The use of mild hybrid systems in remote off-road vehicle operations

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Tech Evolution and Objectives

Mild hybrid technology has evolved significantly over the past two decades, driven by the automotive industry's need to improve fuel efficiency and reduce emissions. The technology combines a conventional internal combustion engine with an electric motor and battery system, offering a balance between performance and efficiency. In the context of remote off-road vehicle operations, mild hybrid systems present unique opportunities and challenges.

The evolution of mild hybrid technology began in the early 2000s with simple start-stop systems. These initial implementations focused on reducing fuel consumption during idle periods by automatically shutting off the engine when the vehicle came to a stop. As the technology progressed, more advanced systems emerged, incorporating regenerative braking and electric assist during acceleration.

By the mid-2010s, 48-volt mild hybrid systems became increasingly prevalent, offering greater power and efficiency benefits compared to their 12-volt predecessors. These systems enabled more sophisticated energy recovery and power boost capabilities, making them particularly suitable for larger vehicles and those operating in demanding conditions.

In recent years, the focus has shifted towards integrating mild hybrid technology with advanced powertrain control systems and connectivity features. This integration allows for more intelligent energy management and predictive control strategies, further enhancing efficiency and performance in various driving scenarios, including off-road operations.

The primary objectives of mild hybrid systems in remote off-road vehicle operations are multifaceted. Firstly, they aim to improve fuel efficiency and reduce emissions, which is crucial in environmentally sensitive areas where off-road vehicles often operate. Secondly, these systems seek to enhance vehicle performance, particularly in low-speed, high-torque situations commonly encountered in off-road conditions.

Another key objective is to increase the overall reliability and durability of vehicles operating in harsh environments. Mild hybrid systems can reduce the strain on the internal combustion engine by providing electric assist during high-load situations, potentially extending engine life and reducing maintenance requirements.

Furthermore, mild hybrid technology in off-road vehicles aims to provide auxiliary power for equipment and tools often used in remote operations. This capability can reduce the need for separate generators or power sources, streamlining vehicle functionality and improving operational efficiency.

Looking ahead, the evolution of mild hybrid systems in off-road vehicles is expected to focus on further integration with advanced driver assistance systems and autonomous capabilities. This integration will likely lead to more intelligent power management and improved vehicle control in challenging terrains, ultimately enhancing both safety and efficiency in remote off-road operations.

The evolution of mild hybrid technology began in the early 2000s with simple start-stop systems. These initial implementations focused on reducing fuel consumption during idle periods by automatically shutting off the engine when the vehicle came to a stop. As the technology progressed, more advanced systems emerged, incorporating regenerative braking and electric assist during acceleration.

By the mid-2010s, 48-volt mild hybrid systems became increasingly prevalent, offering greater power and efficiency benefits compared to their 12-volt predecessors. These systems enabled more sophisticated energy recovery and power boost capabilities, making them particularly suitable for larger vehicles and those operating in demanding conditions.

In recent years, the focus has shifted towards integrating mild hybrid technology with advanced powertrain control systems and connectivity features. This integration allows for more intelligent energy management and predictive control strategies, further enhancing efficiency and performance in various driving scenarios, including off-road operations.

The primary objectives of mild hybrid systems in remote off-road vehicle operations are multifaceted. Firstly, they aim to improve fuel efficiency and reduce emissions, which is crucial in environmentally sensitive areas where off-road vehicles often operate. Secondly, these systems seek to enhance vehicle performance, particularly in low-speed, high-torque situations commonly encountered in off-road conditions.

Another key objective is to increase the overall reliability and durability of vehicles operating in harsh environments. Mild hybrid systems can reduce the strain on the internal combustion engine by providing electric assist during high-load situations, potentially extending engine life and reducing maintenance requirements.

Furthermore, mild hybrid technology in off-road vehicles aims to provide auxiliary power for equipment and tools often used in remote operations. This capability can reduce the need for separate generators or power sources, streamlining vehicle functionality and improving operational efficiency.

Looking ahead, the evolution of mild hybrid systems in off-road vehicles is expected to focus on further integration with advanced driver assistance systems and autonomous capabilities. This integration will likely lead to more intelligent power management and improved vehicle control in challenging terrains, ultimately enhancing both safety and efficiency in remote off-road operations.

Off-Road Vehicle Market Analysis

The off-road vehicle market has experienced significant growth in recent years, driven by increasing demand for recreational activities, adventure tourism, and specialized industrial applications. This market segment encompasses a wide range of vehicles, including all-terrain vehicles (ATVs), utility task vehicles (UTVs), and specialized trucks designed for challenging terrains.

The global off-road vehicle market size was valued at approximately $26 billion in 2020 and is projected to reach $33 billion by 2025, growing at a CAGR of around 4.8% during the forecast period. This growth is attributed to several factors, including rising disposable incomes, growing interest in outdoor recreational activities, and increasing demand for off-road vehicles in agriculture, construction, and mining sectors.

North America dominates the off-road vehicle market, accounting for the largest market share due to the popularity of off-road activities and the presence of major manufacturers. Europe and Asia-Pacific regions are also witnessing substantial growth, driven by increasing urbanization and the expansion of adventure tourism.

The market is segmented based on vehicle type, application, and fuel type. ATVs and UTVs constitute a significant portion of the market, with UTVs experiencing faster growth due to their versatility and ability to accommodate multiple passengers. In terms of application, the recreational segment holds the largest market share, followed by utility and military applications.

The introduction of mild hybrid systems in off-road vehicles presents a new opportunity for market growth and technological advancement. These systems offer improved fuel efficiency, reduced emissions, and enhanced performance, aligning with the growing demand for more environmentally friendly and cost-effective off-road solutions.

Key market trends include the integration of advanced technologies such as GPS navigation, telematics, and autonomous features in off-road vehicles. Additionally, there is a growing focus on electric and hybrid powertrains to meet stringent emission regulations and consumer demand for sustainable options.

The competitive landscape of the off-road vehicle market is characterized by the presence of several established players and new entrants. Major companies are investing in research and development to introduce innovative products and gain a competitive edge. Collaborations and partnerships between automotive manufacturers and technology providers are becoming increasingly common to accelerate the development of advanced off-road vehicle solutions.

The global off-road vehicle market size was valued at approximately $26 billion in 2020 and is projected to reach $33 billion by 2025, growing at a CAGR of around 4.8% during the forecast period. This growth is attributed to several factors, including rising disposable incomes, growing interest in outdoor recreational activities, and increasing demand for off-road vehicles in agriculture, construction, and mining sectors.

North America dominates the off-road vehicle market, accounting for the largest market share due to the popularity of off-road activities and the presence of major manufacturers. Europe and Asia-Pacific regions are also witnessing substantial growth, driven by increasing urbanization and the expansion of adventure tourism.

The market is segmented based on vehicle type, application, and fuel type. ATVs and UTVs constitute a significant portion of the market, with UTVs experiencing faster growth due to their versatility and ability to accommodate multiple passengers. In terms of application, the recreational segment holds the largest market share, followed by utility and military applications.

The introduction of mild hybrid systems in off-road vehicles presents a new opportunity for market growth and technological advancement. These systems offer improved fuel efficiency, reduced emissions, and enhanced performance, aligning with the growing demand for more environmentally friendly and cost-effective off-road solutions.

Key market trends include the integration of advanced technologies such as GPS navigation, telematics, and autonomous features in off-road vehicles. Additionally, there is a growing focus on electric and hybrid powertrains to meet stringent emission regulations and consumer demand for sustainable options.

The competitive landscape of the off-road vehicle market is characterized by the presence of several established players and new entrants. Major companies are investing in research and development to introduce innovative products and gain a competitive edge. Collaborations and partnerships between automotive manufacturers and technology providers are becoming increasingly common to accelerate the development of advanced off-road vehicle solutions.

Mild Hybrid Challenges in Remote Operations

The implementation of mild hybrid systems in remote off-road vehicle operations presents unique challenges that require careful consideration. These systems, which combine a conventional internal combustion engine with an electric motor, offer potential benefits in terms of fuel efficiency and reduced emissions. However, their application in remote and rugged environments introduces a set of specific obstacles.

One of the primary challenges is the durability and reliability of hybrid components in harsh conditions. Off-road vehicles operating in remote areas are often subjected to extreme temperatures, dust, vibration, and moisture. These factors can significantly impact the performance and longevity of sensitive electronic components and battery systems integral to mild hybrid technology. Engineers must develop robust designs that can withstand these environmental stressors while maintaining optimal functionality.

Power management poses another significant challenge in remote operations. Mild hybrid systems rely on efficient energy recuperation and storage, typically during braking or deceleration. However, off-road driving patterns may not provide consistent opportunities for energy recovery, potentially limiting the system's effectiveness. Additionally, the increased electrical load from auxiliary equipment common in remote operations, such as winches or communication devices, can strain the hybrid system's power capacity.

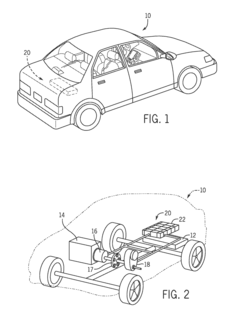

The integration of mild hybrid technology with existing off-road vehicle architectures presents further complications. Many off-road vehicles are designed with emphasis on ground clearance, axle articulation, and overall ruggedness. Incorporating hybrid components without compromising these essential off-road capabilities requires innovative packaging solutions and may necessitate redesigns of traditional vehicle layouts.

Maintenance and serviceability in remote locations also pose significant challenges. Mild hybrid systems introduce complex electronic components and high-voltage systems that require specialized knowledge and tools for diagnosis and repair. Ensuring that these vehicles can be serviced in remote areas with limited resources and expertise is crucial for their practical implementation.

Weight considerations are particularly critical in off-road applications. While mild hybrid systems can offer fuel efficiency benefits, they also add weight to the vehicle. In remote operations where payload capacity is often at a premium, this additional weight must be carefully balanced against the potential fuel savings and performance improvements.

Lastly, the cost-effectiveness of implementing mild hybrid systems in remote off-road vehicles must be carefully evaluated. The initial investment in hybrid technology may be substantial, and the return on investment in terms of fuel savings may take longer to realize in remote operations where vehicles may not accumulate mileage as quickly as in urban environments. Balancing the long-term benefits against the upfront costs is essential for justifying the adoption of this technology in specialized off-road applications.

One of the primary challenges is the durability and reliability of hybrid components in harsh conditions. Off-road vehicles operating in remote areas are often subjected to extreme temperatures, dust, vibration, and moisture. These factors can significantly impact the performance and longevity of sensitive electronic components and battery systems integral to mild hybrid technology. Engineers must develop robust designs that can withstand these environmental stressors while maintaining optimal functionality.

Power management poses another significant challenge in remote operations. Mild hybrid systems rely on efficient energy recuperation and storage, typically during braking or deceleration. However, off-road driving patterns may not provide consistent opportunities for energy recovery, potentially limiting the system's effectiveness. Additionally, the increased electrical load from auxiliary equipment common in remote operations, such as winches or communication devices, can strain the hybrid system's power capacity.

The integration of mild hybrid technology with existing off-road vehicle architectures presents further complications. Many off-road vehicles are designed with emphasis on ground clearance, axle articulation, and overall ruggedness. Incorporating hybrid components without compromising these essential off-road capabilities requires innovative packaging solutions and may necessitate redesigns of traditional vehicle layouts.

Maintenance and serviceability in remote locations also pose significant challenges. Mild hybrid systems introduce complex electronic components and high-voltage systems that require specialized knowledge and tools for diagnosis and repair. Ensuring that these vehicles can be serviced in remote areas with limited resources and expertise is crucial for their practical implementation.

Weight considerations are particularly critical in off-road applications. While mild hybrid systems can offer fuel efficiency benefits, they also add weight to the vehicle. In remote operations where payload capacity is often at a premium, this additional weight must be carefully balanced against the potential fuel savings and performance improvements.

Lastly, the cost-effectiveness of implementing mild hybrid systems in remote off-road vehicles must be carefully evaluated. The initial investment in hybrid technology may be substantial, and the return on investment in terms of fuel savings may take longer to realize in remote operations where vehicles may not accumulate mileage as quickly as in urban environments. Balancing the long-term benefits against the upfront costs is essential for justifying the adoption of this technology in specialized off-road applications.

Current Mild Hybrid Solutions for Off-Road Use

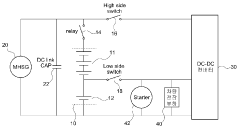

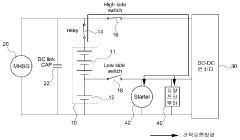

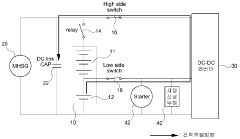

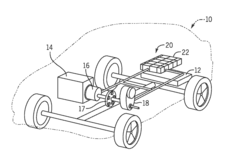

01 Electric motor integration in mild hybrid systems

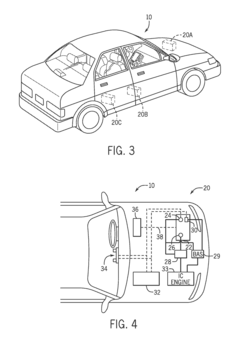

Mild hybrid systems incorporate electric motors to assist the internal combustion engine, improving fuel efficiency and reducing emissions. These motors can provide additional power during acceleration, enable start-stop functionality, and recover energy through regenerative braking. The integration of electric motors in various configurations allows for optimized performance and energy management in hybrid vehicles.- Energy management in mild hybrid systems: Mild hybrid systems employ sophisticated energy management strategies to optimize fuel efficiency and performance. These systems typically involve intelligent control of the electric motor assist, regenerative braking, and start-stop functionality. Advanced algorithms are used to determine the most efficient use of electric power and when to engage the internal combustion engine, based on driving conditions and energy demands.

- Integration of electric motor in mild hybrid powertrains: Mild hybrid systems incorporate an electric motor into the powertrain to provide additional power and improve efficiency. The motor is typically integrated between the engine and transmission, allowing for electric assist during acceleration, regenerative braking, and engine start-stop functionality. This integration requires careful design considerations to ensure seamless operation and optimal packaging within the vehicle.

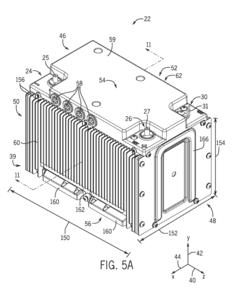

- Battery management and charging strategies: Effective battery management is crucial in mild hybrid systems to ensure optimal performance and longevity. This includes advanced charging strategies that utilize regenerative braking and engine power to maintain the battery at an ideal state of charge. Sophisticated battery management systems monitor temperature, voltage, and current to protect the battery and maximize its efficiency in supporting the hybrid powertrain.

- Transmission adaptations for mild hybrid systems: Mild hybrid systems often require specialized transmissions or adaptations to existing transmissions to accommodate the electric motor and enable smooth power delivery. These may include modified gear ratios, clutch systems, or the integration of the electric motor within the transmission housing. Such adaptations aim to optimize the synergy between the internal combustion engine and the electric motor for improved efficiency and performance.

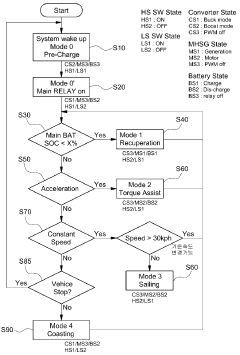

- Control systems and software for mild hybrids: Advanced control systems and software are essential components of mild hybrid systems. These systems manage the complex interactions between the internal combustion engine, electric motor, battery, and other powertrain components. Sophisticated algorithms optimize power distribution, manage thermal systems, and adapt to different driving conditions to maximize efficiency and performance while ensuring a seamless driving experience.

02 Battery management and power distribution

Efficient battery management and power distribution are crucial in mild hybrid systems. This includes optimizing the charging and discharging of the battery, managing power flow between the electric motor and internal combustion engine, and implementing intelligent control strategies to maximize energy efficiency. Advanced battery management systems ensure proper voltage regulation and thermal management for improved performance and longevity.Expand Specific Solutions03 Transmission and drivetrain optimization

Mild hybrid systems often require specialized transmissions and drivetrain components to effectively integrate the electric motor with the internal combustion engine. This may include the use of dual-clutch transmissions, continuously variable transmissions (CVTs), or modified gearboxes to accommodate the hybrid powertrain. Optimizing the transmission and drivetrain helps to improve overall system efficiency and performance.Expand Specific Solutions04 Control strategies and energy management

Advanced control strategies and energy management systems are essential for optimizing the performance of mild hybrid systems. These strategies involve coordinating the operation of the electric motor and internal combustion engine, managing power flow, and implementing intelligent algorithms for efficient energy utilization. Adaptive control systems can adjust parameters based on driving conditions and user preferences to maximize fuel economy and reduce emissions.Expand Specific Solutions05 Integration of regenerative braking systems

Regenerative braking systems are a key component of mild hybrid vehicles, allowing for the recovery of kinetic energy during deceleration and braking. This recovered energy is stored in the battery for later use, improving overall system efficiency. The integration of regenerative braking systems requires careful coordination with the vehicle's conventional braking system and power management to ensure smooth operation and optimal energy recovery.Expand Specific Solutions

Key Players in Off-Road Mild Hybrid Tech

The mild hybrid systems market for remote off-road vehicle operations is in its early growth stage, with increasing adoption driven by the need for improved fuel efficiency and reduced emissions in challenging environments. The market size is expanding, albeit moderately, as off-road vehicle manufacturers integrate these systems into their product lines. Technologically, mild hybrid systems are relatively mature, with companies like Hyundai Motor Co., Kia Corp., and BYD Co., Ltd. leading the way in adaptation for off-road applications. Johnson Controls, Inc. and Cummins, Inc. are also making significant strides in developing robust mild hybrid solutions tailored for rugged, remote operations, leveraging their expertise in powertrain and energy storage technologies.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a mild hybrid system for off-road applications, focusing on their SUV and crossover lineup. Their system utilizes a 48V lithium-ion battery coupled with an electric motor-generator, providing both power assist and regenerative braking capabilities. For remote off-road operations, Hyundai has enhanced the system to provide additional low-end torque, crucial for navigating difficult terrain. The system can deliver up to 14 kW of electric power assist, improving acceleration and hill-climbing performance[5]. Hyundai's mild hybrid technology also includes an advanced start-stop function that can quickly restart the engine, reducing fuel consumption during frequent stops typical in off-road driving. The system is designed to be robust and resistant to dust, water, and vibrations, making it suitable for harsh off-road environments.

Strengths: Improved fuel efficiency, enhanced low-speed torque for off-road use, and seamless integration with existing powertrains. Weaknesses: Limited electric-only range, added complexity in remote servicing, and increased vehicle weight.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative mild hybrid system for off-road vehicles, leveraging their expertise in battery technology. Their system incorporates a high-capacity lithium iron phosphate (LFP) battery, known for its durability and safety, coupled with a powerful electric motor. For remote off-road operations, BYD's system provides significant torque boost, with some models delivering up to 200 Nm of additional torque[6]. The system features advanced thermal management to ensure optimal performance in extreme temperatures often encountered in off-road scenarios. BYD's mild hybrid technology also includes intelligent power distribution that adapts to various terrains, optimizing the balance between the internal combustion engine and electric motor for maximum efficiency and performance. The system's regenerative braking is particularly effective in off-road conditions, recovering energy during descents and improving overall range.

Strengths: High-capacity battery for extended electric assist, robust design suitable for extreme conditions, and advanced thermal management. Weaknesses: Potentially higher cost due to advanced battery technology, added weight that could affect some off-road capabilities, and limited global service network for remote locations.

Core Innovations in Remote Mild Hybrid Systems

Mild hybrid system of vehicle

PatentActiveKR1020170135039A

Innovation

- Integration of a first and second battery unit in series, with a DC-DC converter, relay switch, and control switches to manage power flow efficiently, reducing the overall system size and improving power conversion efficiency.

System and method for roller interconnection of battery cells

PatentActiveUS20150037640A1

Innovation

- The development of a battery module with a lithium ion battery system that provides multiple voltage levels, including 12V and 48V, within a form factor equivalent to a traditional lead acid battery, utilizing a roller housing structure and roller interconnect assemblies for secure tab electrode connections, and incorporating advanced thermal management systems like heat sinks and phase change materials.

Environmental Impact Assessment

The implementation of mild hybrid systems in remote off-road vehicle operations presents both opportunities and challenges for environmental impact. These systems, which combine a conventional internal combustion engine with an electric motor, offer potential benefits in reducing fuel consumption and emissions, particularly in the challenging terrain and conditions typical of off-road operations.

One of the primary environmental advantages of mild hybrid systems in off-road vehicles is the reduction in fuel consumption. By utilizing regenerative braking and providing electric assist during acceleration, these systems can significantly improve fuel efficiency, especially in the stop-start conditions often encountered in rugged terrains. This reduction in fuel usage directly translates to lower greenhouse gas emissions, contributing to the mitigation of climate change impacts in remote areas.

The decreased reliance on fossil fuels also leads to a reduction in local air pollutants, such as particulate matter and nitrogen oxides. This is particularly beneficial in remote and ecologically sensitive areas where off-road vehicles operate, as it helps preserve air quality and protect local flora and fauna from the harmful effects of these pollutants.

However, the environmental impact assessment must also consider the potential negative aspects of implementing mild hybrid systems in off-road vehicles. The production and disposal of hybrid components, particularly batteries, can have significant environmental implications. The mining of rare earth elements for battery production and the challenges associated with battery recycling at the end of their life cycle are important factors to consider in the overall environmental impact.

Additionally, the increased complexity of mild hybrid systems may lead to more frequent maintenance requirements, potentially resulting in more waste generation and resource consumption over the vehicle's lifetime. This aspect needs to be carefully evaluated against the environmental benefits of reduced fuel consumption and emissions.

The noise reduction capabilities of mild hybrid systems offer another environmental advantage, particularly in remote areas where wildlife habitats may be sensitive to acoustic disturbances. The ability to operate in electric-only mode for short distances can significantly reduce noise pollution in these environments.

In terms of land use and ecosystem impact, the improved efficiency of mild hybrid off-road vehicles may lead to reduced need for refueling infrastructure in remote areas. This could potentially decrease the footprint of human activity in these regions, helping to preserve natural habitats and minimize ecosystem disruption.

Overall, while mild hybrid systems in remote off-road vehicle operations offer significant potential for reducing environmental impact through decreased emissions and fuel consumption, a comprehensive assessment must balance these benefits against the lifecycle impacts of hybrid components and the potential for increased maintenance-related waste. The specific environmental conditions of the operational areas and the long-term sustainability of the technology should be key considerations in this assessment.

One of the primary environmental advantages of mild hybrid systems in off-road vehicles is the reduction in fuel consumption. By utilizing regenerative braking and providing electric assist during acceleration, these systems can significantly improve fuel efficiency, especially in the stop-start conditions often encountered in rugged terrains. This reduction in fuel usage directly translates to lower greenhouse gas emissions, contributing to the mitigation of climate change impacts in remote areas.

The decreased reliance on fossil fuels also leads to a reduction in local air pollutants, such as particulate matter and nitrogen oxides. This is particularly beneficial in remote and ecologically sensitive areas where off-road vehicles operate, as it helps preserve air quality and protect local flora and fauna from the harmful effects of these pollutants.

However, the environmental impact assessment must also consider the potential negative aspects of implementing mild hybrid systems in off-road vehicles. The production and disposal of hybrid components, particularly batteries, can have significant environmental implications. The mining of rare earth elements for battery production and the challenges associated with battery recycling at the end of their life cycle are important factors to consider in the overall environmental impact.

Additionally, the increased complexity of mild hybrid systems may lead to more frequent maintenance requirements, potentially resulting in more waste generation and resource consumption over the vehicle's lifetime. This aspect needs to be carefully evaluated against the environmental benefits of reduced fuel consumption and emissions.

The noise reduction capabilities of mild hybrid systems offer another environmental advantage, particularly in remote areas where wildlife habitats may be sensitive to acoustic disturbances. The ability to operate in electric-only mode for short distances can significantly reduce noise pollution in these environments.

In terms of land use and ecosystem impact, the improved efficiency of mild hybrid off-road vehicles may lead to reduced need for refueling infrastructure in remote areas. This could potentially decrease the footprint of human activity in these regions, helping to preserve natural habitats and minimize ecosystem disruption.

Overall, while mild hybrid systems in remote off-road vehicle operations offer significant potential for reducing environmental impact through decreased emissions and fuel consumption, a comprehensive assessment must balance these benefits against the lifecycle impacts of hybrid components and the potential for increased maintenance-related waste. The specific environmental conditions of the operational areas and the long-term sustainability of the technology should be key considerations in this assessment.

Reliability and Maintenance Considerations

The reliability and maintenance considerations for mild hybrid systems in remote off-road vehicle operations are crucial factors that significantly impact the overall performance and operational efficiency of these vehicles. In harsh and isolated environments, the robustness of the hybrid system becomes paramount, as access to specialized maintenance facilities may be limited or non-existent.

One of the primary concerns is the durability of electrical components, particularly the battery pack and power electronics. These components must withstand extreme temperatures, vibrations, and potential exposure to dust and moisture. To address this, manufacturers are developing ruggedized designs with enhanced thermal management systems and improved sealing techniques. Additionally, the integration of advanced diagnostic systems allows for real-time monitoring of component health, enabling predictive maintenance and reducing the risk of unexpected failures during critical operations.

The maintenance strategy for mild hybrid systems in remote settings must be carefully tailored to the unique challenges of off-road environments. This includes developing modular designs that facilitate easy replacement of components in the field, as well as implementing redundancy in critical systems to ensure continued operation in case of partial failures. Training programs for operators and on-site technicians are essential to enable basic troubleshooting and maintenance tasks without the need for specialized equipment or expertise.

Reliability testing for these systems must simulate the extreme conditions encountered in remote off-road operations. This involves extensive field trials in various terrains and climates, as well as accelerated life testing to identify potential weak points in the system. The data gathered from these tests informs design improvements and helps establish realistic maintenance schedules and component life expectancies.

The integration of telematics and remote diagnostics plays a vital role in maintaining the reliability of mild hybrid systems in remote operations. These technologies allow for continuous monitoring of vehicle performance and early detection of potential issues. By leveraging data analytics and machine learning algorithms, predictive maintenance models can be developed to optimize service intervals and minimize downtime.

Lastly, the supply chain for replacement parts and components must be carefully managed to ensure availability in remote locations. This may involve establishing strategic parts depots or developing partnerships with local suppliers to reduce lead times for critical components. The standardization of parts across different vehicle models can also help simplify inventory management and improve the overall reliability of the fleet.

One of the primary concerns is the durability of electrical components, particularly the battery pack and power electronics. These components must withstand extreme temperatures, vibrations, and potential exposure to dust and moisture. To address this, manufacturers are developing ruggedized designs with enhanced thermal management systems and improved sealing techniques. Additionally, the integration of advanced diagnostic systems allows for real-time monitoring of component health, enabling predictive maintenance and reducing the risk of unexpected failures during critical operations.

The maintenance strategy for mild hybrid systems in remote settings must be carefully tailored to the unique challenges of off-road environments. This includes developing modular designs that facilitate easy replacement of components in the field, as well as implementing redundancy in critical systems to ensure continued operation in case of partial failures. Training programs for operators and on-site technicians are essential to enable basic troubleshooting and maintenance tasks without the need for specialized equipment or expertise.

Reliability testing for these systems must simulate the extreme conditions encountered in remote off-road operations. This involves extensive field trials in various terrains and climates, as well as accelerated life testing to identify potential weak points in the system. The data gathered from these tests informs design improvements and helps establish realistic maintenance schedules and component life expectancies.

The integration of telematics and remote diagnostics plays a vital role in maintaining the reliability of mild hybrid systems in remote operations. These technologies allow for continuous monitoring of vehicle performance and early detection of potential issues. By leveraging data analytics and machine learning algorithms, predictive maintenance models can be developed to optimize service intervals and minimize downtime.

Lastly, the supply chain for replacement parts and components must be carefully managed to ensure availability in remote locations. This may involve establishing strategic parts depots or developing partnerships with local suppliers to reduce lead times for critical components. The standardization of parts across different vehicle models can also help simplify inventory management and improve the overall reliability of the fleet.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!