Utilizing Renewable Energy Resources in K24 Engine Design

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has become a cornerstone of Honda's powertrain lineup, finding its way into various models across the Honda and Acura brands.

The original K24A1 engine debuted with 160 horsepower and 161 lb-ft of torque, featuring Honda's i-VTEC technology. This innovative system combined VTEC (Variable Valve Timing and Lift Electronic Control) with VTC (Variable Timing Control), allowing for optimized performance and efficiency across a wide range of engine speeds.

As environmental concerns grew, Honda continuously refined the K24 engine to meet stricter emissions standards while improving fuel efficiency. The introduction of the K24A2 variant in 2003 saw power output increase to 190 horsepower, achieved through enhancements in the i-VTEC system and improvements in intake and exhaust flow.

The K24's versatility became evident as it was adapted for use in a variety of vehicles, from sedans to SUVs. This adaptability led to the development of numerous variants, each tailored to specific vehicle requirements and market demands. The K24Z series, introduced in 2006, further improved upon the engine's design, with some versions producing up to 201 horsepower.

A significant milestone in the K24's evolution came with the Earth Dreams Technology initiative, launched by Honda in 2011. This comprehensive approach to powertrain development focused on balancing high performance with environmental responsibility. The K24W variant, introduced under this initiative, incorporated direct injection technology, resulting in improved fuel efficiency and reduced emissions without sacrificing power output.

The latest iterations of the K24 engine have seen the integration of hybrid technology, marking a pivotal shift towards electrification. The Integrated Motor Assist (IMA) system, paired with the K24 in vehicles like the Accord Hybrid, demonstrates Honda's commitment to leveraging renewable energy resources in traditional internal combustion engine designs.

Throughout its evolution, the K24 engine has consistently pushed the boundaries of efficiency and performance. From its early days as a reliable workhorse to its current role as a platform for hybrid innovation, the K24 exemplifies Honda's dedication to continuous improvement and adaptation to changing market and environmental demands.

The original K24A1 engine debuted with 160 horsepower and 161 lb-ft of torque, featuring Honda's i-VTEC technology. This innovative system combined VTEC (Variable Valve Timing and Lift Electronic Control) with VTC (Variable Timing Control), allowing for optimized performance and efficiency across a wide range of engine speeds.

As environmental concerns grew, Honda continuously refined the K24 engine to meet stricter emissions standards while improving fuel efficiency. The introduction of the K24A2 variant in 2003 saw power output increase to 190 horsepower, achieved through enhancements in the i-VTEC system and improvements in intake and exhaust flow.

The K24's versatility became evident as it was adapted for use in a variety of vehicles, from sedans to SUVs. This adaptability led to the development of numerous variants, each tailored to specific vehicle requirements and market demands. The K24Z series, introduced in 2006, further improved upon the engine's design, with some versions producing up to 201 horsepower.

A significant milestone in the K24's evolution came with the Earth Dreams Technology initiative, launched by Honda in 2011. This comprehensive approach to powertrain development focused on balancing high performance with environmental responsibility. The K24W variant, introduced under this initiative, incorporated direct injection technology, resulting in improved fuel efficiency and reduced emissions without sacrificing power output.

The latest iterations of the K24 engine have seen the integration of hybrid technology, marking a pivotal shift towards electrification. The Integrated Motor Assist (IMA) system, paired with the K24 in vehicles like the Accord Hybrid, demonstrates Honda's commitment to leveraging renewable energy resources in traditional internal combustion engine designs.

Throughout its evolution, the K24 engine has consistently pushed the boundaries of efficiency and performance. From its early days as a reliable workhorse to its current role as a platform for hybrid innovation, the K24 exemplifies Honda's dedication to continuous improvement and adaptation to changing market and environmental demands.

Renewable Energy Market

The renewable energy market has experienced significant growth in recent years, driven by increasing environmental concerns, government policies, and technological advancements. This market encompasses various sectors, including solar, wind, hydroelectric, geothermal, and biomass energy. The global renewable energy market was valued at $881.7 billion in 2020 and is projected to reach $1,977.6 billion by 2030, growing at a CAGR of 8.4% from 2021 to 2030.

Solar energy has emerged as a leading segment within the renewable energy market, accounting for the largest share of installed capacity and investments. The solar photovoltaic (PV) market has witnessed substantial cost reductions, making it increasingly competitive with traditional energy sources. Wind energy, both onshore and offshore, has also seen rapid growth, particularly in regions with favorable wind conditions and supportive policies.

The automotive industry has been increasingly adopting renewable energy solutions, driven by the need to reduce carbon emissions and meet stringent environmental regulations. This trend has led to the development of electric vehicles (EVs) and hybrid powertrains, which can be powered by renewable energy sources. The integration of renewable energy in automotive applications extends beyond vehicle propulsion to include manufacturing processes and charging infrastructure.

In the context of engine design, particularly for the K24 engine, the renewable energy market offers several opportunities for innovation and improvement. Biofuels, derived from renewable sources such as plant biomass or algae, present a potential alternative to traditional fossil fuels. These renewable fuels can be used in modified internal combustion engines, including adaptations of the K24 engine, to reduce overall carbon emissions while maintaining performance characteristics.

The renewable energy market also influences the development of auxiliary power systems for vehicles. Solar panels integrated into vehicle bodies or as standalone charging stations can supplement the energy requirements of electric and hybrid powertrains. This approach can extend the range of EVs and reduce the reliance on grid-based charging, particularly in remote areas or during emergencies.

Furthermore, the renewable energy market is driving advancements in energy storage technologies, such as improved batteries and hydrogen fuel cells. These technologies have the potential to revolutionize vehicle powertrains, including potential applications in modified K24 engine designs or hybrid systems that combine traditional internal combustion engines with electric motors powered by renewable energy sources.

As the renewable energy market continues to expand and mature, it is likely to have an increasingly significant impact on automotive engineering and engine design. The integration of renewable energy solutions in vehicle propulsion systems, including adaptations of the K24 engine, represents a promising avenue for reducing the environmental impact of transportation while meeting the performance demands of modern vehicles.

Solar energy has emerged as a leading segment within the renewable energy market, accounting for the largest share of installed capacity and investments. The solar photovoltaic (PV) market has witnessed substantial cost reductions, making it increasingly competitive with traditional energy sources. Wind energy, both onshore and offshore, has also seen rapid growth, particularly in regions with favorable wind conditions and supportive policies.

The automotive industry has been increasingly adopting renewable energy solutions, driven by the need to reduce carbon emissions and meet stringent environmental regulations. This trend has led to the development of electric vehicles (EVs) and hybrid powertrains, which can be powered by renewable energy sources. The integration of renewable energy in automotive applications extends beyond vehicle propulsion to include manufacturing processes and charging infrastructure.

In the context of engine design, particularly for the K24 engine, the renewable energy market offers several opportunities for innovation and improvement. Biofuels, derived from renewable sources such as plant biomass or algae, present a potential alternative to traditional fossil fuels. These renewable fuels can be used in modified internal combustion engines, including adaptations of the K24 engine, to reduce overall carbon emissions while maintaining performance characteristics.

The renewable energy market also influences the development of auxiliary power systems for vehicles. Solar panels integrated into vehicle bodies or as standalone charging stations can supplement the energy requirements of electric and hybrid powertrains. This approach can extend the range of EVs and reduce the reliance on grid-based charging, particularly in remote areas or during emergencies.

Furthermore, the renewable energy market is driving advancements in energy storage technologies, such as improved batteries and hydrogen fuel cells. These technologies have the potential to revolutionize vehicle powertrains, including potential applications in modified K24 engine designs or hybrid systems that combine traditional internal combustion engines with electric motors powered by renewable energy sources.

As the renewable energy market continues to expand and mature, it is likely to have an increasingly significant impact on automotive engineering and engine design. The integration of renewable energy solutions in vehicle propulsion systems, including adaptations of the K24 engine, represents a promising avenue for reducing the environmental impact of transportation while meeting the performance demands of modern vehicles.

Technical Challenges

The integration of renewable energy resources into K24 engine design presents several significant technical challenges. One of the primary obstacles is the intermittent nature of renewable energy sources, particularly solar and wind power. This inconsistency in energy supply can lead to fluctuations in power output, potentially affecting the engine's performance and reliability.

Another major challenge lies in the energy storage systems required to maintain a stable power supply. Current battery technologies, while improving, still face limitations in terms of energy density, charging speed, and lifecycle. These factors can impact the overall efficiency and practicality of renewable energy integration in K24 engines, especially for applications requiring continuous or high-power output.

The conversion efficiency of renewable energy sources to usable power for the K24 engine is another critical hurdle. Solar panels, for instance, typically have conversion efficiencies ranging from 15% to 22%, while wind turbines can achieve efficiencies of up to 59%. These relatively low conversion rates necessitate larger energy collection systems, which may not be feasible in all applications of K24 engines.

Weight and space constraints pose additional challenges. Renewable energy systems, including solar panels, wind turbines, and associated energy storage components, can add significant weight and bulk to the overall engine system. This increase in size and weight can negatively impact the engine's power-to-weight ratio and potentially limit its applications in certain industries or vehicles.

The integration of renewable energy systems with the existing K24 engine architecture presents complex engineering challenges. Designing an effective interface between the renewable energy sources, energy storage systems, and the engine's power management systems requires sophisticated control algorithms and robust electronic systems. These must be capable of managing varying energy inputs while maintaining optimal engine performance.

Environmental factors also play a crucial role in the effectiveness of renewable energy integration. The performance of solar panels can be significantly affected by factors such as cloud cover, dust accumulation, and temperature variations. Similarly, wind turbines are highly dependent on wind speed and consistency, which can vary greatly depending on location and weather conditions.

Lastly, the cost factor remains a significant barrier to widespread adoption of renewable energy in K24 engine designs. While the long-term operational costs may be lower, the initial investment in renewable energy systems and the necessary modifications to the engine design can be substantial. This economic challenge is further compounded by the rapid pace of technological advancements in renewable energy, which can lead to concerns about system obsolescence and the need for frequent upgrades.

Another major challenge lies in the energy storage systems required to maintain a stable power supply. Current battery technologies, while improving, still face limitations in terms of energy density, charging speed, and lifecycle. These factors can impact the overall efficiency and practicality of renewable energy integration in K24 engines, especially for applications requiring continuous or high-power output.

The conversion efficiency of renewable energy sources to usable power for the K24 engine is another critical hurdle. Solar panels, for instance, typically have conversion efficiencies ranging from 15% to 22%, while wind turbines can achieve efficiencies of up to 59%. These relatively low conversion rates necessitate larger energy collection systems, which may not be feasible in all applications of K24 engines.

Weight and space constraints pose additional challenges. Renewable energy systems, including solar panels, wind turbines, and associated energy storage components, can add significant weight and bulk to the overall engine system. This increase in size and weight can negatively impact the engine's power-to-weight ratio and potentially limit its applications in certain industries or vehicles.

The integration of renewable energy systems with the existing K24 engine architecture presents complex engineering challenges. Designing an effective interface between the renewable energy sources, energy storage systems, and the engine's power management systems requires sophisticated control algorithms and robust electronic systems. These must be capable of managing varying energy inputs while maintaining optimal engine performance.

Environmental factors also play a crucial role in the effectiveness of renewable energy integration. The performance of solar panels can be significantly affected by factors such as cloud cover, dust accumulation, and temperature variations. Similarly, wind turbines are highly dependent on wind speed and consistency, which can vary greatly depending on location and weather conditions.

Lastly, the cost factor remains a significant barrier to widespread adoption of renewable energy in K24 engine designs. While the long-term operational costs may be lower, the initial investment in renewable energy systems and the necessary modifications to the engine design can be substantial. This economic challenge is further compounded by the rapid pace of technological advancements in renewable energy, which can lead to concerns about system obsolescence and the need for frequent upgrades.

Current Solutions

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, efficiency, and reliability.- Engine design and structure: The K24 engine is a 2.4-liter inline-four engine known for its compact design and efficient performance. It features a lightweight aluminum block and cylinder head, dual overhead camshafts, and i-VTEC technology for improved power and fuel efficiency. The engine's design allows for easy integration into various vehicle models.

- Fuel injection and combustion system: The K24 engine utilizes advanced fuel injection and combustion systems to optimize performance and reduce emissions. This includes direct fuel injection technology, variable valve timing, and precise fuel metering for improved combustion efficiency. The engine also incorporates advanced sensors and control systems to maintain optimal air-fuel ratios under various operating conditions.

- Engine cooling and thermal management: Effective cooling and thermal management are crucial for the K24 engine's performance and longevity. The engine features an advanced cooling system with optimized coolant flow paths, efficient radiator design, and temperature-controlled cooling fans. These components work together to maintain optimal operating temperatures and prevent overheating under various driving conditions.

- Engine control and management systems: The K24 engine incorporates sophisticated control and management systems to optimize performance, fuel efficiency, and emissions. This includes advanced engine control units (ECUs), sensors for monitoring various engine parameters, and adaptive control algorithms. These systems work together to adjust engine operation in real-time based on driving conditions and user inputs.

- Engine accessories and auxiliary components: Various accessories and auxiliary components are integrated with the K24 engine to enhance its functionality and performance. These may include advanced alternators, power steering pumps, air conditioning compressors, and belt drive systems. The design and integration of these components are optimized to minimize power loss and improve overall engine efficiency.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct injection technology, variable valve timing, and optimized combustion chamber design. These features help improve fuel efficiency, power output, and emissions control.Expand Specific Solutions03 Engine control and management

Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters for optimal performance and efficiency under different operating conditions.Expand Specific Solutions04 Cooling and lubrication systems

The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow, oil circulation, and heat management techniques. These enhancements contribute to better engine durability, performance, and longevity.Expand Specific Solutions05 Engine accessories and integration

Various accessories and integration features are incorporated into the K24 engine design. This includes components such as alternators, power steering pumps, and air conditioning compressors. The engine is also designed for seamless integration with transmission systems and vehicle platforms.Expand Specific Solutions

Industry Leaders

The renewable energy integration in K24 engine design is in an early development stage, with a growing market driven by increasing environmental concerns and energy efficiency demands. The technology's maturity varies among key players, with companies like Gevo, Inc. and Air Products & Chemicals leading in biofuel and gas processing technologies. Academic institutions such as MIT and Tianjin University contribute significant research. The competitive landscape is diverse, including established automotive manufacturers like AUDI AG and emerging specialists like SPARQ Systems. As the field evolves, collaboration between industry and academia is crucial for advancing this technology towards commercial viability and widespread adoption in engine design.

Gevo, Inc.

Technical Solution: Gevo specializes in the development of renewable hydrocarbons, including sustainable aviation fuel (SAF) and renewable gasoline, which can be utilized in K24 engine designs. Their proprietary technology converts renewable feedstocks into isobutanol, which can then be further processed into drop-in fuels compatible with existing engine infrastructure. Gevo's renewable gasoline has been tested in various engine types, including those similar to the K24, demonstrating comparable performance to conventional gasoline while significantly reducing greenhouse gas emissions[9]. The company is also exploring the production of renewable isooctane, a high-octane component that could enhance the performance of K24 engines when blended with standard gasoline[10].

Strengths: Innovative renewable fuel technology, potential for significant emissions reduction, and compatibility with existing engine designs. Weaknesses: Limited production scale, higher production costs compared to conventional fuels, and dependence on agricultural feedstocks.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries (MHI) has been actively developing technologies to incorporate renewable energy resources into engine designs, including adaptations for K24-type engines. MHI has focused on improving engine efficiency through advanced turbocharging systems and waste heat recovery technologies. Their electric hybrid turbocharger system, which can be applied to K24 engines, uses a motor-generator integrated into the turbocharger to recover exhaust energy and convert it into electrical power[11]. This technology not only improves fuel efficiency but also reduces turbo lag, enhancing overall engine performance. Additionally, MHI is researching the use of hydrogen as a fuel in internal combustion engines, which could potentially be adapted for K24 engine platforms in the future[12].

Strengths: Advanced turbocharging and energy recovery technologies, potential for significant efficiency improvements, and expertise in large-scale engineering projects. Weaknesses: High development and implementation costs, complexity of integrating new technologies into existing engine designs, and potential reliability concerns with novel systems.

Key Innovations

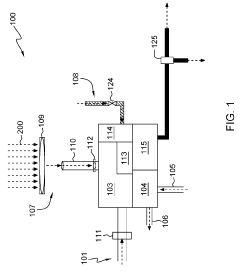

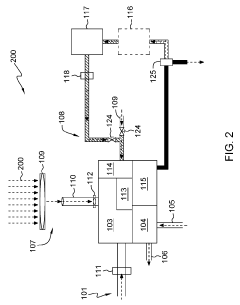

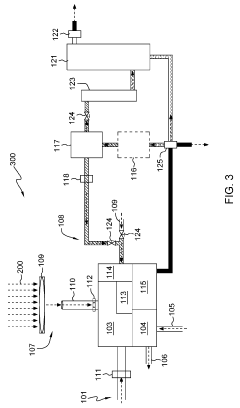

Renewable energy utilizing closed cycle thermodynamic based engine and method of operation

PatentActiveUS20190211808A1

Innovation

- A renewable energy utilization engine power plant integrating a solar radiant energy collecting system, biomass processing system, and combustible fluid processing system to generate thermal energy, which is used to power a closed-cycle thermodynamic engine, converting mechanical energy into electrical energy.

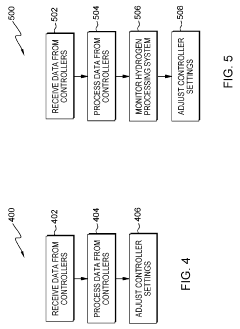

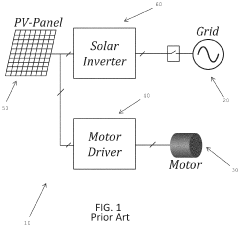

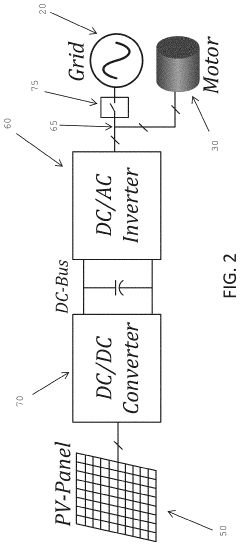

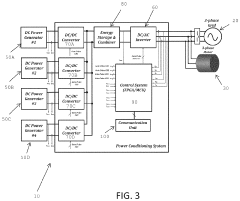

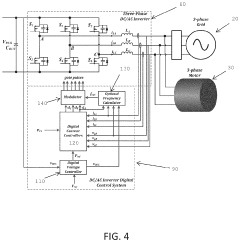

Hybrid solar/motor drive inverter

PatentActiveUS20220209713A1

Innovation

- A system comprising a control module, energy storage/combiner block, and DC/AC inverter that estimates and controls motor speed, provides gate pulses for three-phase AC output, and enables seamless switching between on-grid and off-grid modes, supporting various motor types and multiple inverter configurations.

Environmental Impact

The integration of renewable energy resources in K24 engine design presents significant environmental benefits, aligning with global efforts to reduce carbon emissions and mitigate climate change. This approach addresses the pressing need for sustainable transportation solutions in the face of growing environmental concerns.

By incorporating renewable energy sources, such as solar, wind, or biofuels, into the K24 engine design, manufacturers can substantially reduce the engine's carbon footprint. This reduction in greenhouse gas emissions contributes to improved air quality and helps combat global warming. The shift towards cleaner energy sources also reduces dependence on fossil fuels, thereby conserving non-renewable resources and promoting energy security.

The environmental impact extends beyond emissions reduction. The use of renewable energy in K24 engines can lead to decreased noise pollution, as these power sources often operate more quietly than traditional combustion engines. This improvement in acoustic emissions is particularly beneficial in urban environments, where noise pollution is a growing concern.

Furthermore, the adoption of renewable energy in engine design promotes the development of a circular economy. Many renewable energy technologies, such as solar panels and wind turbines, have high recyclability rates. This characteristic ensures that the environmental impact of the engine is minimized throughout its lifecycle, from production to disposal.

The implementation of renewable energy in K24 engines also has indirect environmental benefits. It stimulates research and development in clean energy technologies, potentially leading to breakthroughs that can be applied across various industries. This ripple effect accelerates the overall transition to a more sustainable energy landscape.

However, it is crucial to consider the full lifecycle environmental impact of renewable energy integration. The production of certain renewable energy components, such as batteries for energy storage, can have environmental implications. Manufacturers must carefully assess and mitigate these impacts to ensure a net positive environmental outcome.

In conclusion, the utilization of renewable energy resources in K24 engine design represents a significant step towards more sustainable transportation. While challenges exist, the potential for reduced emissions, improved air quality, and promotion of clean energy technologies makes this approach a valuable contribution to environmental conservation efforts in the automotive industry.

By incorporating renewable energy sources, such as solar, wind, or biofuels, into the K24 engine design, manufacturers can substantially reduce the engine's carbon footprint. This reduction in greenhouse gas emissions contributes to improved air quality and helps combat global warming. The shift towards cleaner energy sources also reduces dependence on fossil fuels, thereby conserving non-renewable resources and promoting energy security.

The environmental impact extends beyond emissions reduction. The use of renewable energy in K24 engines can lead to decreased noise pollution, as these power sources often operate more quietly than traditional combustion engines. This improvement in acoustic emissions is particularly beneficial in urban environments, where noise pollution is a growing concern.

Furthermore, the adoption of renewable energy in engine design promotes the development of a circular economy. Many renewable energy technologies, such as solar panels and wind turbines, have high recyclability rates. This characteristic ensures that the environmental impact of the engine is minimized throughout its lifecycle, from production to disposal.

The implementation of renewable energy in K24 engines also has indirect environmental benefits. It stimulates research and development in clean energy technologies, potentially leading to breakthroughs that can be applied across various industries. This ripple effect accelerates the overall transition to a more sustainable energy landscape.

However, it is crucial to consider the full lifecycle environmental impact of renewable energy integration. The production of certain renewable energy components, such as batteries for energy storage, can have environmental implications. Manufacturers must carefully assess and mitigate these impacts to ensure a net positive environmental outcome.

In conclusion, the utilization of renewable energy resources in K24 engine design represents a significant step towards more sustainable transportation. While challenges exist, the potential for reduced emissions, improved air quality, and promotion of clean energy technologies makes this approach a valuable contribution to environmental conservation efforts in the automotive industry.

Regulatory Framework

The regulatory framework surrounding the utilization of renewable energy resources in K24 engine design is a complex and evolving landscape. At the international level, the Paris Agreement sets the overarching goal of limiting global temperature rise, which indirectly influences engine design regulations. The United Nations Framework Convention on Climate Change (UNFCCC) provides guidelines for reducing greenhouse gas emissions, impacting the automotive industry's approach to engine development.

In the United States, the Corporate Average Fuel Economy (CAFE) standards, administered by the National Highway Traffic Safety Administration (NHTSA), play a crucial role in shaping engine design. These standards set specific fuel efficiency targets for vehicle manufacturers, encouraging the integration of renewable energy technologies. The Environmental Protection Agency (EPA) complements these efforts through its emissions regulations, which have become increasingly stringent over the years.

The European Union has implemented its own set of regulations, including the Euro emissions standards, which have progressively tightened limits on vehicle emissions. The EU's Renewable Energy Directive (RED) also influences engine design by setting targets for renewable energy use in the transport sector. This directive has led to increased focus on biofuels and other renewable energy sources in engine development.

China, as a major automotive market, has introduced policies such as the New Energy Vehicle (NEV) mandate, which incentivizes the production of vehicles utilizing renewable energy sources. This regulatory push has accelerated research and development in electric and hybrid powertrains, indirectly affecting K24 engine design considerations.

At the state and local levels, various jurisdictions have implemented their own regulations and incentives. California's Zero Emission Vehicle (ZEV) program, for instance, has been particularly influential in driving innovation in low-emission and renewable energy-powered vehicles. Other states have adopted similar programs, creating a patchwork of regulations that engine designers must navigate.

Industry standards also play a significant role in shaping the regulatory landscape. Organizations such as the Society of Automotive Engineers (SAE) develop technical standards that often become the basis for regulations. These standards cover various aspects of engine design, including performance metrics, testing procedures, and safety requirements related to renewable energy integration.

The regulatory framework is not static, and ongoing discussions and proposals continue to shape future requirements. For instance, debates around lifecycle emissions assessments and the environmental impact of battery production are likely to influence future regulations on renewable energy use in engines. Engine designers must stay abreast of these evolving regulations and anticipate future changes to ensure compliance and maintain competitiveness in the market.

In the United States, the Corporate Average Fuel Economy (CAFE) standards, administered by the National Highway Traffic Safety Administration (NHTSA), play a crucial role in shaping engine design. These standards set specific fuel efficiency targets for vehicle manufacturers, encouraging the integration of renewable energy technologies. The Environmental Protection Agency (EPA) complements these efforts through its emissions regulations, which have become increasingly stringent over the years.

The European Union has implemented its own set of regulations, including the Euro emissions standards, which have progressively tightened limits on vehicle emissions. The EU's Renewable Energy Directive (RED) also influences engine design by setting targets for renewable energy use in the transport sector. This directive has led to increased focus on biofuels and other renewable energy sources in engine development.

China, as a major automotive market, has introduced policies such as the New Energy Vehicle (NEV) mandate, which incentivizes the production of vehicles utilizing renewable energy sources. This regulatory push has accelerated research and development in electric and hybrid powertrains, indirectly affecting K24 engine design considerations.

At the state and local levels, various jurisdictions have implemented their own regulations and incentives. California's Zero Emission Vehicle (ZEV) program, for instance, has been particularly influential in driving innovation in low-emission and renewable energy-powered vehicles. Other states have adopted similar programs, creating a patchwork of regulations that engine designers must navigate.

Industry standards also play a significant role in shaping the regulatory landscape. Organizations such as the Society of Automotive Engineers (SAE) develop technical standards that often become the basis for regulations. These standards cover various aspects of engine design, including performance metrics, testing procedures, and safety requirements related to renewable energy integration.

The regulatory framework is not static, and ongoing discussions and proposals continue to shape future requirements. For instance, debates around lifecycle emissions assessments and the environmental impact of battery production are likely to influence future regulations on renewable energy use in engines. Engine designers must stay abreast of these evolving regulations and anticipate future changes to ensure compliance and maintain competitiveness in the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!