Understanding LDPE Environmental Impact and Solutions

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its invention in 1933. This versatile polymer, characterized by its flexibility, durability, and low cost, has found widespread applications in packaging, construction, and consumer goods. However, the ubiquity of LDPE has led to significant environmental concerns, particularly regarding its persistence in ecosystems and contribution to plastic pollution.

The evolution of LDPE technology has been driven by the need for improved material properties and processing efficiency. Initially developed through high-pressure polymerization, LDPE production techniques have advanced to include various catalytic methods, enabling greater control over molecular structure and properties. These advancements have expanded LDPE's utility across diverse sectors, from food packaging to agricultural films.

As global plastic production continues to rise, with LDPE playing a substantial role, the environmental impact of this material has come under increasing scrutiny. The durability that makes LDPE valuable in many applications also contributes to its long-term persistence in the environment. LDPE's resistance to degradation means that it can remain in ecosystems for hundreds of years, fragmenting into microplastics that pose risks to wildlife and potentially enter the food chain.

The growing awareness of these environmental challenges has spurred research into more sustainable alternatives and improved end-of-life solutions for LDPE products. Current technological objectives in this field focus on several key areas: enhancing the recyclability of LDPE, developing biodegradable or compostable alternatives, improving waste management systems, and exploring novel methods for chemical recycling or upcycling of LDPE waste.

One significant trend in LDPE technology is the development of more easily recyclable formulations. This includes efforts to reduce the use of additives that complicate recycling processes and the creation of LDPE blends that maintain desirable properties while improving end-of-life outcomes. Additionally, there is growing interest in bio-based LDPE alternatives, which aim to reduce reliance on fossil fuels and potentially offer improved biodegradability.

The technological trajectory for LDPE is increasingly shaped by circular economy principles, with a focus on designing products for recyclability and developing closed-loop systems for plastic waste. This shift necessitates innovations not only in material science but also in product design, waste collection, and recycling technologies. The ultimate goal is to mitigate the environmental impact of LDPE while preserving its valuable properties and economic benefits.

The evolution of LDPE technology has been driven by the need for improved material properties and processing efficiency. Initially developed through high-pressure polymerization, LDPE production techniques have advanced to include various catalytic methods, enabling greater control over molecular structure and properties. These advancements have expanded LDPE's utility across diverse sectors, from food packaging to agricultural films.

As global plastic production continues to rise, with LDPE playing a substantial role, the environmental impact of this material has come under increasing scrutiny. The durability that makes LDPE valuable in many applications also contributes to its long-term persistence in the environment. LDPE's resistance to degradation means that it can remain in ecosystems for hundreds of years, fragmenting into microplastics that pose risks to wildlife and potentially enter the food chain.

The growing awareness of these environmental challenges has spurred research into more sustainable alternatives and improved end-of-life solutions for LDPE products. Current technological objectives in this field focus on several key areas: enhancing the recyclability of LDPE, developing biodegradable or compostable alternatives, improving waste management systems, and exploring novel methods for chemical recycling or upcycling of LDPE waste.

One significant trend in LDPE technology is the development of more easily recyclable formulations. This includes efforts to reduce the use of additives that complicate recycling processes and the creation of LDPE blends that maintain desirable properties while improving end-of-life outcomes. Additionally, there is growing interest in bio-based LDPE alternatives, which aim to reduce reliance on fossil fuels and potentially offer improved biodegradability.

The technological trajectory for LDPE is increasingly shaped by circular economy principles, with a focus on designing products for recyclability and developing closed-loop systems for plastic waste. This shift necessitates innovations not only in material science but also in product design, waste collection, and recycling technologies. The ultimate goal is to mitigate the environmental impact of LDPE while preserving its valuable properties and economic benefits.

Market Analysis for LDPE Alternatives

The market for LDPE alternatives is experiencing significant growth driven by increasing environmental concerns and regulatory pressures. As consumers and businesses become more aware of the environmental impact of traditional plastics, there is a growing demand for sustainable packaging solutions. This shift in consumer preferences is creating opportunities for bio-based and biodegradable alternatives to LDPE.

The global market for biodegradable plastics is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 15% from 2021 to 2026. This growth is particularly pronounced in sectors such as food packaging, consumer goods, and agriculture. Regions like Europe and North America are leading the adoption of LDPE alternatives due to stringent regulations on single-use plastics and growing environmental consciousness among consumers.

Key players in the LDPE alternatives market include both established chemical companies and innovative startups. Major chemical corporations are investing heavily in research and development of sustainable materials, while startups are focusing on novel bio-based solutions. This competitive landscape is driving innovation and helping to reduce the cost gap between traditional LDPE and its alternatives.

Bio-based plastics, such as PLA (polylactic acid) and PHA (polyhydroxyalkanoates), are gaining traction as LDPE alternatives. These materials offer similar functional properties to LDPE while being derived from renewable resources and offering improved end-of-life options. The market for bio-based plastics is expected to grow substantially, with some estimates suggesting a market value surpassing $10 billion by 2025.

Recycled LDPE is another important segment of the alternatives market. As recycling technologies improve and circular economy principles gain traction, the demand for recycled LDPE is increasing. This trend is particularly strong in the packaging industry, where brands are setting ambitious targets for incorporating recycled content in their products.

Despite the promising growth, challenges remain for LDPE alternatives. Cost competitiveness is a significant barrier, as many alternatives are still more expensive than traditional LDPE. Performance limitations, such as lower heat resistance or moisture barrier properties, can also restrict adoption in certain applications. Additionally, the lack of standardized waste management infrastructure for some bio-based materials poses challenges for widespread adoption.

The market for LDPE alternatives is highly influenced by regulatory landscapes. Policies such as plastic bag bans, extended producer responsibility (EPR) schemes, and recycled content mandates are shaping market dynamics. Countries and regions with more aggressive environmental policies are seeing faster adoption of LDPE alternatives, creating a patchwork of market opportunities globally.

The global market for biodegradable plastics is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) exceeding 15% from 2021 to 2026. This growth is particularly pronounced in sectors such as food packaging, consumer goods, and agriculture. Regions like Europe and North America are leading the adoption of LDPE alternatives due to stringent regulations on single-use plastics and growing environmental consciousness among consumers.

Key players in the LDPE alternatives market include both established chemical companies and innovative startups. Major chemical corporations are investing heavily in research and development of sustainable materials, while startups are focusing on novel bio-based solutions. This competitive landscape is driving innovation and helping to reduce the cost gap between traditional LDPE and its alternatives.

Bio-based plastics, such as PLA (polylactic acid) and PHA (polyhydroxyalkanoates), are gaining traction as LDPE alternatives. These materials offer similar functional properties to LDPE while being derived from renewable resources and offering improved end-of-life options. The market for bio-based plastics is expected to grow substantially, with some estimates suggesting a market value surpassing $10 billion by 2025.

Recycled LDPE is another important segment of the alternatives market. As recycling technologies improve and circular economy principles gain traction, the demand for recycled LDPE is increasing. This trend is particularly strong in the packaging industry, where brands are setting ambitious targets for incorporating recycled content in their products.

Despite the promising growth, challenges remain for LDPE alternatives. Cost competitiveness is a significant barrier, as many alternatives are still more expensive than traditional LDPE. Performance limitations, such as lower heat resistance or moisture barrier properties, can also restrict adoption in certain applications. Additionally, the lack of standardized waste management infrastructure for some bio-based materials poses challenges for widespread adoption.

The market for LDPE alternatives is highly influenced by regulatory landscapes. Policies such as plastic bag bans, extended producer responsibility (EPR) schemes, and recycled content mandates are shaping market dynamics. Countries and regions with more aggressive environmental policies are seeing faster adoption of LDPE alternatives, creating a patchwork of market opportunities globally.

LDPE Environmental Challenges

Low-density polyethylene (LDPE) has become a ubiquitous material in modern society, but its widespread use has led to significant environmental challenges. The primary concern stems from LDPE's persistence in the environment, as it can take hundreds of years to decompose naturally. This longevity results in the accumulation of plastic waste in landfills, oceans, and ecosystems worldwide.

One of the most pressing issues is marine pollution. LDPE products, such as plastic bags and packaging materials, often find their way into oceans and waterways. These plastics break down into smaller particles known as microplastics, which can be ingested by marine life, causing harm to aquatic ecosystems and potentially entering the human food chain.

Landfill management is another critical challenge associated with LDPE waste. As LDPE does not biodegrade easily, it occupies significant space in landfills, contributing to the rapid depletion of available land for waste disposal. This issue is particularly acute in densely populated urban areas where land is already at a premium.

The production of LDPE also raises environmental concerns. The manufacturing process relies heavily on fossil fuels, both as a raw material and energy source. This dependence contributes to greenhouse gas emissions and exacerbates climate change. Additionally, the extraction and processing of these fossil fuels can lead to habitat destruction and pollution.

Recycling LDPE presents its own set of challenges. While technically recyclable, the process is often economically unfeasible due to contamination issues and the low value of recycled LDPE compared to virgin material. This economic barrier has resulted in low recycling rates for LDPE products globally, further contributing to the accumulation of plastic waste.

The widespread use of single-use LDPE products, such as disposable bags and packaging, has created a "throwaway culture" that exacerbates environmental issues. This consumer behavior, coupled with inadequate waste management infrastructure in many regions, leads to increased littering and improper disposal of LDPE products.

Addressing these environmental challenges requires a multifaceted approach. This includes developing more sustainable alternatives to LDPE, improving recycling technologies and infrastructure, implementing stricter regulations on plastic use and disposal, and educating consumers about the environmental impact of their choices. As the world grapples with these issues, finding effective solutions to mitigate the environmental impact of LDPE remains a critical priority for researchers, policymakers, and industry leaders alike.

One of the most pressing issues is marine pollution. LDPE products, such as plastic bags and packaging materials, often find their way into oceans and waterways. These plastics break down into smaller particles known as microplastics, which can be ingested by marine life, causing harm to aquatic ecosystems and potentially entering the human food chain.

Landfill management is another critical challenge associated with LDPE waste. As LDPE does not biodegrade easily, it occupies significant space in landfills, contributing to the rapid depletion of available land for waste disposal. This issue is particularly acute in densely populated urban areas where land is already at a premium.

The production of LDPE also raises environmental concerns. The manufacturing process relies heavily on fossil fuels, both as a raw material and energy source. This dependence contributes to greenhouse gas emissions and exacerbates climate change. Additionally, the extraction and processing of these fossil fuels can lead to habitat destruction and pollution.

Recycling LDPE presents its own set of challenges. While technically recyclable, the process is often economically unfeasible due to contamination issues and the low value of recycled LDPE compared to virgin material. This economic barrier has resulted in low recycling rates for LDPE products globally, further contributing to the accumulation of plastic waste.

The widespread use of single-use LDPE products, such as disposable bags and packaging, has created a "throwaway culture" that exacerbates environmental issues. This consumer behavior, coupled with inadequate waste management infrastructure in many regions, leads to increased littering and improper disposal of LDPE products.

Addressing these environmental challenges requires a multifaceted approach. This includes developing more sustainable alternatives to LDPE, improving recycling technologies and infrastructure, implementing stricter regulations on plastic use and disposal, and educating consumers about the environmental impact of their choices. As the world grapples with these issues, finding effective solutions to mitigate the environmental impact of LDPE remains a critical priority for researchers, policymakers, and industry leaders alike.

Current LDPE Recycling Solutions

01 Biodegradable LDPE composites

Development of biodegradable LDPE composites to reduce environmental impact. These composites incorporate natural fibers or biodegradable additives to enhance the material's degradability while maintaining its desirable properties. This approach aims to address the issue of plastic waste accumulation in the environment.- Biodegradable LDPE composites: Development of biodegradable LDPE composites to reduce environmental impact. These composites incorporate natural fibers or biodegradable additives to enhance the material's degradability while maintaining its desirable properties. This approach aims to address the issue of plastic waste accumulation in the environment.

- Recycling and upcycling of LDPE: Innovative methods for recycling and upcycling LDPE to minimize its environmental footprint. These techniques include chemical recycling, mechanical recycling, and the transformation of LDPE waste into value-added products. By improving recycling efficiency, the overall environmental impact of LDPE can be reduced.

- LDPE alternatives and substitutes: Research and development of environmentally friendly alternatives and substitutes for LDPE. This includes the creation of bio-based polymers, compostable materials, and other sustainable options that can replace LDPE in various applications while offering similar performance characteristics.

- Reduction of LDPE environmental impact in production: Techniques and processes to minimize the environmental impact of LDPE during its production phase. This involves optimizing manufacturing processes, reducing energy consumption, and implementing cleaner production technologies to lower greenhouse gas emissions and resource consumption associated with LDPE production.

- LDPE waste management and disposal: Strategies for improved LDPE waste management and disposal to mitigate its environmental impact. This includes the development of advanced sorting technologies, efficient collection systems, and environmentally sound disposal methods. The focus is on reducing LDPE pollution in landfills, oceans, and other ecosystems.

02 Recycling and upcycling of LDPE

Innovative methods for recycling and upcycling LDPE to minimize its environmental footprint. These techniques include chemical recycling, mechanical recycling, and the transformation of LDPE waste into value-added products. By improving recycling efficiency, the overall environmental impact of LDPE can be reduced.Expand Specific Solutions03 LDPE alternatives and substitutes

Research and development of environmentally friendly alternatives and substitutes for LDPE. This includes the creation of bio-based polymers, compostable materials, and other sustainable options that can replace LDPE in various applications while reducing environmental impact.Expand Specific Solutions04 Reduction of LDPE production emissions

Techniques and technologies aimed at reducing emissions and environmental impact during LDPE production. This involves optimizing manufacturing processes, implementing cleaner production methods, and utilizing renewable energy sources to minimize the carbon footprint associated with LDPE manufacturing.Expand Specific Solutions05 LDPE waste management and disposal

Strategies for improved LDPE waste management and disposal to mitigate environmental impact. This includes the development of advanced sorting technologies, implementation of efficient collection systems, and exploration of alternative disposal methods such as energy recovery from LDPE waste.Expand Specific Solutions

Key Players in LDPE Industry

The environmental impact and solutions for LDPE are in a mature stage of industry development, with a significant global market size. The technology is well-established, with major players like Dow Global Technologies, Basell Polyolefine, and Braskem leading innovation. These companies have extensive experience in polymer production and are investing in sustainable solutions. The market is characterized by ongoing research into biodegradable alternatives and recycling technologies, with companies like ExxonMobil Chemical Patents and SABIC Global Technologies actively developing new processes. Collaboration between industry leaders and academic institutions such as Beijing University of Chemical Technology is driving advancements in eco-friendly LDPE alternatives and improved recycling methods.

Dow Global Technologies LLC

Technical Solution: Dow has developed a recyclable LDPE-based packaging solution called REVOLOOP™. This technology incorporates up to 70% recycled content without compromising on performance[1]. The company has also introduced AGILITY™ CE, a circular economy-based LDPE resin that incorporates post-consumer recycled (PCR) plastic[2]. Dow's approach focuses on mechanical recycling and the development of compatibilizers to improve the quality of recycled LDPE. They are also exploring chemical recycling technologies to break down LDPE into its molecular components for reuse[3].

Strengths: High recycled content, maintained performance, circular economy focus. Weaknesses: Dependence on efficient collection and sorting systems, potential quality variations in recycled content.

Braskem SA

Technical Solution: Braskem has developed a bio-based LDPE made from sugarcane ethanol, marketed as I'm green™ Polyethylene. This renewable LDPE has the same properties as fossil-based LDPE but with a negative carbon footprint, capturing up to 3.09 tons of CO2 for every ton produced[4]. The company is also investing in mechanical and chemical recycling technologies. Their mechanical recycling initiative aims to transform post-consumer plastic waste into high-quality recycled resins, while their chemical recycling project focuses on pyrolysis technology to convert plastic waste back into raw materials[5].

Strengths: Renewable feedstock, negative carbon footprint, dual recycling approach. Weaknesses: Limited availability of bio-based feedstock, potential competition with food crops.

Innovations in Biodegradable Plastics

Methods for degrading low density polyethylene (LDPE) and remediating leachate

PatentActiveUS20200406320A1

Innovation

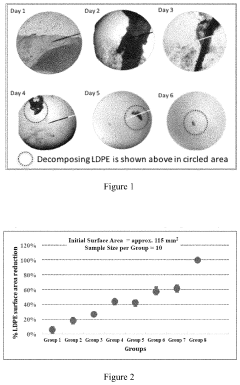

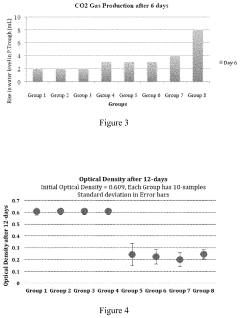

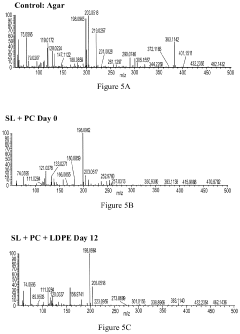

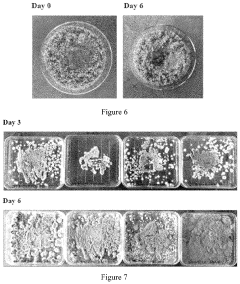

- Contacting pretreated LDPE with white-rot fungi, such as Phanerochaete chrysosporium, at elevated temperatures and potentially etching the LDPE, within the activated sludge infrastructure of landfills to achieve near 100% degradation and leachate remediation without toxic byproducts.

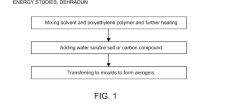

Hydrophobic aerogel for oil spill remediation and its method of preparation thereof

PatentPendingIN202311066682A

Innovation

- A hydrophobic polyethylene-based aerogel is developed, utilizing low-density polyethylene (LDPE) from waste plastics and optionally water-soluble salts or carbon compounds, which is prepared by dissolving LDPE in a solvent, adding optional additives, and drying to create a porous, lightweight, and mechanically strong material for efficient oil-water separation.

Regulatory Framework for Plastics

The regulatory framework for plastics, particularly concerning LDPE (Low-Density Polyethylene), has been evolving rapidly in response to growing environmental concerns. Governments and international organizations are implementing increasingly stringent regulations to address the environmental impact of plastic production, use, and disposal.

At the global level, the United Nations Environment Programme (UNEP) has been instrumental in shaping policies through initiatives like the Global Partnership on Marine Litter and the Clean Seas campaign. These efforts aim to reduce plastic pollution in oceans and encourage sustainable practices in plastic production and consumption.

In the European Union, the Plastic Strategy and the Single-Use Plastics Directive have set ambitious targets for plastic recycling and reduction of single-use plastics. These regulations directly impact LDPE production and usage, as many single-use plastic items are made from this material. The EU has also introduced a plastic tax on non-recycled plastic packaging waste, incentivizing the use of recycled materials in LDPE products.

The United States has seen a patchwork of state-level regulations, with some states banning single-use plastic bags and implementing extended producer responsibility (EPR) programs. The EPA has also been working on updating its regulations under the Resource Conservation and Recovery Act (RCRA) to address plastic waste management more effectively.

In Asia, countries like China and India have introduced bans on certain single-use plastics and implemented stricter waste management policies. China's National Sword policy, which restricted the import of plastic waste, has had global repercussions on the plastic recycling industry, including LDPE recycling.

Many countries have also introduced or are considering plastic packaging taxes, deposit-return schemes, and mandatory recycled content requirements. These measures aim to create a circular economy for plastics, including LDPE, by incentivizing recycling and the use of recycled materials in production.

The regulatory landscape also includes standards and certifications for biodegradable and compostable plastics, which are increasingly seen as alternatives to traditional LDPE in certain applications. However, these standards vary globally, creating challenges for manufacturers and consumers alike.

As the regulatory framework continues to evolve, it is driving innovation in LDPE production and recycling technologies. Companies are investing in research and development to create more environmentally friendly LDPE formulations and improve recycling processes to meet regulatory requirements and consumer demands for sustainable products.

At the global level, the United Nations Environment Programme (UNEP) has been instrumental in shaping policies through initiatives like the Global Partnership on Marine Litter and the Clean Seas campaign. These efforts aim to reduce plastic pollution in oceans and encourage sustainable practices in plastic production and consumption.

In the European Union, the Plastic Strategy and the Single-Use Plastics Directive have set ambitious targets for plastic recycling and reduction of single-use plastics. These regulations directly impact LDPE production and usage, as many single-use plastic items are made from this material. The EU has also introduced a plastic tax on non-recycled plastic packaging waste, incentivizing the use of recycled materials in LDPE products.

The United States has seen a patchwork of state-level regulations, with some states banning single-use plastic bags and implementing extended producer responsibility (EPR) programs. The EPA has also been working on updating its regulations under the Resource Conservation and Recovery Act (RCRA) to address plastic waste management more effectively.

In Asia, countries like China and India have introduced bans on certain single-use plastics and implemented stricter waste management policies. China's National Sword policy, which restricted the import of plastic waste, has had global repercussions on the plastic recycling industry, including LDPE recycling.

Many countries have also introduced or are considering plastic packaging taxes, deposit-return schemes, and mandatory recycled content requirements. These measures aim to create a circular economy for plastics, including LDPE, by incentivizing recycling and the use of recycled materials in production.

The regulatory landscape also includes standards and certifications for biodegradable and compostable plastics, which are increasingly seen as alternatives to traditional LDPE in certain applications. However, these standards vary globally, creating challenges for manufacturers and consumers alike.

As the regulatory framework continues to evolve, it is driving innovation in LDPE production and recycling technologies. Companies are investing in research and development to create more environmentally friendly LDPE formulations and improve recycling processes to meet regulatory requirements and consumer demands for sustainable products.

Economic Impact of LDPE Alternatives

The economic impact of LDPE alternatives is a critical consideration in the transition towards more sustainable packaging solutions. As industries and governments worldwide seek to reduce plastic pollution, the shift away from traditional LDPE products has significant economic implications across various sectors.

One of the primary economic factors to consider is the cost of production for LDPE alternatives. Many biodegradable and compostable materials, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), currently have higher production costs compared to conventional LDPE. This price differential can be attributed to factors including raw material expenses, manufacturing processes, and economies of scale. However, as demand for these alternatives grows and production technologies improve, their costs are expected to decrease over time.

The adoption of LDPE alternatives also has implications for the recycling and waste management industries. While LDPE recycling infrastructure is well-established in many regions, the introduction of new materials may require significant investments in sorting and processing technologies. This could lead to short-term economic challenges for recycling facilities but may also create opportunities for innovation and job creation in the long run.

Consumer behavior and market demand play a crucial role in the economic impact of LDPE alternatives. As environmental awareness increases, consumers may be willing to pay a premium for more sustainable packaging options. This shift in consumer preferences can drive market growth for LDPE alternatives, potentially offsetting higher production costs and stimulating further investment in research and development.

The transition to LDPE alternatives may also have broader economic effects on related industries. For instance, the agricultural sector could benefit from increased demand for bio-based raw materials used in the production of certain LDPE alternatives. Conversely, traditional petrochemical industries may face challenges as demand for fossil fuel-based plastics declines.

Government policies and regulations play a significant role in shaping the economic landscape for LDPE alternatives. Incentives, subsidies, and taxes on conventional plastics can influence the competitiveness of alternative materials. For example, plastic bag bans and taxes in various countries have accelerated the adoption of reusable bags and biodegradable alternatives, creating new market opportunities.

The global trade of plastics and packaging materials may also be affected by the shift towards LDPE alternatives. Countries with advanced technologies and production capabilities for sustainable materials may gain a competitive advantage in the international market. This could lead to changes in trade patterns and potentially impact economic relationships between nations.

One of the primary economic factors to consider is the cost of production for LDPE alternatives. Many biodegradable and compostable materials, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), currently have higher production costs compared to conventional LDPE. This price differential can be attributed to factors including raw material expenses, manufacturing processes, and economies of scale. However, as demand for these alternatives grows and production technologies improve, their costs are expected to decrease over time.

The adoption of LDPE alternatives also has implications for the recycling and waste management industries. While LDPE recycling infrastructure is well-established in many regions, the introduction of new materials may require significant investments in sorting and processing technologies. This could lead to short-term economic challenges for recycling facilities but may also create opportunities for innovation and job creation in the long run.

Consumer behavior and market demand play a crucial role in the economic impact of LDPE alternatives. As environmental awareness increases, consumers may be willing to pay a premium for more sustainable packaging options. This shift in consumer preferences can drive market growth for LDPE alternatives, potentially offsetting higher production costs and stimulating further investment in research and development.

The transition to LDPE alternatives may also have broader economic effects on related industries. For instance, the agricultural sector could benefit from increased demand for bio-based raw materials used in the production of certain LDPE alternatives. Conversely, traditional petrochemical industries may face challenges as demand for fossil fuel-based plastics declines.

Government policies and regulations play a significant role in shaping the economic landscape for LDPE alternatives. Incentives, subsidies, and taxes on conventional plastics can influence the competitiveness of alternative materials. For example, plastic bag bans and taxes in various countries have accelerated the adoption of reusable bags and biodegradable alternatives, creating new market opportunities.

The global trade of plastics and packaging materials may also be affected by the shift towards LDPE alternatives. Countries with advanced technologies and production capabilities for sustainable materials may gain a competitive advantage in the international market. This could lead to changes in trade patterns and potentially impact economic relationships between nations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!