What Role Do Sodium-Ion Battery Cathode Materials Play in Cycle Life Extension

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium-Ion Battery Cathode Evolution and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The evolution of cathode materials for SIBs has been a critical factor in determining their performance, particularly in terms of cycle life extension. The journey of sodium-ion battery cathode development began in the 1980s with the discovery of P2-type layered oxide materials, but significant progress has accelerated only in the past decade.

Early cathode materials for SIBs were primarily focused on layered transition metal oxides, which demonstrated reasonable sodium storage capabilities but suffered from structural instability during repeated charge-discharge cycles. This instability led to rapid capacity fading and limited cycle life, presenting a major obstacle to commercial viability. The technological evolution then shifted toward polyanionic compounds, Prussian blue analogs, and various nanostructured materials designed to accommodate the larger ionic radius of sodium compared to lithium.

The development trajectory has been guided by several key objectives. Primary among these is structural stability enhancement during sodium insertion/extraction processes. Researchers have focused on designing cathode materials with robust frameworks that can withstand the mechanical stress associated with the larger sodium ions' movement. This has led to the exploration of various crystal structures including layered oxides (P2, O3, P3 types), polyanionic compounds (NASICON-type), and Prussian blue analogs.

Another critical objective has been addressing the kinetic limitations of sodium-ion transport. The larger size of sodium ions compared to lithium ions results in slower diffusion kinetics, which negatively impacts rate capability and cycle life. Consequently, significant research efforts have been directed toward optimizing particle morphology, reducing diffusion pathways through nanostructuring, and enhancing the intrinsic ionic conductivity of cathode materials.

The evolution of SIB cathode materials has also been driven by the need to increase energy density while maintaining cycle stability. This has prompted investigations into high-voltage cathode materials capable of delivering higher specific capacities without compromising structural integrity. Recent advances include the development of sodium-rich layered oxides and composite materials that combine the advantages of different structural types.

Current research objectives focus on understanding and mitigating degradation mechanisms at the electrode-electrolyte interface, which significantly impact cycle life. This includes surface coating strategies, electrolyte optimization, and the development of artificial solid-electrolyte interphases to protect cathode materials from parasitic reactions. Additionally, there is growing emphasis on sustainable and environmentally friendly cathode materials that can be synthesized using low-energy processes and abundant precursors.

Early cathode materials for SIBs were primarily focused on layered transition metal oxides, which demonstrated reasonable sodium storage capabilities but suffered from structural instability during repeated charge-discharge cycles. This instability led to rapid capacity fading and limited cycle life, presenting a major obstacle to commercial viability. The technological evolution then shifted toward polyanionic compounds, Prussian blue analogs, and various nanostructured materials designed to accommodate the larger ionic radius of sodium compared to lithium.

The development trajectory has been guided by several key objectives. Primary among these is structural stability enhancement during sodium insertion/extraction processes. Researchers have focused on designing cathode materials with robust frameworks that can withstand the mechanical stress associated with the larger sodium ions' movement. This has led to the exploration of various crystal structures including layered oxides (P2, O3, P3 types), polyanionic compounds (NASICON-type), and Prussian blue analogs.

Another critical objective has been addressing the kinetic limitations of sodium-ion transport. The larger size of sodium ions compared to lithium ions results in slower diffusion kinetics, which negatively impacts rate capability and cycle life. Consequently, significant research efforts have been directed toward optimizing particle morphology, reducing diffusion pathways through nanostructuring, and enhancing the intrinsic ionic conductivity of cathode materials.

The evolution of SIB cathode materials has also been driven by the need to increase energy density while maintaining cycle stability. This has prompted investigations into high-voltage cathode materials capable of delivering higher specific capacities without compromising structural integrity. Recent advances include the development of sodium-rich layered oxides and composite materials that combine the advantages of different structural types.

Current research objectives focus on understanding and mitigating degradation mechanisms at the electrode-electrolyte interface, which significantly impact cycle life. This includes surface coating strategies, electrolyte optimization, and the development of artificial solid-electrolyte interphases to protect cathode materials from parasitic reactions. Additionally, there is growing emphasis on sustainable and environmentally friendly cathode materials that can be synthesized using low-energy processes and abundant precursors.

Market Demand Analysis for Long-Cycle Sodium-Ion Batteries

The global energy storage market is witnessing a significant shift towards sustainable and cost-effective solutions, with sodium-ion batteries emerging as a promising alternative to lithium-ion technologies. Market research indicates that the global energy storage market is projected to reach $546 billion by 2035, with a substantial portion potentially addressable by sodium-ion batteries, particularly in stationary storage applications where energy density constraints are less critical than in electric vehicles.

Long-cycle sodium-ion batteries address a critical market need across multiple sectors. In grid-scale energy storage, where batteries must withstand thousands of charge-discharge cycles over 10-15 year lifespans, the demand for durable and cost-effective solutions is particularly acute. Utility companies and renewable energy developers require storage solutions that maintain capacity retention above 80% after 3,000-5,000 cycles to ensure economic viability of their investments.

The electric transportation sector represents another significant market opportunity, especially for two and three-wheelers in emerging economies where cost sensitivity outweighs energy density requirements. Market analysis reveals that in countries like India and China, the potential market for sodium-ion batteries in light electric vehicles could exceed $20 billion by 2030, provided cycle life improvements make total cost of ownership competitive with lead-acid alternatives.

Consumer electronics manufacturers are increasingly seeking alternatives to lithium-ion batteries due to supply chain vulnerabilities and cost volatility. Extended cycle life in sodium-ion batteries would enable manufacturers to offer longer warranty periods and improved product longevity, addressing growing consumer demand for sustainable electronics with reduced environmental impact.

Industrial applications, including backup power systems and material handling equipment, represent a market segment where the trade-off between initial cost and operational lifetime is carefully evaluated. Research indicates that if sodium-ion batteries can achieve 2,000+ cycles at competitive costs, they could capture up to 25% of the industrial battery market within the next decade.

Market adoption trends suggest that early commercial applications of sodium-ion batteries are focusing on stationary storage, where the technology's advantages in safety, low-temperature performance, and potentially longer cycle life outweigh its current energy density limitations. Several major utility companies have announced pilot projects to evaluate sodium-ion technology for grid applications, signaling growing market interest.

The demand for extended cycle life is further driven by sustainability considerations, as longer-lasting batteries reduce resource consumption and waste generation. This aligns with increasingly stringent environmental regulations and corporate sustainability commitments, creating market pull for technologies that demonstrate improved lifecycle performance metrics.

Long-cycle sodium-ion batteries address a critical market need across multiple sectors. In grid-scale energy storage, where batteries must withstand thousands of charge-discharge cycles over 10-15 year lifespans, the demand for durable and cost-effective solutions is particularly acute. Utility companies and renewable energy developers require storage solutions that maintain capacity retention above 80% after 3,000-5,000 cycles to ensure economic viability of their investments.

The electric transportation sector represents another significant market opportunity, especially for two and three-wheelers in emerging economies where cost sensitivity outweighs energy density requirements. Market analysis reveals that in countries like India and China, the potential market for sodium-ion batteries in light electric vehicles could exceed $20 billion by 2030, provided cycle life improvements make total cost of ownership competitive with lead-acid alternatives.

Consumer electronics manufacturers are increasingly seeking alternatives to lithium-ion batteries due to supply chain vulnerabilities and cost volatility. Extended cycle life in sodium-ion batteries would enable manufacturers to offer longer warranty periods and improved product longevity, addressing growing consumer demand for sustainable electronics with reduced environmental impact.

Industrial applications, including backup power systems and material handling equipment, represent a market segment where the trade-off between initial cost and operational lifetime is carefully evaluated. Research indicates that if sodium-ion batteries can achieve 2,000+ cycles at competitive costs, they could capture up to 25% of the industrial battery market within the next decade.

Market adoption trends suggest that early commercial applications of sodium-ion batteries are focusing on stationary storage, where the technology's advantages in safety, low-temperature performance, and potentially longer cycle life outweigh its current energy density limitations. Several major utility companies have announced pilot projects to evaluate sodium-ion technology for grid applications, signaling growing market interest.

The demand for extended cycle life is further driven by sustainability considerations, as longer-lasting batteries reduce resource consumption and waste generation. This aligns with increasingly stringent environmental regulations and corporate sustainability commitments, creating market pull for technologies that demonstrate improved lifecycle performance metrics.

Current Cathode Materials Landscape and Technical Barriers

The sodium-ion battery cathode materials landscape is currently dominated by several key material families, each with distinct advantages and limitations affecting cycle life. Layered transition metal oxides (NaxMO2, where M represents metals like Fe, Mn, Ni, Co) represent the most extensively studied category, offering high theoretical capacities (>200 mAh/g) and operating voltages. However, these materials suffer from structural instability during repeated sodium insertion/extraction, leading to capacity fading after extended cycling. Phase transitions and irreversible structural changes during cycling remain significant barriers to their commercial viability.

Polyanionic compounds, particularly sodium vanadium phosphates (Na3V2(PO4)3) and sodium iron phosphates (NaFePO4), demonstrate superior structural stability during cycling compared to layered oxides. Their robust three-dimensional frameworks better accommodate sodium-ion movement without significant structural degradation. Nevertheless, these materials typically deliver lower specific capacities (100-120 mAh/g) and face challenges related to electronic conductivity limitations that necessitate carbon coating or nanostructuring strategies.

Prussian blue analogs (PBAs) with the general formula NaxM[Fe(CN)6]·yH2O have emerged as promising candidates due to their open framework structure and excellent cycling stability. Their ability to withstand thousands of cycles without significant capacity loss makes them particularly attractive for long-life applications. However, technical barriers include water sensitivity during synthesis, sodium vacancy control, and relatively low energy density compared to lithium-ion counterparts.

Organic cathode materials represent an emerging class with potential sustainability advantages but face significant cycle life limitations due to dissolution in electrolytes and poor electronic conductivity. Current research focuses on polymer-based materials and organic-inorganic composites to address these shortcomings.

The technical barriers limiting cathode performance in cycle life extension include sodium-ion diffusion kinetics, which are inherently slower than lithium ions due to the larger ionic radius (1.02Å vs. 0.76Å). This leads to increased mechanical stress during cycling and accelerated structural degradation. Additionally, electrolyte compatibility issues persist, with many cathode materials experiencing surface degradation from side reactions with conventional electrolytes.

Interfacial stability represents another critical challenge, with cathode-electrolyte interfaces often developing resistive layers that impede ion transport over extended cycling. Current research approaches focus on surface modifications, dopant strategies, and advanced electrolyte formulations to mitigate these effects. Computational modeling and in-situ characterization techniques are increasingly employed to understand degradation mechanisms at atomic and molecular levels, guiding rational design of next-generation materials with enhanced cycle life.

Polyanionic compounds, particularly sodium vanadium phosphates (Na3V2(PO4)3) and sodium iron phosphates (NaFePO4), demonstrate superior structural stability during cycling compared to layered oxides. Their robust three-dimensional frameworks better accommodate sodium-ion movement without significant structural degradation. Nevertheless, these materials typically deliver lower specific capacities (100-120 mAh/g) and face challenges related to electronic conductivity limitations that necessitate carbon coating or nanostructuring strategies.

Prussian blue analogs (PBAs) with the general formula NaxM[Fe(CN)6]·yH2O have emerged as promising candidates due to their open framework structure and excellent cycling stability. Their ability to withstand thousands of cycles without significant capacity loss makes them particularly attractive for long-life applications. However, technical barriers include water sensitivity during synthesis, sodium vacancy control, and relatively low energy density compared to lithium-ion counterparts.

Organic cathode materials represent an emerging class with potential sustainability advantages but face significant cycle life limitations due to dissolution in electrolytes and poor electronic conductivity. Current research focuses on polymer-based materials and organic-inorganic composites to address these shortcomings.

The technical barriers limiting cathode performance in cycle life extension include sodium-ion diffusion kinetics, which are inherently slower than lithium ions due to the larger ionic radius (1.02Å vs. 0.76Å). This leads to increased mechanical stress during cycling and accelerated structural degradation. Additionally, electrolyte compatibility issues persist, with many cathode materials experiencing surface degradation from side reactions with conventional electrolytes.

Interfacial stability represents another critical challenge, with cathode-electrolyte interfaces often developing resistive layers that impede ion transport over extended cycling. Current research approaches focus on surface modifications, dopant strategies, and advanced electrolyte formulations to mitigate these effects. Computational modeling and in-situ characterization techniques are increasingly employed to understand degradation mechanisms at atomic and molecular levels, guiding rational design of next-generation materials with enhanced cycle life.

Current Cathode Design Strategies for Cycle Life Extension

01 Layered transition metal oxide cathode materials

Layered transition metal oxides, particularly sodium-containing compounds like Na₃V₂(PO₄)₂F₃, NaxMO₂ (where M represents transition metals such as Fe, Mn, Co, Ni), are widely used as cathode materials for sodium-ion batteries. These materials offer high theoretical capacity and good structural stability during sodium insertion/extraction processes. Modifications to their crystal structure and composition can significantly improve cycle life by reducing structural degradation during repeated charge-discharge cycles.- Layered transition metal oxide cathode materials: Layered transition metal oxides, particularly sodium transition metal oxides with structures similar to NaxMO2 (where M represents transition metals like Fe, Mn, Ni, Co), are widely used as cathode materials in sodium-ion batteries. These materials offer high theoretical capacity and good structural stability during sodium ion insertion/extraction. Various doping strategies and composition optimizations can significantly improve their cycle life by stabilizing the crystal structure during repeated charge-discharge cycles.

- Prussian blue analogs for enhanced cycling stability: Prussian blue analogs (PBAs) with the general formula NaxM[Fe(CN)6]·yH2O (where M is a transition metal) represent an important class of cathode materials for sodium-ion batteries. These materials feature an open framework structure that facilitates fast sodium ion diffusion and minimal structural changes during cycling. Modified synthesis methods and compositional engineering of PBAs can effectively reduce lattice water content and structural defects, leading to significantly improved cycle life and capacity retention.

- Polyanionic compounds as stable cathode materials: Polyanionic compounds, including phosphates (NaMPO4), pyrophosphates (Na2MP2O7), fluorophosphates (NaMPO4F), and NASICON-type materials, offer excellent cycling stability for sodium-ion batteries. The strong covalent bonds between oxygen and the non-metal elements (P, S, Si) create stable three-dimensional frameworks that resist structural degradation during repeated sodium insertion/extraction. These materials typically deliver moderate capacity but exceptional cycle life, making them suitable for long-term energy storage applications.

- Surface coating and interface engineering: Surface modification techniques, including carbon coating, metal oxide coating, and polymer coating, significantly enhance the cycle life of sodium-ion battery cathode materials. These protective layers prevent direct contact between the cathode material and the electrolyte, reducing unwanted side reactions and electrolyte decomposition. Additionally, they improve the electronic conductivity and mechanical stability of the cathode particles, leading to better capacity retention and extended cycle life under various operating conditions.

- Electrolyte optimization for cathode stability: The composition and properties of the electrolyte significantly impact the cycle life of sodium-ion battery cathodes. Advanced electrolyte formulations containing specific additives can form stable solid electrolyte interphase (SEI) layers on cathode surfaces, preventing continuous electrolyte decomposition and cathode dissolution. Optimized electrolyte systems with appropriate sodium salts, solvents, and functional additives effectively mitigate cathode degradation mechanisms, including transition metal dissolution, structural collapse, and gas evolution, thereby extending the cycle life of various cathode materials.

02 Prussian blue analogs for enhanced cycle stability

Prussian blue analogs (PBAs) with the general formula NaxM[Fe(CN)6]·yH₂O (where M represents transition metals) demonstrate excellent cycle life due to their open framework structure that facilitates rapid sodium-ion insertion/extraction with minimal volume change. These materials exhibit high structural stability during cycling, reduced voltage hysteresis, and good capacity retention. Modifications including controlling water content, reducing defects, and incorporating specific transition metals can further enhance their electrochemical performance and longevity.Expand Specific Solutions03 Polyanionic compounds for long-term cycling

Polyanionic compounds, including phosphates (NaMPO₄), pyrophosphates (Na₂MP₂O₇), fluorophosphates (NaMPO₄F), and NASICON-type materials (Na₃V₂(PO₄)₃), offer excellent cycle life due to their robust three-dimensional frameworks. The strong covalent bonds between oxygen and phosphorus create stable structures that resist degradation during repeated sodium insertion/extraction. These materials typically demonstrate lower capacity but superior cycling stability compared to layered oxides, making them suitable for applications requiring long-term reliability.Expand Specific Solutions04 Carbon-based composite cathode materials

Incorporating carbon-based materials (graphene, carbon nanotubes, amorphous carbon) with active cathode materials creates composite structures that significantly improve cycle life. The carbon component enhances electrical conductivity, buffers volume changes during cycling, prevents particle agglomeration, and provides structural support. These composites demonstrate improved rate capability, reduced polarization, and enhanced structural integrity during long-term cycling, resulting in superior capacity retention compared to non-composite counterparts.Expand Specific Solutions05 Electrolyte optimization for cathode stability

The composition and additives in electrolytes significantly impact cathode material cycle life. Optimized electrolyte formulations can form stable solid electrolyte interphase (SEI) layers on cathode surfaces, preventing unwanted side reactions and dissolution of active materials. Additives such as fluoroethylene carbonate (FEC), vinylene carbonate (VC), and various salts can passivate cathode surfaces, suppress structural degradation, and mitigate the effects of moisture and oxygen contamination, thereby extending cycle life of sodium-ion battery cathode materials.Expand Specific Solutions

Leading Companies and Research Institutions in Na-Ion Cathode Development

Sodium-ion battery cathode materials play a crucial role in cycle life extension, with the market currently in an early growth phase characterized by increasing R&D investments. The global market is expanding rapidly, driven by the need for sustainable energy storage solutions, with projections showing significant growth potential. Technologically, companies like Shenzhen Zhenhua New Materials, CATL, and LG Energy Solution are leading development efforts, while research institutions such as Nankai University and Waseda University contribute fundamental innovations. The technology is approaching commercial viability, with Zhenhua achieving ten-ton sales by 2022, though challenges in energy density and stability remain. Industry collaboration between established battery manufacturers and specialized material developers is accelerating maturity in this promising alternative to lithium-ion technology.

Shenzhen Zhenhua New Material Co., Ltd.

Technical Solution: Shenzhen Zhenhua New Material has developed advanced sodium-ion battery cathode materials based on Prussian blue analogues (PBAs) with optimized framework structures. Their proprietary cathode formulation features a Na2FeFe(CN)6 framework with controlled vacancies and water content, addressing the key challenges of structural stability during long-term cycling. The company employs a specialized synthesis method that minimizes lattice defects and ensures uniform particle morphology, resulting in consistent sodium storage performance. Zhenhua's cathode materials undergo a proprietary carbon coating process that enhances electronic conductivity while protecting the active material from direct electrolyte contact. Their research demonstrates that these PBA-based cathodes can achieve over 5000 cycles with capacity retention exceeding 80% at 2C rate, positioning them as industry leaders in sodium-ion battery longevity. Additionally, Zhenhua has developed complementary electrolyte formulations containing film-forming additives that create a stable cathode-electrolyte interface, further enhancing cycle life by preventing continuous electrolyte decomposition during extended operation. The company's manufacturing process employs precise control of reaction parameters to ensure consistent crystal water content, which has been identified as a critical factor affecting the cycling stability of PBA cathodes.

Strengths: Exceptional cycling stability exceeding 5000 cycles; excellent rate capability supporting high-power applications; low-cost manufacturing using abundant raw materials. Weaknesses: Lower energy density compared to oxide-based cathodes; sensitivity to environmental moisture during manufacturing and storage; challenges in scaling production while maintaining precise control of crystal water content.

Xiamen Hithium New Energy Technology Co., Ltd.

Technical Solution: Xiamen Hithium has developed an innovative sodium-ion battery cathode technology focused on extending cycle life through structural optimization and surface engineering. Their approach centers on a layered oxide cathode material with a P2-type structure, specifically Na0.67Ni0.33Mn0.67O2, which has been modified with strategic dopants including copper and magnesium to stabilize the crystal structure during repeated sodium insertion/extraction. The company employs a proprietary gradient concentration design where the composition varies from surface to core, effectively distributing mechanical stress during cycling. Hithium's cathode particles undergo a specialized carbon coating process that creates a conductive network while protecting active materials from direct electrolyte contact. Their research demonstrates that this cathode design achieves over 3000 cycles with capacity retention exceeding 85% at 1C rate. Additionally, Hithium has developed a complementary electrolyte formulation containing film-forming additives that create a stable cathode-electrolyte interface, further enhancing cycle life by preventing continuous electrolyte decomposition and cathode dissolution during long-term operation.

Strengths: Superior cycling stability suitable for stationary energy storage applications; excellent rate capability supporting grid frequency regulation; cost-effective manufacturing using earth-abundant elements. Weaknesses: Lower energy density compared to commercial lithium-ion batteries; performance degradation at low temperatures; challenges in achieving consistent quality in large-scale production.

Key Patents and Research on Cathode Structural Stability

Sodium ion battery positive electrode material, preparation method therefor and application thereof

PatentActiveUS20210151767A1

Innovation

- A method involving the preparation of sulfur-nitrogen doped carbon cathode materials using a sol-gel process with zwitterionic polymers, where methyl allyl polyoxyethylene ether, N,N-dimethyl (methacryloxyethyl) ammonium propanesulfonate, and acrylic acid are reacted to form a zwitterionic polymer solution, mixed with sodium vanadium phosphate, and then sintered to enhance conductivity and stability.

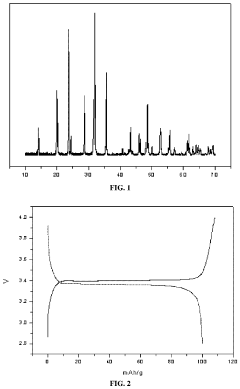

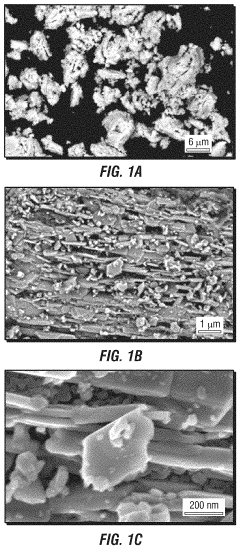

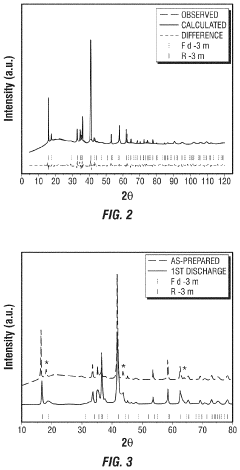

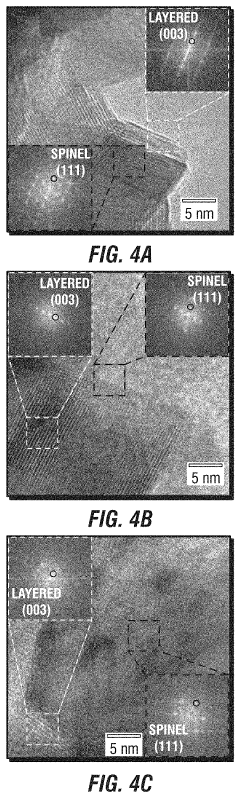

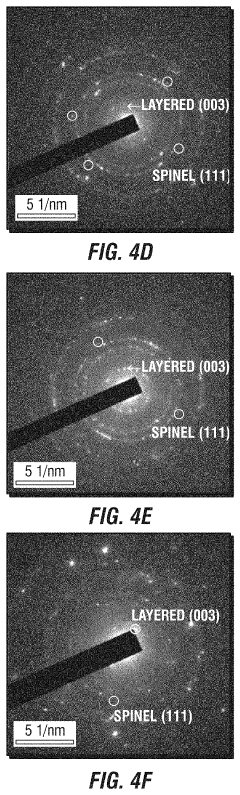

Li-substituted layered spinel cathode materials for sodium ion batteries

PatentActiveUS20210104742A1

Innovation

- A Li-substituted layered-tunneled O3/spinel cathode material, Na0.87Li0.25Ni0.4Fe0.2Mn0.4O2, is developed, which maintains a mixed-phase structure with 94% layered and 6% spinel components, enhancing structural compatibility and Na ion diffusivity through intergrown phases, thereby improving cycling stability and rate capability.

Sustainability Impact of Advanced Na-Ion Cathode Materials

The advancement of sodium-ion battery cathode materials represents a significant step toward more sustainable energy storage solutions. Unlike lithium-ion batteries that rely on scarce and geographically concentrated lithium resources, sodium-ion batteries utilize sodium, which is abundant in the Earth's crust and oceans. This fundamental shift in raw material sourcing dramatically reduces the environmental footprint associated with resource extraction and processing.

Advanced Na-ion cathode materials, particularly those designed for extended cycle life, contribute to sustainability through multiple pathways. By enabling batteries to withstand thousands of charge-discharge cycles without significant degradation, these materials directly extend product lifespans. This longevity translates to fewer batteries produced and disposed of over time, reducing manufacturing energy requirements and waste generation throughout the product lifecycle.

The environmental benefits extend to carbon emissions as well. Manufacturing processes for advanced sodium-based cathodes typically require lower temperatures compared to their lithium counterparts, resulting in reduced energy consumption and associated greenhouse gas emissions. Research indicates that the carbon footprint of sodium-ion battery production could be up to 30% lower than equivalent lithium-ion technologies when optimized cathode materials are employed.

From a circular economy perspective, these advanced cathode materials offer promising recyclability characteristics. Many emerging sodium-ion cathode formulations are designed with end-of-life considerations, allowing for more efficient material recovery and reuse. This closed-loop approach minimizes waste and further reduces the need for virgin material extraction, aligning with sustainable development principles.

The socioeconomic sustainability impacts are equally significant. By reducing dependence on geopolitically sensitive materials like cobalt and lithium, sodium-ion technology promotes supply chain resilience and ethical sourcing. Communities previously impacted by exploitative mining practices stand to benefit from this transition to more abundant, widely distributed resources.

Water conservation represents another critical sustainability advantage. Lithium extraction, particularly from brine deposits, consumes substantial water resources in often water-stressed regions. In contrast, sodium processing typically requires significantly less water, helping preserve this vital resource in vulnerable ecosystems and communities.

As grid-scale energy storage becomes increasingly crucial for renewable energy integration, the sustainability benefits of advanced Na-ion cathode materials will scale accordingly, potentially transforming the environmental profile of global energy systems while supporting climate change mitigation efforts.

Advanced Na-ion cathode materials, particularly those designed for extended cycle life, contribute to sustainability through multiple pathways. By enabling batteries to withstand thousands of charge-discharge cycles without significant degradation, these materials directly extend product lifespans. This longevity translates to fewer batteries produced and disposed of over time, reducing manufacturing energy requirements and waste generation throughout the product lifecycle.

The environmental benefits extend to carbon emissions as well. Manufacturing processes for advanced sodium-based cathodes typically require lower temperatures compared to their lithium counterparts, resulting in reduced energy consumption and associated greenhouse gas emissions. Research indicates that the carbon footprint of sodium-ion battery production could be up to 30% lower than equivalent lithium-ion technologies when optimized cathode materials are employed.

From a circular economy perspective, these advanced cathode materials offer promising recyclability characteristics. Many emerging sodium-ion cathode formulations are designed with end-of-life considerations, allowing for more efficient material recovery and reuse. This closed-loop approach minimizes waste and further reduces the need for virgin material extraction, aligning with sustainable development principles.

The socioeconomic sustainability impacts are equally significant. By reducing dependence on geopolitically sensitive materials like cobalt and lithium, sodium-ion technology promotes supply chain resilience and ethical sourcing. Communities previously impacted by exploitative mining practices stand to benefit from this transition to more abundant, widely distributed resources.

Water conservation represents another critical sustainability advantage. Lithium extraction, particularly from brine deposits, consumes substantial water resources in often water-stressed regions. In contrast, sodium processing typically requires significantly less water, helping preserve this vital resource in vulnerable ecosystems and communities.

As grid-scale energy storage becomes increasingly crucial for renewable energy integration, the sustainability benefits of advanced Na-ion cathode materials will scale accordingly, potentially transforming the environmental profile of global energy systems while supporting climate change mitigation efforts.

Cost-Performance Analysis of Emerging Cathode Technologies

When evaluating sodium-ion battery cathode materials for cycle life extension, cost-performance analysis becomes a critical factor in determining commercial viability. Current emerging cathode technologies for sodium-ion batteries present varying cost structures that directly impact their market adoption potential. Layered oxide materials (NaxMO2, where M represents transition metals) offer moderate production costs due to established manufacturing processes, but their performance-to-cost ratio is challenged by capacity fading over extended cycling.

Prussian blue analogs (PBAs) represent one of the most cost-effective cathode options, with raw material costs approximately 30-40% lower than comparable lithium-ion cathode materials. Their simple synthesis routes and abundant precursors contribute to manufacturing scalability. However, this cost advantage must be weighed against their lower energy density, which necessitates larger battery packs for equivalent energy storage.

Polyanionic compounds such as NaFePO4 and Na3V2(PO4)3 present an intermediate cost profile. While their synthesis requires more complex procedures than PBAs, their exceptional structural stability translates to longer cycle life, potentially offsetting initial higher production costs through extended service lifetimes. Economic modeling suggests that these materials may achieve cost parity with lithium-ion technologies when factoring in total lifecycle costs.

Recent advancements in organic cathode materials show promising cost trajectories, with potential raw material cost reductions of up to 60% compared to inorganic alternatives. However, their current performance limitations, particularly lower conductivity and dissolution issues, require additional engineering solutions that increase overall system costs.

Manufacturing scale remains a significant cost factor across all cathode technologies. Current small-scale production inflates costs by 2-3 times compared to projected mass production scenarios. Industry analysis indicates that achieving cost parity with lithium-ion batteries requires production volumes exceeding 1 GWh annually, a threshold that has not yet been reached for sodium-ion battery manufacturing.

Performance metrics directly tied to cycle life extension—such as capacity retention and coulombic efficiency—must be evaluated against manufacturing complexity and material costs. Cathode materials demonstrating superior cycle life often incorporate more expensive dopants or require precision-controlled synthesis conditions, creating a complex optimization challenge between longevity and affordability. This balance will ultimately determine which sodium-ion cathode technologies achieve commercial breakthrough.

Prussian blue analogs (PBAs) represent one of the most cost-effective cathode options, with raw material costs approximately 30-40% lower than comparable lithium-ion cathode materials. Their simple synthesis routes and abundant precursors contribute to manufacturing scalability. However, this cost advantage must be weighed against their lower energy density, which necessitates larger battery packs for equivalent energy storage.

Polyanionic compounds such as NaFePO4 and Na3V2(PO4)3 present an intermediate cost profile. While their synthesis requires more complex procedures than PBAs, their exceptional structural stability translates to longer cycle life, potentially offsetting initial higher production costs through extended service lifetimes. Economic modeling suggests that these materials may achieve cost parity with lithium-ion technologies when factoring in total lifecycle costs.

Recent advancements in organic cathode materials show promising cost trajectories, with potential raw material cost reductions of up to 60% compared to inorganic alternatives. However, their current performance limitations, particularly lower conductivity and dissolution issues, require additional engineering solutions that increase overall system costs.

Manufacturing scale remains a significant cost factor across all cathode technologies. Current small-scale production inflates costs by 2-3 times compared to projected mass production scenarios. Industry analysis indicates that achieving cost parity with lithium-ion batteries requires production volumes exceeding 1 GWh annually, a threshold that has not yet been reached for sodium-ion battery manufacturing.

Performance metrics directly tied to cycle life extension—such as capacity retention and coulombic efficiency—must be evaluated against manufacturing complexity and material costs. Cathode materials demonstrating superior cycle life often incorporate more expensive dopants or require precision-controlled synthesis conditions, creating a complex optimization challenge between longevity and affordability. This balance will ultimately determine which sodium-ion cathode technologies achieve commercial breakthrough.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!