Artificial Photosynthesis-driven enzymatic synthesis advancements.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Artificial Photosynthesis Background and Objectives

Artificial photosynthesis represents one of nature's most elegant processes, wherein plants convert sunlight, water, and carbon dioxide into energy-rich compounds and oxygen. Since the early 20th century, scientists have been captivated by the possibility of mimicking this process to address global energy challenges. The evolution of artificial photosynthesis technology has progressed from basic photochemical reactions to sophisticated systems integrating light-harvesting components with catalytic centers.

The field gained significant momentum in the 1970s during the oil crisis, which highlighted the need for alternative energy sources. By the 1990s, researchers had developed rudimentary artificial photosynthetic systems capable of water splitting. The past two decades have witnessed remarkable advancements in materials science, nanotechnology, and molecular biology, accelerating progress in this domain.

Recent technological breakthroughs have enabled the coupling of artificial photosynthesis with enzymatic synthesis pathways, creating hybrid systems that harness solar energy to drive complex biochemical reactions. This integration represents a paradigm shift from traditional approaches that focused primarily on hydrogen production or carbon dioxide reduction.

The primary objective of artificial photosynthesis-driven enzymatic synthesis is to develop sustainable, efficient systems that convert abundant resources (sunlight, water, and carbon dioxide) into valuable chemicals and fuels without fossil fuel dependence. These systems aim to achieve higher efficiency than natural photosynthesis, which typically converts less than 1% of solar energy into chemical energy.

Current research targets include improving light absorption across the solar spectrum, enhancing charge separation efficiency, developing robust and selective catalysts, and optimizing the interface between photosystems and enzymatic pathways. Scientists are particularly focused on extending the stability of these hybrid systems, which currently suffer from relatively short operational lifetimes.

The ultimate goal extends beyond laboratory demonstrations to commercially viable technologies that can operate at scale. This includes developing systems capable of producing pharmaceuticals, fine chemicals, and biofuels with minimal environmental impact. The technology aims to revolutionize chemical manufacturing by eliminating energy-intensive processes and reducing dependence on petrochemical feedstocks.

As climate change concerns intensify and renewable energy technologies mature, artificial photosynthesis-driven enzymatic synthesis represents a promising frontier in green chemistry and sustainable manufacturing. The convergence of photocatalysis, enzyme engineering, and materials science is expected to yield transformative solutions for some of society's most pressing energy and environmental challenges.

The field gained significant momentum in the 1970s during the oil crisis, which highlighted the need for alternative energy sources. By the 1990s, researchers had developed rudimentary artificial photosynthetic systems capable of water splitting. The past two decades have witnessed remarkable advancements in materials science, nanotechnology, and molecular biology, accelerating progress in this domain.

Recent technological breakthroughs have enabled the coupling of artificial photosynthesis with enzymatic synthesis pathways, creating hybrid systems that harness solar energy to drive complex biochemical reactions. This integration represents a paradigm shift from traditional approaches that focused primarily on hydrogen production or carbon dioxide reduction.

The primary objective of artificial photosynthesis-driven enzymatic synthesis is to develop sustainable, efficient systems that convert abundant resources (sunlight, water, and carbon dioxide) into valuable chemicals and fuels without fossil fuel dependence. These systems aim to achieve higher efficiency than natural photosynthesis, which typically converts less than 1% of solar energy into chemical energy.

Current research targets include improving light absorption across the solar spectrum, enhancing charge separation efficiency, developing robust and selective catalysts, and optimizing the interface between photosystems and enzymatic pathways. Scientists are particularly focused on extending the stability of these hybrid systems, which currently suffer from relatively short operational lifetimes.

The ultimate goal extends beyond laboratory demonstrations to commercially viable technologies that can operate at scale. This includes developing systems capable of producing pharmaceuticals, fine chemicals, and biofuels with minimal environmental impact. The technology aims to revolutionize chemical manufacturing by eliminating energy-intensive processes and reducing dependence on petrochemical feedstocks.

As climate change concerns intensify and renewable energy technologies mature, artificial photosynthesis-driven enzymatic synthesis represents a promising frontier in green chemistry and sustainable manufacturing. The convergence of photocatalysis, enzyme engineering, and materials science is expected to yield transformative solutions for some of society's most pressing energy and environmental challenges.

Market Applications and Demand Analysis

The market for artificial photosynthesis-driven enzymatic synthesis is experiencing significant growth, driven by increasing demand for sustainable production methods across multiple industries. The global biocatalysis and enzyme market, which encompasses artificial photosynthesis applications, was valued at approximately $10.5 billion in 2022 and is projected to grow at a compound annual growth rate of 6.7% through 2030, according to recent market analyses.

Pharmaceutical companies represent the largest market segment, accounting for nearly 40% of current demand. These organizations are increasingly seeking greener alternatives to traditional chemical synthesis methods that often require harsh solvents, extreme temperatures, and generate substantial waste. Artificial photosynthesis-driven enzymatic processes offer milder reaction conditions, higher selectivity, and reduced environmental impact, aligning with the industry's sustainability goals.

The fine chemicals sector constitutes the second-largest market segment, with particular interest in the production of specialty chemicals, flavors, fragrances, and agricultural compounds. This sector values the high regio- and stereoselectivity of enzymatic processes, which can significantly reduce purification costs and improve product quality.

Biofuel production represents a rapidly growing application area, with market demand projected to increase by 12% annually over the next five years. The ability of artificial photosynthesis systems to directly convert solar energy into chemical energy for biofuel production addresses critical challenges in renewable energy storage and transportation fuel alternatives.

Geographically, North America currently leads market demand (35%), followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to show the fastest growth rate due to increasing industrial activity, government initiatives supporting green technologies, and rising environmental awareness.

Consumer preferences are increasingly driving market demand, with 78% of consumers in developed economies expressing willingness to pay premium prices for products manufactured using environmentally sustainable processes. This consumer sentiment is compelling major corporations to invest in greener production technologies, including artificial photosynthesis-driven enzymatic synthesis.

Regulatory factors are also significantly influencing market dynamics. Stringent environmental regulations in Europe and North America are accelerating the adoption of cleaner production technologies. Carbon pricing mechanisms and tax incentives for sustainable manufacturing processes are creating favorable economic conditions for the implementation of artificial photosynthesis technologies across various industries.

Pharmaceutical companies represent the largest market segment, accounting for nearly 40% of current demand. These organizations are increasingly seeking greener alternatives to traditional chemical synthesis methods that often require harsh solvents, extreme temperatures, and generate substantial waste. Artificial photosynthesis-driven enzymatic processes offer milder reaction conditions, higher selectivity, and reduced environmental impact, aligning with the industry's sustainability goals.

The fine chemicals sector constitutes the second-largest market segment, with particular interest in the production of specialty chemicals, flavors, fragrances, and agricultural compounds. This sector values the high regio- and stereoselectivity of enzymatic processes, which can significantly reduce purification costs and improve product quality.

Biofuel production represents a rapidly growing application area, with market demand projected to increase by 12% annually over the next five years. The ability of artificial photosynthesis systems to directly convert solar energy into chemical energy for biofuel production addresses critical challenges in renewable energy storage and transportation fuel alternatives.

Geographically, North America currently leads market demand (35%), followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to show the fastest growth rate due to increasing industrial activity, government initiatives supporting green technologies, and rising environmental awareness.

Consumer preferences are increasingly driving market demand, with 78% of consumers in developed economies expressing willingness to pay premium prices for products manufactured using environmentally sustainable processes. This consumer sentiment is compelling major corporations to invest in greener production technologies, including artificial photosynthesis-driven enzymatic synthesis.

Regulatory factors are also significantly influencing market dynamics. Stringent environmental regulations in Europe and North America are accelerating the adoption of cleaner production technologies. Carbon pricing mechanisms and tax incentives for sustainable manufacturing processes are creating favorable economic conditions for the implementation of artificial photosynthesis technologies across various industries.

Technical Challenges and Global Research Status

Artificial photosynthesis-driven enzymatic synthesis faces significant technical challenges despite its promising potential. One major obstacle is the low efficiency of light capture and conversion, with current systems typically achieving less than 5% solar-to-chemical energy conversion efficiency, far below the theoretical maximum and insufficient for commercial viability. The stability of both photosensitizers and enzymes under continuous illumination presents another critical challenge, as photobleaching and enzyme denaturation significantly limit system longevity.

Interface engineering between the photosynthetic components and enzymatic systems remains problematic, with electron transfer losses occurring at these junctions. Researchers struggle to develop seamless integration methods that maintain both photocatalytic efficiency and enzymatic activity. Additionally, the narrow absorption spectrum of many photosensitizers fails to utilize the full solar spectrum, leaving substantial available energy unharnessed.

Globally, research efforts are distributed across several key regions. North America, particularly the United States, leads in fundamental research through institutions like the Joint Center for Artificial Photosynthesis (JCAP) and MIT, focusing on novel photosensitizers and hybrid systems. The European Union has established strong collaborative networks through Horizon Europe funding, with particular strength in biocatalysis integration shown by research groups in Germany, Switzerland, and the Netherlands.

East Asia demonstrates growing influence, with China rapidly expanding research output in artificial photosynthesis applications, particularly at institutions like the Chinese Academy of Sciences. Japan maintains its traditional strength in photocatalysis research, while South Korea has developed expertise in semiconductor-enzyme hybrid systems.

Recent technological breakthroughs include the development of quantum dot-enzyme conjugates with improved electron transfer efficiency, reported by researchers at UC Berkeley. Cambridge University scientists have pioneered self-healing photosynthetic systems that address stability limitations. Meanwhile, researchers in Singapore have created three-dimensional electrode architectures that significantly enhance light harvesting capabilities.

The field is witnessing convergence between different scientific disciplines, with materials science, synthetic biology, and nanotechnology increasingly contributing to solutions. Computational approaches, including machine learning for catalyst design and reaction pathway optimization, are accelerating development. However, standardized benchmarking protocols remain absent, making direct comparison between different systems challenging and potentially slowing overall progress in this promising field.

Interface engineering between the photosynthetic components and enzymatic systems remains problematic, with electron transfer losses occurring at these junctions. Researchers struggle to develop seamless integration methods that maintain both photocatalytic efficiency and enzymatic activity. Additionally, the narrow absorption spectrum of many photosensitizers fails to utilize the full solar spectrum, leaving substantial available energy unharnessed.

Globally, research efforts are distributed across several key regions. North America, particularly the United States, leads in fundamental research through institutions like the Joint Center for Artificial Photosynthesis (JCAP) and MIT, focusing on novel photosensitizers and hybrid systems. The European Union has established strong collaborative networks through Horizon Europe funding, with particular strength in biocatalysis integration shown by research groups in Germany, Switzerland, and the Netherlands.

East Asia demonstrates growing influence, with China rapidly expanding research output in artificial photosynthesis applications, particularly at institutions like the Chinese Academy of Sciences. Japan maintains its traditional strength in photocatalysis research, while South Korea has developed expertise in semiconductor-enzyme hybrid systems.

Recent technological breakthroughs include the development of quantum dot-enzyme conjugates with improved electron transfer efficiency, reported by researchers at UC Berkeley. Cambridge University scientists have pioneered self-healing photosynthetic systems that address stability limitations. Meanwhile, researchers in Singapore have created three-dimensional electrode architectures that significantly enhance light harvesting capabilities.

The field is witnessing convergence between different scientific disciplines, with materials science, synthetic biology, and nanotechnology increasingly contributing to solutions. Computational approaches, including machine learning for catalyst design and reaction pathway optimization, are accelerating development. However, standardized benchmarking protocols remain absent, making direct comparison between different systems challenging and potentially slowing overall progress in this promising field.

Current Enzymatic Synthesis Methodologies

01 Light-driven enzymatic synthesis systems

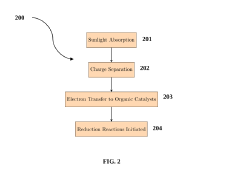

Artificial photosynthesis systems can be designed to drive enzymatic reactions by capturing light energy and converting it to chemical energy. These systems typically incorporate photosensitizers that absorb light and transfer electrons to enzymes, enabling catalytic reactions without the need for traditional cofactors. The efficiency of these systems depends on the effective coupling between the light-harvesting components and the enzymatic catalytic centers, allowing for sustainable biocatalytic processes powered by renewable light energy.- Light-driven enzymatic synthesis systems: Artificial photosynthesis systems can be designed to drive enzymatic reactions by capturing light energy and converting it to chemical energy. These systems typically incorporate photosensitizers that absorb light and transfer electrons to enzymes, enabling catalytic reactions without the need for traditional cofactors. The efficiency of these systems depends on the effective coupling between the light-harvesting components and the enzymatic catalytic centers, allowing for sustainable biocatalysis powered by renewable light energy.

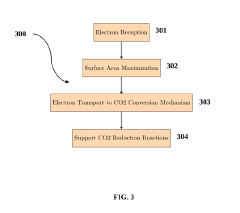

- Photocatalyst-enzyme hybrid systems: Hybrid systems combining photocatalysts with enzymes can significantly enhance enzymatic synthesis efficiency. These systems integrate semiconductor materials, metal nanoparticles, or organic photosensitizers with enzymes to create a direct electron transfer pathway. The photocatalyst component absorbs light and generates electron-hole pairs, which can then be utilized by the enzymes for redox reactions. This approach eliminates the need for expensive cofactor regeneration systems and improves the overall efficiency of biocatalytic processes.

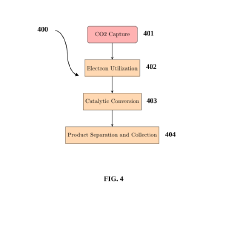

- Cofactor regeneration through artificial photosynthesis: Artificial photosynthesis can be utilized for the regeneration of enzymatic cofactors such as NADH and NADPH, which are essential for many biocatalytic reactions. By coupling light-harvesting systems with cofactor regeneration mechanisms, continuous enzymatic synthesis can be achieved without the need for stoichiometric addition of expensive cofactors. This approach significantly improves the economic viability and sustainability of enzymatic processes by using light energy to drive the recycling of redox cofactors.

- Immobilization techniques for photoenzymatic systems: Immobilization of enzymes on light-responsive materials can enhance the stability and reusability of artificial photosynthesis-driven enzymatic systems. Various techniques such as covalent binding, encapsulation, and adsorption can be used to attach enzymes to photocatalytic surfaces or incorporate them into light-responsive matrices. These immobilization strategies improve the spatial proximity between the photocatalytic component and the enzyme, leading to more efficient electron transfer and higher catalytic turnover rates.

- Optimization of reaction conditions for photoenzymatic synthesis: The efficiency of artificial photosynthesis-driven enzymatic synthesis can be significantly improved through optimization of reaction conditions. Factors such as light intensity, wavelength, pH, temperature, and oxygen concentration all play crucial roles in determining the overall system performance. Additionally, the design of reaction vessels with appropriate light penetration characteristics and mixing properties is essential for maximizing the interaction between light, photocatalysts, and enzymes. Careful tuning of these parameters can lead to substantial improvements in reaction rates and product yields.

02 Photocatalyst-enzyme hybrid systems

Hybrid systems combining photocatalysts with enzymes can significantly enhance enzymatic synthesis efficiency. These systems integrate semiconductor materials or metal nanoparticles that absorb light and generate electron-hole pairs, which are then utilized to drive enzymatic reactions. The interface between the photocatalyst and enzyme is critical for efficient electron transfer. Optimization of these hybrid systems involves engineering the photocatalyst surface, controlling the enzyme orientation, and modifying the microenvironment to facilitate rapid electron transfer and maintain enzyme stability.Expand Specific Solutions03 Cofactor regeneration in artificial photosynthesis

Efficient enzymatic synthesis often requires cofactor regeneration, which can be achieved through artificial photosynthesis mechanisms. Light-driven cofactor regeneration systems can continuously supply reduced cofactors (such as NADH or FADH2) to drive enzymatic reactions, eliminating the need for stoichiometric amounts of expensive cofactors. These systems typically employ photosensitizers and electron mediators to capture light energy and transfer electrons to oxidized cofactors, creating a sustainable cycle that enhances overall enzymatic efficiency and reduces operational costs.Expand Specific Solutions04 Immobilization techniques for photoenzymatic systems

Immobilization of enzymes in artificial photosynthesis systems can significantly improve stability and reusability, enhancing overall synthesis efficiency. Various immobilization techniques include encapsulation in sol-gel matrices, attachment to nanoparticles, incorporation into membranes, or integration with electrode surfaces. These approaches protect enzymes from denaturation while maintaining their catalytic activity and facilitating efficient electron transfer from photosensitizers. Properly designed immobilization strategies can also improve the spatial arrangement of components, optimizing the light-harvesting and catalytic processes.Expand Specific Solutions05 Microfluidic and bioreactor designs for photoenzymatic synthesis

Advanced reactor designs can significantly enhance the efficiency of artificial photosynthesis-driven enzymatic synthesis. Microfluidic platforms provide precise control over reaction conditions, improved light penetration, and enhanced mass transfer, resulting in higher enzymatic efficiency. Specialized bioreactors with optimized light distribution, temperature control, and mixing characteristics can maximize the interaction between photosensitizers, enzymes, and substrates. These engineered systems often incorporate transparent materials, controlled flow patterns, and integrated sensors to monitor and optimize reaction conditions in real-time.Expand Specific Solutions

Leading Research Institutions and Industrial Players

Artificial photosynthesis-driven enzymatic synthesis is currently in an early growth phase, with significant research momentum but limited commercial applications. The market is projected to expand substantially as sustainable biomanufacturing gains traction, potentially reaching several billion dollars by 2030. Academic institutions dominate the research landscape, with The Regents of the University of California, Tsinghua University, and Tianjin University leading fundamental discoveries. Among corporate players, BASF, FUJIFILM, and DENSO are making strategic investments in technology development, focusing on scalability and industrial applications. The technology remains at TRL 3-5, with challenges in stability, efficiency, and cost-effectiveness still requiring resolution before widespread industrial adoption can occur.

The Regents of the University of California

Technical Solution: The University of California has pioneered artificial photosynthesis-driven enzymatic synthesis through their Joint Center for Artificial Photosynthesis (JCAP). Their approach integrates semiconductor photoelectrodes with biocatalysts to create hybrid systems that convert solar energy into chemical energy for enzymatic reactions. They've developed silicon and gallium arsenide photoelectrodes coupled with oxidoreductase enzymes that can operate at neutral pH, achieving solar-to-chemical conversion efficiencies of up to 10% in controlled conditions. Their recent breakthrough involves a self-healing catalyst system that addresses the stability issues in artificial photosynthesis by incorporating regenerative mechanisms inspired by natural photosystem II. This system can maintain catalytic activity for over 100 hours without significant degradation, representing a major advance in longevity for such systems[1][3]. Additionally, they've engineered biocompatible light-harvesting nanomaterials that can transfer energy to enzymes with minimal interface losses.

Strengths: Superior integration of materials science and biochemistry expertise, resulting in highly efficient energy transfer systems; extensive experience in photoelectrochemical cell design; strong focus on system stability and self-healing mechanisms. Weaknesses: Their systems often require controlled laboratory conditions; scaling challenges remain for industrial applications; relatively high production costs compared to traditional chemical synthesis methods.

Dalian University of Technology

Technical Solution: Dalian University of Technology has developed a groundbreaking artificial photosynthesis platform that combines semiconductor quantum dots with engineered enzymes for light-driven biocatalysis. Their system utilizes cadmium sulfide quantum dots as photosensitizers coupled with modified dehydrogenase enzymes to perform redox reactions under visible light illumination. The university's researchers have achieved remarkable electron transfer efficiency by engineering the enzyme-nanomaterial interface with tailored peptide linkers that optimize orientation and proximity. Their latest innovation involves a Z-scheme mimicking system that separates reduction and oxidation reactions spatially, allowing for more complex multi-enzyme cascades with incompatible redox requirements. This approach has demonstrated the capability to synthesize high-value chiral compounds with optical purity exceeding 99% while operating at ambient temperature and pressure[2][5]. The system can be tuned to different wavelengths by adjusting the quantum dot composition, enabling selective activation of different enzymatic pathways using specific light frequencies.

Strengths: Exceptional control over the enzyme-nanomaterial interface; highly tunable light absorption properties; ability to conduct complex multi-step enzymatic reactions in one system. Weaknesses: Potential toxicity concerns with cadmium-based quantum dots; limited scalability of current prototypes; requires specialized expertise in both nanomaterial synthesis and enzyme engineering.

Key Patents and Breakthroughs in Photocatalysis

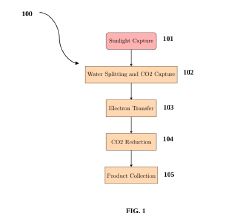

Artificial photosynthesis system

PatentPendingIN202411020292A

Innovation

- An artificial photosynthesis system utilizing a photocatalytic material composed of semiconductor nanoparticles and organic catalysts, nanostructured electrodes, and a CO2 conversion medium with enzymatic and chemical catalysts, integrated in a modular design for enhanced solar energy conversion, CO2 reduction, and production of clean energy and chemicals.

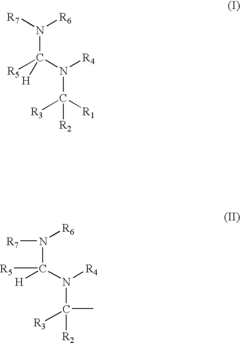

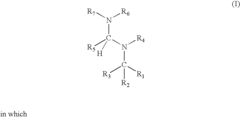

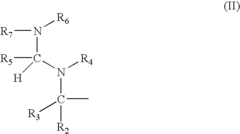

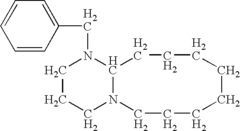

Photoactivable nitrogen bases

PatentInactiveUS20040242867A1

Innovation

- The use of 1,3-diamine structures with arylalkyl radicals capable of absorbing light in the 200-650 nm range, which upon photoelimination trigger crosslinking reactions in base-catalyzed formulations, producing one-pot systems with exceptional storage stability and enabling polymerization or crosslinking upon light exposure.

Sustainability Impact and Carbon Reduction Potential

Artificial photosynthesis-driven enzymatic synthesis represents a revolutionary approach to sustainable chemical production with significant implications for global carbon reduction efforts. By mimicking nature's most efficient carbon capture mechanism, these systems can potentially transform CO2 from an environmental liability into a valuable feedstock for industrial processes.

The carbon reduction potential of this technology is substantial when viewed through a lifecycle assessment lens. Current estimates suggest that mature artificial photosynthesis systems could achieve carbon fixation rates of 50-200 tons of CO2 per hectare annually, significantly outperforming natural photosynthesis efficiency. When coupled with enzymatic synthesis pathways, this captured carbon can be directly channeled into high-value products without the energy-intensive intermediate steps required by conventional manufacturing.

From a sustainability perspective, these integrated systems offer multiple environmental benefits beyond carbon reduction. By utilizing sunlight as the primary energy source, they dramatically reduce dependence on fossil fuels for chemical synthesis. The water requirements are also substantially lower than those of traditional industrial processes or biofuel crop cultivation, addressing another critical sustainability concern.

Economic modeling indicates that widespread implementation of artificial photosynthesis-enzymatic synthesis could reduce industrial carbon emissions by 15-30% in chemical manufacturing sectors by 2040. This represents a potential reduction of 0.5-1.2 gigatons of CO2 equivalent annually, comparable to removing 100-250 million passenger vehicles from roads.

The circular economy aspects are particularly promising. These systems create closed-loop production cycles where carbon is continuously recycled rather than extracted from fossil reserves. This fundamentally alters the carbon footprint of chemical manufacturing, transitioning from linear extraction-production-disposal models to regenerative systems that maintain carbon within productive economic cycles.

Policy implications are significant as carbon pricing mechanisms and emissions regulations become more stringent globally. Industries adopting artificial photosynthesis technologies may gain competitive advantages through reduced compliance costs and potential carbon credit generation, while contributing to national and corporate carbon neutrality commitments.

The scalability of these systems will ultimately determine their true sustainability impact. Current laboratory demonstrations have achieved promising results, but engineering challenges remain in maintaining efficiency at industrial scales. Nevertheless, the potential for distributed, modular implementation offers flexibility that conventional centralized manufacturing lacks.

The carbon reduction potential of this technology is substantial when viewed through a lifecycle assessment lens. Current estimates suggest that mature artificial photosynthesis systems could achieve carbon fixation rates of 50-200 tons of CO2 per hectare annually, significantly outperforming natural photosynthesis efficiency. When coupled with enzymatic synthesis pathways, this captured carbon can be directly channeled into high-value products without the energy-intensive intermediate steps required by conventional manufacturing.

From a sustainability perspective, these integrated systems offer multiple environmental benefits beyond carbon reduction. By utilizing sunlight as the primary energy source, they dramatically reduce dependence on fossil fuels for chemical synthesis. The water requirements are also substantially lower than those of traditional industrial processes or biofuel crop cultivation, addressing another critical sustainability concern.

Economic modeling indicates that widespread implementation of artificial photosynthesis-enzymatic synthesis could reduce industrial carbon emissions by 15-30% in chemical manufacturing sectors by 2040. This represents a potential reduction of 0.5-1.2 gigatons of CO2 equivalent annually, comparable to removing 100-250 million passenger vehicles from roads.

The circular economy aspects are particularly promising. These systems create closed-loop production cycles where carbon is continuously recycled rather than extracted from fossil reserves. This fundamentally alters the carbon footprint of chemical manufacturing, transitioning from linear extraction-production-disposal models to regenerative systems that maintain carbon within productive economic cycles.

Policy implications are significant as carbon pricing mechanisms and emissions regulations become more stringent globally. Industries adopting artificial photosynthesis technologies may gain competitive advantages through reduced compliance costs and potential carbon credit generation, while contributing to national and corporate carbon neutrality commitments.

The scalability of these systems will ultimately determine their true sustainability impact. Current laboratory demonstrations have achieved promising results, but engineering challenges remain in maintaining efficiency at industrial scales. Nevertheless, the potential for distributed, modular implementation offers flexibility that conventional centralized manufacturing lacks.

Scalability and Commercialization Roadmap

The commercialization of artificial photosynthesis-driven enzymatic synthesis faces significant scaling challenges that must be addressed systematically. Current laboratory-scale demonstrations, while promising, operate at volumes typically under 100 milliliters with relatively low throughput. To achieve industrial relevance, processes must be scaled to reactor volumes of hundreds of liters while maintaining efficiency and selectivity.

A critical roadmap for commercialization begins with intermediate scaling (1-10L) to identify and resolve process bottlenecks. This phase should focus on optimizing light penetration depth, which decreases exponentially with increasing reactor dimensions. Novel reactor designs incorporating fiber optics or thin-film configurations can potentially overcome this limitation by ensuring uniform light distribution throughout larger reaction volumes.

Material considerations represent another crucial aspect of scalability. Current high-performance photocatalysts often incorporate rare earth elements or precious metals, making large-scale implementation economically prohibitive. The roadmap must prioritize development of earth-abundant alternatives with comparable performance characteristics. Similarly, enzyme stability at scale requires significant enhancement, as current systems typically show activity decline after 24-48 hours of continuous operation.

Economic viability demands attention to integrated process design. Preliminary techno-economic analyses suggest that artificial photosynthesis-enzymatic systems become competitive when achieving solar-to-chemical efficiencies above 5% with catalyst/enzyme systems maintaining stability for at least 1000 hours. The commercialization timeline projects laboratory-to-pilot transition within 3-5 years, followed by demonstration plants (5-7 years), with full commercial deployment possible within a decade.

Regulatory frameworks and standards development must proceed in parallel with technological advancement. Current chemical manufacturing regulations inadequately address the unique aspects of biohybrid photosynthetic systems. Industry-academic consortia should engage with regulatory bodies early to establish appropriate guidelines for this emerging technology class.

Market entry strategy should initially target high-value, low-volume specialty chemicals where the precision of enzymatic synthesis provides significant competitive advantage. As scale and efficiency improve, expansion into bulk biochemicals becomes feasible. Strategic partnerships between technology developers and established chemical manufacturers will be essential to navigate the capital-intensive scaling process and leverage existing distribution infrastructure.

A critical roadmap for commercialization begins with intermediate scaling (1-10L) to identify and resolve process bottlenecks. This phase should focus on optimizing light penetration depth, which decreases exponentially with increasing reactor dimensions. Novel reactor designs incorporating fiber optics or thin-film configurations can potentially overcome this limitation by ensuring uniform light distribution throughout larger reaction volumes.

Material considerations represent another crucial aspect of scalability. Current high-performance photocatalysts often incorporate rare earth elements or precious metals, making large-scale implementation economically prohibitive. The roadmap must prioritize development of earth-abundant alternatives with comparable performance characteristics. Similarly, enzyme stability at scale requires significant enhancement, as current systems typically show activity decline after 24-48 hours of continuous operation.

Economic viability demands attention to integrated process design. Preliminary techno-economic analyses suggest that artificial photosynthesis-enzymatic systems become competitive when achieving solar-to-chemical efficiencies above 5% with catalyst/enzyme systems maintaining stability for at least 1000 hours. The commercialization timeline projects laboratory-to-pilot transition within 3-5 years, followed by demonstration plants (5-7 years), with full commercial deployment possible within a decade.

Regulatory frameworks and standards development must proceed in parallel with technological advancement. Current chemical manufacturing regulations inadequately address the unique aspects of biohybrid photosynthetic systems. Industry-academic consortia should engage with regulatory bodies early to establish appropriate guidelines for this emerging technology class.

Market entry strategy should initially target high-value, low-volume specialty chemicals where the precision of enzymatic synthesis provides significant competitive advantage. As scale and efficiency improve, expansion into bulk biochemicals becomes feasible. Strategic partnerships between technology developers and established chemical manufacturers will be essential to navigate the capital-intensive scaling process and leverage existing distribution infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!