficiency or even system shutdown. Simultaneously, the thermal management system must also address the need for rapid warm-up of the internal combustion engine to reduce emissions and improve fuel efficiency.

Another critical objective is the integration of thermal management with the overall energy management strategy of the hybrid system. This involves optimizing the use of waste heat, implementing intelligent control strategies, and leveraging the thermal mass of various components to improve overall system efficiency. The goal is to create a holistic approach that considers the thermal interactions between all subsystems.

As environmental regulations become more stringent, thermal management systems are also tasked with contributing to reduced emissions and improved fuel economy. This has led to the development of innovative solutions such as exhaust heat recovery systems and the use of phase change materials for thermal energy storage.

Looking forward, the objectives of thermal management in mild hybrid systems are likely to focus on further integration, miniaturization, and increased efficiency. This may include the development of smart materials with adaptive thermal properties, advanced predictive control algorithms, and the use of artificial intelligence to optimize thermal management strategies in real-time based on driving conditions and vehicle state.

In the early stages of hybrid vehicle development, thermal management primarily focused on maintaining optimal operating temperatures for the internal combustion engine. As hybrid systems became more prevalent, the scope expanded to include cooling of electric motors, power electronics, and battery packs. This expansion necessitated the development of more complex cooling circuits and the integration of multiple heat exchangers.

The objectives of thermal management in mild hybrid systems have become increasingly multifaceted. The primary goal remains to maintain all components within their optimal temperature ranges to ensure efficiency, performance, and longevity. However, this must now be achieved while minimizing energy consumption, reducing system weight, and optimizing packaging within the limited space of a vehicle.

A key objective is to manage the thermal loads during extended operations, particularly in challenging environments or during high-performance driving scenarios. This includes preventing overheating of electric components, which can lead to reduced efficiency or even system shutdown. Simultaneously, the thermal management system must also address the need for rapid warm-up of the internal combustion engine to reduce emissions and improve fuel efficiency.

Another critical objective is the integration of thermal management with the overall energy management strategy of the hybrid system. This involves optimizing the use of waste heat, implementing intelligent control strategies, and leveraging the thermal mass of various components to improve overall system efficiency. The goal is to create a holistic approach that considers the thermal interactions between all subsystems.

As environmental regulations become more stringent, thermal management systems are also tasked with contributing to reduced emissions and improved fuel economy. This has led to the development of innovative solutions such as exhaust heat recovery systems and the use of phase change materials for thermal energy storage.

Looking forward, the objectives of thermal management in mild hybrid systems are likely to focus on further integration, miniaturization, and increased efficiency. This may include the development of smart materials with adaptive thermal properties, advanced predictive control algorithms, and the use of artificial intelligence to optimize thermal management strategies in real-time based on driving conditions and vehicle state.

Market Demand for Efficient Mild Hybrid Systems

The market demand for efficient mild hybrid systems has been steadily increasing in recent years, driven by stringent emissions regulations, fuel economy standards, and consumer preferences for more environmentally friendly vehicles. Automotive manufacturers are under pressure to reduce their fleet-wide emissions and improve fuel efficiency, making mild hybrid technology an attractive solution.

Mild hybrid systems offer a cost-effective compromise between conventional internal combustion engines and full hybrid or electric vehicles. They provide improved fuel economy and reduced emissions without the complexity and high costs associated with full hybrid powertrains. This positioning has led to a growing adoption of mild hybrid technology across various vehicle segments, from compact cars to SUVs and light commercial vehicles.

The global mild hybrid market is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is particularly pronounced in regions with strict emissions regulations, such as Europe and China. In Europe, the implementation of the Euro 7 emissions standards is expected to further accelerate the adoption of mild hybrid systems as automakers seek to comply with increasingly stringent requirements.

Consumer demand for improved fuel efficiency and lower running costs is also driving the market for mild hybrid vehicles. As fuel prices remain volatile and environmental concerns grow, consumers are increasingly looking for vehicles that offer better fuel economy without compromising on performance or affordability. Mild hybrid systems address this need by providing a noticeable improvement in fuel efficiency, typically ranging from 10% to 15% compared to conventional powertrains.

The automotive industry's shift towards electrification has created a favorable environment for mild hybrid systems. Many automakers view mild hybrids as a transitional technology, allowing them to improve the efficiency of their existing vehicle platforms while developing more advanced electrification solutions. This approach enables manufacturers to meet short-term emissions targets while preparing for a long-term transition to fully electric vehicles.

However, the market demand for efficient mild hybrid systems also presents challenges, particularly in thermal management during extended operations. As mild hybrid systems become more prevalent and are used in a wider range of driving conditions, the need for effective thermal management solutions becomes critical. Consumers expect consistent performance and reliability, even during prolonged use or in extreme weather conditions. This has led to increased focus on developing advanced thermal management technologies that can maintain optimal operating temperatures for both the electric components and the internal combustion engine.

Mild hybrid systems offer a cost-effective compromise between conventional internal combustion engines and full hybrid or electric vehicles. They provide improved fuel economy and reduced emissions without the complexity and high costs associated with full hybrid powertrains. This positioning has led to a growing adoption of mild hybrid technology across various vehicle segments, from compact cars to SUVs and light commercial vehicles.

The global mild hybrid market is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is particularly pronounced in regions with strict emissions regulations, such as Europe and China. In Europe, the implementation of the Euro 7 emissions standards is expected to further accelerate the adoption of mild hybrid systems as automakers seek to comply with increasingly stringent requirements.

Consumer demand for improved fuel efficiency and lower running costs is also driving the market for mild hybrid vehicles. As fuel prices remain volatile and environmental concerns grow, consumers are increasingly looking for vehicles that offer better fuel economy without compromising on performance or affordability. Mild hybrid systems address this need by providing a noticeable improvement in fuel efficiency, typically ranging from 10% to 15% compared to conventional powertrains.

The automotive industry's shift towards electrification has created a favorable environment for mild hybrid systems. Many automakers view mild hybrids as a transitional technology, allowing them to improve the efficiency of their existing vehicle platforms while developing more advanced electrification solutions. This approach enables manufacturers to meet short-term emissions targets while preparing for a long-term transition to fully electric vehicles.

However, the market demand for efficient mild hybrid systems also presents challenges, particularly in thermal management during extended operations. As mild hybrid systems become more prevalent and are used in a wider range of driving conditions, the need for effective thermal management solutions becomes critical. Consumers expect consistent performance and reliability, even during prolonged use or in extreme weather conditions. This has led to increased focus on developing advanced thermal management technologies that can maintain optimal operating temperatures for both the electric components and the internal combustion engine.

Current Thermal Challenges in Extended Operations

Mild hybrid systems, while offering improved fuel efficiency and reduced emissions, face significant thermal management challenges during extended operations. These challenges primarily stem from the increased heat generation due to the integration of electric components with traditional internal combustion engines.

One of the main issues is the thermal stress on the battery pack. During prolonged use, especially in high-load conditions or hot environments, the battery temperature can rise significantly. This not only affects the battery's performance and lifespan but also poses safety risks. Efficient cooling systems are crucial to maintain optimal battery temperature, but designing such systems within the space and weight constraints of a vehicle remains a challenge.

The electric motor-generator unit (MGU) in mild hybrid systems also contributes to thermal management complexities. During extended operations, the MGU generates considerable heat, particularly when frequently switching between motor and generator modes. This heat must be effectively dissipated to prevent performance degradation and potential damage to the unit.

Furthermore, the integration of the hybrid system with the internal combustion engine creates additional thermal loads. The engine's cooling system must now accommodate not only its own heat generation but also that of the hybrid components. This increased thermal load can lead to higher coolant temperatures and potentially reduced engine efficiency during extended operations.

The power electronics, including inverters and converters, are another source of heat in mild hybrid systems. These components are critical for managing power flow between the battery, electric motor, and engine. However, they generate significant heat during operation, especially under high-load conditions. Effective cooling of these components is essential to maintain system efficiency and reliability.

Thermal management challenges are further exacerbated in stop-start traffic conditions, which are common in urban environments. The frequent cycling between electric and combustion power can lead to rapid temperature fluctuations, putting additional stress on the cooling systems and thermal management strategies.

Addressing these challenges requires innovative approaches to thermal management. This includes advanced cooling technologies, such as liquid cooling systems for batteries and power electronics, improved heat exchanger designs, and intelligent thermal management strategies that can adapt to varying operating conditions. Additionally, the development of more heat-resistant materials and components can help mitigate some of the thermal stress issues in mild hybrid systems during extended operations.

One of the main issues is the thermal stress on the battery pack. During prolonged use, especially in high-load conditions or hot environments, the battery temperature can rise significantly. This not only affects the battery's performance and lifespan but also poses safety risks. Efficient cooling systems are crucial to maintain optimal battery temperature, but designing such systems within the space and weight constraints of a vehicle remains a challenge.

The electric motor-generator unit (MGU) in mild hybrid systems also contributes to thermal management complexities. During extended operations, the MGU generates considerable heat, particularly when frequently switching between motor and generator modes. This heat must be effectively dissipated to prevent performance degradation and potential damage to the unit.

Furthermore, the integration of the hybrid system with the internal combustion engine creates additional thermal loads. The engine's cooling system must now accommodate not only its own heat generation but also that of the hybrid components. This increased thermal load can lead to higher coolant temperatures and potentially reduced engine efficiency during extended operations.

The power electronics, including inverters and converters, are another source of heat in mild hybrid systems. These components are critical for managing power flow between the battery, electric motor, and engine. However, they generate significant heat during operation, especially under high-load conditions. Effective cooling of these components is essential to maintain system efficiency and reliability.

Thermal management challenges are further exacerbated in stop-start traffic conditions, which are common in urban environments. The frequent cycling between electric and combustion power can lead to rapid temperature fluctuations, putting additional stress on the cooling systems and thermal management strategies.

Addressing these challenges requires innovative approaches to thermal management. This includes advanced cooling technologies, such as liquid cooling systems for batteries and power electronics, improved heat exchanger designs, and intelligent thermal management strategies that can adapt to varying operating conditions. Additionally, the development of more heat-resistant materials and components can help mitigate some of the thermal stress issues in mild hybrid systems during extended operations.

Existing Thermal Management Strategies

01 Thermal management systems for mild hybrid vehicles

Mild hybrid vehicles employ specialized thermal management systems to regulate temperatures of various components, including the engine, battery, and electric motor. These systems often utilize coolant circuits, heat exchangers, and intelligent control strategies to optimize efficiency and performance across different operating conditions.- Thermal management systems for mild hybrid vehicles: Advanced thermal management systems are designed for mild hybrid vehicles to optimize the performance and efficiency of both the internal combustion engine and the electric components. These systems often include intelligent cooling circuits, heat exchangers, and temperature sensors to maintain optimal operating temperatures for various components, enhancing overall system efficiency and reducing emissions.

- Integration of electric components in mild hybrid powertrains: Mild hybrid systems incorporate electric components such as starter-generators and small battery packs into traditional internal combustion engine powertrains. The thermal management of these integrated systems requires careful consideration to balance the cooling needs of both electrical and mechanical components, often utilizing shared cooling circuits or separate, optimized cooling loops.

- Energy recovery and thermal management in mild hybrids: Mild hybrid systems often employ energy recovery mechanisms, such as regenerative braking, which can generate significant heat. Thermal management strategies are developed to effectively dissipate this heat while also utilizing it for other vehicle functions, such as cabin heating or battery temperature regulation, thereby improving overall energy efficiency.

- Cooling strategies for power electronics in mild hybrids: Power electronics in mild hybrid systems, including inverters and DC-DC converters, require efficient cooling to maintain performance and longevity. Innovative cooling strategies, such as liquid cooling systems or advanced air cooling designs, are implemented to manage the thermal load of these components while minimizing the impact on overall vehicle packaging and weight.

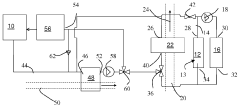

- Thermal management control algorithms for mild hybrid systems: Sophisticated control algorithms are developed to manage the thermal aspects of mild hybrid systems dynamically. These algorithms optimize the operation of cooling systems, manage heat distribution, and balance the thermal needs of various components in real-time, adapting to different driving conditions and power demands to maximize efficiency and performance.

02 Integration of electric components in mild hybrid powertrains

Mild hybrid systems incorporate electric components such as starter-generators and small battery packs into traditional internal combustion engine powertrains. The thermal management of these integrated systems requires careful consideration to balance the cooling needs of both electrical and mechanical components while maintaining overall system efficiency.Expand Specific Solutions03 Energy recovery and thermal optimization in mild hybrids

Mild hybrid systems often employ energy recovery mechanisms, such as regenerative braking, to capture and store energy. The thermal management system plays a crucial role in optimizing the energy flow between different components, ensuring efficient energy recovery and utilization while maintaining optimal operating temperatures.Expand Specific Solutions04 Cooling strategies for mild hybrid batteries and power electronics

Effective cooling of batteries and power electronics is essential in mild hybrid systems to maintain performance and longevity. Various cooling strategies, including air cooling, liquid cooling, and phase-change materials, are employed to manage the thermal loads generated by these components during different driving conditions.Expand Specific Solutions05 Intelligent thermal management control systems

Advanced control systems are implemented in mild hybrid vehicles to manage thermal loads dynamically. These systems use sensors, predictive algorithms, and real-time data to optimize coolant flow, fan speeds, and component temperatures, enhancing overall system efficiency and reducing energy consumption.Expand Specific Solutions

Key Players in Mild Hybrid Thermal Solutions

The thermal management challenges in mild hybrid systems during extended operations present a competitive landscape in a rapidly evolving sector. The industry is in a growth phase, with increasing market size driven by the global push for vehicle electrification. The technology is maturing, but still offers significant room for innovation. Companies like Valeo Thermal Systems, Hanon Systems, and Cummins are at the forefront, developing advanced cooling solutions. Automotive giants such as Renault, Nissan, and Volkswagen are integrating these systems into their hybrid vehicles, while suppliers like Vitesco Technologies and Siemens are providing critical components. The competition is fierce, with both established players and new entrants vying for market share in this crucial aspect of hybrid vehicle performance and efficiency.

Cummins, Inc.

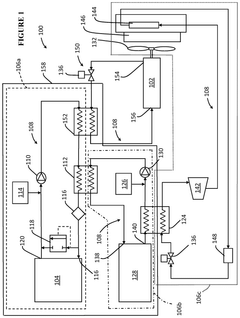

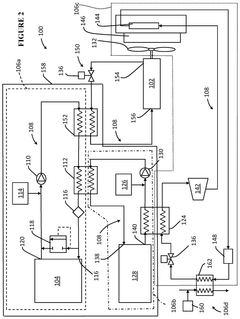

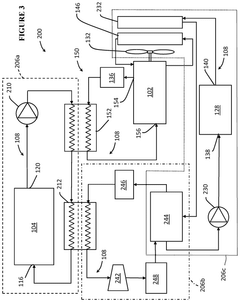

Technical Solution: Cummins has developed an advanced thermal management system for mild hybrid powertrains that integrates a high-efficiency electric water pump, smart thermostat, and optimized coolant flow paths. This system utilizes predictive algorithms to anticipate cooling needs based on driving conditions and battery state of charge. The electric water pump allows for precise coolant flow control, reducing parasitic losses compared to traditional belt-driven pumps. Cummins has also implemented a dual-loop cooling circuit that separates engine and power electronics cooling for improved thermal efficiency[1][3]. Their system incorporates phase change materials in critical components to absorb excess heat during peak loads, helping maintain optimal operating temperatures for extended periods[2].

Strengths: Precise coolant flow control, reduced parasitic losses, predictive cooling algorithms. Weaknesses: Increased system complexity, potential higher initial costs.

Hanon Systems

Technical Solution: Hanon Systems has developed a comprehensive thermal management solution for mild hybrid vehicles that focuses on integrating the cooling systems of the internal combustion engine and electric components. Their approach utilizes a centralized coolant control valve that dynamically manages coolant flow between multiple loops, including the engine, battery, and power electronics circuits. This system is complemented by an electric compressor for the air conditioning system, which can operate independently of the engine state. Hanon's solution also incorporates a heat pump functionality, allowing for efficient cabin heating by recovering waste heat from electric components and the environment[4]. The company has implemented advanced thermal modeling and simulation techniques to optimize the entire system's performance under various driving conditions and ambient temperatures[5].

Strengths: Integrated cooling approach, efficient heat recovery, adaptable to various hybrid configurations. Weaknesses: Complexity in control algorithms, potential for increased weight due to additional components.

Innovative Heat Dissipation Techniques

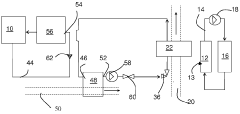

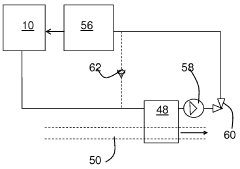

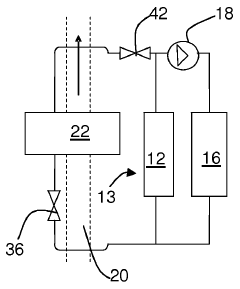

Hybrid thermal management system

PatentPendingUS20240347813A1

Innovation

- A thermal management system utilizing three interconnected cooling circuits: a dielectric thermal fluid circuit for batteries, an electrically conductive fluid circuit for electronic units, and a vapor-compression refrigerant circuit, allowing for efficient heat transfer and management without the need for a dedicated radiator, thereby reducing component count and space requirements.

Multifunction thermal management system and method for a hybrid vehicle

PatentWO2008087342A2

Innovation

- A multifunction thermal management system that uses a single radiator to cool both electrical components and charge air, coupled with a heat recovery circuit on the exhaust gas line to enhance engine temperature rise, reducing energy consumption and pollution, and includes an air/liquid heat exchanger and a liquid coolant circulation loop with a pump, as well as a unit heater for passenger compartment heating.

Environmental Impact and Regulations

The environmental impact and regulatory landscape surrounding mild hybrid systems are critical considerations in the context of thermal management challenges during extended operations. As global efforts to reduce carbon emissions intensify, automotive manufacturers face increasing pressure to develop more efficient and environmentally friendly vehicles. Mild hybrid systems, while offering improved fuel efficiency and reduced emissions compared to conventional internal combustion engines, still face scrutiny regarding their overall environmental impact.

Regulatory bodies worldwide have implemented stringent emissions standards that directly affect the design and operation of mild hybrid systems. In the European Union, for instance, the Euro 6d standard sets strict limits on nitrogen oxide (NOx) and particulate matter emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Corporate Average Fuel Economy (CAFE) standards, which incentivize the adoption of hybrid technologies to meet fleet-wide fuel efficiency targets.

These regulations have a significant impact on thermal management strategies in mild hybrid systems. Extended operations, particularly in urban environments with frequent start-stop cycles, can lead to increased thermal loads on various components. This presents a challenge for engineers to develop cooling systems that not only maintain optimal operating temperatures but also minimize energy consumption and emissions.

The environmental impact of thermal management solutions themselves must also be considered. Traditional cooling systems often rely on refrigerants with high global warming potential (GWP). As a result, there is a growing push towards the use of more environmentally friendly alternatives, such as CO2-based refrigerants or phase-change materials. These solutions, while potentially more sustainable, may present new challenges in terms of system design and efficiency.

Furthermore, the end-of-life considerations for mild hybrid systems and their thermal management components are becoming increasingly important from an environmental perspective. Regulations such as the European Union's End-of-Life Vehicles Directive mandate high levels of recyclability and recoverability for automotive components. This necessitates the development of thermal management solutions that not only perform efficiently during the vehicle's operational life but also minimize environmental impact upon disposal or recycling.

As mild hybrid technology continues to evolve, it is crucial for manufacturers to anticipate and adapt to future regulatory changes. This may include more stringent emissions standards, expanded lifecycle assessments, and potentially new regulations specifically targeting hybrid vehicle technologies. By proactively addressing these environmental and regulatory challenges, manufacturers can ensure that their mild hybrid systems remain compliant and competitive in an increasingly eco-conscious market.

Regulatory bodies worldwide have implemented stringent emissions standards that directly affect the design and operation of mild hybrid systems. In the European Union, for instance, the Euro 6d standard sets strict limits on nitrogen oxide (NOx) and particulate matter emissions. Similarly, the United States Environmental Protection Agency (EPA) has established Corporate Average Fuel Economy (CAFE) standards, which incentivize the adoption of hybrid technologies to meet fleet-wide fuel efficiency targets.

These regulations have a significant impact on thermal management strategies in mild hybrid systems. Extended operations, particularly in urban environments with frequent start-stop cycles, can lead to increased thermal loads on various components. This presents a challenge for engineers to develop cooling systems that not only maintain optimal operating temperatures but also minimize energy consumption and emissions.

The environmental impact of thermal management solutions themselves must also be considered. Traditional cooling systems often rely on refrigerants with high global warming potential (GWP). As a result, there is a growing push towards the use of more environmentally friendly alternatives, such as CO2-based refrigerants or phase-change materials. These solutions, while potentially more sustainable, may present new challenges in terms of system design and efficiency.

Furthermore, the end-of-life considerations for mild hybrid systems and their thermal management components are becoming increasingly important from an environmental perspective. Regulations such as the European Union's End-of-Life Vehicles Directive mandate high levels of recyclability and recoverability for automotive components. This necessitates the development of thermal management solutions that not only perform efficiently during the vehicle's operational life but also minimize environmental impact upon disposal or recycling.

As mild hybrid technology continues to evolve, it is crucial for manufacturers to anticipate and adapt to future regulatory changes. This may include more stringent emissions standards, expanded lifecycle assessments, and potentially new regulations specifically targeting hybrid vehicle technologies. By proactively addressing these environmental and regulatory challenges, manufacturers can ensure that their mild hybrid systems remain compliant and competitive in an increasingly eco-conscious market.

Cost-Benefit Analysis of Thermal Solutions

The cost-benefit analysis of thermal solutions for mild hybrid systems during extended operations is a critical aspect of system design and optimization. Various thermal management strategies must be evaluated not only for their technical efficacy but also for their economic viability. This analysis encompasses both the initial investment costs and the long-term operational expenses associated with different thermal solutions.

Active cooling systems, such as liquid cooling circuits, offer superior heat dissipation capabilities but come with higher upfront costs. These systems typically require pumps, radiators, and coolant, which increase the overall system complexity and weight. However, their ability to maintain optimal operating temperatures during extended operations can lead to improved system efficiency and longevity, potentially offsetting the initial investment over time.

Passive cooling solutions, including heat sinks and thermal interface materials, present a more cost-effective initial option. These components are generally less expensive and simpler to implement, reducing both material and labor costs during production. However, their limited heat dissipation capacity may result in suboptimal performance during extended operations, potentially leading to increased wear and reduced system efficiency.

The integration of phase change materials (PCMs) into thermal management systems represents a middle ground between active and passive solutions. PCMs can absorb and release large amounts of thermal energy at a constant temperature, providing effective temperature regulation without the need for complex mechanical systems. While more expensive than basic passive solutions, PCMs can offer significant benefits in terms of thermal stability and energy efficiency, particularly during intermittent high-load periods.

When considering the cost-benefit trade-offs, it is essential to factor in the long-term operational costs. More effective thermal management can lead to reduced fuel consumption, lower emissions, and extended component lifespans. These benefits can translate into substantial cost savings over the vehicle's lifetime, potentially justifying higher initial investments in advanced thermal solutions.

The analysis must also consider the impact on vehicle weight and packaging. Heavier or bulkier thermal management systems may negatively affect fuel efficiency and vehicle design, potentially offsetting some of the gains achieved through improved thermal performance. Conversely, compact and lightweight solutions may command a premium price but could yield better overall system efficiency.

Ultimately, the optimal thermal solution will depend on the specific requirements of the mild hybrid system, the expected duty cycle, and the target market segment. A comprehensive cost-benefit analysis should incorporate factors such as production volume, regulatory requirements, and consumer preferences to determine the most economically viable thermal management strategy for extended operations in mild hybrid systems.

Active cooling systems, such as liquid cooling circuits, offer superior heat dissipation capabilities but come with higher upfront costs. These systems typically require pumps, radiators, and coolant, which increase the overall system complexity and weight. However, their ability to maintain optimal operating temperatures during extended operations can lead to improved system efficiency and longevity, potentially offsetting the initial investment over time.

Passive cooling solutions, including heat sinks and thermal interface materials, present a more cost-effective initial option. These components are generally less expensive and simpler to implement, reducing both material and labor costs during production. However, their limited heat dissipation capacity may result in suboptimal performance during extended operations, potentially leading to increased wear and reduced system efficiency.

The integration of phase change materials (PCMs) into thermal management systems represents a middle ground between active and passive solutions. PCMs can absorb and release large amounts of thermal energy at a constant temperature, providing effective temperature regulation without the need for complex mechanical systems. While more expensive than basic passive solutions, PCMs can offer significant benefits in terms of thermal stability and energy efficiency, particularly during intermittent high-load periods.

When considering the cost-benefit trade-offs, it is essential to factor in the long-term operational costs. More effective thermal management can lead to reduced fuel consumption, lower emissions, and extended component lifespans. These benefits can translate into substantial cost savings over the vehicle's lifetime, potentially justifying higher initial investments in advanced thermal solutions.

The analysis must also consider the impact on vehicle weight and packaging. Heavier or bulkier thermal management systems may negatively affect fuel efficiency and vehicle design, potentially offsetting some of the gains achieved through improved thermal performance. Conversely, compact and lightweight solutions may command a premium price but could yield better overall system efficiency.

Ultimately, the optimal thermal solution will depend on the specific requirements of the mild hybrid system, the expected duty cycle, and the target market segment. A comprehensive cost-benefit analysis should incorporate factors such as production volume, regulatory requirements, and consumer preferences to determine the most economically viable thermal management strategy for extended operations in mild hybrid systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!