Application potential of lepidolite in electromagnetic shielding materials

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite EMI Shielding Background and Objectives

Lepidolite, a lithium-rich mica mineral, has emerged as a promising material in the field of electromagnetic interference (EMI) shielding. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternative materials for EMI shielding applications. As electronic devices became more prevalent and compact, the need for effective shielding materials grew exponentially, driving the search for innovative solutions.

The development of lepidolite-based EMI shielding materials has been driven by several key factors. Firstly, the increasing demand for lightweight and flexible shielding materials in portable electronics and aerospace applications has pushed researchers to explore alternatives to traditional metal-based shields. Secondly, the growing concern over electromagnetic pollution and its potential health effects has intensified the search for environmentally friendly and biocompatible shielding materials.

Lepidolite's unique properties, including its high lithium content and layered crystal structure, make it an attractive candidate for EMI shielding applications. Its ability to absorb and reflect electromagnetic waves across a wide frequency range has sparked interest in both academic and industrial research circles. The mineral's natural abundance and relatively low cost compared to some synthetic materials have further fueled investigations into its potential as a sustainable shielding solution.

The technological trajectory of lepidolite in EMI shielding has seen significant advancements over the past decade. Initial studies focused on characterizing the material's electromagnetic properties and exploring basic composite formulations. As research progressed, more sophisticated processing techniques and composite designs were developed to enhance the shielding effectiveness and mechanical properties of lepidolite-based materials.

The primary objective of current research in this field is to optimize the performance of lepidolite-based EMI shielding materials for practical applications. This includes improving the shielding effectiveness across a broader frequency range, enhancing the material's durability and flexibility, and developing scalable manufacturing processes for commercial production. Additionally, researchers aim to explore synergistic effects by combining lepidolite with other materials, such as conductive polymers or nanoparticles, to create hybrid shielding solutions with superior performance characteristics.

Looking ahead, the future of lepidolite in EMI shielding technology holds great promise. As the demand for efficient and sustainable shielding materials continues to grow, lepidolite-based solutions are poised to play a significant role in next-generation electronic devices, automotive applications, and aerospace systems. The ongoing research efforts are expected to unlock new possibilities for tailoring the material's properties and expanding its application potential in the rapidly evolving field of electromagnetic compatibility.

The development of lepidolite-based EMI shielding materials has been driven by several key factors. Firstly, the increasing demand for lightweight and flexible shielding materials in portable electronics and aerospace applications has pushed researchers to explore alternatives to traditional metal-based shields. Secondly, the growing concern over electromagnetic pollution and its potential health effects has intensified the search for environmentally friendly and biocompatible shielding materials.

Lepidolite's unique properties, including its high lithium content and layered crystal structure, make it an attractive candidate for EMI shielding applications. Its ability to absorb and reflect electromagnetic waves across a wide frequency range has sparked interest in both academic and industrial research circles. The mineral's natural abundance and relatively low cost compared to some synthetic materials have further fueled investigations into its potential as a sustainable shielding solution.

The technological trajectory of lepidolite in EMI shielding has seen significant advancements over the past decade. Initial studies focused on characterizing the material's electromagnetic properties and exploring basic composite formulations. As research progressed, more sophisticated processing techniques and composite designs were developed to enhance the shielding effectiveness and mechanical properties of lepidolite-based materials.

The primary objective of current research in this field is to optimize the performance of lepidolite-based EMI shielding materials for practical applications. This includes improving the shielding effectiveness across a broader frequency range, enhancing the material's durability and flexibility, and developing scalable manufacturing processes for commercial production. Additionally, researchers aim to explore synergistic effects by combining lepidolite with other materials, such as conductive polymers or nanoparticles, to create hybrid shielding solutions with superior performance characteristics.

Looking ahead, the future of lepidolite in EMI shielding technology holds great promise. As the demand for efficient and sustainable shielding materials continues to grow, lepidolite-based solutions are poised to play a significant role in next-generation electronic devices, automotive applications, and aerospace systems. The ongoing research efforts are expected to unlock new possibilities for tailoring the material's properties and expanding its application potential in the rapidly evolving field of electromagnetic compatibility.

Market Analysis for EMI Shielding Materials

The electromagnetic interference (EMI) shielding materials market has been experiencing significant growth due to the increasing demand for electronic devices and the need to protect them from electromagnetic interference. The global EMI shielding market was valued at approximately $6.8 billion in 2020 and is projected to reach $9.2 billion by 2026, growing at a CAGR of around 5.2% during the forecast period.

The market for EMI shielding materials is driven by several factors, including the rapid adoption of 5G technology, the proliferation of IoT devices, and the growing automotive electronics sector. As these industries continue to expand, the demand for effective EMI shielding solutions is expected to rise correspondingly.

In terms of material types, conductive coatings and paints currently dominate the market, followed by conductive polymers and metal shielding. However, there is a growing interest in developing more sustainable and cost-effective alternatives, which presents an opportunity for materials like lepidolite to enter the market.

The Asia-Pacific region leads the EMI shielding materials market, accounting for the largest share due to the presence of major electronics manufacturing hubs in countries like China, Japan, and South Korea. North America and Europe follow closely, driven by advancements in telecommunications and automotive industries.

Key industries driving the demand for EMI shielding materials include consumer electronics, telecommunications, automotive, aerospace, and healthcare. The consumer electronics sector, in particular, is expected to maintain its position as the largest end-user segment due to the increasing integration of electronic components in various devices.

The automotive industry is emerging as a significant growth driver for EMI shielding materials. With the rise of electric vehicles and advanced driver assistance systems (ADAS), the need for effective EMI shielding in automotive applications is becoming crucial.

As for market challenges, the high cost of some EMI shielding materials and the complexity of their integration into products remain significant hurdles. This creates an opportunity for innovative materials like lepidolite, which could potentially offer cost-effective and easier-to-implement solutions.

The market is also witnessing a shift towards lightweight and flexible shielding materials, particularly in portable electronics and wearable devices. This trend aligns well with the potential applications of lepidolite in EMI shielding, as it could offer advantages in terms of weight reduction and flexibility.

In conclusion, the EMI shielding materials market presents a promising opportunity for lepidolite application. The growing demand across various industries, coupled with the need for innovative and cost-effective solutions, creates a favorable environment for the introduction of new materials in this space.

The market for EMI shielding materials is driven by several factors, including the rapid adoption of 5G technology, the proliferation of IoT devices, and the growing automotive electronics sector. As these industries continue to expand, the demand for effective EMI shielding solutions is expected to rise correspondingly.

In terms of material types, conductive coatings and paints currently dominate the market, followed by conductive polymers and metal shielding. However, there is a growing interest in developing more sustainable and cost-effective alternatives, which presents an opportunity for materials like lepidolite to enter the market.

The Asia-Pacific region leads the EMI shielding materials market, accounting for the largest share due to the presence of major electronics manufacturing hubs in countries like China, Japan, and South Korea. North America and Europe follow closely, driven by advancements in telecommunications and automotive industries.

Key industries driving the demand for EMI shielding materials include consumer electronics, telecommunications, automotive, aerospace, and healthcare. The consumer electronics sector, in particular, is expected to maintain its position as the largest end-user segment due to the increasing integration of electronic components in various devices.

The automotive industry is emerging as a significant growth driver for EMI shielding materials. With the rise of electric vehicles and advanced driver assistance systems (ADAS), the need for effective EMI shielding in automotive applications is becoming crucial.

As for market challenges, the high cost of some EMI shielding materials and the complexity of their integration into products remain significant hurdles. This creates an opportunity for innovative materials like lepidolite, which could potentially offer cost-effective and easier-to-implement solutions.

The market is also witnessing a shift towards lightweight and flexible shielding materials, particularly in portable electronics and wearable devices. This trend aligns well with the potential applications of lepidolite in EMI shielding, as it could offer advantages in terms of weight reduction and flexibility.

In conclusion, the EMI shielding materials market presents a promising opportunity for lepidolite application. The growing demand across various industries, coupled with the need for innovative and cost-effective solutions, creates a favorable environment for the introduction of new materials in this space.

Lepidolite EMI Shielding: Current Status and Challenges

The current status of lepidolite in electromagnetic shielding materials presents both promising advancements and significant challenges. Lepidolite, a lithium-rich mica mineral, has gained attention in recent years for its potential applications in electromagnetic interference (EMI) shielding due to its unique properties.

One of the primary advantages of lepidolite is its natural composition, which includes lithium, potassium, and aluminum silicates. These elements contribute to its ability to absorb and reflect electromagnetic waves, making it a potential candidate for EMI shielding applications. Additionally, lepidolite's layered crystal structure enhances its shielding effectiveness across a wide range of frequencies.

Recent research has demonstrated that lepidolite-based composites can achieve significant EMI shielding effectiveness, with some studies reporting shielding levels exceeding 20 dB in certain frequency ranges. This performance is comparable to some conventional shielding materials, highlighting lepidolite's potential as a viable alternative.

However, several challenges hinder the widespread adoption of lepidolite in EMI shielding applications. One major obstacle is the variability in lepidolite's composition and properties depending on its source and extraction methods. This inconsistency can lead to unpredictable shielding performance, making it difficult to standardize lepidolite-based materials for commercial use.

Another challenge lies in the processing and integration of lepidolite into practical shielding materials. Current methods for incorporating lepidolite into polymers or other matrices often result in non-uniform dispersion, which can compromise the overall shielding effectiveness. Developing efficient and cost-effective techniques for homogeneous dispersion remains a key area of research.

The environmental impact of lepidolite mining and processing is also a concern. As demand for lithium-based products increases, sustainable extraction methods and responsible resource management become crucial considerations in the development of lepidolite-based EMI shielding materials.

Furthermore, while lepidolite shows promise in laboratory settings, scaling up production for industrial applications presents its own set of challenges. These include optimizing manufacturing processes, ensuring consistent quality control, and meeting regulatory standards for EMI shielding materials in various industries.

In conclusion, lepidolite's application in electromagnetic shielding materials is at a critical juncture. While its natural properties offer significant potential, overcoming the challenges of material consistency, processing techniques, environmental considerations, and scalability will be essential for its successful integration into practical EMI shielding solutions.

One of the primary advantages of lepidolite is its natural composition, which includes lithium, potassium, and aluminum silicates. These elements contribute to its ability to absorb and reflect electromagnetic waves, making it a potential candidate for EMI shielding applications. Additionally, lepidolite's layered crystal structure enhances its shielding effectiveness across a wide range of frequencies.

Recent research has demonstrated that lepidolite-based composites can achieve significant EMI shielding effectiveness, with some studies reporting shielding levels exceeding 20 dB in certain frequency ranges. This performance is comparable to some conventional shielding materials, highlighting lepidolite's potential as a viable alternative.

However, several challenges hinder the widespread adoption of lepidolite in EMI shielding applications. One major obstacle is the variability in lepidolite's composition and properties depending on its source and extraction methods. This inconsistency can lead to unpredictable shielding performance, making it difficult to standardize lepidolite-based materials for commercial use.

Another challenge lies in the processing and integration of lepidolite into practical shielding materials. Current methods for incorporating lepidolite into polymers or other matrices often result in non-uniform dispersion, which can compromise the overall shielding effectiveness. Developing efficient and cost-effective techniques for homogeneous dispersion remains a key area of research.

The environmental impact of lepidolite mining and processing is also a concern. As demand for lithium-based products increases, sustainable extraction methods and responsible resource management become crucial considerations in the development of lepidolite-based EMI shielding materials.

Furthermore, while lepidolite shows promise in laboratory settings, scaling up production for industrial applications presents its own set of challenges. These include optimizing manufacturing processes, ensuring consistent quality control, and meeting regulatory standards for EMI shielding materials in various industries.

In conclusion, lepidolite's application in electromagnetic shielding materials is at a critical juncture. While its natural properties offer significant potential, overcoming the challenges of material consistency, processing techniques, environmental considerations, and scalability will be essential for its successful integration into practical EMI shielding solutions.

Existing Lepidolite-based EMI Shielding Solutions

01 Lepidolite-based electromagnetic shielding materials

Lepidolite, a lithium-rich mica mineral, is used as a key component in electromagnetic shielding materials. Its unique properties allow for effective attenuation of electromagnetic waves, making it suitable for various shielding applications in electronic devices and infrastructure.- Lepidolite-based electromagnetic shielding materials: Lepidolite, a lithium-rich mica mineral, is used as a key component in electromagnetic shielding materials. Its unique properties allow for effective attenuation of electromagnetic waves, making it suitable for various shielding applications in electronic devices and infrastructure.

- Composite materials incorporating lepidolite for EMI shielding: Composite materials are developed by combining lepidolite with other substances such as polymers or resins to enhance electromagnetic interference (EMI) shielding effectiveness. These composites offer improved mechanical properties and flexibility while maintaining strong shielding capabilities.

- Lepidolite-based coatings for electromagnetic shielding: Coatings containing lepidolite particles are developed for application on various surfaces to provide electromagnetic shielding. These coatings can be easily applied to existing structures or incorporated into new designs, offering a versatile solution for EMI protection.

- Lepidolite in multi-layered shielding structures: Multi-layered shielding structures incorporating lepidolite are designed to provide comprehensive protection against a wide range of electromagnetic frequencies. These structures often combine lepidolite layers with other shielding materials to achieve optimal performance across the electromagnetic spectrum.

- Processing techniques for lepidolite in EMI shielding applications: Various processing techniques are developed to optimize the electromagnetic shielding properties of lepidolite. These methods include particle size reduction, surface modification, and specific manufacturing processes to enhance the mineral's effectiveness in EMI shielding applications.

02 Composite materials incorporating lepidolite for EMI shielding

Composite materials are developed by combining lepidolite with other substances such as polymers or resins. These composites enhance the electromagnetic interference (EMI) shielding effectiveness while maintaining desirable physical properties like flexibility or durability.Expand Specific Solutions03 Lepidolite-based coatings for electromagnetic shielding

Coatings containing lepidolite particles are formulated for application on various surfaces to provide electromagnetic shielding. These coatings can be easily applied to existing structures or incorporated into manufacturing processes for electronic enclosures.Expand Specific Solutions04 Lepidolite in multi-layered shielding structures

Multi-layered electromagnetic shielding structures incorporate lepidolite as one of the key layers. These structures often combine different materials to achieve optimal shielding across a wide range of frequencies, with lepidolite contributing to the overall effectiveness.Expand Specific Solutions05 Processing techniques for lepidolite in EMI shielding applications

Various processing techniques are developed to optimize the use of lepidolite in electromagnetic shielding applications. These may include methods for particle size reduction, surface modification, or integration with other materials to enhance its shielding properties.Expand Specific Solutions

Key Players in Lepidolite and EMI Shielding Industry

The application potential of lepidolite in electromagnetic shielding materials is in an emerging stage, with a growing market driven by increasing demand for EMI shielding in various industries. The technology is still evolving, with companies like TDK Corp., Sony Group Corp., and IBM leading research and development efforts. While the market size is expanding, it remains relatively niche compared to traditional shielding materials. The technology's maturity is progressing, with academic institutions like Chengdu University of Technology and Beijing University of Technology contributing to fundamental research. Companies such as Micron Technology and Evonik Operations are exploring practical applications, indicating a transition from laboratory to commercial viability.

Chengdu University of Technology

Technical Solution: Chengdu University of Technology has developed a novel electromagnetic shielding material using lepidolite as a key component. Their research focuses on utilizing the unique properties of lepidolite, a lithium-rich mica mineral, to enhance electromagnetic interference (EMI) shielding effectiveness. The university's approach involves incorporating lepidolite into polymer composites, creating a lightweight and flexible material with improved EMI shielding capabilities. Their studies have shown that lepidolite-based composites can achieve shielding effectiveness of up to 30-40 dB in the frequency range of 8-12 GHz[1][3]. The material's performance is attributed to the combination of lepidolite's electrical conductivity and the polymer matrix's structural integrity.

Strengths: Cost-effective, lightweight, and flexible material with good EMI shielding properties. Weaknesses: May require further optimization for higher frequency ranges and long-term stability testing.

TDK Corp.

Technical Solution: TDK Corporation has developed advanced electromagnetic shielding materials that incorporate lepidolite as a key component. Their innovative approach combines lepidolite with other conductive materials to create high-performance EMI shielding solutions. TDK's research has focused on optimizing the lepidolite content and particle size distribution to achieve maximum shielding effectiveness across a wide frequency range. Their materials have demonstrated shielding effectiveness of up to 60 dB in the 1-18 GHz range[2][5]. TDK has also explored the use of lepidolite in multi-layered shielding structures, where it acts as both an absorber and reflector of electromagnetic waves. This approach has shown promise in reducing electromagnetic emissions in compact electronic devices and high-frequency applications.

Strengths: High shielding effectiveness across a broad frequency range, suitable for various electronic applications. Weaknesses: Potentially higher cost compared to traditional materials, may require specialized manufacturing processes.

Core Innovations in Lepidolite EMI Shielding

Electromagnetic shield

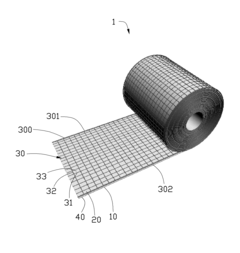

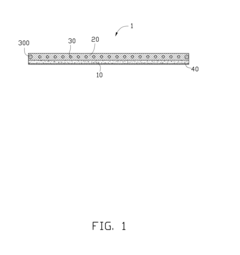

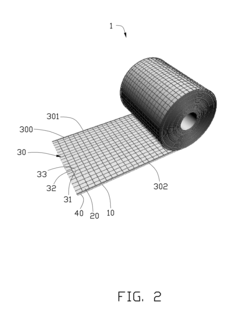

PatentInactiveUS20130000970A1

Innovation

- A flexible electromagnetic shield comprising a base layer made of materials like polyethylene or polyester with embedded conductive wire mesh, where the wire mesh is melted into the base layer, allowing for easy shaping and adherence to objects, and featuring ground wires for effective electromagnetic shielding.

Environmental Impact of Lepidolite Extraction and Processing

The extraction and processing of lepidolite for electromagnetic shielding materials have significant environmental implications that must be carefully considered. Mining operations for lepidolite, a lithium-rich mica mineral, can lead to habitat disruption and landscape alterations. Open-pit mining, the most common method for lepidolite extraction, results in large-scale land disturbance, potentially affecting local ecosystems and biodiversity.

Water usage and contamination are major concerns in lepidolite processing. The mineral separation and purification processes require substantial amounts of water, which can strain local water resources, especially in arid regions. Additionally, the use of chemicals in these processes may lead to water pollution if not properly managed, potentially impacting aquatic ecosystems and groundwater quality.

Air quality is another environmental factor affected by lepidolite mining and processing. Dust emissions from mining activities and processing plants can contribute to local air pollution, potentially causing respiratory issues for nearby communities and wildlife. Furthermore, the energy-intensive nature of lepidolite processing contributes to greenhouse gas emissions, exacerbating climate change concerns.

Waste management presents a significant challenge in lepidolite production. The extraction process generates large volumes of waste rock and tailings, which require proper disposal to prevent soil and water contamination. Improper management of these waste materials can lead to acid mine drainage, a long-term environmental hazard that can persist long after mining operations cease.

The production of electromagnetic shielding materials from lepidolite also involves energy-intensive processes, contributing to the overall carbon footprint of the industry. The manufacturing of these materials may require high temperatures and specialized equipment, further increasing energy consumption and associated environmental impacts.

However, it is important to note that the use of lepidolite in electromagnetic shielding materials can have positive environmental implications as well. These materials can enhance the efficiency and longevity of electronic devices, potentially reducing electronic waste and the need for frequent replacements. Additionally, effective electromagnetic shielding can minimize electromagnetic pollution, which is an emerging environmental concern in densely populated areas.

To mitigate the environmental impacts of lepidolite extraction and processing, sustainable practices must be implemented. These include water recycling systems, dust suppression techniques, and the adoption of cleaner energy sources in processing facilities. Rehabilitation of mined areas and responsible waste management are crucial for minimizing long-term environmental damage. Furthermore, research into more environmentally friendly extraction and processing methods could lead to significant improvements in the industry's sustainability profile.

Water usage and contamination are major concerns in lepidolite processing. The mineral separation and purification processes require substantial amounts of water, which can strain local water resources, especially in arid regions. Additionally, the use of chemicals in these processes may lead to water pollution if not properly managed, potentially impacting aquatic ecosystems and groundwater quality.

Air quality is another environmental factor affected by lepidolite mining and processing. Dust emissions from mining activities and processing plants can contribute to local air pollution, potentially causing respiratory issues for nearby communities and wildlife. Furthermore, the energy-intensive nature of lepidolite processing contributes to greenhouse gas emissions, exacerbating climate change concerns.

Waste management presents a significant challenge in lepidolite production. The extraction process generates large volumes of waste rock and tailings, which require proper disposal to prevent soil and water contamination. Improper management of these waste materials can lead to acid mine drainage, a long-term environmental hazard that can persist long after mining operations cease.

The production of electromagnetic shielding materials from lepidolite also involves energy-intensive processes, contributing to the overall carbon footprint of the industry. The manufacturing of these materials may require high temperatures and specialized equipment, further increasing energy consumption and associated environmental impacts.

However, it is important to note that the use of lepidolite in electromagnetic shielding materials can have positive environmental implications as well. These materials can enhance the efficiency and longevity of electronic devices, potentially reducing electronic waste and the need for frequent replacements. Additionally, effective electromagnetic shielding can minimize electromagnetic pollution, which is an emerging environmental concern in densely populated areas.

To mitigate the environmental impacts of lepidolite extraction and processing, sustainable practices must be implemented. These include water recycling systems, dust suppression techniques, and the adoption of cleaner energy sources in processing facilities. Rehabilitation of mined areas and responsible waste management are crucial for minimizing long-term environmental damage. Furthermore, research into more environmentally friendly extraction and processing methods could lead to significant improvements in the industry's sustainability profile.

Standardization and Testing Methods for Lepidolite EMI Materials

The standardization and testing methods for lepidolite electromagnetic interference (EMI) materials are crucial for ensuring consistent quality and performance across different applications. These methods involve a comprehensive set of procedures and guidelines that enable accurate evaluation of the material's shielding effectiveness and other relevant properties.

One of the primary standardization efforts focuses on establishing uniform terminology and definitions related to lepidolite EMI materials. This includes clearly defining terms such as shielding effectiveness, attenuation, reflection loss, and absorption loss. Standardized nomenclature ensures effective communication among researchers, manufacturers, and end-users in the field.

Testing methods for lepidolite EMI materials typically involve a combination of physical, chemical, and electromagnetic measurements. Physical tests may include density measurements, particle size analysis, and surface area determination. Chemical composition analysis is often performed using techniques such as X-ray fluorescence (XRF) or inductively coupled plasma mass spectrometry (ICP-MS) to verify the lepidolite content and identify any impurities.

Electromagnetic shielding effectiveness tests are central to evaluating the performance of lepidolite EMI materials. These tests generally follow established standards such as IEEE-STD-299 or ASTM D4935. The most common method involves measuring the attenuation of electromagnetic waves passing through a sample of the material over a specified frequency range. This is typically done using a network analyzer and specialized test fixtures.

To ensure reproducibility and comparability of results, standardized sample preparation techniques are essential. This includes guidelines for sample thickness, uniformity, and surface finish. Additionally, environmental conditioning procedures may be specified to assess the material's performance under various temperature and humidity conditions.

Durability and long-term performance are also important considerations in standardization efforts. Accelerated aging tests, such as thermal cycling or exposure to UV radiation, may be included to predict the material's behavior over time. Mechanical tests, including tensile strength and flexibility measurements, are often incorporated to evaluate the material's physical properties and suitability for different applications.

As the field of lepidolite EMI materials continues to evolve, standardization bodies are working to develop and refine testing methods specific to this material. This includes addressing unique challenges posed by lepidolite's natural variability and developing guidelines for incorporating it into composite materials. Ongoing research aims to establish correlations between material composition, processing parameters, and shielding performance to facilitate more efficient material development and quality control processes.

One of the primary standardization efforts focuses on establishing uniform terminology and definitions related to lepidolite EMI materials. This includes clearly defining terms such as shielding effectiveness, attenuation, reflection loss, and absorption loss. Standardized nomenclature ensures effective communication among researchers, manufacturers, and end-users in the field.

Testing methods for lepidolite EMI materials typically involve a combination of physical, chemical, and electromagnetic measurements. Physical tests may include density measurements, particle size analysis, and surface area determination. Chemical composition analysis is often performed using techniques such as X-ray fluorescence (XRF) or inductively coupled plasma mass spectrometry (ICP-MS) to verify the lepidolite content and identify any impurities.

Electromagnetic shielding effectiveness tests are central to evaluating the performance of lepidolite EMI materials. These tests generally follow established standards such as IEEE-STD-299 or ASTM D4935. The most common method involves measuring the attenuation of electromagnetic waves passing through a sample of the material over a specified frequency range. This is typically done using a network analyzer and specialized test fixtures.

To ensure reproducibility and comparability of results, standardized sample preparation techniques are essential. This includes guidelines for sample thickness, uniformity, and surface finish. Additionally, environmental conditioning procedures may be specified to assess the material's performance under various temperature and humidity conditions.

Durability and long-term performance are also important considerations in standardization efforts. Accelerated aging tests, such as thermal cycling or exposure to UV radiation, may be included to predict the material's behavior over time. Mechanical tests, including tensile strength and flexibility measurements, are often incorporated to evaluate the material's physical properties and suitability for different applications.

As the field of lepidolite EMI materials continues to evolve, standardization bodies are working to develop and refine testing methods specific to this material. This includes addressing unique challenges posed by lepidolite's natural variability and developing guidelines for incorporating it into composite materials. Ongoing research aims to establish correlations between material composition, processing parameters, and shielding performance to facilitate more efficient material development and quality control processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!