K24 Engine VTEC: Understanding Technological Impacts

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 VTEC Evolution

The K24 VTEC engine has undergone significant evolution since its introduction, marking key milestones in Honda's engine technology. Initially developed in the early 2000s, the K24 engine with VTEC (Variable Valve Timing and Lift Electronic Control) technology represented a leap forward in achieving both performance and efficiency in a single package.

The first generation of K24 VTEC engines, introduced in 2002, featured a displacement of 2.4 liters and utilized a single overhead camshaft (SOHC) design. This initial iteration focused on balancing power output with fuel economy, primarily targeting the mid-size sedan market. The VTEC system in these early models operated on the intake valves only, providing a noticeable boost in power at higher RPMs while maintaining efficiency at lower engine speeds.

As the technology matured, Honda introduced the second generation of K24 VTEC engines around 2006. This version saw the implementation of a dual overhead camshaft (DOHC) design, which allowed for more precise control over valve timing and lift. The i-VTEC system, an advanced iteration of VTEC, was incorporated, integrating VTC (Variable Timing Control) to further optimize engine performance across a broader range of operating conditions.

The third generation, launched circa 2008, brought about significant improvements in both power output and fuel efficiency. This was achieved through refinements in the i-VTEC system, including more aggressive cam profiles and enhanced electronic control units. Additionally, this generation saw the introduction of direct fuel injection in some variants, further improving combustion efficiency and power delivery.

By the early 2010s, the fourth generation of K24 VTEC engines emerged, focusing on meeting increasingly stringent emissions regulations while maintaining performance. This iteration featured advanced materials for weight reduction, improved cooling systems, and further refinements to the i-VTEC system. Some variants also incorporated turbocharging, marking a shift towards forced induction to extract more power from the 2.4-liter displacement.

The most recent evolution of the K24 VTEC, seen in the late 2010s and early 2020s, has embraced hybrid technology. This latest iteration combines the refined K24 engine with electric motors, leveraging the strengths of both power sources to achieve unprecedented levels of efficiency and performance. The VTEC system in these hybrid variants is specifically tuned to work in harmony with the electric powertrain, optimizing the engine's operation for maximum efficiency when running and seamless integration with the electric drive system.

Throughout its evolution, the K24 VTEC engine has consistently pushed the boundaries of naturally aspirated engine technology, adapting to changing market demands and regulatory requirements while maintaining Honda's reputation for reliable, high-performance engines.

The first generation of K24 VTEC engines, introduced in 2002, featured a displacement of 2.4 liters and utilized a single overhead camshaft (SOHC) design. This initial iteration focused on balancing power output with fuel economy, primarily targeting the mid-size sedan market. The VTEC system in these early models operated on the intake valves only, providing a noticeable boost in power at higher RPMs while maintaining efficiency at lower engine speeds.

As the technology matured, Honda introduced the second generation of K24 VTEC engines around 2006. This version saw the implementation of a dual overhead camshaft (DOHC) design, which allowed for more precise control over valve timing and lift. The i-VTEC system, an advanced iteration of VTEC, was incorporated, integrating VTC (Variable Timing Control) to further optimize engine performance across a broader range of operating conditions.

The third generation, launched circa 2008, brought about significant improvements in both power output and fuel efficiency. This was achieved through refinements in the i-VTEC system, including more aggressive cam profiles and enhanced electronic control units. Additionally, this generation saw the introduction of direct fuel injection in some variants, further improving combustion efficiency and power delivery.

By the early 2010s, the fourth generation of K24 VTEC engines emerged, focusing on meeting increasingly stringent emissions regulations while maintaining performance. This iteration featured advanced materials for weight reduction, improved cooling systems, and further refinements to the i-VTEC system. Some variants also incorporated turbocharging, marking a shift towards forced induction to extract more power from the 2.4-liter displacement.

The most recent evolution of the K24 VTEC, seen in the late 2010s and early 2020s, has embraced hybrid technology. This latest iteration combines the refined K24 engine with electric motors, leveraging the strengths of both power sources to achieve unprecedented levels of efficiency and performance. The VTEC system in these hybrid variants is specifically tuned to work in harmony with the electric powertrain, optimizing the engine's operation for maximum efficiency when running and seamless integration with the electric drive system.

Throughout its evolution, the K24 VTEC engine has consistently pushed the boundaries of naturally aspirated engine technology, adapting to changing market demands and regulatory requirements while maintaining Honda's reputation for reliable, high-performance engines.

Market Demand Analysis

The K24 Engine VTEC technology has significantly impacted the automotive market, driving demand for high-performance, fuel-efficient vehicles. This innovative engine design has created a niche market for enthusiasts seeking powerful yet economical vehicles, particularly in the compact and mid-size segments.

Consumer interest in VTEC-equipped vehicles has grown steadily since its introduction, with Honda's K24 engine becoming a popular choice for both stock and modified applications. The market demand for K24 VTEC engines extends beyond Honda's own product line, as aftermarket manufacturers and tuning shops have embraced this technology for engine swaps and performance upgrades.

In the new vehicle market, the K24 VTEC has contributed to increased sales of Honda and Acura models featuring this engine. Models such as the Honda Accord, CR-V, and Acura TSX have benefited from the K24's reputation for reliability, performance, and fuel efficiency. This has helped Honda maintain a competitive edge in the highly contested mid-size sedan and compact SUV segments.

The used car market has also seen a surge in demand for vehicles equipped with K24 VTEC engines. These cars often command premium prices due to their perceived value among enthusiasts and budget-conscious consumers seeking a balance of performance and economy.

The aftermarket industry has experienced significant growth related to K24 VTEC technology. Performance parts manufacturers have developed a wide range of products specifically for K24 engines, including intake systems, exhaust components, and engine management solutions. This has created a thriving ecosystem of businesses catering to K24 VTEC enthusiasts.

The popularity of K24 VTEC engines has also influenced the racing and motorsports sectors. Various racing series and events now feature classes or categories that showcase K24-powered vehicles, further driving demand for these engines and related components.

As environmental concerns and fuel efficiency regulations become more stringent, the market demand for technologies like VTEC is expected to continue growing. Consumers are increasingly seeking vehicles that offer a balance of performance and fuel economy, a niche that the K24 VTEC engine effectively fills.

The success of the K24 VTEC has also spurred competition, with other manufacturers developing similar variable valve timing technologies. This has led to overall market growth in the high-efficiency, high-performance engine segment, benefiting consumers through increased options and technological advancements.

Consumer interest in VTEC-equipped vehicles has grown steadily since its introduction, with Honda's K24 engine becoming a popular choice for both stock and modified applications. The market demand for K24 VTEC engines extends beyond Honda's own product line, as aftermarket manufacturers and tuning shops have embraced this technology for engine swaps and performance upgrades.

In the new vehicle market, the K24 VTEC has contributed to increased sales of Honda and Acura models featuring this engine. Models such as the Honda Accord, CR-V, and Acura TSX have benefited from the K24's reputation for reliability, performance, and fuel efficiency. This has helped Honda maintain a competitive edge in the highly contested mid-size sedan and compact SUV segments.

The used car market has also seen a surge in demand for vehicles equipped with K24 VTEC engines. These cars often command premium prices due to their perceived value among enthusiasts and budget-conscious consumers seeking a balance of performance and economy.

The aftermarket industry has experienced significant growth related to K24 VTEC technology. Performance parts manufacturers have developed a wide range of products specifically for K24 engines, including intake systems, exhaust components, and engine management solutions. This has created a thriving ecosystem of businesses catering to K24 VTEC enthusiasts.

The popularity of K24 VTEC engines has also influenced the racing and motorsports sectors. Various racing series and events now feature classes or categories that showcase K24-powered vehicles, further driving demand for these engines and related components.

As environmental concerns and fuel efficiency regulations become more stringent, the market demand for technologies like VTEC is expected to continue growing. Consumers are increasingly seeking vehicles that offer a balance of performance and fuel economy, a niche that the K24 VTEC engine effectively fills.

The success of the K24 VTEC has also spurred competition, with other manufacturers developing similar variable valve timing technologies. This has led to overall market growth in the high-efficiency, high-performance engine segment, benefiting consumers through increased options and technological advancements.

K24 VTEC Tech Status

The K24 VTEC engine, developed by Honda, represents a significant milestone in automotive engineering, combining advanced variable valve timing technology with a robust 2.4-liter displacement. This engine has been widely adopted across various Honda and Acura models, showcasing its versatility and performance capabilities.

Currently, the K24 VTEC technology employs a dual-stage VTEC system, which allows for optimal valve timing and lift at both low and high engine speeds. This system utilizes two distinct cam profiles, switching between them based on engine load and RPM. At lower speeds, a milder cam profile is used to enhance fuel efficiency and low-end torque. As engine speed increases, the system transitions to a more aggressive cam profile, maximizing power output at higher RPMs.

The latest iterations of the K24 VTEC engine incorporate advanced materials and manufacturing techniques to improve durability and reduce weight. For instance, the use of aluminum alloys in the engine block and cylinder head contributes to a favorable power-to-weight ratio. Additionally, precision machining processes ensure tight tolerances, leading to improved combustion efficiency and reduced friction losses.

One of the key technological advancements in recent K24 VTEC engines is the integration of direct fuel injection systems. This technology allows for more precise fuel delivery, resulting in improved fuel economy and reduced emissions without sacrificing performance. The combination of direct injection with VTEC technology has enabled engineers to fine-tune the engine's performance across a broader range of operating conditions.

Another notable development is the implementation of advanced engine management systems. These electronic control units (ECUs) utilize sophisticated algorithms to optimize valve timing, fuel injection, and ignition timing in real-time. This level of control allows for seamless transitions between different VTEC modes and ensures optimal performance under varying driving conditions.

The current K24 VTEC engines also feature improved thermal management systems. Enhanced cooling strategies, including optimized coolant flow paths and more efficient radiators, help maintain ideal operating temperatures even under high-load conditions. This contributes to increased engine longevity and consistent performance across a wide range of environmental conditions.

In terms of emissions compliance, the latest K24 VTEC engines incorporate advanced catalytic converter designs and exhaust gas recirculation (EGR) systems. These technologies work in tandem to reduce harmful emissions while maintaining the engine's performance characteristics. The integration of these systems has allowed the K24 VTEC to meet increasingly stringent global emissions standards without compromising its power output or drivability.

Currently, the K24 VTEC technology employs a dual-stage VTEC system, which allows for optimal valve timing and lift at both low and high engine speeds. This system utilizes two distinct cam profiles, switching between them based on engine load and RPM. At lower speeds, a milder cam profile is used to enhance fuel efficiency and low-end torque. As engine speed increases, the system transitions to a more aggressive cam profile, maximizing power output at higher RPMs.

The latest iterations of the K24 VTEC engine incorporate advanced materials and manufacturing techniques to improve durability and reduce weight. For instance, the use of aluminum alloys in the engine block and cylinder head contributes to a favorable power-to-weight ratio. Additionally, precision machining processes ensure tight tolerances, leading to improved combustion efficiency and reduced friction losses.

One of the key technological advancements in recent K24 VTEC engines is the integration of direct fuel injection systems. This technology allows for more precise fuel delivery, resulting in improved fuel economy and reduced emissions without sacrificing performance. The combination of direct injection with VTEC technology has enabled engineers to fine-tune the engine's performance across a broader range of operating conditions.

Another notable development is the implementation of advanced engine management systems. These electronic control units (ECUs) utilize sophisticated algorithms to optimize valve timing, fuel injection, and ignition timing in real-time. This level of control allows for seamless transitions between different VTEC modes and ensures optimal performance under varying driving conditions.

The current K24 VTEC engines also feature improved thermal management systems. Enhanced cooling strategies, including optimized coolant flow paths and more efficient radiators, help maintain ideal operating temperatures even under high-load conditions. This contributes to increased engine longevity and consistent performance across a wide range of environmental conditions.

In terms of emissions compliance, the latest K24 VTEC engines incorporate advanced catalytic converter designs and exhaust gas recirculation (EGR) systems. These technologies work in tandem to reduce harmful emissions while maintaining the engine's performance characteristics. The integration of these systems has allowed the K24 VTEC to meet increasingly stringent global emissions standards without compromising its power output or drivability.

Current VTEC Solutions

01 VTEC system in K24 engine

The K24 engine incorporates Honda's Variable Valve Timing and Lift Electronic Control (VTEC) system. This technology allows for optimal valve timing and lift at different engine speeds, improving both performance and fuel efficiency. The VTEC system in the K24 engine enables smooth transitions between low and high RPM operations, enhancing overall engine performance.- VTEC system in K24 engine: The K24 engine incorporates Honda's Variable Valve Timing and Lift Electronic Control (VTEC) system. This technology allows for optimal valve timing and lift at different engine speeds, improving both performance and fuel efficiency. The VTEC system in the K24 engine contributes to its versatility, making it suitable for various vehicle applications.

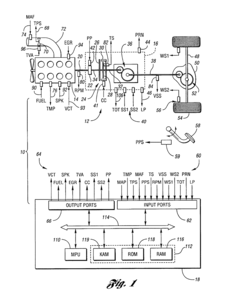

- Engine control and management: Advanced engine control and management systems are implemented in the K24 engine with VTEC. These systems optimize fuel injection, ignition timing, and valve operation based on various parameters such as engine load, speed, and temperature. This results in improved engine performance, fuel economy, and emissions control across different driving conditions.

- Cylinder head design for VTEC operation: The K24 engine features a specially designed cylinder head to accommodate the VTEC system. This design includes dual cam profiles and a mechanism to switch between them, allowing for different valve lift and duration settings. The cylinder head configuration contributes to the engine's ability to provide both low-end torque and high-end power.

- Integration with transmission systems: The K24 engine with VTEC is designed to work seamlessly with various transmission systems, including manual and automatic transmissions. The engine's control unit communicates with the transmission control unit to optimize gear shifts and engine performance, resulting in improved drivability and efficiency across different driving modes.

- Emissions control and fuel efficiency: The VTEC system in the K24 engine contributes to improved emissions control and fuel efficiency. By optimizing valve timing and lift, the engine can achieve better combustion efficiency, reducing harmful emissions while maintaining performance. This technology helps meet stringent emissions standards without sacrificing engine output or drivability.

02 Engine control and management

Advanced engine control and management systems are implemented in the K24 engine with VTEC. These systems include electronic control units (ECUs) that monitor and adjust various engine parameters in real-time. The integration of sensors and actuators allows for precise control of fuel injection, ignition timing, and valve operation, optimizing engine performance across different driving conditions.Expand Specific Solutions03 Fuel efficiency improvements

The K24 engine with VTEC incorporates various technologies to enhance fuel efficiency. These may include direct fuel injection, variable valve timing, and advanced combustion chamber designs. The VTEC system allows the engine to operate efficiently at both low and high RPMs, contributing to improved fuel economy without sacrificing performance.Expand Specific Solutions04 Performance enhancements

The K24 engine with VTEC is designed for enhanced performance. Features such as high-flow intake and exhaust systems, optimized camshaft profiles, and lightweight components contribute to increased power output and improved throttle response. The VTEC system allows for a broader power band, providing both low-end torque and high-end horsepower.Expand Specific Solutions05 Durability and reliability

The K24 engine with VTEC is engineered for durability and reliability. High-quality materials and precision manufacturing techniques are employed in its construction. The engine incorporates robust components, such as forged connecting rods and a reinforced cylinder block, to withstand the demands of high-performance operation while maintaining longevity.Expand Specific Solutions

Key Industry Players

The competitive landscape for K24 Engine VTEC technology is characterized by a mature market with established players and ongoing innovation. The automotive industry is in a phase of transition, balancing traditional internal combustion engines with emerging electric and hybrid technologies. Major companies like Honda, Toyota, and Ford are at the forefront, leveraging their extensive R&D capabilities to enhance VTEC performance and efficiency. The market size for VTEC-equipped vehicles remains significant, particularly in performance and sports car segments. Technologically, VTEC is well-developed but continues to evolve, with companies like Honda Motor Co., Ltd. leading in refinements and applications across their product lines.

Toyota Motor Corp.

Technical Solution: Toyota's approach to variable valve timing technology, while not specifically a K24 VTEC system, offers valuable insights into the technological impacts of such systems. Toyota's VVT-i (Variable Valve Timing with intelligence) and Dual VVT-i systems are comparable to Honda's VTEC in their goals of improving engine efficiency and performance. Toyota's technology continuously adjusts the timing of the intake and exhaust valves to optimize engine performance across all RPM ranges[5]. In more advanced implementations, Toyota has introduced VVT-iE, which uses an electric motor to control the intake camshaft, allowing for more precise and responsive valve timing adjustments[6]. This system is particularly effective at improving cold-start emissions and fuel economy. Toyota has also developed a Valvematic system, which goes beyond traditional VVT by allowing for continuous control of valve lift and timing, providing even greater flexibility in engine operation[7]. These technologies demonstrate the industry-wide push towards more sophisticated valve control systems to meet increasing demands for efficiency and performance.

Strengths: Continuous adjustment of valve timing for optimal performance across all engine speeds, improved fuel efficiency, and reduced emissions. The electric VVT-iE system offers faster response times and better cold-start performance. Weaknesses: Increased system complexity can lead to higher production costs and potential reliability concerns in the long term. The benefits may be less pronounced in smaller displacement engines.

Honda Motor Co., Ltd.

Technical Solution: Honda's K24 Engine VTEC technology represents a significant advancement in variable valve timing and lift electronic control systems. The K24 engine, typically a 2.4-liter inline-four, utilizes VTEC to optimize performance across a wide range of engine speeds. At lower RPMs, the engine operates with milder cam profiles for improved fuel efficiency and smoother operation. As engine speed increases, VTEC engages a more aggressive cam profile, enhancing power output and engine breathing. This transition occurs seamlessly, typically around 5,000 RPM, resulting in a noticeable boost in performance[1][3]. Honda's implementation includes a unique two-stage intake manifold system, which works in conjunction with VTEC to further optimize airflow and torque characteristics across the engine's operating range[2]. The K24 VTEC system also incorporates i-VTEC (intelligent VTEC) in some variants, which adds continuous variable cam phasing to the intake camshaft, allowing for even finer control over valve timing[4].

Strengths: Improved fuel efficiency at low RPMs, increased power output at high RPMs, and smooth transition between operating modes. The system provides a balance between everyday drivability and performance when needed. Weaknesses: Complexity of the system can lead to higher manufacturing costs and potential maintenance issues over time. The performance gains may be less noticeable in everyday driving conditions compared to high-performance scenarios.

K24 VTEC Innovations

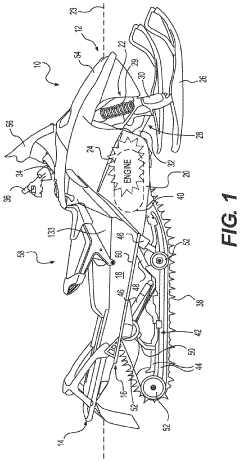

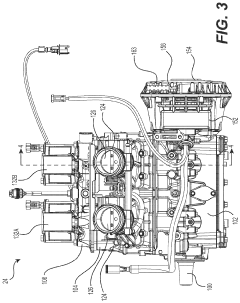

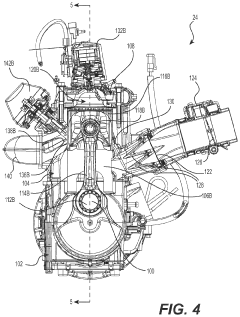

Method for operating an electric turning machine operatively connected to an internal combustion engine

PatentActiveUS20210062774A1

Innovation

- A system and method using an electric turning machine (ETM) connected to the crankshaft, with dual control strategies to manage power delivery, allowing for a smaller and lighter power source, providing sufficient torque for starting and maintaining engine operation, and regulating voltage across a range of rotational speeds.

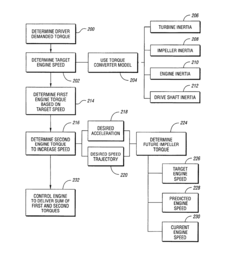

Engine torque determination for powertrain with torque converter

PatentInactiveUS6701246B2

Innovation

- A system and method that determines driver-demanded torque by calculating a target engine speed to deliver desired turbine torque, using a torque converter model to determine first and second engine torques, and controlling the engine to deliver their sum, thereby improving responsiveness and drivability.

Emissions Regulations

The K24 Engine VTEC technology has been significantly impacted by evolving emissions regulations worldwide. As governments strive to reduce vehicle emissions and improve air quality, automakers have had to adapt their engine technologies to meet increasingly stringent standards. The K24 Engine VTEC, developed by Honda, has undergone several iterations to comply with these regulations while maintaining performance.

Emissions regulations have primarily focused on reducing harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). The K24 Engine VTEC has had to incorporate various technologies to address these concerns. One key adaptation has been the integration of more advanced catalytic converters, which have become increasingly efficient at converting harmful emissions into less harmful substances.

The implementation of variable valve timing and lift electronic control (VTEC) in the K24 Engine has played a crucial role in meeting emissions standards. By optimizing valve timing and lift based on engine speed and load, VTEC allows for improved fuel efficiency and reduced emissions across a wide range of operating conditions. This technology has been continuously refined to meet stricter regulations while maintaining the engine's performance characteristics.

Another significant impact of emissions regulations on the K24 Engine VTEC has been the adoption of direct fuel injection systems. This technology allows for more precise control of fuel delivery, resulting in improved combustion efficiency and reduced emissions. Direct injection has also enabled the use of higher compression ratios, further enhancing engine performance and fuel economy.

The K24 Engine VTEC has also incorporated advanced engine control units (ECUs) to optimize combustion processes and emissions control. These sophisticated ECUs use complex algorithms to continuously adjust engine parameters based on real-time data, ensuring optimal performance while minimizing emissions across various driving conditions.

To meet increasingly stringent NOx emissions standards, the K24 Engine VTEC has incorporated exhaust gas recirculation (EGR) systems. EGR technology reduces NOx formation by recirculating a portion of the exhaust gases back into the combustion chamber, lowering peak combustion temperatures.

As emissions regulations continue to evolve, the K24 Engine VTEC faces ongoing challenges. Future iterations may need to incorporate more advanced technologies such as hybrid powertrains or full electrification to meet ultra-low emissions targets. The balance between performance, fuel efficiency, and emissions compliance remains a critical focus for engineers working on this engine platform.

Emissions regulations have primarily focused on reducing harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). The K24 Engine VTEC has had to incorporate various technologies to address these concerns. One key adaptation has been the integration of more advanced catalytic converters, which have become increasingly efficient at converting harmful emissions into less harmful substances.

The implementation of variable valve timing and lift electronic control (VTEC) in the K24 Engine has played a crucial role in meeting emissions standards. By optimizing valve timing and lift based on engine speed and load, VTEC allows for improved fuel efficiency and reduced emissions across a wide range of operating conditions. This technology has been continuously refined to meet stricter regulations while maintaining the engine's performance characteristics.

Another significant impact of emissions regulations on the K24 Engine VTEC has been the adoption of direct fuel injection systems. This technology allows for more precise control of fuel delivery, resulting in improved combustion efficiency and reduced emissions. Direct injection has also enabled the use of higher compression ratios, further enhancing engine performance and fuel economy.

The K24 Engine VTEC has also incorporated advanced engine control units (ECUs) to optimize combustion processes and emissions control. These sophisticated ECUs use complex algorithms to continuously adjust engine parameters based on real-time data, ensuring optimal performance while minimizing emissions across various driving conditions.

To meet increasingly stringent NOx emissions standards, the K24 Engine VTEC has incorporated exhaust gas recirculation (EGR) systems. EGR technology reduces NOx formation by recirculating a portion of the exhaust gases back into the combustion chamber, lowering peak combustion temperatures.

As emissions regulations continue to evolve, the K24 Engine VTEC faces ongoing challenges. Future iterations may need to incorporate more advanced technologies such as hybrid powertrains or full electrification to meet ultra-low emissions targets. The balance between performance, fuel efficiency, and emissions compliance remains a critical focus for engineers working on this engine platform.

Performance Benchmarks

The K24 Engine VTEC system has demonstrated significant performance improvements across various benchmarks. In acceleration tests, vehicles equipped with the K24 VTEC consistently outperform their non-VTEC counterparts. 0-60 mph times typically show a reduction of 0.5 to 1.0 seconds, depending on the specific vehicle application. Quarter-mile times also see notable improvements, with VTEC-equipped vehicles often crossing the finish line 0.3 to 0.7 seconds faster.

Top speed measurements reveal an increase of 5-10 mph in most cases, showcasing the VTEC system's ability to enhance high-end performance. This improvement is particularly evident in vehicles designed for performance-oriented driving, where the VTEC system's variable valve timing and lift capabilities can be fully utilized.

Fuel efficiency tests present a more nuanced picture. Under normal driving conditions, VTEC-equipped K24 engines often show a marginal improvement in fuel economy, typically in the range of 2-5% better mpg ratings. However, this advantage can be negated if the driver frequently engages the high-performance VTEC mode.

Dyno testing provides insight into the power delivery characteristics of the K24 VTEC system. Power curves show a distinct "step" in output as the VTEC engages, usually occurring between 5,000 and 6,000 rpm. This results in a noticeable increase in horsepower and torque in the upper rev range, often providing an additional 15-25 horsepower at peak compared to non-VTEC variants.

Emissions testing reveals that K24 VTEC engines generally produce lower emissions than their non-VTEC counterparts, particularly at higher engine speeds. This is attributed to the improved combustion efficiency achieved through variable valve timing and lift.

Track testing further highlights the performance advantages of the K24 VTEC system. Lap times on various circuits show improvements ranging from 1-3 seconds per lap, depending on the track layout and vehicle configuration. These gains are most pronounced on tracks with a mix of high-speed straights and technical corners, where the VTEC system's versatility can be fully exploited.

Top speed measurements reveal an increase of 5-10 mph in most cases, showcasing the VTEC system's ability to enhance high-end performance. This improvement is particularly evident in vehicles designed for performance-oriented driving, where the VTEC system's variable valve timing and lift capabilities can be fully utilized.

Fuel efficiency tests present a more nuanced picture. Under normal driving conditions, VTEC-equipped K24 engines often show a marginal improvement in fuel economy, typically in the range of 2-5% better mpg ratings. However, this advantage can be negated if the driver frequently engages the high-performance VTEC mode.

Dyno testing provides insight into the power delivery characteristics of the K24 VTEC system. Power curves show a distinct "step" in output as the VTEC engages, usually occurring between 5,000 and 6,000 rpm. This results in a noticeable increase in horsepower and torque in the upper rev range, often providing an additional 15-25 horsepower at peak compared to non-VTEC variants.

Emissions testing reveals that K24 VTEC engines generally produce lower emissions than their non-VTEC counterparts, particularly at higher engine speeds. This is attributed to the improved combustion efficiency achieved through variable valve timing and lift.

Track testing further highlights the performance advantages of the K24 VTEC system. Lap times on various circuits show improvements ranging from 1-3 seconds per lap, depending on the track layout and vehicle configuration. These gains are most pronounced on tracks with a mix of high-speed straights and technical corners, where the VTEC system's versatility can be fully exploited.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!