Innovative reactor designs for enhancing Artificial Photosynthesis.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Artificial Photosynthesis Reactor Evolution and Objectives

Artificial photosynthesis represents one of the most promising approaches to sustainable energy production, mimicking nature's ability to convert sunlight into chemical energy. The evolution of this technology spans several decades, beginning with rudimentary attempts in the 1970s to replicate photosynthetic processes using simple semiconductor materials. Early reactor designs primarily focused on water splitting for hydrogen production, with limited efficiency and stability.

The 1990s marked a significant shift with the introduction of photoelectrochemical cells that separated light absorption from catalytic reactions. These designs improved efficiency but struggled with scalability and durability under real-world conditions. By the early 2000s, researchers began developing integrated systems that combined multiple functional components, leading to the emergence of artificial leaf concepts pioneered by Daniel Nocera and others.

Recent technological advancements have accelerated reactor innovation, particularly in three critical areas: light harvesting, charge separation, and catalytic conversion. Modern designs increasingly incorporate nanomaterials, quantum dots, and biomimetic structures to enhance performance. The Z-scheme reactor architecture, inspired by natural photosynthesis, has emerged as a particularly promising approach for achieving higher solar-to-fuel conversion efficiencies.

Current reactor objectives focus on addressing several persistent challenges. Efficiency remains paramount, with researchers targeting solar-to-fuel conversion rates exceeding 10% for commercial viability. Stability presents another critical hurdle, as many promising materials degrade rapidly under operating conditions. Scalability considerations have driven interest in modular designs that can be deployed across various settings while maintaining performance.

Selectivity in product formation represents another key objective, particularly for carbon dioxide reduction reactions where multiple products are possible. Advanced reactor designs now incorporate strategies to direct reactions toward specific high-value products such as methanol, ethylene, or syngas rather than simple mixtures.

Integration with existing infrastructure constitutes an increasingly important design consideration. Next-generation reactors aim for compatibility with renewable energy systems, enabling intermittent operation and storage capabilities. This includes hybrid approaches that combine artificial photosynthesis with biological systems or conventional renewable technologies.

The ultimate objective remains developing economically viable artificial photosynthesis systems that can operate at industrial scales. This requires holistic reactor designs that balance efficiency, durability, and cost while minimizing environmental impacts throughout the lifecycle. Recent techno-economic analyses suggest that achieving cost parity with fossil fuels requires further breakthroughs in materials science and engineering, driving continued innovation in reactor architectures.

The 1990s marked a significant shift with the introduction of photoelectrochemical cells that separated light absorption from catalytic reactions. These designs improved efficiency but struggled with scalability and durability under real-world conditions. By the early 2000s, researchers began developing integrated systems that combined multiple functional components, leading to the emergence of artificial leaf concepts pioneered by Daniel Nocera and others.

Recent technological advancements have accelerated reactor innovation, particularly in three critical areas: light harvesting, charge separation, and catalytic conversion. Modern designs increasingly incorporate nanomaterials, quantum dots, and biomimetic structures to enhance performance. The Z-scheme reactor architecture, inspired by natural photosynthesis, has emerged as a particularly promising approach for achieving higher solar-to-fuel conversion efficiencies.

Current reactor objectives focus on addressing several persistent challenges. Efficiency remains paramount, with researchers targeting solar-to-fuel conversion rates exceeding 10% for commercial viability. Stability presents another critical hurdle, as many promising materials degrade rapidly under operating conditions. Scalability considerations have driven interest in modular designs that can be deployed across various settings while maintaining performance.

Selectivity in product formation represents another key objective, particularly for carbon dioxide reduction reactions where multiple products are possible. Advanced reactor designs now incorporate strategies to direct reactions toward specific high-value products such as methanol, ethylene, or syngas rather than simple mixtures.

Integration with existing infrastructure constitutes an increasingly important design consideration. Next-generation reactors aim for compatibility with renewable energy systems, enabling intermittent operation and storage capabilities. This includes hybrid approaches that combine artificial photosynthesis with biological systems or conventional renewable technologies.

The ultimate objective remains developing economically viable artificial photosynthesis systems that can operate at industrial scales. This requires holistic reactor designs that balance efficiency, durability, and cost while minimizing environmental impacts throughout the lifecycle. Recent techno-economic analyses suggest that achieving cost parity with fossil fuels requires further breakthroughs in materials science and engineering, driving continued innovation in reactor architectures.

Market Analysis for Sustainable Carbon Capture Technologies

The sustainable carbon capture technology market is experiencing significant growth driven by increasing global focus on climate change mitigation and carbon neutrality goals. Current market valuation stands at approximately $2 billion, with projections indicating expansion to $7 billion by 2028, representing a compound annual growth rate of 19.2%. This growth trajectory is supported by stringent environmental regulations, carbon pricing mechanisms, and corporate sustainability commitments across major economies.

Artificial photosynthesis technologies, particularly innovative reactor designs, represent a promising segment within this market. Unlike conventional carbon capture methods that focus on point-source emissions, artificial photosynthesis offers the advantage of direct air capture while simultaneously producing valuable chemical feedstocks or fuels. This dual functionality creates multiple revenue streams, enhancing the economic viability of deployment.

Market demand is particularly strong in regions with ambitious climate targets, including the European Union, North America, and increasingly in Asia-Pacific countries. Industries seeking these technologies include energy production, chemical manufacturing, cement production, and transportation - sectors facing significant pressure to decarbonize operations while maintaining economic competitiveness.

Investment patterns reveal growing interest from both public and private sectors. Government funding for artificial photosynthesis research has increased substantially, with the US Department of Energy allocating over $100 million to related projects in recent years. Venture capital investment in this space has similarly grown, with funding rounds for startups developing novel reactor designs reaching record levels in 2022.

Consumer willingness to pay premiums for carbon-neutral products is creating downstream market pull for these technologies. Major corporations have announced carbon-neutral pledges that will require implementation of advanced carbon capture solutions, including artificial photosynthesis systems, to achieve their sustainability goals.

Market barriers include high capital costs, scalability challenges, and competition from established carbon capture technologies. The levelized cost of carbon capture using current artificial photosynthesis systems ranges from $200-600 per ton of CO2, significantly higher than some alternative approaches. However, technological improvements in reactor design efficiency could reduce these costs by 40-60% within the next decade.

Regional analysis indicates that North America currently leads in research and development activities, while Europe demonstrates the strongest regulatory framework supporting market adoption. Asia-Pacific represents the fastest-growing market, driven by China's ambitious carbon neutrality targets and Japan's hydrogen economy initiatives.

Artificial photosynthesis technologies, particularly innovative reactor designs, represent a promising segment within this market. Unlike conventional carbon capture methods that focus on point-source emissions, artificial photosynthesis offers the advantage of direct air capture while simultaneously producing valuable chemical feedstocks or fuels. This dual functionality creates multiple revenue streams, enhancing the economic viability of deployment.

Market demand is particularly strong in regions with ambitious climate targets, including the European Union, North America, and increasingly in Asia-Pacific countries. Industries seeking these technologies include energy production, chemical manufacturing, cement production, and transportation - sectors facing significant pressure to decarbonize operations while maintaining economic competitiveness.

Investment patterns reveal growing interest from both public and private sectors. Government funding for artificial photosynthesis research has increased substantially, with the US Department of Energy allocating over $100 million to related projects in recent years. Venture capital investment in this space has similarly grown, with funding rounds for startups developing novel reactor designs reaching record levels in 2022.

Consumer willingness to pay premiums for carbon-neutral products is creating downstream market pull for these technologies. Major corporations have announced carbon-neutral pledges that will require implementation of advanced carbon capture solutions, including artificial photosynthesis systems, to achieve their sustainability goals.

Market barriers include high capital costs, scalability challenges, and competition from established carbon capture technologies. The levelized cost of carbon capture using current artificial photosynthesis systems ranges from $200-600 per ton of CO2, significantly higher than some alternative approaches. However, technological improvements in reactor design efficiency could reduce these costs by 40-60% within the next decade.

Regional analysis indicates that North America currently leads in research and development activities, while Europe demonstrates the strongest regulatory framework supporting market adoption. Asia-Pacific represents the fastest-growing market, driven by China's ambitious carbon neutrality targets and Japan's hydrogen economy initiatives.

Current Reactor Designs and Technical Barriers

Artificial photosynthesis reactor designs have evolved significantly over the past decade, with several distinct architectures emerging as dominant approaches. Currently, the field is characterized by four primary reactor configurations: planar thin-film systems, particle suspension reactors, fixed-bed reactors, and membrane-integrated designs. Each offers unique advantages while facing specific technical limitations.

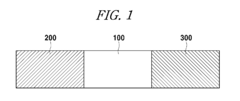

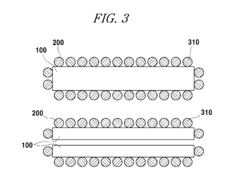

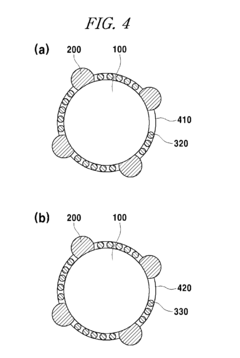

Planar thin-film reactors represent the most straightforward design, featuring layered photoactive materials on conductive substrates. These systems benefit from precise control over light absorption pathways and charge carrier transport. However, they suffer from limited active surface area and mass transport constraints, particularly when scaling beyond laboratory dimensions.

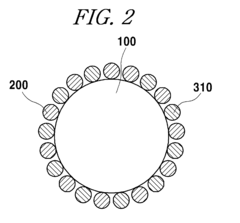

Particle suspension reactors utilize dispersed photocatalyst particles in aqueous solutions, offering superior surface area-to-volume ratios and enhanced mass transfer characteristics. While these systems demonstrate excellent scalability potential, they face significant challenges in product separation, catalyst recovery, and maintaining uniform light distribution throughout the suspension volume.

Fixed-bed reactors immobilize photocatalysts on structured supports, balancing the benefits of both planar and suspension approaches. These designs facilitate easier product separation while maintaining reasonable surface areas. The primary technical barriers include non-uniform illumination, potential mass transfer limitations at catalyst-support interfaces, and gradual photocatalyst deactivation.

Membrane-integrated systems represent the most advanced current design paradigm, incorporating selective membranes to separate reaction environments while facilitating product separation. These reactors show promising performance for selective product formation but face challenges in membrane stability under prolonged photocatalytic conditions.

Several critical technical barriers persist across all reactor configurations. Light management remains problematic, with issues of light scattering, reflection losses, and non-uniform photon distribution limiting overall system efficiency. Mass transport limitations, particularly at the catalyst-solution interface, create concentration gradients that reduce reaction rates. Heat management presents another significant challenge, as temperature fluctuations can dramatically affect reaction kinetics and catalyst stability.

Scale-up considerations represent perhaps the most formidable barrier to commercial implementation. Laboratory-scale demonstrations often fail to translate to larger systems due to non-linear scaling of light penetration, mass transport phenomena, and thermal management requirements. Additionally, current reactor materials face durability challenges under prolonged operation, with photocorrosion and catalyst poisoning significantly reducing system lifetimes.

Planar thin-film reactors represent the most straightforward design, featuring layered photoactive materials on conductive substrates. These systems benefit from precise control over light absorption pathways and charge carrier transport. However, they suffer from limited active surface area and mass transport constraints, particularly when scaling beyond laboratory dimensions.

Particle suspension reactors utilize dispersed photocatalyst particles in aqueous solutions, offering superior surface area-to-volume ratios and enhanced mass transfer characteristics. While these systems demonstrate excellent scalability potential, they face significant challenges in product separation, catalyst recovery, and maintaining uniform light distribution throughout the suspension volume.

Fixed-bed reactors immobilize photocatalysts on structured supports, balancing the benefits of both planar and suspension approaches. These designs facilitate easier product separation while maintaining reasonable surface areas. The primary technical barriers include non-uniform illumination, potential mass transfer limitations at catalyst-support interfaces, and gradual photocatalyst deactivation.

Membrane-integrated systems represent the most advanced current design paradigm, incorporating selective membranes to separate reaction environments while facilitating product separation. These reactors show promising performance for selective product formation but face challenges in membrane stability under prolonged photocatalytic conditions.

Several critical technical barriers persist across all reactor configurations. Light management remains problematic, with issues of light scattering, reflection losses, and non-uniform photon distribution limiting overall system efficiency. Mass transport limitations, particularly at the catalyst-solution interface, create concentration gradients that reduce reaction rates. Heat management presents another significant challenge, as temperature fluctuations can dramatically affect reaction kinetics and catalyst stability.

Scale-up considerations represent perhaps the most formidable barrier to commercial implementation. Laboratory-scale demonstrations often fail to translate to larger systems due to non-linear scaling of light penetration, mass transport phenomena, and thermal management requirements. Additionally, current reactor materials face durability challenges under prolonged operation, with photocorrosion and catalyst poisoning significantly reducing system lifetimes.

State-of-the-Art Reactor Configurations

01 Catalyst and Material Innovations for Artificial Photosynthesis

Advanced catalysts and materials are being developed to enhance the efficiency of artificial photosynthesis reactors. These innovations include novel photocatalysts, semiconductor materials, and nanostructured surfaces that can better capture light energy and facilitate electron transfer. By optimizing these materials, researchers can improve the conversion of solar energy into chemical energy, leading to more efficient artificial photosynthesis systems.- Catalyst and electrode design for artificial photosynthesis: Advanced catalyst and electrode designs are crucial for enhancing artificial photosynthesis reactors. These include novel materials and structures that improve electron transfer efficiency and reaction kinetics. Optimized electrodes can significantly increase the conversion of light energy to chemical energy, while specialized catalysts can reduce activation energy requirements for key reactions in the photosynthetic process.

- Light harvesting and utilization systems: Efficient light harvesting systems are essential components of artificial photosynthesis reactors. These systems include specialized materials and structures designed to capture a broader spectrum of light and channel the energy effectively to reaction centers. Innovations in this area focus on maximizing photon absorption, reducing energy loss during transfer, and ensuring optimal light distribution throughout the reactor system.

- Reactor design and configuration optimization: The physical design and configuration of artificial photosynthesis reactors significantly impact their efficiency. Innovations include modular designs, flow optimization, and novel geometries that enhance mass transfer and reaction kinetics. Advanced reactor configurations can improve the interaction between catalysts, light, and reactants while minimizing energy losses and maximizing product yield.

- Integration of biological components with synthetic systems: Hybrid systems that combine biological components with synthetic materials offer unique advantages for artificial photosynthesis. These bio-inspired approaches incorporate enzymes, proteins, or even modified microorganisms to enhance specific reaction pathways. The integration of biological elements can improve selectivity, reduce energy requirements, and enable more efficient carbon fixation processes.

- CO2 capture and conversion mechanisms: Enhanced CO2 capture and conversion mechanisms are critical for improving artificial photosynthesis efficiency. These innovations focus on selective CO2 adsorption materials, novel reduction pathways, and integrated systems that combine capture and conversion processes. Advanced techniques enable more efficient carbon dioxide utilization and transformation into valuable products such as fuels and chemical feedstocks.

02 Reactor Design and Configuration Optimization

The physical design and configuration of artificial photosynthesis reactors significantly impact their performance. Innovations in this area include optimized reactor geometries, improved light distribution systems, and enhanced mass transfer mechanisms. These design improvements help maximize light absorption, reduce energy losses, and ensure efficient reactant flow, ultimately leading to higher conversion efficiencies in artificial photosynthesis processes.Expand Specific Solutions03 Integration of Biological Components with Synthetic Systems

Hybrid systems that combine biological components with synthetic materials are emerging as promising approaches for artificial photosynthesis. These systems may incorporate enzymes, microorganisms, or biomimetic structures that replicate natural photosynthetic processes. By leveraging the efficiency of biological systems while overcoming their limitations through synthetic components, these hybrid reactors can achieve enhanced stability and performance in converting solar energy to chemical fuels.Expand Specific Solutions04 Advanced Control Systems and Monitoring Technologies

Sophisticated control systems and monitoring technologies are being implemented to optimize the operation of artificial photosynthesis reactors. These include real-time sensors, feedback control mechanisms, and predictive algorithms that can adjust operating conditions based on performance metrics. By maintaining optimal reaction conditions and responding to changes in input parameters, these control systems help maximize efficiency and product yield in artificial photosynthesis processes.Expand Specific Solutions05 Scalable and Sustainable Reactor Designs

Developing scalable and sustainable reactor designs is crucial for the practical implementation of artificial photosynthesis technologies. These designs focus on cost-effective materials, modular construction, and energy-efficient operation. Additionally, they incorporate considerations for long-term durability, environmental impact, and integration with existing energy infrastructure. Such approaches aim to facilitate the transition of artificial photosynthesis from laboratory-scale demonstrations to commercially viable systems for renewable energy production.Expand Specific Solutions

Leading Research Groups and Commercial Entities

Artificial Photosynthesis reactor design innovation is currently in an early growth phase, with the market expected to expand significantly as clean energy demands increase. The competitive landscape features both established corporations and academic institutions driving technological advancement. Companies like Syzygy Plasmonics lead with photocatalytic reactor technology that operates at significantly lower temperatures than conventional methods, while DENSO, Toyota Central R&D Labs, and FUJIFILM bring industrial scale and manufacturing expertise. Academic institutions including Peking University, University of California, and Xi'an Jiaotong University contribute fundamental research breakthroughs. The technology remains in development with varying maturity levels across different approaches, suggesting a pre-commercialization phase with significant potential for disruptive innovation as reactor designs continue to evolve.

Syzygy Plasmonics, Inc.

Technical Solution: Syzygy Plasmonics has developed a groundbreaking photocatalytic reactor design that utilizes light-activated catalysts for artificial photosynthesis. Their technology employs plasmonic nanoparticles that enhance light absorption and energy conversion efficiency. The reactor architecture features a distributed light delivery system that ensures uniform illumination throughout the reaction chamber, maximizing photon utilization. Their proprietary "Rigel" reactor platform integrates advanced materials including gold and silver nanostructures that create localized surface plasmon resonance effects, dramatically increasing reaction rates and quantum efficiency. The system operates at ambient temperatures and pressures, significantly reducing energy requirements compared to traditional thermocatalytic processes. Syzygy's modular design allows for scalable implementation across various applications, from hydrogen production to carbon dioxide conversion into valuable chemicals and fuels.

Strengths: Superior energy efficiency through ambient temperature operation; exceptional scalability through modular design; significantly reduced carbon footprint compared to thermal catalysis methods. Weaknesses: Higher initial capital costs; requires specialized catalyst materials that may have limited availability; technology still scaling to industrial production volumes.

The Regents of the University of California

Technical Solution: The University of California has pioneered several innovative reactor designs for artificial photosynthesis through their Joint Center for Artificial Photosynthesis (JCAP). Their most advanced system features a tandem photoelectrochemical cell architecture that separates water oxidation and CO2 reduction reactions into distinct compartments while maintaining electrical connectivity. This design incorporates specialized semiconductor photoelectrodes with tailored band gaps to absorb complementary portions of the solar spectrum, maximizing energy harvesting efficiency. The reactor employs a membrane-electrode assembly configuration with integrated catalysts that facilitate selective product formation while minimizing crossover effects. Their latest prototypes achieve solar-to-fuel conversion efficiencies exceeding 5% for sustained operation periods, representing significant advances over previous generations. The system also incorporates novel protection layers that enhance the stability of semiconductor materials in aqueous environments, addressing one of the key challenges in artificial photosynthesis technology.

Strengths: Exceptional scientific foundation with comprehensive understanding of fundamental photosynthetic processes; demonstrated long-term stability improvements; integrated systems approach addressing multiple technical challenges simultaneously. Weaknesses: Complex fabrication requirements may limit large-scale manufacturing; relatively high materials costs; still requires further efficiency improvements for commercial viability.

Breakthrough Patents in Photocatalytic Reactor Design

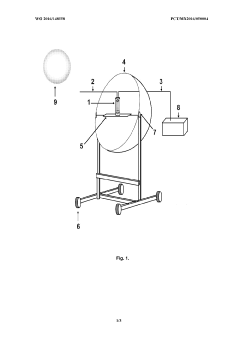

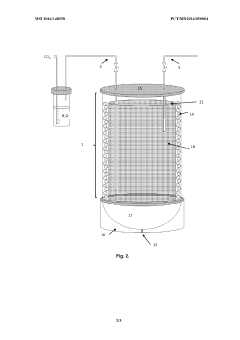

Process for producing carbon-hydrogen compounds by means of artificial photosynthesis

PatentWO2016148558A1

Innovation

- A process using a photocatalytic structure with a parabolic light concentrator to exponentially increase photon incidence on a photocatalyst, such as 50%Cu/Semiconductor, within a tubular quartz reactor, allowing for the production of hydrocarbons and oxygen-containing molecules from carbon dioxide and water vapor without external voltage, utilizing low-cost materials and abundant elements like Co, Cu, Zn, and Ti, and optimizing energy efficiency.

Method for reducing carbon dioxide by using sunlight and hydrogen and apparatus for same

PatentInactiveUS20140179810A1

Innovation

- A method and apparatus using a composite catalyst containing a metal, metal compound, and photosensitizer to reduce carbon dioxide using sunlight and hydrogen, producing liquid fuels like hydrocarbons by reacting hydrogen and carbon dioxide gases under sunlight irradiation.

Scalability and Industrial Implementation Challenges

The scaling of artificial photosynthesis technologies from laboratory prototypes to industrial-scale implementations presents significant challenges that must be addressed for commercial viability. Current reactor designs often demonstrate promising efficiency at small scales but encounter substantial hurdles when expanded to production volumes. These challenges include maintaining reaction efficiency across larger surface areas, ensuring uniform light distribution, and managing heat dissipation in scaled-up systems.

Material constraints represent another critical barrier to industrial implementation. Many high-performance catalysts for artificial photosynthesis rely on rare earth elements or precious metals with limited availability and high costs. The development of abundant, low-cost materials that maintain catalytic performance at industrial scales remains an ongoing research priority. Additionally, the durability of components under continuous operation conditions must be significantly improved to meet commercial requirements for system longevity.

Engineering challenges further complicate the scaling process. Reactor designs must accommodate the integration of multiple components—light-harvesting systems, catalysts, membranes, and product separation mechanisms—while maintaining optimal operating conditions across larger dimensions. The complexity increases when considering requirements for modular design to facilitate maintenance and component replacement in industrial settings.

Economic factors ultimately determine the feasibility of large-scale implementation. Current artificial photosynthesis systems typically have high capital costs and relatively low energy conversion efficiencies compared to conventional renewable energy technologies. The levelized cost of products (whether hydrogen, carbon-based fuels, or chemicals) must be competitive with existing production methods to justify industrial adoption. This necessitates reactor designs that maximize throughput while minimizing material and operational costs.

Infrastructure compatibility presents additional implementation challenges. Industrial-scale artificial photosynthesis systems must integrate with existing energy and chemical production infrastructure or justify the development of new supporting systems. This includes considerations for product storage, transportation, and utilization pathways that may require significant investment beyond the reactor technology itself.

Regulatory frameworks and standardization also influence scalability. The development of industry standards for safety, performance metrics, and product quality will be essential for widespread adoption. Reactor designs must accommodate these evolving requirements while maintaining flexibility to adapt to different regulatory environments across global markets.

Material constraints represent another critical barrier to industrial implementation. Many high-performance catalysts for artificial photosynthesis rely on rare earth elements or precious metals with limited availability and high costs. The development of abundant, low-cost materials that maintain catalytic performance at industrial scales remains an ongoing research priority. Additionally, the durability of components under continuous operation conditions must be significantly improved to meet commercial requirements for system longevity.

Engineering challenges further complicate the scaling process. Reactor designs must accommodate the integration of multiple components—light-harvesting systems, catalysts, membranes, and product separation mechanisms—while maintaining optimal operating conditions across larger dimensions. The complexity increases when considering requirements for modular design to facilitate maintenance and component replacement in industrial settings.

Economic factors ultimately determine the feasibility of large-scale implementation. Current artificial photosynthesis systems typically have high capital costs and relatively low energy conversion efficiencies compared to conventional renewable energy technologies. The levelized cost of products (whether hydrogen, carbon-based fuels, or chemicals) must be competitive with existing production methods to justify industrial adoption. This necessitates reactor designs that maximize throughput while minimizing material and operational costs.

Infrastructure compatibility presents additional implementation challenges. Industrial-scale artificial photosynthesis systems must integrate with existing energy and chemical production infrastructure or justify the development of new supporting systems. This includes considerations for product storage, transportation, and utilization pathways that may require significant investment beyond the reactor technology itself.

Regulatory frameworks and standardization also influence scalability. The development of industry standards for safety, performance metrics, and product quality will be essential for widespread adoption. Reactor designs must accommodate these evolving requirements while maintaining flexibility to adapt to different regulatory environments across global markets.

Environmental Impact and Policy Frameworks

Artificial photosynthesis technologies, particularly innovative reactor designs, present significant environmental implications that must be carefully evaluated within existing and emerging policy frameworks. The environmental benefits of these systems are substantial, offering potential carbon dioxide reduction pathways that align with global climate goals. Studies indicate that optimized artificial photosynthesis reactors could potentially capture 10-100 times more carbon per unit area than natural forests, representing a critical tool for atmospheric carbon management.

Water consumption represents a key environmental consideration, as most reactor designs require water as both a reaction medium and hydrogen source. Advanced membrane-integrated systems have demonstrated up to 40% reduction in water requirements compared to first-generation designs, though water usage efficiency remains a challenge in scaling these technologies. The environmental footprint of reactor materials must also be considered, with lifecycle assessments revealing that rare earth elements in certain catalyst systems create extraction-related environmental burdens that partially offset carbon benefits.

Policy frameworks governing artificial photosynthesis development vary significantly across regions. The European Union has established the most comprehensive regulatory approach through its Renewable Energy Directive II, which specifically includes provisions for synthetic fuels produced via artificial photosynthesis pathways. These regulations mandate lifecycle carbon accounting and establish minimum efficiency thresholds for commercial deployment eligibility.

In the United States, policy support remains fragmented, with the Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) providing targeted funding for reactor innovations, but without corresponding regulatory frameworks to facilitate commercial deployment. The recent Infrastructure Investment and Jobs Act allocates $100 million specifically for artificial photosynthesis demonstration projects, signaling increased policy attention.

Asian markets, particularly China and Japan, have integrated artificial photosynthesis into broader industrial decarbonization strategies. China's 14th Five-Year Plan explicitly mentions artificial photosynthesis as a strategic technology, with corresponding incentives for industrial adoption and research funding mechanisms that prioritize reactor efficiency improvements.

International coordination efforts through the Mission Innovation initiative have established shared research priorities and performance metrics for artificial photosynthesis technologies. These frameworks emphasize standardized efficiency reporting, environmental impact assessments, and technology readiness level definitions that enable cross-border collaboration and technology transfer. The International Energy Agency estimates that harmonized policy approaches could accelerate commercial deployment timelines by 5-7 years compared to fragmented national strategies.

Water consumption represents a key environmental consideration, as most reactor designs require water as both a reaction medium and hydrogen source. Advanced membrane-integrated systems have demonstrated up to 40% reduction in water requirements compared to first-generation designs, though water usage efficiency remains a challenge in scaling these technologies. The environmental footprint of reactor materials must also be considered, with lifecycle assessments revealing that rare earth elements in certain catalyst systems create extraction-related environmental burdens that partially offset carbon benefits.

Policy frameworks governing artificial photosynthesis development vary significantly across regions. The European Union has established the most comprehensive regulatory approach through its Renewable Energy Directive II, which specifically includes provisions for synthetic fuels produced via artificial photosynthesis pathways. These regulations mandate lifecycle carbon accounting and establish minimum efficiency thresholds for commercial deployment eligibility.

In the United States, policy support remains fragmented, with the Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) providing targeted funding for reactor innovations, but without corresponding regulatory frameworks to facilitate commercial deployment. The recent Infrastructure Investment and Jobs Act allocates $100 million specifically for artificial photosynthesis demonstration projects, signaling increased policy attention.

Asian markets, particularly China and Japan, have integrated artificial photosynthesis into broader industrial decarbonization strategies. China's 14th Five-Year Plan explicitly mentions artificial photosynthesis as a strategic technology, with corresponding incentives for industrial adoption and research funding mechanisms that prioritize reactor efficiency improvements.

International coordination efforts through the Mission Innovation initiative have established shared research priorities and performance metrics for artificial photosynthesis technologies. These frameworks emphasize standardized efficiency reporting, environmental impact assessments, and technology readiness level definitions that enable cross-border collaboration and technology transfer. The International Energy Agency estimates that harmonized policy approaches could accelerate commercial deployment timelines by 5-7 years compared to fragmented national strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!