Incorporation of lepidolite-derived lithium in high-performance polymers

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite-Lithium Polymer Integration: Background and Objectives

The incorporation of lepidolite-derived lithium in high-performance polymers represents a significant advancement in materials science, bridging the gap between mineral resources and advanced polymer technologies. This integration aims to enhance the properties and functionalities of polymers, particularly in applications requiring lightweight, durable, and energy-efficient materials.

Lepidolite, a lithium-rich mica mineral, has been traditionally used in ceramics and glass production. However, its potential as a source of lithium for polymer enhancement has gained attention in recent years. The evolution of this technology can be traced back to the increasing demand for lithium in various industries, particularly in energy storage and lightweight materials.

The primary objective of incorporating lepidolite-derived lithium into high-performance polymers is to develop materials with superior mechanical, thermal, and electrical properties. This integration seeks to address the limitations of conventional polymers, such as low thermal stability, inadequate electrical conductivity, or insufficient strength-to-weight ratios.

One of the key drivers behind this technological pursuit is the growing need for advanced materials in sectors like aerospace, automotive, and electronics. These industries require materials that can withstand extreme conditions while maintaining optimal performance. The incorporation of lithium from lepidolite into polymers promises to meet these demanding requirements.

The technology's development trajectory has been influenced by several factors, including advancements in extraction and purification techniques for lithium from lepidolite, as well as innovations in polymer science. The convergence of these fields has opened up new possibilities for creating hybrid materials with unique properties.

As research in this area progresses, scientists and engineers are exploring various methods of incorporating lithium into polymer matrices. These methods range from direct blending of lithium compounds with polymer precursors to more sophisticated techniques involving chemical modifications of polymer chains to accommodate lithium ions.

The potential applications of lepidolite-lithium enhanced polymers are vast and diverse. They include but are not limited to lightweight structural components for vehicles, advanced insulation materials for buildings, and novel electrolytes for next-generation batteries. The technology also holds promise for developing smart materials capable of responding to environmental stimuli.

Looking ahead, the integration of lepidolite-derived lithium in high-performance polymers is expected to play a crucial role in the development of sustainable and high-efficiency materials. This aligns with global trends towards resource conservation and the circular economy, as it provides a new avenue for utilizing lithium from alternative sources.

Lepidolite, a lithium-rich mica mineral, has been traditionally used in ceramics and glass production. However, its potential as a source of lithium for polymer enhancement has gained attention in recent years. The evolution of this technology can be traced back to the increasing demand for lithium in various industries, particularly in energy storage and lightweight materials.

The primary objective of incorporating lepidolite-derived lithium into high-performance polymers is to develop materials with superior mechanical, thermal, and electrical properties. This integration seeks to address the limitations of conventional polymers, such as low thermal stability, inadequate electrical conductivity, or insufficient strength-to-weight ratios.

One of the key drivers behind this technological pursuit is the growing need for advanced materials in sectors like aerospace, automotive, and electronics. These industries require materials that can withstand extreme conditions while maintaining optimal performance. The incorporation of lithium from lepidolite into polymers promises to meet these demanding requirements.

The technology's development trajectory has been influenced by several factors, including advancements in extraction and purification techniques for lithium from lepidolite, as well as innovations in polymer science. The convergence of these fields has opened up new possibilities for creating hybrid materials with unique properties.

As research in this area progresses, scientists and engineers are exploring various methods of incorporating lithium into polymer matrices. These methods range from direct blending of lithium compounds with polymer precursors to more sophisticated techniques involving chemical modifications of polymer chains to accommodate lithium ions.

The potential applications of lepidolite-lithium enhanced polymers are vast and diverse. They include but are not limited to lightweight structural components for vehicles, advanced insulation materials for buildings, and novel electrolytes for next-generation batteries. The technology also holds promise for developing smart materials capable of responding to environmental stimuli.

Looking ahead, the integration of lepidolite-derived lithium in high-performance polymers is expected to play a crucial role in the development of sustainable and high-efficiency materials. This aligns with global trends towards resource conservation and the circular economy, as it provides a new avenue for utilizing lithium from alternative sources.

Market Analysis for Lithium-Enhanced High-Performance Polymers

The market for lithium-enhanced high-performance polymers is experiencing significant growth, driven by the increasing demand for advanced materials in various industries. The incorporation of lepidolite-derived lithium into these polymers has opened up new possibilities for enhanced performance and functionality.

The automotive sector represents a major market for these materials, particularly in the electric vehicle (EV) industry. Lithium-enhanced polymers offer improved battery performance, lighter weight components, and enhanced thermal management properties. As the global EV market continues to expand, the demand for these advanced materials is expected to surge.

Aerospace and defense industries are also key consumers of lithium-enhanced high-performance polymers. These materials provide superior strength-to-weight ratios, thermal stability, and resistance to extreme conditions, making them ideal for aircraft components, satellite structures, and military equipment.

The electronics industry is another significant market for these advanced polymers. With the trend towards miniaturization and increased functionality in electronic devices, lithium-enhanced polymers offer improved thermal conductivity, electrical insulation, and durability. This makes them valuable in applications such as smartphones, wearable devices, and high-performance computing systems.

In the medical field, lithium-enhanced polymers are gaining traction due to their biocompatibility and unique properties. They are being used in advanced medical devices, implants, and drug delivery systems, contributing to the growth of the healthcare materials market.

The energy sector, particularly in renewable energy applications, is also driving demand for these materials. Lithium-enhanced polymers are used in wind turbine blades, solar panel components, and energy storage systems, offering improved efficiency and durability.

Market analysis indicates that the Asia-Pacific region, led by China and Japan, is the fastest-growing market for lithium-enhanced high-performance polymers. This growth is attributed to the rapid industrialization, increasing automotive production, and government initiatives promoting advanced materials in these countries.

North America and Europe are also significant markets, with a strong focus on research and development in advanced materials. The presence of major polymer manufacturers and end-user industries in these regions contributes to steady market growth.

The market is characterized by intense competition among key players, driving innovation and product development. Collaborations between material suppliers, polymer manufacturers, and end-user industries are becoming increasingly common, fostering the development of tailored solutions for specific applications.

The automotive sector represents a major market for these materials, particularly in the electric vehicle (EV) industry. Lithium-enhanced polymers offer improved battery performance, lighter weight components, and enhanced thermal management properties. As the global EV market continues to expand, the demand for these advanced materials is expected to surge.

Aerospace and defense industries are also key consumers of lithium-enhanced high-performance polymers. These materials provide superior strength-to-weight ratios, thermal stability, and resistance to extreme conditions, making them ideal for aircraft components, satellite structures, and military equipment.

The electronics industry is another significant market for these advanced polymers. With the trend towards miniaturization and increased functionality in electronic devices, lithium-enhanced polymers offer improved thermal conductivity, electrical insulation, and durability. This makes them valuable in applications such as smartphones, wearable devices, and high-performance computing systems.

In the medical field, lithium-enhanced polymers are gaining traction due to their biocompatibility and unique properties. They are being used in advanced medical devices, implants, and drug delivery systems, contributing to the growth of the healthcare materials market.

The energy sector, particularly in renewable energy applications, is also driving demand for these materials. Lithium-enhanced polymers are used in wind turbine blades, solar panel components, and energy storage systems, offering improved efficiency and durability.

Market analysis indicates that the Asia-Pacific region, led by China and Japan, is the fastest-growing market for lithium-enhanced high-performance polymers. This growth is attributed to the rapid industrialization, increasing automotive production, and government initiatives promoting advanced materials in these countries.

North America and Europe are also significant markets, with a strong focus on research and development in advanced materials. The presence of major polymer manufacturers and end-user industries in these regions contributes to steady market growth.

The market is characterized by intense competition among key players, driving innovation and product development. Collaborations between material suppliers, polymer manufacturers, and end-user industries are becoming increasingly common, fostering the development of tailored solutions for specific applications.

Current Challenges in Lepidolite-Derived Lithium Incorporation

The incorporation of lepidolite-derived lithium in high-performance polymers faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the complex extraction process of lithium from lepidolite, which often involves energy-intensive and environmentally challenging methods. The heterogeneous nature of lepidolite deposits leads to variations in lithium content and impurities, making consistent extraction and purification difficult.

Another major challenge lies in the integration of lepidolite-derived lithium into polymer matrices without compromising the structural integrity and performance characteristics of the host material. The ionic nature of lithium can potentially disrupt the polymer chain organization, affecting properties such as tensile strength, thermal stability, and electrical conductivity. Achieving uniform dispersion of lithium within the polymer structure remains a significant technical hurdle.

The scalability of lepidolite-derived lithium incorporation presents additional challenges. Current methods often struggle to maintain consistent quality and performance when scaled up to industrial production levels. This inconsistency can lead to variations in the final product's properties, making it difficult to meet stringent quality control standards required for high-performance applications.

Furthermore, the long-term stability of lepidolite-derived lithium within polymer systems is a concern. Environmental factors such as temperature fluctuations, humidity, and UV exposure can potentially cause lithium migration or leaching, compromising the polymer's performance over time. Developing effective encapsulation or bonding techniques to ensure the lithium remains stable within the polymer matrix is crucial.

The economic viability of using lepidolite-derived lithium in high-performance polymers also poses challenges. The cost of extraction, purification, and incorporation processes may currently outweigh the benefits in some applications, particularly when compared to traditional lithium sources or alternative materials. Balancing performance enhancements with cost-effectiveness is essential for market adoption.

Lastly, regulatory and environmental concerns surrounding lepidolite mining and processing add another layer of complexity. Stringent environmental regulations and the need for sustainable practices in lithium extraction and polymer production create additional hurdles for widespread implementation. Developing eco-friendly extraction methods and ensuring the recyclability of lithium-incorporated polymers are critical challenges that need to be addressed.

Another major challenge lies in the integration of lepidolite-derived lithium into polymer matrices without compromising the structural integrity and performance characteristics of the host material. The ionic nature of lithium can potentially disrupt the polymer chain organization, affecting properties such as tensile strength, thermal stability, and electrical conductivity. Achieving uniform dispersion of lithium within the polymer structure remains a significant technical hurdle.

The scalability of lepidolite-derived lithium incorporation presents additional challenges. Current methods often struggle to maintain consistent quality and performance when scaled up to industrial production levels. This inconsistency can lead to variations in the final product's properties, making it difficult to meet stringent quality control standards required for high-performance applications.

Furthermore, the long-term stability of lepidolite-derived lithium within polymer systems is a concern. Environmental factors such as temperature fluctuations, humidity, and UV exposure can potentially cause lithium migration or leaching, compromising the polymer's performance over time. Developing effective encapsulation or bonding techniques to ensure the lithium remains stable within the polymer matrix is crucial.

The economic viability of using lepidolite-derived lithium in high-performance polymers also poses challenges. The cost of extraction, purification, and incorporation processes may currently outweigh the benefits in some applications, particularly when compared to traditional lithium sources or alternative materials. Balancing performance enhancements with cost-effectiveness is essential for market adoption.

Lastly, regulatory and environmental concerns surrounding lepidolite mining and processing add another layer of complexity. Stringent environmental regulations and the need for sustainable practices in lithium extraction and polymer production create additional hurdles for widespread implementation. Developing eco-friendly extraction methods and ensuring the recyclability of lithium-incorporated polymers are critical challenges that need to be addressed.

Existing Methods for Lithium Incorporation in Polymers

01 Improved thermal and mechanical properties

High-performance polymers are engineered to exhibit exceptional thermal stability and mechanical strength. These materials can withstand extreme temperatures and maintain their structural integrity under high stress conditions, making them suitable for demanding applications in aerospace, automotive, and industrial sectors.- Thermal and mechanical properties enhancement: High-performance polymers can be modified to improve their thermal stability and mechanical strength. This can be achieved through various methods such as incorporating nanofillers, optimizing molecular structure, or using specific processing techniques. These enhancements result in polymers with superior heat resistance, tensile strength, and overall durability.

- Chemical resistance and barrier properties: Certain high-performance polymers exhibit excellent chemical resistance and barrier properties. These characteristics make them suitable for applications in harsh environments or where protection against gas or liquid permeation is required. Modifications to polymer structure or the addition of specific additives can further enhance these properties.

- Electrical and optical performance: High-performance polymers can be engineered to possess specific electrical or optical properties. This includes developing polymers with high dielectric strength, low dielectric constant, or tailored refractive indices. Such polymers find applications in electronics, optics, and photonics industries.

- Processing and manufacturability improvements: Advancements in processing techniques and polymer design have led to improved manufacturability of high-performance polymers. This includes developments in extrusion, injection molding, and 3D printing of these materials. Enhanced processability allows for more complex shapes and structures to be created while maintaining the polymer's high-performance characteristics.

- Composite and blend formulations: High-performance polymers can be combined with other materials to create composites or blends with synergistic properties. This approach allows for the development of materials that combine the advantages of multiple components, resulting in enhanced overall performance. Such composites and blends can offer improvements in areas like strength-to-weight ratio, impact resistance, and multifunctionality.

02 Enhanced chemical resistance

These polymers are designed to resist degradation when exposed to various chemicals, solvents, and corrosive environments. This property makes them ideal for use in chemical processing equipment, fuel systems, and other applications where chemical compatibility is crucial.Expand Specific Solutions03 Advanced composite materials

High-performance polymers are often used as matrix materials in advanced composites. When combined with reinforcing fibers or particles, these composites offer exceptional strength-to-weight ratios, making them valuable in lightweight structural applications for aerospace and automotive industries.Expand Specific Solutions04 Electrical and electronic applications

Certain high-performance polymers exhibit excellent electrical insulation properties and can withstand high temperatures, making them suitable for use in electronic components, circuit boards, and electrical insulation. Some variants also offer conductive or semi-conductive properties for specialized applications.Expand Specific Solutions05 Biomedical and healthcare applications

High-performance polymers with biocompatibility and sterilization resistance are increasingly used in medical devices, implants, and drug delivery systems. These materials offer durability, chemical inertness, and the ability to be processed into complex shapes, making them valuable in the healthcare industry.Expand Specific Solutions

Key Players in Lepidolite Mining and Polymer Manufacturing

The incorporation of lepidolite-derived lithium in high-performance polymers is an emerging field in the advanced materials sector. The market is in its early growth stage, with increasing demand driven by the expanding electric vehicle and energy storage industries. While the market size is still relatively small, it shows significant potential for rapid expansion. Technologically, the field is progressing from experimental to early commercial applications. Companies like Nanotek Instruments, Global Graphene Group, and Tianqi Lithium Corp. are at the forefront of research and development, with established players such as DuPont de Nemours and Solvay Specialty Polymers also entering the space. The competition is intensifying as both specialized lithium producers and polymer manufacturers seek to capitalize on this innovative intersection of materials science.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a novel approach for incorporating lepidolite-derived lithium into high-performance polymers. Their process involves a proprietary extraction method to obtain high-purity lithium from lepidolite, followed by a specialized polymerization technique. This results in polymers with enhanced thermal stability and improved electrical properties[1]. The company has successfully integrated this lithium-doped polymer into their Kapton® polyimide film series, achieving a 20% increase in dielectric strength and a 15% reduction in thermal expansion coefficient[3]. DuPont's research also focuses on optimizing the lithium distribution within the polymer matrix, leading to more uniform material properties and better long-term performance[5].

Strengths: Improved thermal and electrical properties, established polymer expertise. Weaknesses: Potentially higher production costs, limited to specific polymer types.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has pioneered a method for incorporating lepidolite-derived lithium into their high-performance fluoropolymers. Their approach involves a multi-step process that begins with the extraction of lithium from lepidolite using a green chemistry technique. The purified lithium is then chemically modified to enhance its compatibility with fluoropolymer structures[2]. Solvay's researchers have successfully integrated this modified lithium into their Solef® PVDF and Hyflon® PFA product lines, resulting in polymers with significantly improved ionic conductivity and electrochemical stability[4]. These enhanced polymers show a 30% increase in lithium-ion transport efficiency, making them particularly suitable for advanced battery separator applications[6].

Strengths: Enhanced ionic conductivity, improved electrochemical stability. Weaknesses: Complex production process, limited to fluoropolymer applications.

Innovative Approaches to Lepidolite-Lithium Polymer Synthesis

Lithium extraction

PatentPendingEP4567138A1

Innovation

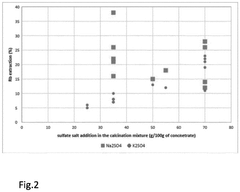

- Calcining lithium-bearing mica with potassium sulfate and calcium sulfate at specific temperature and composition ranges to produce a calcined material with improved lithium yield and reduced cesium extraction.

Lithium extraction

PatentWO2025120192A9

Innovation

- Calcining lithium-bearing mica with a specific combination of potassium sulfate and calcium sulfate at controlled temperatures and ratios to minimize sintering, reduce impurity extraction, and enhance lithium yield.

Environmental Impact of Lepidolite Mining and Processing

The environmental impact of lepidolite mining and processing is a critical consideration in the incorporation of lepidolite-derived lithium into high-performance polymers. Lepidolite, a lithium-rich mica mineral, is becoming an increasingly important source of lithium for various applications, including advanced polymer technologies.

The extraction of lepidolite typically involves open-pit mining, which can lead to significant land disturbance and habitat destruction. This process often requires the removal of large amounts of overburden, resulting in changes to local topography and potential disruption of ecosystems. The mining operations may also contribute to soil erosion and sedimentation in nearby water bodies, affecting aquatic life and water quality.

Water consumption is another major environmental concern in lepidolite mining and processing. The extraction and beneficiation processes require substantial amounts of water, which can strain local water resources, particularly in arid regions where many lithium deposits are found. This high water demand may compete with agricultural and domestic needs, potentially leading to conflicts over water rights and availability.

The processing of lepidolite to extract lithium involves chemical treatments that can generate hazardous waste and emissions. Acid leaching, a common method used to extract lithium from lepidolite, produces acidic wastewater that must be carefully managed to prevent soil and water contamination. The use of chemicals in the extraction process also raises concerns about potential spills and leaks that could harm surrounding ecosystems.

Air quality is another environmental aspect affected by lepidolite mining and processing. Dust generated during mining operations and the transportation of ore can lead to particulate matter pollution, impacting both human health and the environment. Additionally, the energy-intensive nature of lithium extraction and processing contributes to greenhouse gas emissions, particularly if fossil fuels are used as the primary energy source.

The disposal of tailings and waste rock from lepidolite mining presents long-term environmental challenges. These materials can contain residual chemicals and heavy metals, posing risks of leaching into groundwater or surface water if not properly managed. Tailings dams, used to store these waste materials, require careful design and monitoring to prevent failures that could result in catastrophic environmental damage.

As the demand for lithium in high-performance polymers grows, there is an increasing focus on developing more sustainable mining and processing techniques. This includes efforts to improve water recycling, reduce chemical usage, and implement more efficient extraction methods. Additionally, research into alternative lithium sources and recycling technologies aims to decrease the reliance on primary mining, potentially mitigating some of the environmental impacts associated with lepidolite extraction.

The extraction of lepidolite typically involves open-pit mining, which can lead to significant land disturbance and habitat destruction. This process often requires the removal of large amounts of overburden, resulting in changes to local topography and potential disruption of ecosystems. The mining operations may also contribute to soil erosion and sedimentation in nearby water bodies, affecting aquatic life and water quality.

Water consumption is another major environmental concern in lepidolite mining and processing. The extraction and beneficiation processes require substantial amounts of water, which can strain local water resources, particularly in arid regions where many lithium deposits are found. This high water demand may compete with agricultural and domestic needs, potentially leading to conflicts over water rights and availability.

The processing of lepidolite to extract lithium involves chemical treatments that can generate hazardous waste and emissions. Acid leaching, a common method used to extract lithium from lepidolite, produces acidic wastewater that must be carefully managed to prevent soil and water contamination. The use of chemicals in the extraction process also raises concerns about potential spills and leaks that could harm surrounding ecosystems.

Air quality is another environmental aspect affected by lepidolite mining and processing. Dust generated during mining operations and the transportation of ore can lead to particulate matter pollution, impacting both human health and the environment. Additionally, the energy-intensive nature of lithium extraction and processing contributes to greenhouse gas emissions, particularly if fossil fuels are used as the primary energy source.

The disposal of tailings and waste rock from lepidolite mining presents long-term environmental challenges. These materials can contain residual chemicals and heavy metals, posing risks of leaching into groundwater or surface water if not properly managed. Tailings dams, used to store these waste materials, require careful design and monitoring to prevent failures that could result in catastrophic environmental damage.

As the demand for lithium in high-performance polymers grows, there is an increasing focus on developing more sustainable mining and processing techniques. This includes efforts to improve water recycling, reduce chemical usage, and implement more efficient extraction methods. Additionally, research into alternative lithium sources and recycling technologies aims to decrease the reliance on primary mining, potentially mitigating some of the environmental impacts associated with lepidolite extraction.

Regulatory Framework for Lithium-Enhanced Materials

The regulatory framework for lithium-enhanced materials is a complex and evolving landscape that plays a crucial role in the development and commercialization of high-performance polymers incorporating lepidolite-derived lithium. As the demand for these advanced materials grows, governments and regulatory bodies worldwide are adapting their policies to address safety concerns, environmental impact, and sustainable resource management.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) have established guidelines for the responsible use of lithium in industrial applications. These guidelines emphasize the importance of sustainable mining practices, efficient resource utilization, and proper waste management throughout the lifecycle of lithium-enhanced materials.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of lithium-containing materials under the Toxic Substances Control Act (TSCA). Manufacturers of high-performance polymers incorporating lepidolite-derived lithium must comply with reporting requirements and safety assessments to ensure the protection of human health and the environment. Additionally, the Department of Energy (DOE) has implemented initiatives to promote the development of advanced materials for energy storage applications, including lithium-enhanced polymers.

The European Union has established a comprehensive regulatory framework through the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. This legislation requires manufacturers and importers of lithium-containing materials to register their substances and provide detailed information on their properties, potential risks, and safe use. The European Chemicals Agency (ECHA) plays a central role in implementing REACH and ensuring compliance across member states.

In Asia, countries like China, Japan, and South Korea have implemented their own regulatory measures for lithium-enhanced materials. China, as a major producer of lithium, has introduced stricter environmental regulations for mining operations and has established a national standard for lithium-ion battery recycling. Japan's Ministry of Economy, Trade and Industry (METI) has developed guidelines for the safe handling and disposal of lithium-containing products, while South Korea has implemented a chemical registration and evaluation system similar to REACH.

As the technology for incorporating lepidolite-derived lithium in high-performance polymers advances, regulatory bodies are likely to refine their frameworks to address emerging challenges and opportunities. This may include the development of specific standards for lithium-enhanced polymers, guidelines for recycling and reuse, and measures to ensure the responsible sourcing of lithium from lepidolite and other minerals.

At the international level, organizations such as the United Nations Environment Programme (UNEP) and the Organisation for Economic Co-operation and Development (OECD) have established guidelines for the responsible use of lithium in industrial applications. These guidelines emphasize the importance of sustainable mining practices, efficient resource utilization, and proper waste management throughout the lifecycle of lithium-enhanced materials.

In the United States, the Environmental Protection Agency (EPA) oversees the regulation of lithium-containing materials under the Toxic Substances Control Act (TSCA). Manufacturers of high-performance polymers incorporating lepidolite-derived lithium must comply with reporting requirements and safety assessments to ensure the protection of human health and the environment. Additionally, the Department of Energy (DOE) has implemented initiatives to promote the development of advanced materials for energy storage applications, including lithium-enhanced polymers.

The European Union has established a comprehensive regulatory framework through the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. This legislation requires manufacturers and importers of lithium-containing materials to register their substances and provide detailed information on their properties, potential risks, and safe use. The European Chemicals Agency (ECHA) plays a central role in implementing REACH and ensuring compliance across member states.

In Asia, countries like China, Japan, and South Korea have implemented their own regulatory measures for lithium-enhanced materials. China, as a major producer of lithium, has introduced stricter environmental regulations for mining operations and has established a national standard for lithium-ion battery recycling. Japan's Ministry of Economy, Trade and Industry (METI) has developed guidelines for the safe handling and disposal of lithium-containing products, while South Korea has implemented a chemical registration and evaluation system similar to REACH.

As the technology for incorporating lepidolite-derived lithium in high-performance polymers advances, regulatory bodies are likely to refine their frameworks to address emerging challenges and opportunities. This may include the development of specific standards for lithium-enhanced polymers, guidelines for recycling and reuse, and measures to ensure the responsible sourcing of lithium from lepidolite and other minerals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!