K24 Engine: Understanding Variable Valve Timing

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 VVT Background

The K24 engine, developed by Honda, has been a cornerstone of the company's powertrain lineup since its introduction in 2001. This inline-four cylinder engine is renowned for its reliability, efficiency, and performance, particularly in Honda's popular Accord and CR-V models. The K24's Variable Valve Timing (VVT) system, known as i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control), represents a significant advancement in engine technology.

Variable Valve Timing is a crucial component in modern engine design, allowing for optimized performance across a wide range of operating conditions. In the K24 engine, the VVT system adjusts the timing of the intake and exhaust valves to improve fuel efficiency, increase power output, and reduce emissions. This technology enables the engine to adapt to different driving scenarios, from low-speed city driving to high-speed highway cruising.

The evolution of VVT in Honda engines can be traced back to the late 1980s with the introduction of VTEC (Variable Valve Timing and Lift Electronic Control). The K24's i-VTEC system, introduced in the early 2000s, builds upon this foundation by incorporating continuous variable cam phasing on the intake side. This advancement allows for more precise control over valve timing throughout the engine's operating range.

One of the key features of the K24's VVT system is its ability to seamlessly transition between different cam profiles. At lower engine speeds, the system prioritizes fuel efficiency and smooth operation. As the engine speed increases, the VVT system shifts to a high-performance cam profile, providing increased power and torque. This dual-mode operation contributes significantly to the K24's versatility and broad appeal across various vehicle applications.

The implementation of VVT in the K24 engine has also played a crucial role in meeting increasingly stringent emissions standards. By optimizing valve timing, the system can reduce pumping losses, improve combustion efficiency, and minimize the production of harmful exhaust gases. This has allowed Honda to maintain compliance with evolving environmental regulations while still delivering the performance characteristics expected by consumers.

Over the years, Honda has continued to refine the VVT system in the K24 engine. Advancements in electronic control units, sensor technology, and manufacturing processes have led to improvements in response time, precision, and overall system efficiency. These ongoing developments have ensured that the K24 engine remains competitive in an ever-evolving automotive landscape.

Variable Valve Timing is a crucial component in modern engine design, allowing for optimized performance across a wide range of operating conditions. In the K24 engine, the VVT system adjusts the timing of the intake and exhaust valves to improve fuel efficiency, increase power output, and reduce emissions. This technology enables the engine to adapt to different driving scenarios, from low-speed city driving to high-speed highway cruising.

The evolution of VVT in Honda engines can be traced back to the late 1980s with the introduction of VTEC (Variable Valve Timing and Lift Electronic Control). The K24's i-VTEC system, introduced in the early 2000s, builds upon this foundation by incorporating continuous variable cam phasing on the intake side. This advancement allows for more precise control over valve timing throughout the engine's operating range.

One of the key features of the K24's VVT system is its ability to seamlessly transition between different cam profiles. At lower engine speeds, the system prioritizes fuel efficiency and smooth operation. As the engine speed increases, the VVT system shifts to a high-performance cam profile, providing increased power and torque. This dual-mode operation contributes significantly to the K24's versatility and broad appeal across various vehicle applications.

The implementation of VVT in the K24 engine has also played a crucial role in meeting increasingly stringent emissions standards. By optimizing valve timing, the system can reduce pumping losses, improve combustion efficiency, and minimize the production of harmful exhaust gases. This has allowed Honda to maintain compliance with evolving environmental regulations while still delivering the performance characteristics expected by consumers.

Over the years, Honda has continued to refine the VVT system in the K24 engine. Advancements in electronic control units, sensor technology, and manufacturing processes have led to improvements in response time, precision, and overall system efficiency. These ongoing developments have ensured that the K24 engine remains competitive in an ever-evolving automotive landscape.

Market Demand Analysis

The market demand for variable valve timing (VVT) technology in K24 engines has been steadily increasing due to its significant impact on engine performance, fuel efficiency, and emissions reduction. As automotive manufacturers face stricter environmental regulations and consumer demands for more fuel-efficient vehicles, VVT systems have become a crucial component in modern engine design.

The K24 engine, primarily used in Honda vehicles, has seen widespread adoption across various models, including the popular Accord, CR-V, and Civic Si. This widespread use has created a substantial market for VVT technology specifically tailored to the K24 engine platform. The aftermarket sector has also shown considerable interest in VVT systems for K24 engines, as performance enthusiasts seek to optimize their vehicles for improved power output and efficiency.

In recent years, the global automotive VVT system market has experienced significant growth. This growth is largely attributed to the increasing demand for fuel-efficient vehicles and the stringent emission norms imposed by various governments worldwide. The VVT system market is expected to continue its upward trajectory, with a particular focus on emerging markets in Asia-Pacific and Latin America.

The demand for VVT technology in K24 engines is not limited to new vehicle production. There is also a growing market for retrofitting older K24 engines with advanced VVT systems, especially in regions where vehicle longevity is prioritized. This trend is driven by consumers looking to improve the performance and efficiency of their existing vehicles without the need for a complete engine replacement.

Furthermore, the integration of VVT technology with other advanced engine management systems, such as direct injection and turbocharging, has opened up new market opportunities. These combined technologies offer even greater improvements in engine performance and efficiency, meeting the evolving needs of both manufacturers and consumers.

The automotive industry's shift towards electrification has not diminished the importance of VVT technology. In fact, it has created a new market segment for hybrid powertrains that utilize both internal combustion engines and electric motors. In these applications, VVT systems play a crucial role in optimizing the performance of the combustion engine, working in tandem with electric propulsion systems to maximize overall vehicle efficiency.

As the automotive industry continues to evolve, the market demand for VVT technology in K24 engines is expected to remain strong. This demand is driven by the ongoing need for improved engine performance, increased fuel efficiency, and reduced emissions across various vehicle segments. The technology's adaptability to different engine configurations and its potential for further optimization ensure its relevance in the automotive market for the foreseeable future.

The K24 engine, primarily used in Honda vehicles, has seen widespread adoption across various models, including the popular Accord, CR-V, and Civic Si. This widespread use has created a substantial market for VVT technology specifically tailored to the K24 engine platform. The aftermarket sector has also shown considerable interest in VVT systems for K24 engines, as performance enthusiasts seek to optimize their vehicles for improved power output and efficiency.

In recent years, the global automotive VVT system market has experienced significant growth. This growth is largely attributed to the increasing demand for fuel-efficient vehicles and the stringent emission norms imposed by various governments worldwide. The VVT system market is expected to continue its upward trajectory, with a particular focus on emerging markets in Asia-Pacific and Latin America.

The demand for VVT technology in K24 engines is not limited to new vehicle production. There is also a growing market for retrofitting older K24 engines with advanced VVT systems, especially in regions where vehicle longevity is prioritized. This trend is driven by consumers looking to improve the performance and efficiency of their existing vehicles without the need for a complete engine replacement.

Furthermore, the integration of VVT technology with other advanced engine management systems, such as direct injection and turbocharging, has opened up new market opportunities. These combined technologies offer even greater improvements in engine performance and efficiency, meeting the evolving needs of both manufacturers and consumers.

The automotive industry's shift towards electrification has not diminished the importance of VVT technology. In fact, it has created a new market segment for hybrid powertrains that utilize both internal combustion engines and electric motors. In these applications, VVT systems play a crucial role in optimizing the performance of the combustion engine, working in tandem with electric propulsion systems to maximize overall vehicle efficiency.

As the automotive industry continues to evolve, the market demand for VVT technology in K24 engines is expected to remain strong. This demand is driven by the ongoing need for improved engine performance, increased fuel efficiency, and reduced emissions across various vehicle segments. The technology's adaptability to different engine configurations and its potential for further optimization ensure its relevance in the automotive market for the foreseeable future.

VVT Tech Challenges

Variable Valve Timing (VVT) technology in the K24 engine faces several significant challenges that engineers and researchers continue to address. One of the primary obstacles is achieving optimal valve timing across a wide range of engine speeds and load conditions. The K24 engine, known for its versatility, requires a VVT system that can adapt quickly and efficiently to varying driving scenarios, from low-speed city driving to high-speed highway cruising.

Another challenge lies in the mechanical complexity of VVT systems. The K24 engine's VVT mechanism must be robust enough to withstand the high temperatures and pressures within the engine while maintaining precision in valve actuation. This demands advanced materials and manufacturing techniques to ensure longevity and reliability, which can significantly impact production costs.

The control system for VVT in the K24 engine presents its own set of challenges. Developing algorithms that can accurately predict and adjust valve timing based on real-time engine parameters requires sophisticated software and sensor integration. The system must respond instantaneously to driver inputs and changing environmental conditions, all while maintaining smooth engine operation and minimizing emissions.

Fuel efficiency and emissions reduction are critical factors driving VVT development in the K24 engine. Engineers must balance the desire for improved performance with increasingly stringent environmental regulations. This often involves complex trade-offs between power output, fuel consumption, and emissions control, necessitating advanced modeling and testing procedures.

Durability and maintenance considerations also pose significant challenges. The VVT system in the K24 engine must be designed to operate reliably over the vehicle's lifetime with minimal maintenance requirements. This includes addressing issues such as oil contamination, which can affect the hydraulic components of some VVT systems, potentially leading to reduced performance or system failure over time.

Lastly, the integration of VVT technology with other engine management systems presents ongoing challenges. The K24 engine's VVT must work seamlessly with fuel injection, ignition timing, and exhaust gas recirculation systems to achieve optimal overall engine performance. This requires a holistic approach to engine design and calibration, often necessitating extensive testing and refinement.

Another challenge lies in the mechanical complexity of VVT systems. The K24 engine's VVT mechanism must be robust enough to withstand the high temperatures and pressures within the engine while maintaining precision in valve actuation. This demands advanced materials and manufacturing techniques to ensure longevity and reliability, which can significantly impact production costs.

The control system for VVT in the K24 engine presents its own set of challenges. Developing algorithms that can accurately predict and adjust valve timing based on real-time engine parameters requires sophisticated software and sensor integration. The system must respond instantaneously to driver inputs and changing environmental conditions, all while maintaining smooth engine operation and minimizing emissions.

Fuel efficiency and emissions reduction are critical factors driving VVT development in the K24 engine. Engineers must balance the desire for improved performance with increasingly stringent environmental regulations. This often involves complex trade-offs between power output, fuel consumption, and emissions control, necessitating advanced modeling and testing procedures.

Durability and maintenance considerations also pose significant challenges. The VVT system in the K24 engine must be designed to operate reliably over the vehicle's lifetime with minimal maintenance requirements. This includes addressing issues such as oil contamination, which can affect the hydraulic components of some VVT systems, potentially leading to reduced performance or system failure over time.

Lastly, the integration of VVT technology with other engine management systems presents ongoing challenges. The K24 engine's VVT must work seamlessly with fuel injection, ignition timing, and exhaust gas recirculation systems to achieve optimal overall engine performance. This requires a holistic approach to engine design and calibration, often necessitating extensive testing and refinement.

Current VVT Solutions

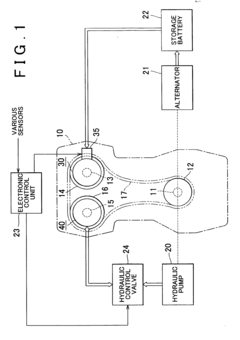

01 Variable valve timing system for K24 engine

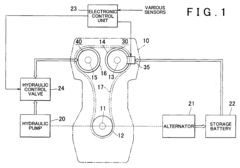

The K24 engine employs a variable valve timing system to optimize engine performance across different operating conditions. This system allows for adjustable timing of valve opening and closing, improving fuel efficiency, power output, and emissions control.- Variable valve timing system for K24 engine: The K24 engine employs a variable valve timing system to optimize engine performance across different operating conditions. This system allows for adjustable timing of valve opening and closing, improving fuel efficiency, power output, and emissions control.

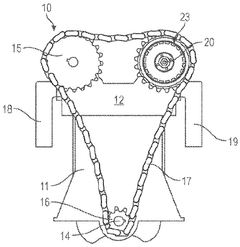

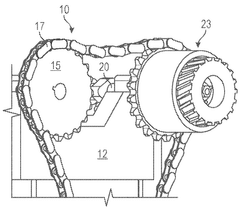

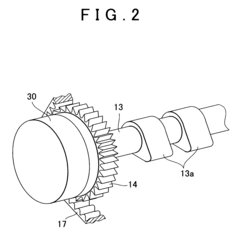

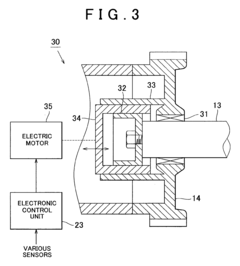

- Cam phasing mechanism: A cam phasing mechanism is utilized in the K24 engine's variable valve timing system. This mechanism allows for the rotation of the camshaft relative to the crankshaft, enabling precise control over valve timing. The phaser can be hydraulically or electrically actuated to achieve the desired timing adjustments.

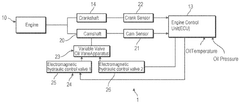

- Electronic control unit for VVT: An electronic control unit (ECU) manages the variable valve timing system in the K24 engine. The ECU processes various sensor inputs to determine optimal valve timing and sends commands to the actuators. This ensures that the engine operates efficiently across different load and speed conditions.

- Oil pressure control for VVT actuation: The K24 engine's variable valve timing system often utilizes oil pressure for actuation. A dedicated oil control valve regulates the oil flow to the cam phaser, allowing for precise adjustment of the camshaft timing. This hydraulic system provides quick response and reliable operation of the VVT mechanism.

- Integration with i-VTEC system: The variable valve timing in the K24 engine is often integrated with Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system. This combination allows for both variable valve timing and variable valve lift, providing enhanced engine performance and efficiency across a wider range of operating conditions.

02 Cam phasing mechanism

A cam phasing mechanism is utilized in the K24 engine's variable valve timing system. This mechanism allows for the rotation of the camshaft relative to its drive, enabling precise control over valve timing. The phaser can be hydraulically or electrically actuated to achieve the desired timing adjustments.Expand Specific Solutions03 Electronic control unit for VVT

An electronic control unit (ECU) manages the variable valve timing system in the K24 engine. The ECU processes various sensor inputs to determine optimal valve timing and sends commands to the actuators. This ensures that the engine operates efficiently across different load and speed conditions.Expand Specific Solutions04 Oil control valve for VVT actuation

The variable valve timing system in the K24 engine often uses an oil control valve to regulate hydraulic pressure. This valve directs oil flow to the cam phaser, allowing for precise control of the camshaft's angular position relative to the crankshaft. The oil control valve is typically electronically controlled for rapid response.Expand Specific Solutions05 VVT system integration with engine management

The variable valve timing system of the K24 engine is integrated with the overall engine management system. This integration allows for coordinated control of valve timing with other engine parameters such as fuel injection and ignition timing. The result is optimized engine performance, improved fuel economy, and reduced emissions across various operating conditions.Expand Specific Solutions

Key Engine Manufacturers

The variable valve timing (VVT) technology in K24 engines represents a mature and competitive field within the automotive industry. The market is characterized by established players like Toyota, Honda, and Nissan, who have been refining VVT systems for decades. With global automotive market growth, the demand for efficient engine technologies continues to expand. Companies such as DENSO, Hitachi Automotive Systems, and Schaeffler Technologies are key suppliers, providing innovative VVT solutions to major automakers. The technology's maturity is evident in its widespread adoption, with ongoing research focused on further optimizing performance and fuel efficiency in modern engines.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced Variable Valve Timing with intelligence (VVT-i) system for their K24 engine. This system uses hydraulic pressure to continuously adjust the intake and exhaust camshaft timing, optimizing engine performance across various operating conditions. Toyota's VVT-i can advance or retard valve timing by up to 60 degrees[1], allowing for improved fuel efficiency, reduced emissions, and enhanced power output. The system utilizes oil pressure controlled by the Engine Control Unit (ECU) to rotate the camshaft relative to its drive gear, effectively changing the valve timing[2]. Toyota has also implemented Dual VVT-i in some K24 variants, which independently controls both intake and exhaust valve timing for even greater optimization[3].

Strengths: Improved fuel efficiency, reduced emissions, and enhanced power output across a wide range of engine speeds. Weaknesses: Increased system complexity and potential for oil-related issues if not properly maintained.

DENSO Corp.

Technical Solution: DENSO has developed a Variable Valve Timing (VVT) system that utilizes an electric motor-driven actuator instead of the traditional hydraulic system. This innovative approach, known as Electric Variable Valve Timing (e-VVT), offers faster response times and more precise control over valve timing. The e-VVT system can adjust valve timing within 0.3 seconds, compared to 0.5-1 second for hydraulic systems[4]. DENSO's e-VVT also operates independently of oil pressure, allowing for optimal valve timing even during cold starts or low engine speeds. The system incorporates a high-precision angle sensor and a compact, high-output motor to achieve accurate control and space efficiency[5]. DENSO's e-VVT can be applied to both intake and exhaust camshafts, enabling Dual VVT configurations for maximum engine performance and efficiency.

Strengths: Faster response time, precise control, and operation independent of oil pressure. Weaknesses: Potentially higher cost due to electric components and increased electrical system complexity.

K24 VVT Innovations

System and method for variable valve timing

PatentWO2025053875A1

Innovation

- A variable valve timing assembly that includes a phaser with an advancing and retarding chamber, where the volume of these chambers can be inversely varied to control the linear position of the phaser, which in turn adjusts the rotational position of the camshaft.

Valve characteristic changing apparatus for internal combustion engine

PatentInactiveEP1571301A2

Innovation

- The apparatus employs separate power source groups for each mechanism group, allowing for independent power supply to intake and exhaust valve timing mechanisms, using power sources such as electric motors and hydraulic pumps that are optimized for specific engine speed regions to ensure adequate power and response speed, thereby stabilizing engine combustion and improving exhaust efficiency.

Emissions Regulations

Emissions regulations have played a significant role in shaping the development and implementation of variable valve timing (VVT) technology in engines, including the K24 engine. These regulations, aimed at reducing harmful emissions and improving fuel efficiency, have become increasingly stringent over the years, pushing manufacturers to innovate and adopt advanced technologies like VVT.

The introduction of stricter emissions standards, such as the Euro 6 in Europe and Tier 3 in the United States, has necessitated more precise control over engine operations. VVT systems, by allowing for dynamic adjustment of valve timing, enable engines to optimize combustion processes across different operating conditions. This adaptability is crucial for meeting emissions targets while maintaining performance and fuel economy.

In the context of the K24 engine, VVT technology has been instrumental in achieving compliance with emissions regulations. By adjusting the timing of valve opening and closing, the engine can reduce overlap between intake and exhaust valve operations, leading to more efficient fuel burning and reduced emissions of nitrogen oxides (NOx) and hydrocarbons (HC).

The ability of VVT to optimize air-fuel mixture and exhaust gas recirculation (EGR) rates also contributes to lower carbon monoxide (CO) and particulate matter emissions. This is particularly important for meeting the increasingly strict particulate number (PN) limits imposed by recent emissions standards.

Furthermore, emissions regulations have driven the evolution of VVT systems themselves. Early implementations focused primarily on intake valve timing, but as regulations tightened, more sophisticated systems that control both intake and exhaust valve timing independently have become prevalent. This dual VVT approach allows for even greater control over the combustion process and emissions reduction.

The impact of emissions regulations on VVT technology extends beyond just meeting current standards. Manufacturers must also anticipate future regulatory changes, leading to ongoing research and development in this area. This forward-looking approach has resulted in continuous improvements in VVT systems, including the integration with other technologies such as direct injection and turbocharging.

As emissions regulations continue to evolve, particularly with the increasing focus on reducing greenhouse gas emissions, VVT technology is expected to play an even more critical role. Future developments may include more advanced control algorithms, integration with hybrid powertrains, and potentially the use of camless valve actuation systems for even greater flexibility in valve timing control.

The introduction of stricter emissions standards, such as the Euro 6 in Europe and Tier 3 in the United States, has necessitated more precise control over engine operations. VVT systems, by allowing for dynamic adjustment of valve timing, enable engines to optimize combustion processes across different operating conditions. This adaptability is crucial for meeting emissions targets while maintaining performance and fuel economy.

In the context of the K24 engine, VVT technology has been instrumental in achieving compliance with emissions regulations. By adjusting the timing of valve opening and closing, the engine can reduce overlap between intake and exhaust valve operations, leading to more efficient fuel burning and reduced emissions of nitrogen oxides (NOx) and hydrocarbons (HC).

The ability of VVT to optimize air-fuel mixture and exhaust gas recirculation (EGR) rates also contributes to lower carbon monoxide (CO) and particulate matter emissions. This is particularly important for meeting the increasingly strict particulate number (PN) limits imposed by recent emissions standards.

Furthermore, emissions regulations have driven the evolution of VVT systems themselves. Early implementations focused primarily on intake valve timing, but as regulations tightened, more sophisticated systems that control both intake and exhaust valve timing independently have become prevalent. This dual VVT approach allows for even greater control over the combustion process and emissions reduction.

The impact of emissions regulations on VVT technology extends beyond just meeting current standards. Manufacturers must also anticipate future regulatory changes, leading to ongoing research and development in this area. This forward-looking approach has resulted in continuous improvements in VVT systems, including the integration with other technologies such as direct injection and turbocharging.

As emissions regulations continue to evolve, particularly with the increasing focus on reducing greenhouse gas emissions, VVT technology is expected to play an even more critical role. Future developments may include more advanced control algorithms, integration with hybrid powertrains, and potentially the use of camless valve actuation systems for even greater flexibility in valve timing control.

Fuel Efficiency Impact

Variable Valve Timing (VVT) in the K24 engine has a significant impact on fuel efficiency, making it a crucial technology in modern automotive engineering. The implementation of VVT allows for optimized valve timing across different engine speeds and load conditions, resulting in improved fuel economy.

At lower engine speeds, VVT can adjust the valve timing to reduce overlap between the intake and exhaust valves. This reduction in overlap minimizes the amount of unburned fuel escaping through the exhaust, thereby increasing fuel efficiency. Conversely, at higher engine speeds, VVT can increase valve overlap to improve engine breathing and volumetric efficiency, which contributes to better fuel economy under high-load conditions.

The K24 engine's VVT system also enables a more efficient combustion process by optimizing the air-fuel mixture. By precisely controlling the opening and closing of valves, the engine can achieve a more complete burn of the fuel, extracting more energy from each combustion cycle. This improved combustion efficiency directly translates to reduced fuel consumption.

Furthermore, VVT allows for a wider range of engine operation in its most efficient zones. By adjusting valve timing, the engine can maintain optimal performance characteristics across a broader range of RPMs, reducing the need for frequent gear changes and allowing the engine to operate in its most fuel-efficient range for longer periods.

The fuel efficiency gains from VVT in the K24 engine are particularly noticeable during part-load conditions, which are common in everyday driving scenarios. Under these conditions, VVT can be used to implement strategies such as early intake valve closing, which reduces pumping losses and improves thermal efficiency.

In city driving, where stop-and-go traffic is common, VVT contributes to fuel savings by optimizing valve timing for smooth idling and low-speed operation. This results in reduced fuel consumption during periods of frequent acceleration and deceleration.

On highways, where steady-state operation is more common, VVT helps maintain optimal combustion efficiency at cruising speeds, leading to improved fuel economy over long distances. The system's ability to adapt to changing driving conditions ensures that the engine operates at peak efficiency regardless of the driving scenario.

Overall, the implementation of VVT in the K24 engine represents a significant advancement in fuel efficiency technology. By allowing for dynamic adjustment of valve timing, the system provides a balance between performance and economy, contributing to reduced fuel consumption and lower emissions across various driving conditions.

At lower engine speeds, VVT can adjust the valve timing to reduce overlap between the intake and exhaust valves. This reduction in overlap minimizes the amount of unburned fuel escaping through the exhaust, thereby increasing fuel efficiency. Conversely, at higher engine speeds, VVT can increase valve overlap to improve engine breathing and volumetric efficiency, which contributes to better fuel economy under high-load conditions.

The K24 engine's VVT system also enables a more efficient combustion process by optimizing the air-fuel mixture. By precisely controlling the opening and closing of valves, the engine can achieve a more complete burn of the fuel, extracting more energy from each combustion cycle. This improved combustion efficiency directly translates to reduced fuel consumption.

Furthermore, VVT allows for a wider range of engine operation in its most efficient zones. By adjusting valve timing, the engine can maintain optimal performance characteristics across a broader range of RPMs, reducing the need for frequent gear changes and allowing the engine to operate in its most fuel-efficient range for longer periods.

The fuel efficiency gains from VVT in the K24 engine are particularly noticeable during part-load conditions, which are common in everyday driving scenarios. Under these conditions, VVT can be used to implement strategies such as early intake valve closing, which reduces pumping losses and improves thermal efficiency.

In city driving, where stop-and-go traffic is common, VVT contributes to fuel savings by optimizing valve timing for smooth idling and low-speed operation. This results in reduced fuel consumption during periods of frequent acceleration and deceleration.

On highways, where steady-state operation is more common, VVT helps maintain optimal combustion efficiency at cruising speeds, leading to improved fuel economy over long distances. The system's ability to adapt to changing driving conditions ensures that the engine operates at peak efficiency regardless of the driving scenario.

Overall, the implementation of VVT in the K24 engine represents a significant advancement in fuel efficiency technology. By allowing for dynamic adjustment of valve timing, the system provides a balance between performance and economy, contributing to reduced fuel consumption and lower emissions across various driving conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!