Vehicle noise reduction strategies with mild hybrid powertrains

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid NVH Challenges

The integration of mild hybrid powertrains in vehicles presents unique challenges in terms of Noise, Vibration, and Harshness (NVH). These systems, which combine traditional internal combustion engines with small electric motors, introduce new sources of noise and vibration that must be carefully managed to maintain or improve overall vehicle comfort.

One of the primary challenges is the frequent starting and stopping of the internal combustion engine, a key feature of mild hybrid systems. This start-stop functionality can lead to increased low-frequency vibrations and noise, particularly during transitions between electric and combustion power. The sudden engagement and disengagement of the engine can create noticeable jolts and sound intrusions if not properly dampened.

Another significant issue is the noise generated by the electric components of the hybrid system. Electric motors, while generally quieter than combustion engines, produce high-frequency whines that can be particularly noticeable in the absence of engine noise. Power electronics and inverters also contribute to electromagnetic noise that may interfere with vehicle audio systems or create audible buzzing sounds.

The complexity of the powertrain system in mild hybrids also introduces potential for resonance issues. The interaction between the electric motor, combustion engine, and various drivetrain components can create new resonant frequencies that were not present in traditional powertrains. These resonances may amplify vibrations at certain speeds or operating conditions, requiring careful analysis and mitigation strategies.

Furthermore, the reduced masking effect of engine noise in hybrid vehicles can make other noise sources more apparent. Road noise, wind noise, and auxiliary system sounds that were previously obscured by the constant hum of a combustion engine may become more noticeable to occupants, necessitating additional focus on these secondary noise sources.

Weight distribution and packaging constraints in mild hybrid vehicles can also impact NVH characteristics. The addition of batteries and electric motors may alter the vehicle's center of gravity and weight distribution, potentially affecting its dynamic behavior and introducing new vibration paths. Engineers must carefully consider the placement of these components to minimize their impact on vehicle dynamics and noise transmission.

Lastly, the varying operating modes of mild hybrid systems present a challenge in maintaining consistent NVH performance across all driving conditions. The system may switch between electric-only, combustion-only, and combined power modes, each with its own NVH signature. Ensuring a smooth and imperceptible transition between these modes, while maintaining a consistent and pleasant sound character, requires sophisticated control strategies and sound design techniques.

One of the primary challenges is the frequent starting and stopping of the internal combustion engine, a key feature of mild hybrid systems. This start-stop functionality can lead to increased low-frequency vibrations and noise, particularly during transitions between electric and combustion power. The sudden engagement and disengagement of the engine can create noticeable jolts and sound intrusions if not properly dampened.

Another significant issue is the noise generated by the electric components of the hybrid system. Electric motors, while generally quieter than combustion engines, produce high-frequency whines that can be particularly noticeable in the absence of engine noise. Power electronics and inverters also contribute to electromagnetic noise that may interfere with vehicle audio systems or create audible buzzing sounds.

The complexity of the powertrain system in mild hybrids also introduces potential for resonance issues. The interaction between the electric motor, combustion engine, and various drivetrain components can create new resonant frequencies that were not present in traditional powertrains. These resonances may amplify vibrations at certain speeds or operating conditions, requiring careful analysis and mitigation strategies.

Furthermore, the reduced masking effect of engine noise in hybrid vehicles can make other noise sources more apparent. Road noise, wind noise, and auxiliary system sounds that were previously obscured by the constant hum of a combustion engine may become more noticeable to occupants, necessitating additional focus on these secondary noise sources.

Weight distribution and packaging constraints in mild hybrid vehicles can also impact NVH characteristics. The addition of batteries and electric motors may alter the vehicle's center of gravity and weight distribution, potentially affecting its dynamic behavior and introducing new vibration paths. Engineers must carefully consider the placement of these components to minimize their impact on vehicle dynamics and noise transmission.

Lastly, the varying operating modes of mild hybrid systems present a challenge in maintaining consistent NVH performance across all driving conditions. The system may switch between electric-only, combustion-only, and combined power modes, each with its own NVH signature. Ensuring a smooth and imperceptible transition between these modes, while maintaining a consistent and pleasant sound character, requires sophisticated control strategies and sound design techniques.

Market Demand Analysis

The market demand for vehicle noise reduction strategies in mild hybrid powertrains has been steadily increasing in recent years. This growth is primarily driven by stringent noise regulations, consumer preferences for quieter vehicles, and the expanding market share of hybrid vehicles.

Regulatory bodies worldwide have been implementing stricter noise emission standards for vehicles. The European Union, for example, has set a target to reduce vehicle noise levels by 3 decibels by 2024. Similarly, countries like Japan and the United States have introduced more rigorous noise regulations. These regulatory pressures have created a significant market demand for advanced noise reduction technologies in mild hybrid powertrains.

Consumer preferences have also shifted towards quieter and more comfortable vehicles. As urban populations grow and traffic congestion increases, the desire for a peaceful in-car environment has become a key factor in purchasing decisions. This trend is particularly evident in the premium and luxury vehicle segments, where noise reduction is often a distinguishing feature.

The global mild hybrid vehicle market has been experiencing robust growth. According to industry reports, the mild hybrid market is expected to grow at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is fueled by the increasing adoption of mild hybrid systems as a cost-effective solution to meet emissions regulations while providing improved fuel efficiency.

The integration of noise reduction strategies in mild hybrid powertrains presents unique challenges and opportunities. The start-stop functionality of mild hybrid systems can create additional noise and vibration issues, particularly during engine restarts. This has led to increased demand for specialized noise reduction solutions tailored to mild hybrid powertrains.

Market analysis indicates that the automotive NVH (Noise, Vibration, and Harshness) materials market, which includes components used for noise reduction, is projected to grow significantly. This growth is partly attributed to the rising demand for noise reduction in hybrid and electric vehicles.

Geographically, the demand for noise reduction technologies in mild hybrid powertrains is strongest in regions with high hybrid vehicle adoption rates and strict noise regulations. Europe and Asia-Pacific, particularly countries like Germany, Japan, and South Korea, are leading markets for these technologies.

In conclusion, the market demand for vehicle noise reduction strategies in mild hybrid powertrains is robust and growing. This demand is driven by regulatory pressures, evolving consumer preferences, and the expanding mild hybrid vehicle market. As the automotive industry continues to shift towards electrification, the importance of effective noise reduction strategies in hybrid powertrains is expected to increase further, presenting significant opportunities for innovation and market growth.

Regulatory bodies worldwide have been implementing stricter noise emission standards for vehicles. The European Union, for example, has set a target to reduce vehicle noise levels by 3 decibels by 2024. Similarly, countries like Japan and the United States have introduced more rigorous noise regulations. These regulatory pressures have created a significant market demand for advanced noise reduction technologies in mild hybrid powertrains.

Consumer preferences have also shifted towards quieter and more comfortable vehicles. As urban populations grow and traffic congestion increases, the desire for a peaceful in-car environment has become a key factor in purchasing decisions. This trend is particularly evident in the premium and luxury vehicle segments, where noise reduction is often a distinguishing feature.

The global mild hybrid vehicle market has been experiencing robust growth. According to industry reports, the mild hybrid market is expected to grow at a compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is fueled by the increasing adoption of mild hybrid systems as a cost-effective solution to meet emissions regulations while providing improved fuel efficiency.

The integration of noise reduction strategies in mild hybrid powertrains presents unique challenges and opportunities. The start-stop functionality of mild hybrid systems can create additional noise and vibration issues, particularly during engine restarts. This has led to increased demand for specialized noise reduction solutions tailored to mild hybrid powertrains.

Market analysis indicates that the automotive NVH (Noise, Vibration, and Harshness) materials market, which includes components used for noise reduction, is projected to grow significantly. This growth is partly attributed to the rising demand for noise reduction in hybrid and electric vehicles.

Geographically, the demand for noise reduction technologies in mild hybrid powertrains is strongest in regions with high hybrid vehicle adoption rates and strict noise regulations. Europe and Asia-Pacific, particularly countries like Germany, Japan, and South Korea, are leading markets for these technologies.

In conclusion, the market demand for vehicle noise reduction strategies in mild hybrid powertrains is robust and growing. This demand is driven by regulatory pressures, evolving consumer preferences, and the expanding mild hybrid vehicle market. As the automotive industry continues to shift towards electrification, the importance of effective noise reduction strategies in hybrid powertrains is expected to increase further, presenting significant opportunities for innovation and market growth.

Current Noise Issues

Mild hybrid powertrains, while offering improved fuel efficiency and reduced emissions, present unique challenges in vehicle noise reduction. The current noise issues associated with these systems stem from several key factors that require careful consideration and innovative solutions.

One of the primary concerns is the intermittent operation of the internal combustion engine (ICE) in mild hybrid systems. The frequent starting and stopping of the engine can create noticeable and potentially irritating sound transitions for passengers. This start-stop functionality, while beneficial for fuel economy, introduces abrupt changes in the vehicle's sound profile that can be perceived as unpleasant or disruptive.

Additionally, the electric motor in mild hybrid systems, though quieter than the ICE, introduces its own set of noise challenges. High-frequency whining or humming sounds from the electric motor and power electronics can become more noticeable, especially during low-speed operation or when the ICE is not running. These electric drivetrain noises, previously masked by the louder combustion engine, now require specific attention in the overall noise reduction strategy.

The integration of regenerative braking systems in mild hybrids also contributes to the current noise landscape. The transition between regenerative and friction braking can produce unfamiliar sounds and vibrations that may be perceived negatively by drivers and passengers accustomed to conventional braking systems.

Furthermore, the reduced overall noise levels in mild hybrid vehicles have paradoxically highlighted other noise sources that were previously less noticeable. Road noise, wind noise, and various mechanical sounds from the vehicle's components now become more prominent, requiring a holistic approach to noise reduction that extends beyond the powertrain itself.

The complexity of managing the noise, vibration, and harshness (NVH) characteristics in mild hybrid vehicles is further compounded by the need to balance performance, efficiency, and cost considerations. Engineers must navigate the challenge of implementing effective noise reduction strategies without significantly impacting the vehicle's weight, aerodynamics, or production costs.

Lastly, the current regulatory landscape and consumer expectations add another layer of complexity to noise reduction efforts. Increasingly stringent noise emission regulations, particularly in urban environments, necessitate innovative approaches to meet legal requirements while still maintaining the desired vehicle character and performance attributes that consumers expect.

One of the primary concerns is the intermittent operation of the internal combustion engine (ICE) in mild hybrid systems. The frequent starting and stopping of the engine can create noticeable and potentially irritating sound transitions for passengers. This start-stop functionality, while beneficial for fuel economy, introduces abrupt changes in the vehicle's sound profile that can be perceived as unpleasant or disruptive.

Additionally, the electric motor in mild hybrid systems, though quieter than the ICE, introduces its own set of noise challenges. High-frequency whining or humming sounds from the electric motor and power electronics can become more noticeable, especially during low-speed operation or when the ICE is not running. These electric drivetrain noises, previously masked by the louder combustion engine, now require specific attention in the overall noise reduction strategy.

The integration of regenerative braking systems in mild hybrids also contributes to the current noise landscape. The transition between regenerative and friction braking can produce unfamiliar sounds and vibrations that may be perceived negatively by drivers and passengers accustomed to conventional braking systems.

Furthermore, the reduced overall noise levels in mild hybrid vehicles have paradoxically highlighted other noise sources that were previously less noticeable. Road noise, wind noise, and various mechanical sounds from the vehicle's components now become more prominent, requiring a holistic approach to noise reduction that extends beyond the powertrain itself.

The complexity of managing the noise, vibration, and harshness (NVH) characteristics in mild hybrid vehicles is further compounded by the need to balance performance, efficiency, and cost considerations. Engineers must navigate the challenge of implementing effective noise reduction strategies without significantly impacting the vehicle's weight, aerodynamics, or production costs.

Lastly, the current regulatory landscape and consumer expectations add another layer of complexity to noise reduction efforts. Increasingly stringent noise emission regulations, particularly in urban environments, necessitate innovative approaches to meet legal requirements while still maintaining the desired vehicle character and performance attributes that consumers expect.

Existing NVH Solutions

01 Noise reduction in mild hybrid powertrains

Various techniques are employed to reduce noise in mild hybrid powertrains. These may include active noise control systems, sound insulation materials, and optimized engine mounts. The goal is to minimize vibrations and acoustic emissions from the hybrid powertrain components, enhancing overall vehicle comfort.- Noise reduction in mild hybrid powertrains: Various techniques are employed to reduce noise in mild hybrid powertrains. These may include active noise control systems, sound insulation materials, and optimized engine mounts. The goal is to minimize vibrations and acoustic emissions from the hybrid powertrain components, enhancing overall vehicle comfort.

- Engine start-stop noise management: Strategies are implemented to manage noise during engine start-stop events in mild hybrid vehicles. This includes controlling the timing of engine restarts, using electric motors to smooth transitions, and implementing software algorithms to predict and mitigate potential noise sources during these frequent events.

- Electric motor noise reduction: Techniques are developed to minimize noise from electric motors in mild hybrid systems. This may involve optimizing motor design, using advanced materials, implementing active vibration control, and fine-tuning motor control strategies to reduce electromagnetic noise and mechanical vibrations.

- Powertrain integration for noise minimization: Holistic approaches to integrating hybrid powertrain components are employed to minimize overall system noise. This includes optimizing the layout of components, using flexible couplings, and implementing advanced control strategies that coordinate the operation of the internal combustion engine and electric motor to reduce noise and vibration.

- Adaptive noise control systems: Advanced adaptive noise control systems are developed for mild hybrid powertrains. These systems use sensors to detect noise and vibration in real-time, and then generate counteracting signals or adjust powertrain operation to minimize perceived noise. Machine learning algorithms may be employed to continuously improve noise cancellation effectiveness.

02 Engine start-stop noise management

Strategies are implemented to manage noise during engine start-stop events in mild hybrid vehicles. This involves controlling the timing and smoothness of engine restarts, as well as using electric motors to assist in reducing the abruptness of these transitions. The aim is to minimize noise and vibration perceived by occupants during frequent start-stop cycles.Expand Specific Solutions03 Electric motor noise reduction

Techniques are developed to reduce noise generated by electric motors in mild hybrid systems. This includes optimizing motor design, using advanced materials, and implementing noise-cancelling technologies. The focus is on minimizing high-frequency whine and other electromagnetic noises associated with electric motor operation.Expand Specific Solutions04 Powertrain integration for noise minimization

Holistic approaches to powertrain integration are used to minimize overall noise in mild hybrid vehicles. This involves optimizing the layout and mounting of powertrain components, using advanced control algorithms to coordinate between electric and combustion power sources, and implementing adaptive noise reduction strategies based on driving conditions.Expand Specific Solutions05 Acoustic encapsulation and insulation

Advanced acoustic encapsulation and insulation techniques are applied to mild hybrid powertrain components. This includes the use of specialized materials and designs to contain and absorb noise from both the internal combustion engine and electric drive components. The goal is to create a more isolated and quieter powertrain system.Expand Specific Solutions

Key Industry Players

The vehicle noise reduction strategies with mild hybrid powertrains market is in a growth phase, driven by increasing demand for quieter and more fuel-efficient vehicles. The market size is expanding as automakers invest in hybrid technologies to meet stricter emissions regulations. Major players like Toyota, Ford, Nissan, and GM are at the forefront of technology development, with varying levels of maturity in their mild hybrid systems. Emerging competitors such as BYD and Hyundai are also making significant strides, while traditional European manufacturers like Volkswagen and Mercedes-Benz are rapidly advancing their hybrid technologies to maintain competitiveness in this evolving landscape.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced mild hybrid system for noise reduction in vehicles. Their strategy involves a 48V mild hybrid system that integrates a belt-driven integrated starter generator (B-ISG) with a small lithium-ion battery[1]. This system allows for smoother engine start-stop operations, reducing noise and vibration during restarts. Toyota also employs active noise control (ANC) technology, which uses the vehicle's audio system to generate sound waves that cancel out unwanted engine noise[2]. Additionally, they have implemented improved engine mounts and sound-absorbing materials strategically placed throughout the vehicle to further minimize noise transmission[3].

Strengths: Seamless integration of mild hybrid technology with existing powertrains, improved fuel efficiency, and significant noise reduction. Weaknesses: Higher initial cost compared to conventional powertrains, added complexity in the electrical system.

Ford Global Technologies LLC

Technical Solution: Ford's approach to vehicle noise reduction in mild hybrid powertrains focuses on their EcoBoost engines combined with a 48V mild hybrid system. They utilize a belt-driven integrated starter generator (BISG) that replaces the standard alternator, enabling faster and quieter engine shutdowns and restarts[4]. Ford has also developed an advanced active noise control system that uses strategically placed microphones and the vehicle's audio system to counteract low-frequency engine noise[5]. Furthermore, they have implemented a "dual-mass flywheel" technology that helps dampen torsional vibrations from the engine, reducing overall powertrain noise[6].

Strengths: Effective noise reduction across a wide range of engine speeds, improved fuel efficiency, and enhanced driving comfort. Weaknesses: Increased system complexity and potential for higher maintenance costs.

Core NVH Innovations

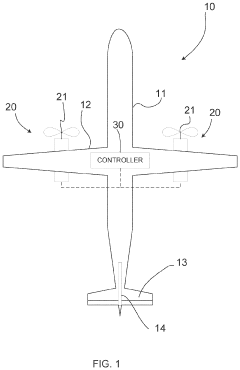

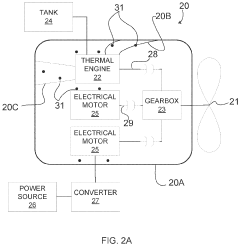

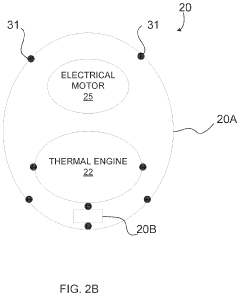

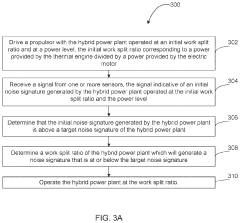

Method and system for reducing noise of hybrid power plant

PatentInactiveUS20230311847A1

Innovation

- A method and system that utilize sensors to measure noise signatures and adjust the work split ratio between thermal engines and electrical motors based on a database correlation, allowing the hybrid power plant to operate within target noise signature ranges, and optionally switch to a whisper mode during noise-restricted flight phases.

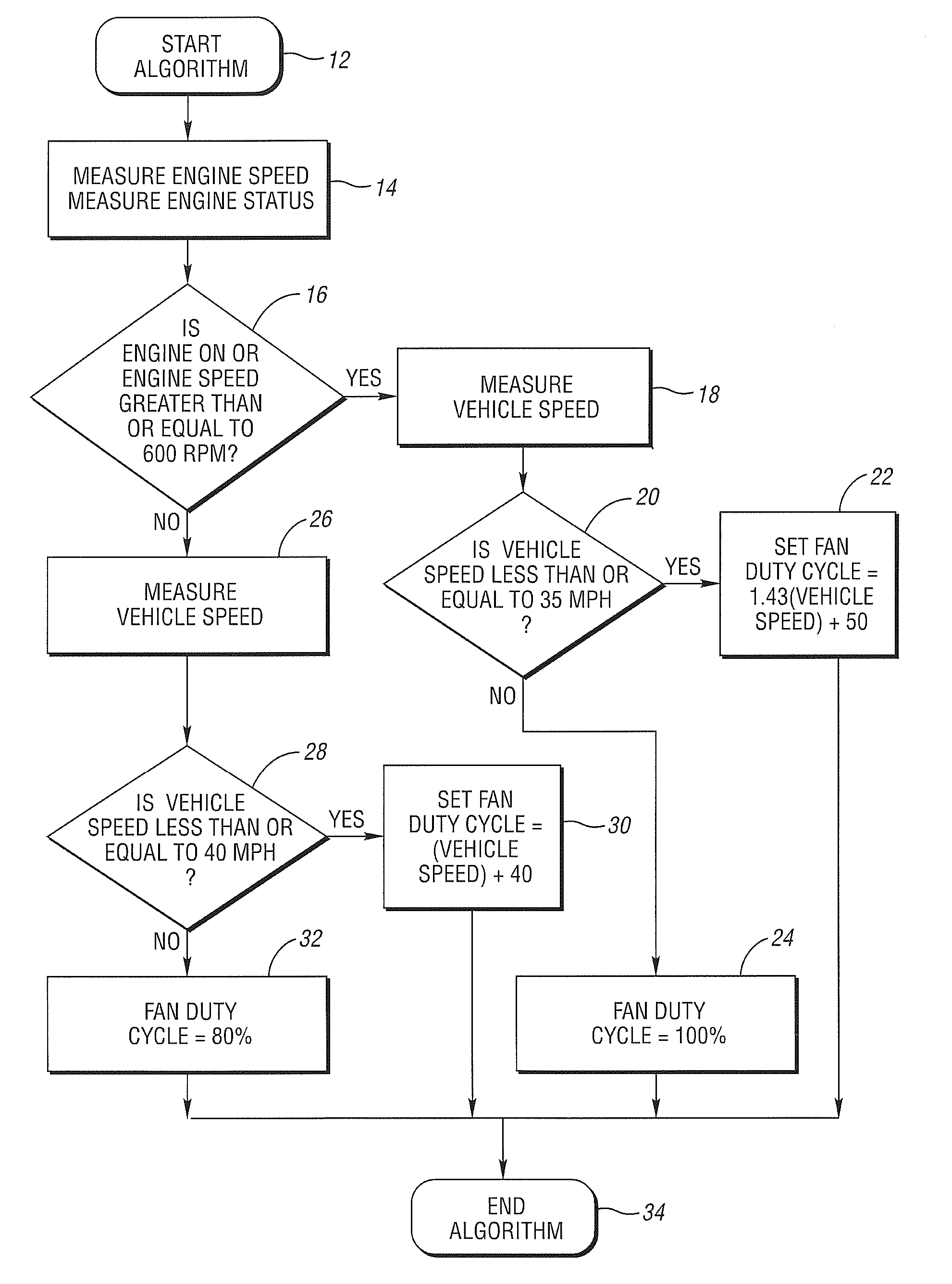

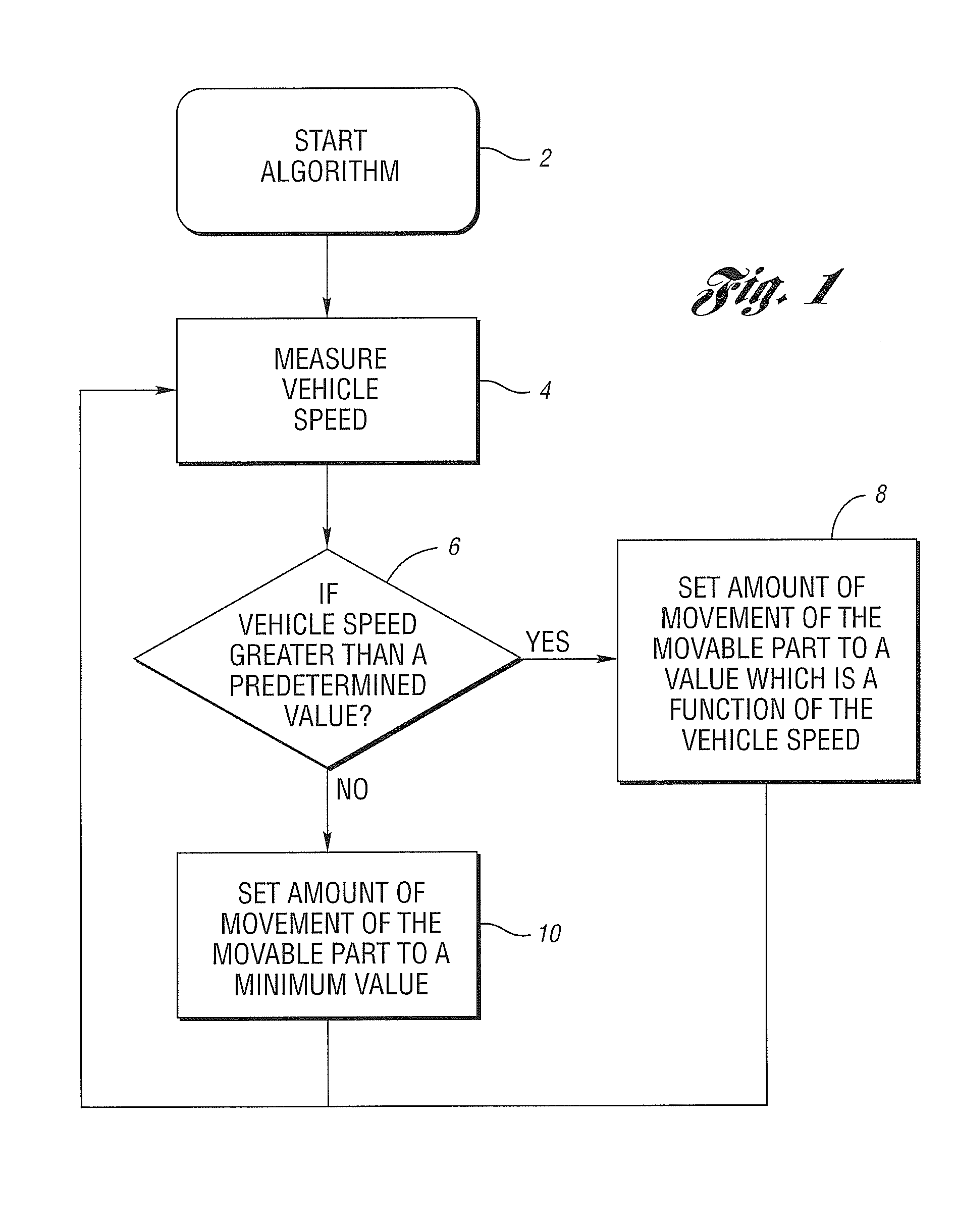

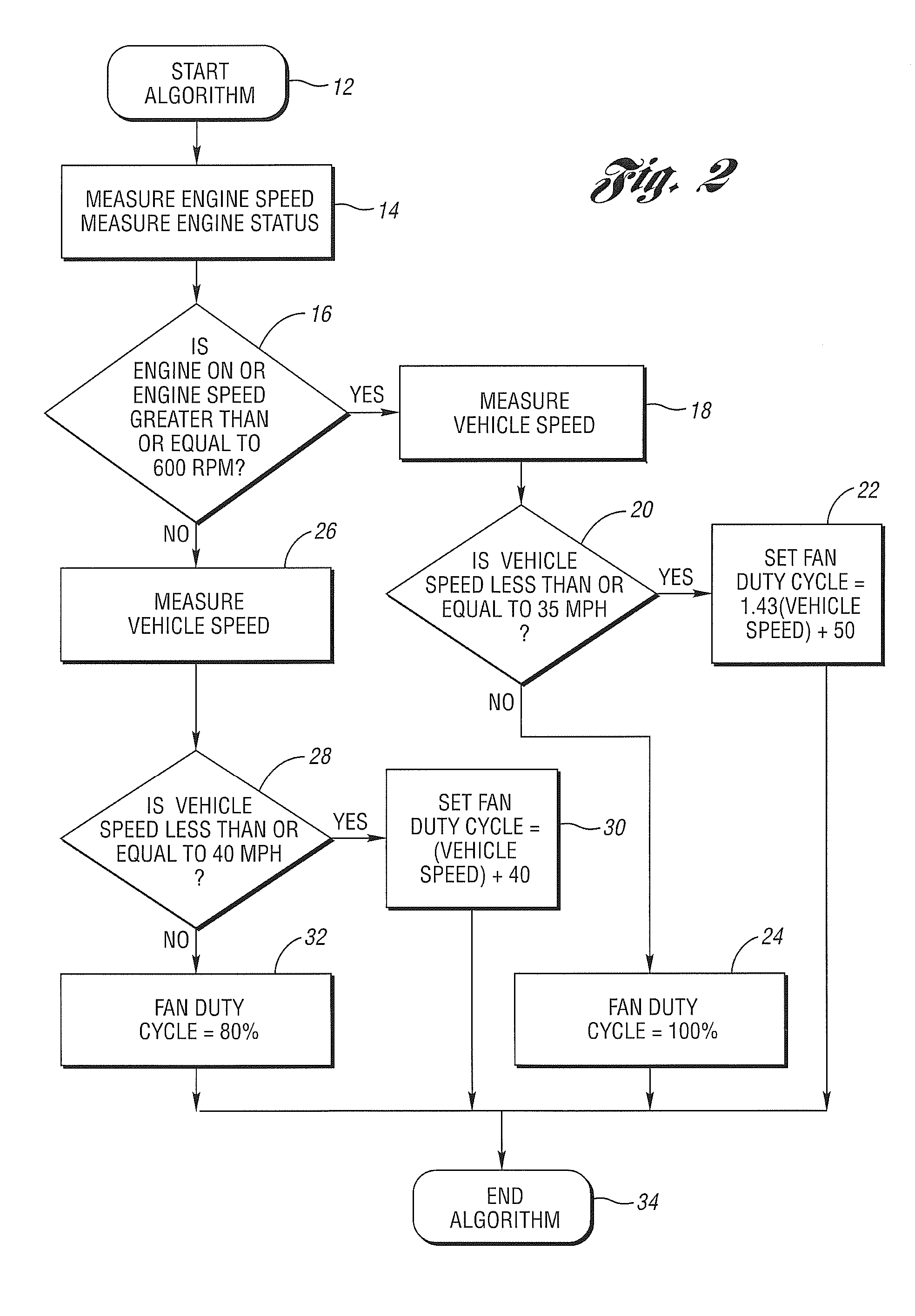

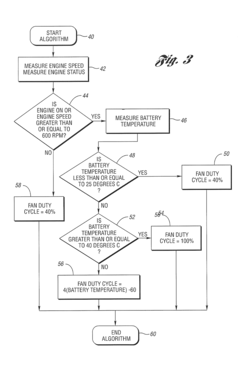

Strategy for minimizing noise perception in a vehicle

PatentInactiveUS7024871B2

Innovation

- A method that involves monitoring the vehicle speed and increasing the movement of noise-producing components, such as cooling fans, by adjusting their duty cycle based on predetermined speed thresholds, with the fan duty cycle set to a minimum at zero speed and linearly increasing as the speed increases, and optionally adjusting based on battery temperature.

Regulatory Landscape

The regulatory landscape for vehicle noise reduction, particularly in the context of mild hybrid powertrains, has been evolving rapidly in recent years. Governments and regulatory bodies worldwide are implementing increasingly stringent noise emission standards to address the growing concerns about environmental noise pollution and its impact on public health.

In the European Union, the regulation (EU) No 540/2014 sets the framework for vehicle noise emissions. This regulation has introduced a phased approach to reducing noise limits, with the final phase set to be implemented in 2024. For mild hybrid vehicles, these regulations require compliance with both internal combustion engine (ICE) and electric motor noise standards, presenting unique challenges for manufacturers.

The United States has also been tightening its regulations on vehicle noise emissions. The National Highway Traffic Safety Administration (NHTSA) has proposed new rules that would require hybrid and electric vehicles to emit artificial sounds when traveling at low speeds to alert pedestrians and cyclists. This regulation, known as the "Quiet Vehicle Safety Standard," has implications for the design and implementation of noise reduction strategies in mild hybrid powertrains.

In Asia, countries like Japan and China have been following suit with their own noise reduction regulations. Japan's Ministry of Land, Infrastructure, Transport and Tourism has set noise limits for different vehicle categories, including hybrid vehicles. China's Ministry of Environmental Protection has also introduced national standards for vehicle noise emissions, which are becoming progressively more stringent.

These regulatory changes are driving innovation in the automotive industry, particularly in the development of mild hybrid powertrains. Manufacturers are now required to balance the need for efficient, low-emission engines with the requirement to meet noise reduction targets. This has led to the development of advanced noise control technologies, such as active noise control systems, improved engine mounts, and sophisticated exhaust systems.

The regulatory landscape also extends to urban planning and traffic management. Many cities are implementing "quiet zones" or time-based noise restrictions, which further incentivize the adoption of quieter vehicle technologies. This trend is likely to accelerate the development and deployment of mild hybrid powertrains with advanced noise reduction capabilities.

As regulations continue to evolve, manufacturers must stay ahead of the curve by investing in research and development of innovative noise reduction technologies. The challenge lies in developing solutions that not only meet current standards but also anticipate future regulatory requirements while maintaining vehicle performance and consumer appeal.

In the European Union, the regulation (EU) No 540/2014 sets the framework for vehicle noise emissions. This regulation has introduced a phased approach to reducing noise limits, with the final phase set to be implemented in 2024. For mild hybrid vehicles, these regulations require compliance with both internal combustion engine (ICE) and electric motor noise standards, presenting unique challenges for manufacturers.

The United States has also been tightening its regulations on vehicle noise emissions. The National Highway Traffic Safety Administration (NHTSA) has proposed new rules that would require hybrid and electric vehicles to emit artificial sounds when traveling at low speeds to alert pedestrians and cyclists. This regulation, known as the "Quiet Vehicle Safety Standard," has implications for the design and implementation of noise reduction strategies in mild hybrid powertrains.

In Asia, countries like Japan and China have been following suit with their own noise reduction regulations. Japan's Ministry of Land, Infrastructure, Transport and Tourism has set noise limits for different vehicle categories, including hybrid vehicles. China's Ministry of Environmental Protection has also introduced national standards for vehicle noise emissions, which are becoming progressively more stringent.

These regulatory changes are driving innovation in the automotive industry, particularly in the development of mild hybrid powertrains. Manufacturers are now required to balance the need for efficient, low-emission engines with the requirement to meet noise reduction targets. This has led to the development of advanced noise control technologies, such as active noise control systems, improved engine mounts, and sophisticated exhaust systems.

The regulatory landscape also extends to urban planning and traffic management. Many cities are implementing "quiet zones" or time-based noise restrictions, which further incentivize the adoption of quieter vehicle technologies. This trend is likely to accelerate the development and deployment of mild hybrid powertrains with advanced noise reduction capabilities.

As regulations continue to evolve, manufacturers must stay ahead of the curve by investing in research and development of innovative noise reduction technologies. The challenge lies in developing solutions that not only meet current standards but also anticipate future regulatory requirements while maintaining vehicle performance and consumer appeal.

Environmental Impact

The environmental impact of mild hybrid powertrains in vehicle noise reduction strategies is a crucial aspect to consider. These systems offer significant benefits in terms of reducing both noise pollution and greenhouse gas emissions. By integrating electric motors with conventional internal combustion engines, mild hybrid powertrains enable more efficient operation and reduced fuel consumption, leading to lower CO2 emissions.

One of the primary environmental advantages of mild hybrid systems is their ability to enable start-stop functionality. This feature automatically shuts off the engine when the vehicle is stationary, eliminating idle noise and emissions in urban environments. When the vehicle resumes motion, the electric motor assists in restarting the engine quickly and smoothly, further reducing noise and fuel consumption during frequent stops in city traffic.

Regenerative braking is another key feature of mild hybrid powertrains that contributes to environmental benefits. By capturing energy typically lost during deceleration and braking, these systems reduce overall energy consumption and, consequently, emissions. This process also helps to minimize brake wear, reducing the release of particulate matter from brake pads into the environment.

The electric assist provided by mild hybrid systems allows for downsizing of the internal combustion engine without compromising performance. Smaller engines generally produce less noise and vibration, contributing to a quieter driving experience and reduced noise pollution in urban areas. Additionally, the reduced engine size leads to improved fuel efficiency and lower emissions across various driving conditions.

Mild hybrid powertrains also enable more precise control over engine operation, allowing for optimization of combustion processes. This results in cleaner exhaust emissions and reduced noise from the engine, particularly during acceleration and at low speeds. The electric motor's ability to provide instant torque can smooth out power delivery, further reducing noise and vibration associated with traditional powertrains.

In terms of lifecycle environmental impact, mild hybrid systems generally require fewer additional components compared to full hybrid or electric vehicles. This can lead to reduced manufacturing complexity and potentially lower environmental costs associated with production and end-of-life disposal. However, the additional battery and electric components do introduce some environmental considerations, particularly regarding the sourcing and recycling of materials used in their production.

Overall, the implementation of mild hybrid powertrains in vehicle noise reduction strategies offers a balanced approach to improving environmental performance. By addressing both noise pollution and emissions, these systems contribute to creating more sustainable and livable urban environments while providing a stepping stone towards more comprehensive electrification of transportation.

One of the primary environmental advantages of mild hybrid systems is their ability to enable start-stop functionality. This feature automatically shuts off the engine when the vehicle is stationary, eliminating idle noise and emissions in urban environments. When the vehicle resumes motion, the electric motor assists in restarting the engine quickly and smoothly, further reducing noise and fuel consumption during frequent stops in city traffic.

Regenerative braking is another key feature of mild hybrid powertrains that contributes to environmental benefits. By capturing energy typically lost during deceleration and braking, these systems reduce overall energy consumption and, consequently, emissions. This process also helps to minimize brake wear, reducing the release of particulate matter from brake pads into the environment.

The electric assist provided by mild hybrid systems allows for downsizing of the internal combustion engine without compromising performance. Smaller engines generally produce less noise and vibration, contributing to a quieter driving experience and reduced noise pollution in urban areas. Additionally, the reduced engine size leads to improved fuel efficiency and lower emissions across various driving conditions.

Mild hybrid powertrains also enable more precise control over engine operation, allowing for optimization of combustion processes. This results in cleaner exhaust emissions and reduced noise from the engine, particularly during acceleration and at low speeds. The electric motor's ability to provide instant torque can smooth out power delivery, further reducing noise and vibration associated with traditional powertrains.

In terms of lifecycle environmental impact, mild hybrid systems generally require fewer additional components compared to full hybrid or electric vehicles. This can lead to reduced manufacturing complexity and potentially lower environmental costs associated with production and end-of-life disposal. However, the additional battery and electric components do introduce some environmental considerations, particularly regarding the sourcing and recycling of materials used in their production.

Overall, the implementation of mild hybrid powertrains in vehicle noise reduction strategies offers a balanced approach to improving environmental performance. By addressing both noise pollution and emissions, these systems contribute to creating more sustainable and livable urban environments while providing a stepping stone towards more comprehensive electrification of transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!