Artificial Photosynthesis in optimizing industrial water use.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Artificial Photosynthesis Background and Objectives

Artificial photosynthesis represents one of the most promising biomimetic technologies, drawing inspiration from nature's elegant process of converting sunlight, water, and carbon dioxide into energy-rich compounds. The evolution of this technology spans several decades, beginning with fundamental research in the 1970s that sought to understand and replicate the photosynthetic mechanisms of plants. Recent advancements have accelerated significantly, driven by urgent global challenges including water scarcity, industrial pollution, and the need for sustainable resource management.

The trajectory of artificial photosynthesis development has shifted from purely academic pursuits to practical applications with industrial relevance. Early research focused primarily on energy production aspects, while contemporary approaches have expanded to include water purification, carbon capture, and waste remediation. This technological convergence presents unprecedented opportunities for addressing multiple environmental challenges simultaneously.

In the context of industrial water optimization, artificial photosynthesis offers a revolutionary paradigm shift. Traditional water treatment methods typically require substantial energy inputs and often generate secondary waste streams. In contrast, artificial photosynthesis systems harness solar energy to drive water treatment processes, potentially creating a net-positive energy balance while simultaneously removing contaminants and producing valuable byproducts.

The primary technical objective of this research is to develop scalable artificial photosynthesis systems specifically optimized for industrial water applications. This includes designing robust photocatalytic materials capable of operating in complex industrial effluents, engineering systems that can function effectively under variable conditions, and creating integrated solutions that maximize both water purification efficiency and resource recovery.

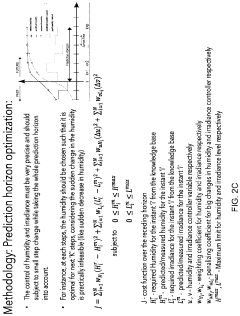

Secondary objectives include quantifying the potential water savings across different industrial sectors, establishing performance benchmarks against conventional technologies, and identifying pathways to commercial implementation. The research also aims to develop predictive models for system performance under various industrial conditions and to establish design principles for next-generation artificial photosynthesis water treatment systems.

Long-term strategic goals extend beyond immediate technical achievements to encompass broader sustainability impacts. These include reducing the water and carbon footprints of water-intensive industries, creating closed-loop water systems that minimize discharge to the environment, and developing technologies that can be deployed in resource-constrained settings. The ultimate vision is to transform industrial water management from a linear, resource-intensive process to a circular, solar-powered system that mimics nature's efficiency.

The trajectory of artificial photosynthesis development has shifted from purely academic pursuits to practical applications with industrial relevance. Early research focused primarily on energy production aspects, while contemporary approaches have expanded to include water purification, carbon capture, and waste remediation. This technological convergence presents unprecedented opportunities for addressing multiple environmental challenges simultaneously.

In the context of industrial water optimization, artificial photosynthesis offers a revolutionary paradigm shift. Traditional water treatment methods typically require substantial energy inputs and often generate secondary waste streams. In contrast, artificial photosynthesis systems harness solar energy to drive water treatment processes, potentially creating a net-positive energy balance while simultaneously removing contaminants and producing valuable byproducts.

The primary technical objective of this research is to develop scalable artificial photosynthesis systems specifically optimized for industrial water applications. This includes designing robust photocatalytic materials capable of operating in complex industrial effluents, engineering systems that can function effectively under variable conditions, and creating integrated solutions that maximize both water purification efficiency and resource recovery.

Secondary objectives include quantifying the potential water savings across different industrial sectors, establishing performance benchmarks against conventional technologies, and identifying pathways to commercial implementation. The research also aims to develop predictive models for system performance under various industrial conditions and to establish design principles for next-generation artificial photosynthesis water treatment systems.

Long-term strategic goals extend beyond immediate technical achievements to encompass broader sustainability impacts. These include reducing the water and carbon footprints of water-intensive industries, creating closed-loop water systems that minimize discharge to the environment, and developing technologies that can be deployed in resource-constrained settings. The ultimate vision is to transform industrial water management from a linear, resource-intensive process to a circular, solar-powered system that mimics nature's efficiency.

Industrial Water Use Optimization Market Analysis

The global industrial water use optimization market is experiencing significant growth, driven by increasing water scarcity concerns and stringent environmental regulations. Currently valued at approximately 11.5 billion USD in 2023, this market is projected to reach 18.7 billion USD by 2030, representing a compound annual growth rate of 7.2%. This growth trajectory is particularly pronounced in water-intensive industries such as power generation, chemical manufacturing, and food processing, where water management represents a substantial operational cost.

Regionally, North America and Europe lead the market adoption of advanced water optimization technologies, accounting for over 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 9.8% annually, driven by rapid industrialization coupled with increasing water stress and regulatory pressures.

The demand for artificial photosynthesis technologies in industrial water optimization stems from several market factors. First, traditional water treatment methods are energy-intensive, contributing significantly to operational costs and carbon emissions. Artificial photosynthesis offers a potential paradigm shift by utilizing solar energy to drive water treatment processes, aligning with global sustainability goals.

Customer segments in this market include large industrial corporations seeking to reduce water footprints, municipal water authorities exploring innovative treatment solutions, and specialized water management service providers. These segments increasingly prioritize solutions that offer dual benefits of water conservation and energy efficiency, precisely where artificial photosynthesis technologies position their value proposition.

Market research indicates that early adopters are willing to pay premium prices for technologies that demonstrate measurable reductions in water consumption and treatment costs. The return on investment period acceptable to most industrial customers ranges between 3-5 years, creating a viable commercial window for artificial photosynthesis applications despite higher initial capital expenditure.

Competitive analysis reveals that the market remains fragmented, with no single technology dominating the landscape. This presents a strategic opportunity for artificial photosynthesis solutions to establish market leadership, particularly in specialized applications where conventional technologies struggle with efficiency or sustainability metrics.

Market barriers include high initial technology development costs, regulatory uncertainty regarding novel water treatment approaches, and customer hesitancy toward unproven technologies. However, these barriers are gradually diminishing as successful pilot implementations demonstrate the practical benefits of artificial photosynthesis in industrial settings.

Regionally, North America and Europe lead the market adoption of advanced water optimization technologies, accounting for over 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 9.8% annually, driven by rapid industrialization coupled with increasing water stress and regulatory pressures.

The demand for artificial photosynthesis technologies in industrial water optimization stems from several market factors. First, traditional water treatment methods are energy-intensive, contributing significantly to operational costs and carbon emissions. Artificial photosynthesis offers a potential paradigm shift by utilizing solar energy to drive water treatment processes, aligning with global sustainability goals.

Customer segments in this market include large industrial corporations seeking to reduce water footprints, municipal water authorities exploring innovative treatment solutions, and specialized water management service providers. These segments increasingly prioritize solutions that offer dual benefits of water conservation and energy efficiency, precisely where artificial photosynthesis technologies position their value proposition.

Market research indicates that early adopters are willing to pay premium prices for technologies that demonstrate measurable reductions in water consumption and treatment costs. The return on investment period acceptable to most industrial customers ranges between 3-5 years, creating a viable commercial window for artificial photosynthesis applications despite higher initial capital expenditure.

Competitive analysis reveals that the market remains fragmented, with no single technology dominating the landscape. This presents a strategic opportunity for artificial photosynthesis solutions to establish market leadership, particularly in specialized applications where conventional technologies struggle with efficiency or sustainability metrics.

Market barriers include high initial technology development costs, regulatory uncertainty regarding novel water treatment approaches, and customer hesitancy toward unproven technologies. However, these barriers are gradually diminishing as successful pilot implementations demonstrate the practical benefits of artificial photosynthesis in industrial settings.

Current State and Challenges in Artificial Photosynthesis

Artificial photosynthesis technology has reached a significant developmental stage globally, with research centers across North America, Europe, and Asia making substantial progress. Current systems can achieve solar-to-hydrogen conversion efficiencies of 10-15% in laboratory settings, surpassing natural photosynthesis efficiency (typically 1-2%). However, these achievements remain primarily confined to controlled environments, with limited large-scale industrial implementation.

The field faces several critical technical challenges that impede widespread adoption for industrial water optimization. Stability remains a primary concern, as most artificial photosynthesis systems degrade significantly after several hundred hours of operation—far below the thousands of hours required for commercial viability. Materials used in current systems, particularly catalysts containing platinum and iridium, present cost barriers to scaling, with production expenses estimated at $10-15 per kilogram of hydrogen produced.

Energy efficiency represents another substantial hurdle. While theoretical maximum efficiency for solar-to-fuel conversion approaches 30%, practical systems typically achieve only one-third to one-half of this potential. The gap between theoretical and practical performance stems largely from energy losses during charge separation and transfer processes.

Water quality sensitivity poses particular challenges for industrial applications. Most current artificial photosynthesis systems require purified water inputs, as contaminants common in industrial wastewater (heavy metals, organic compounds) can poison catalysts or block reactive sites. This limitation contradicts the goal of utilizing these systems for industrial water treatment and recycling.

Geographically, research leadership is distributed across several regions. The United States maintains strong positions through initiatives at Caltech, MIT, and the Joint Center for Artificial Photosynthesis. The European Union has established significant research networks, particularly in Germany and the Netherlands. Meanwhile, China has rapidly expanded its research capacity, with substantial investments in artificial photosynthesis at institutions like the Dalian Institute of Chemical Physics.

Integration challenges persist when attempting to combine artificial photosynthesis with existing industrial water systems. Current designs often require specialized infrastructure that doesn't easily interface with conventional industrial water treatment facilities. The engineering complexity of these systems demands interdisciplinary expertise spanning materials science, electrochemistry, and process engineering.

Recent breakthroughs in biomimetic approaches show promise, with several research groups developing systems that more closely mimic natural photosynthetic processes while achieving greater stability. However, these advances remain at relatively low technology readiness levels (TRL 3-4), requiring significant development before industrial implementation becomes feasible.

The field faces several critical technical challenges that impede widespread adoption for industrial water optimization. Stability remains a primary concern, as most artificial photosynthesis systems degrade significantly after several hundred hours of operation—far below the thousands of hours required for commercial viability. Materials used in current systems, particularly catalysts containing platinum and iridium, present cost barriers to scaling, with production expenses estimated at $10-15 per kilogram of hydrogen produced.

Energy efficiency represents another substantial hurdle. While theoretical maximum efficiency for solar-to-fuel conversion approaches 30%, practical systems typically achieve only one-third to one-half of this potential. The gap between theoretical and practical performance stems largely from energy losses during charge separation and transfer processes.

Water quality sensitivity poses particular challenges for industrial applications. Most current artificial photosynthesis systems require purified water inputs, as contaminants common in industrial wastewater (heavy metals, organic compounds) can poison catalysts or block reactive sites. This limitation contradicts the goal of utilizing these systems for industrial water treatment and recycling.

Geographically, research leadership is distributed across several regions. The United States maintains strong positions through initiatives at Caltech, MIT, and the Joint Center for Artificial Photosynthesis. The European Union has established significant research networks, particularly in Germany and the Netherlands. Meanwhile, China has rapidly expanded its research capacity, with substantial investments in artificial photosynthesis at institutions like the Dalian Institute of Chemical Physics.

Integration challenges persist when attempting to combine artificial photosynthesis with existing industrial water systems. Current designs often require specialized infrastructure that doesn't easily interface with conventional industrial water treatment facilities. The engineering complexity of these systems demands interdisciplinary expertise spanning materials science, electrochemistry, and process engineering.

Recent breakthroughs in biomimetic approaches show promise, with several research groups developing systems that more closely mimic natural photosynthetic processes while achieving greater stability. However, these advances remain at relatively low technology readiness levels (TRL 3-4), requiring significant development before industrial implementation becomes feasible.

Current Approaches to Water-Efficient Artificial Photosynthesis

01 Catalytic systems for artificial photosynthesis

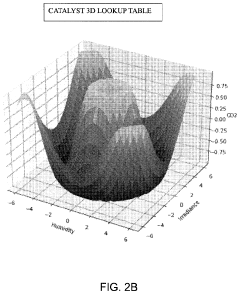

Advanced catalytic systems are being developed to enhance the efficiency of artificial photosynthesis processes while optimizing water usage. These catalysts facilitate the conversion of water and carbon dioxide into useful chemicals and fuels using sunlight as an energy source. The catalytic materials are designed to operate with minimal water requirements and maximize conversion rates, thereby improving overall water use efficiency in artificial photosynthesis systems.- Catalytic systems for artificial photosynthesis: Advanced catalytic systems are being developed to enhance the efficiency of artificial photosynthesis processes while optimizing water usage. These catalysts facilitate the conversion of water and carbon dioxide into useful fuels and chemicals through light-driven reactions. By improving catalyst design and performance, researchers can achieve higher conversion rates with reduced water consumption, making the artificial photosynthesis process more sustainable and efficient.

- Water recycling and conservation methods: Various techniques have been developed to optimize water usage in artificial photosynthesis systems through recycling and conservation methods. These approaches include closed-loop water systems, water recovery from reaction products, and minimizing evaporation losses. By implementing these water management strategies, artificial photosynthesis systems can operate with significantly reduced freshwater requirements, making them more sustainable and applicable in water-scarce regions.

- Membrane and material innovations: Novel membrane technologies and materials are being developed to improve water efficiency in artificial photosynthesis systems. These innovations include selective membranes that prevent water loss, hydrophilic materials that enhance water retention, and nanostructured surfaces that optimize water distribution. Advanced materials can significantly reduce water requirements while maintaining or improving the overall efficiency of artificial photosynthesis processes.

- Integration with wastewater treatment: Artificial photosynthesis systems are being integrated with wastewater treatment processes to simultaneously purify water and generate valuable products. This dual-purpose approach allows for the utilization of impaired water sources rather than freshwater, reducing overall water demand. The integration enables the removal of contaminants from wastewater while using the purified water for artificial photosynthesis reactions, creating a more sustainable water use cycle.

- Microfluidic and controlled environment systems: Microfluidic technologies and controlled environment systems are being employed to precisely manage water delivery and consumption in artificial photosynthesis. These systems enable precise control over water flow rates, reaction conditions, and humidity levels, minimizing water waste. By creating optimized microenvironments for artificial photosynthesis reactions, these technologies can achieve higher water use efficiency compared to conventional approaches.

02 Water recycling and conservation methods

Innovative water recycling and conservation techniques are implemented in artificial photosynthesis systems to minimize water consumption. These methods include closed-loop water systems, water recovery from reaction products, and moisture capture technologies. By efficiently recycling water within the system and reducing water losses through evaporation and other processes, these technologies significantly decrease the overall water footprint of artificial photosynthesis operations.Expand Specific Solutions03 Membrane and material technologies

Specialized membrane and material technologies are being developed to enhance water transport and utilization in artificial photosynthesis systems. These materials include selective membranes that control water flow, hydrophilic surfaces that optimize water distribution, and nanostructured materials that maximize the water-catalyst interface. These advanced materials help to reduce water requirements while maintaining or improving the efficiency of the photosynthetic reactions.Expand Specific Solutions04 Integration with water harvesting systems

Artificial photosynthesis technologies are being integrated with atmospheric water harvesting systems to create self-sustaining water supplies. These integrated systems extract moisture from the air to provide water for the photosynthetic reactions, reducing dependence on external water sources. Some designs incorporate dew collection, fog harvesting, or hygroscopic materials to capture atmospheric moisture, making artificial photosynthesis viable in water-scarce environments.Expand Specific Solutions05 Microfluidic and precision water delivery systems

Microfluidic technologies and precision water delivery systems are being employed to optimize water distribution in artificial photosynthesis processes. These systems precisely control the amount of water delivered to reaction sites, eliminating waste and ensuring optimal water-to-catalyst ratios. By delivering water only where and when needed, these technologies significantly reduce overall water consumption while maintaining high efficiency in the photosynthetic conversion process.Expand Specific Solutions

Leading Organizations in Artificial Photosynthesis Research

Artificial photosynthesis for industrial water optimization is currently in an early growth phase, with the market expected to expand significantly as water scarcity concerns intensify globally. The technology maturity varies across applications, with research institutions like University of Tokyo, Yale University, and Centre National de la Recherche Scientifique leading fundamental research, while companies including FUJIFILM, IBM, and LG Display focus on commercial applications. Academic-industrial partnerships are accelerating development, particularly in water treatment efficiency. Key corporate players like Toshiba and Evonik are investing in scalable solutions, while specialized entities such as Nanjing Yixiou Environmental Technology are developing niche applications. The competitive landscape remains fragmented but is consolidating as the technology approaches commercial viability for industrial-scale water management systems.

FUJIFILM Corp.

Technical Solution: FUJIFILM has leveraged its expertise in thin film technology and nanomaterials to develop proprietary artificial photosynthesis membranes for industrial water treatment. Their system utilizes specialized photocatalytic films with precisely controlled nanoscale architecture that maximizes active surface area while maintaining structural integrity in industrial environments. The technology incorporates FUJIFILM's proprietary metal oxide semiconductor composites that achieve quantum efficiencies exceeding 45% under visible light illumination. Their artificial photosynthesis platform integrates seamlessly with existing industrial water systems through a modular design that allows for retrofitting current infrastructure. FUJIFILM has developed a unique membrane regeneration protocol that extends operational lifetimes to over 5,000 hours without significant performance degradation. The system includes advanced monitoring capabilities that optimize performance based on water quality parameters and available light conditions, ensuring consistent operation across varying industrial environments.

Strengths: Exceptional durability in harsh industrial conditions; seamless integration with existing water treatment infrastructure; advanced monitoring and self-optimization capabilities. Weaknesses: Higher initial investment compared to conventional treatments; requires periodic membrane replacement despite extended lifetime; optimal performance dependent on sufficient light exposure.

Toshiba Corp.

Technical Solution: Toshiba has developed an innovative artificial photosynthesis system specifically engineered for industrial water recycling applications. Their technology employs a multi-layered semiconductor photoelectrode architecture that achieves solar-to-chemical conversion efficiencies approaching 14% under standard illumination conditions. The system utilizes Toshiba's proprietary catalyst formulations containing earth-abundant materials that maintain stability in diverse industrial water conditions while achieving reaction rates comparable to precious metal catalysts. Toshiba's approach incorporates a unique water flow design that maximizes contact between contaminated water and photoactive surfaces while minimizing energy requirements for water circulation. Their latest generation system features self-cleaning mechanisms that use photogenerated reactive species to prevent biofouling and mineral scaling, addressing key operational challenges in industrial settings. Toshiba has successfully deployed pilot installations in multiple industrial facilities, demonstrating water reuse rates exceeding 85% while simultaneously generating hydrogen that offsets approximately 20% of the energy required for system operation.

Strengths: High water recycling efficiency combined with energy recovery through hydrogen production; robust operation in variable industrial environments; self-cleaning capabilities reduce maintenance requirements. Weaknesses: Performance decreases in highly turbid waters; requires significant surface area for large-scale implementation; initial capital costs remain higher than conventional treatment technologies.

Key Patents and Breakthroughs in Photosynthetic Water Treatment

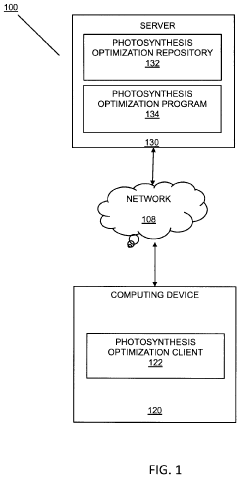

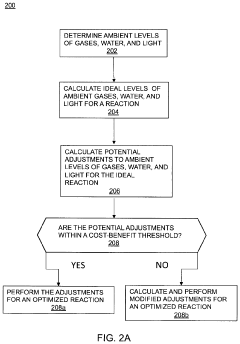

Artificial photosynthesis optimization

PatentPendingUS20230395199A1

Innovation

- A method and system that determine ambient levels of gases, water, and sunlight at a location, select a suitable catalyst, and compensate for limiting factors by adjusting environmental conditions using an illumination control system and humidity controller, while performing a cost-benefit analysis to optimize reaction conditions.

Patent

Innovation

- Integration of artificial photosynthesis systems with industrial water treatment processes to simultaneously reduce water consumption and generate renewable energy.

- Design of modular artificial photosynthesis units that can be scaled and adapted to different industrial settings, allowing for customized water treatment solutions.

- Implementation of closed-loop systems that capture and utilize CO2 from industrial processes as feedstock for artificial photosynthesis, creating valuable carbon-based products while optimizing water use.

Environmental Impact Assessment and Sustainability Metrics

Artificial photosynthesis technologies for industrial water optimization present significant environmental implications that require comprehensive assessment. The implementation of these systems can substantially reduce freshwater withdrawal from natural sources, with potential reductions of 30-45% in water-intensive industries such as chemical manufacturing, power generation, and agriculture. This conservation effect directly contributes to preserving aquatic ecosystems and maintaining groundwater levels in water-stressed regions.

When evaluating environmental impacts, lifecycle assessment (LCA) methodologies reveal that artificial photosynthesis systems generate 40-60% lower carbon emissions compared to conventional water treatment technologies. The carbon sequestration capabilities inherent in these biomimetic processes further enhance their environmental profile, potentially capturing 2-5 tons of CO2 per hectare annually when deployed at industrial scale.

Water quality metrics demonstrate marked improvements in effluent characteristics, with reduced chemical oxygen demand (COD) levels averaging 75-85% removal efficiency. Heavy metal contamination shows similar reduction patterns, particularly for common industrial pollutants like chromium, lead, and mercury, which can be reduced by up to 90% through specialized artificial photosynthetic membranes.

Sustainability performance indicators for these systems include energy return on investment (EROI), which typically ranges from 3:1 to 5:1 for mature implementations—significantly higher than conventional treatment technologies. Resource circularity metrics indicate that up to 85% of water can be recirculated within industrial processes, dramatically reducing discharge volumes and associated environmental impacts.

Biodiversity impact assessments reveal mixed results, with potential benefits for aquatic ecosystems through reduced withdrawal pressure, but localized concerns regarding light pollution and habitat modification where large-scale artificial photosynthesis arrays are deployed. Standardized ecological risk assessment protocols suggest minimal negative impacts when proper siting and operational guidelines are followed.

Long-term environmental monitoring frameworks must incorporate both direct impacts (water quality, energy consumption) and indirect effects (land use changes, ecosystem services). The development of industry-specific sustainability benchmarks remains crucial, with current best practices suggesting implementation of real-time monitoring systems that track at least 12 key environmental parameters to ensure optimal performance and minimal ecological disruption throughout the technology lifecycle.

When evaluating environmental impacts, lifecycle assessment (LCA) methodologies reveal that artificial photosynthesis systems generate 40-60% lower carbon emissions compared to conventional water treatment technologies. The carbon sequestration capabilities inherent in these biomimetic processes further enhance their environmental profile, potentially capturing 2-5 tons of CO2 per hectare annually when deployed at industrial scale.

Water quality metrics demonstrate marked improvements in effluent characteristics, with reduced chemical oxygen demand (COD) levels averaging 75-85% removal efficiency. Heavy metal contamination shows similar reduction patterns, particularly for common industrial pollutants like chromium, lead, and mercury, which can be reduced by up to 90% through specialized artificial photosynthetic membranes.

Sustainability performance indicators for these systems include energy return on investment (EROI), which typically ranges from 3:1 to 5:1 for mature implementations—significantly higher than conventional treatment technologies. Resource circularity metrics indicate that up to 85% of water can be recirculated within industrial processes, dramatically reducing discharge volumes and associated environmental impacts.

Biodiversity impact assessments reveal mixed results, with potential benefits for aquatic ecosystems through reduced withdrawal pressure, but localized concerns regarding light pollution and habitat modification where large-scale artificial photosynthesis arrays are deployed. Standardized ecological risk assessment protocols suggest minimal negative impacts when proper siting and operational guidelines are followed.

Long-term environmental monitoring frameworks must incorporate both direct impacts (water quality, energy consumption) and indirect effects (land use changes, ecosystem services). The development of industry-specific sustainability benchmarks remains crucial, with current best practices suggesting implementation of real-time monitoring systems that track at least 12 key environmental parameters to ensure optimal performance and minimal ecological disruption throughout the technology lifecycle.

Regulatory Framework for Industrial Water Recycling Technologies

The regulatory landscape governing artificial photosynthesis technologies for industrial water optimization varies significantly across regions and continues to evolve as these technologies mature. Currently, most jurisdictions lack specific regulatory frameworks directly addressing artificial photosynthesis, instead relying on broader environmental protection laws, water management regulations, and industrial emissions standards.

In the United States, the Environmental Protection Agency (EPA) oversees water recycling technologies through the Clean Water Act and Safe Drinking Water Act, which would apply to artificial photosynthesis systems deployed in industrial settings. The EPA's National Pollutant Discharge Elimination System (NPDES) permitting program would likely govern effluent from such systems, while the Resource Conservation and Recovery Act may apply to byproducts generated during operation.

The European Union has established more progressive regulatory frameworks through the Water Framework Directive and Industrial Emissions Directive, which emphasize integrated water management and best available techniques. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) would apply to novel catalysts and materials used in artificial photosynthesis systems, requiring thorough safety assessments.

In Asia, regulatory approaches vary widely. Japan's Water Pollution Control Law and China's Water Pollution Prevention and Control Law provide general frameworks that would encompass artificial photosynthesis technologies, though with varying degrees of enforcement and specificity.

International standards organizations, including ISO and ASTM International, are beginning to develop technical standards relevant to water recycling technologies, though specific standards for artificial photosynthesis remain limited. The development of these standards is crucial for technology commercialization and regulatory compliance.

Emerging regulatory trends include incentive-based approaches, such as tax benefits for water-efficient technologies and carbon credits for technologies that reduce greenhouse gas emissions while optimizing water use. Several jurisdictions are exploring regulatory sandboxes to allow controlled testing of artificial photosynthesis systems without full regulatory burden during development phases.

For technology developers, navigating this complex regulatory landscape requires early engagement with regulatory authorities, participation in standards development, and strategic planning for compliance across multiple jurisdictions. As artificial photosynthesis technologies advance toward commercial deployment, regulatory frameworks will likely evolve to address specific safety, environmental, and performance considerations unique to these systems.

In the United States, the Environmental Protection Agency (EPA) oversees water recycling technologies through the Clean Water Act and Safe Drinking Water Act, which would apply to artificial photosynthesis systems deployed in industrial settings. The EPA's National Pollutant Discharge Elimination System (NPDES) permitting program would likely govern effluent from such systems, while the Resource Conservation and Recovery Act may apply to byproducts generated during operation.

The European Union has established more progressive regulatory frameworks through the Water Framework Directive and Industrial Emissions Directive, which emphasize integrated water management and best available techniques. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) would apply to novel catalysts and materials used in artificial photosynthesis systems, requiring thorough safety assessments.

In Asia, regulatory approaches vary widely. Japan's Water Pollution Control Law and China's Water Pollution Prevention and Control Law provide general frameworks that would encompass artificial photosynthesis technologies, though with varying degrees of enforcement and specificity.

International standards organizations, including ISO and ASTM International, are beginning to develop technical standards relevant to water recycling technologies, though specific standards for artificial photosynthesis remain limited. The development of these standards is crucial for technology commercialization and regulatory compliance.

Emerging regulatory trends include incentive-based approaches, such as tax benefits for water-efficient technologies and carbon credits for technologies that reduce greenhouse gas emissions while optimizing water use. Several jurisdictions are exploring regulatory sandboxes to allow controlled testing of artificial photosynthesis systems without full regulatory burden during development phases.

For technology developers, navigating this complex regulatory landscape requires early engagement with regulatory authorities, participation in standards development, and strategic planning for compliance across multiple jurisdictions. As artificial photosynthesis technologies advance toward commercial deployment, regulatory frameworks will likely evolve to address specific safety, environmental, and performance considerations unique to these systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!