Artificial Photosynthesis in photochemical energy storage systems.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Artificial Photosynthesis Background and Objectives

Artificial photosynthesis represents one of the most promising approaches to sustainable energy production, drawing inspiration from nature's elegant solution to energy conversion. Since the early 1970s, researchers have been attempting to mimic the natural photosynthetic process that plants use to convert sunlight, water, and carbon dioxide into carbohydrates and oxygen. The evolution of this technology has accelerated significantly in the past decade, driven by urgent global needs for carbon-neutral energy solutions and advances in materials science, nanotechnology, and catalysis.

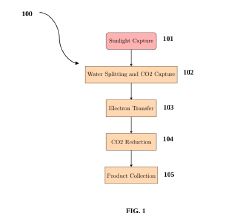

The fundamental goal of artificial photosynthesis in photochemical energy storage systems is to develop efficient, scalable, and economically viable methods to convert solar energy into chemical bonds, creating storable fuels that can be used on demand. Unlike conventional solar panels that produce electricity directly, artificial photosynthesis systems aim to produce hydrogen, methanol, or other hydrocarbon fuels that can be stored, transported, and utilized within existing energy infrastructure.

Historical development in this field has progressed through several distinct phases. Early research focused primarily on understanding the natural photosynthetic process at a molecular level. This was followed by attempts to create simplified synthetic systems that could replicate key aspects of photosynthesis. Recent advances have centered on developing more efficient catalysts, improving light-harvesting capabilities, and enhancing overall system stability and durability.

The technical objectives for artificial photosynthesis research include achieving solar-to-fuel conversion efficiencies exceeding 10%, developing systems with operational lifetimes of several years, reducing dependence on rare or expensive materials, and designing scalable architectures suitable for industrial implementation. Additionally, researchers aim to integrate artificial photosynthesis with carbon capture technologies to address both energy production and carbon dioxide reduction simultaneously.

Current research trends are moving toward integrated systems that combine multiple functions—light absorption, charge separation, catalysis, and product separation—into cohesive devices. Biomimetic approaches that more closely replicate natural photosynthetic structures are gaining traction, as are hybrid systems that combine biological and synthetic components to leverage the advantages of both.

The long-term vision for artificial photosynthesis extends beyond simple fuel production to creating versatile platforms for chemical synthesis powered directly by sunlight. This could potentially revolutionize not only energy production but also chemical manufacturing processes, offering pathways to produce valuable chemicals and materials with minimal environmental impact and reduced dependence on fossil resources.

The fundamental goal of artificial photosynthesis in photochemical energy storage systems is to develop efficient, scalable, and economically viable methods to convert solar energy into chemical bonds, creating storable fuels that can be used on demand. Unlike conventional solar panels that produce electricity directly, artificial photosynthesis systems aim to produce hydrogen, methanol, or other hydrocarbon fuels that can be stored, transported, and utilized within existing energy infrastructure.

Historical development in this field has progressed through several distinct phases. Early research focused primarily on understanding the natural photosynthetic process at a molecular level. This was followed by attempts to create simplified synthetic systems that could replicate key aspects of photosynthesis. Recent advances have centered on developing more efficient catalysts, improving light-harvesting capabilities, and enhancing overall system stability and durability.

The technical objectives for artificial photosynthesis research include achieving solar-to-fuel conversion efficiencies exceeding 10%, developing systems with operational lifetimes of several years, reducing dependence on rare or expensive materials, and designing scalable architectures suitable for industrial implementation. Additionally, researchers aim to integrate artificial photosynthesis with carbon capture technologies to address both energy production and carbon dioxide reduction simultaneously.

Current research trends are moving toward integrated systems that combine multiple functions—light absorption, charge separation, catalysis, and product separation—into cohesive devices. Biomimetic approaches that more closely replicate natural photosynthetic structures are gaining traction, as are hybrid systems that combine biological and synthetic components to leverage the advantages of both.

The long-term vision for artificial photosynthesis extends beyond simple fuel production to creating versatile platforms for chemical synthesis powered directly by sunlight. This could potentially revolutionize not only energy production but also chemical manufacturing processes, offering pathways to produce valuable chemicals and materials with minimal environmental impact and reduced dependence on fossil resources.

Market Analysis for Photochemical Energy Storage

The global market for photochemical energy storage systems, particularly those utilizing artificial photosynthesis technologies, is experiencing significant growth driven by increasing energy demands and environmental concerns. Current market valuations indicate that the photochemical energy storage sector is positioned to reach approximately $2.5 billion by 2030, with a compound annual growth rate of 15-18% from 2023 onwards. This growth trajectory is substantially higher than conventional energy storage technologies, reflecting the increasing recognition of artificial photosynthesis as a viable solution for sustainable energy storage.

Demand patterns show regional variations, with North America and Europe leading in research investments and early commercial applications. Asia-Pacific markets, particularly China, Japan, and South Korea, are rapidly expanding their market presence through aggressive government funding programs and industrial partnerships. These regions collectively account for over 70% of the current market activity in photochemical energy storage technologies.

Consumer and industrial sectors represent distinct market segments with different adoption drivers. The industrial sector currently dominates market share, with applications in grid-scale energy storage solutions and integration with renewable energy generation facilities. The consumer market remains nascent but shows promising growth potential as miniaturization and cost reduction efforts advance.

Market analysis reveals several key drivers accelerating adoption. Environmental regulations and carbon reduction commitments are creating favorable policy environments for clean energy technologies. The declining costs of photocatalytic materials and system components have improved economic feasibility, with production costs decreasing by approximately 22% over the past five years. Additionally, increasing grid instability and energy security concerns are pushing utilities and governments to invest in diverse energy storage solutions.

Barriers to market expansion include technological limitations in efficiency and durability of artificial photosynthesis systems. Current commercial systems typically achieve solar-to-fuel conversion efficiencies between 5-12%, below the theoretical maximum but showing steady improvement. Cost competitiveness remains challenging when compared to established energy storage technologies like lithium-ion batteries, though the gap is narrowing as scale economies develop.

Future market projections indicate that photochemical energy storage will likely follow a similar adoption curve to solar photovoltaics, with an initial period of specialized applications followed by broader market penetration as costs decrease and performance improves. Strategic partnerships between research institutions, technology developers, and energy utilities are emerging as the dominant business model, creating integrated value chains that accelerate commercialization timelines.

Demand patterns show regional variations, with North America and Europe leading in research investments and early commercial applications. Asia-Pacific markets, particularly China, Japan, and South Korea, are rapidly expanding their market presence through aggressive government funding programs and industrial partnerships. These regions collectively account for over 70% of the current market activity in photochemical energy storage technologies.

Consumer and industrial sectors represent distinct market segments with different adoption drivers. The industrial sector currently dominates market share, with applications in grid-scale energy storage solutions and integration with renewable energy generation facilities. The consumer market remains nascent but shows promising growth potential as miniaturization and cost reduction efforts advance.

Market analysis reveals several key drivers accelerating adoption. Environmental regulations and carbon reduction commitments are creating favorable policy environments for clean energy technologies. The declining costs of photocatalytic materials and system components have improved economic feasibility, with production costs decreasing by approximately 22% over the past five years. Additionally, increasing grid instability and energy security concerns are pushing utilities and governments to invest in diverse energy storage solutions.

Barriers to market expansion include technological limitations in efficiency and durability of artificial photosynthesis systems. Current commercial systems typically achieve solar-to-fuel conversion efficiencies between 5-12%, below the theoretical maximum but showing steady improvement. Cost competitiveness remains challenging when compared to established energy storage technologies like lithium-ion batteries, though the gap is narrowing as scale economies develop.

Future market projections indicate that photochemical energy storage will likely follow a similar adoption curve to solar photovoltaics, with an initial period of specialized applications followed by broader market penetration as costs decrease and performance improves. Strategic partnerships between research institutions, technology developers, and energy utilities are emerging as the dominant business model, creating integrated value chains that accelerate commercialization timelines.

Technical Challenges in Artificial Photosynthesis

Despite significant advancements in artificial photosynthesis research, numerous technical challenges continue to impede widespread implementation in photochemical energy storage systems. The primary obstacle remains the development of efficient and stable catalysts for water oxidation and CO2 reduction reactions. Current catalysts often suffer from low turnover frequencies, limited selectivity, and rapid degradation under operating conditions, particularly when exposed to reactive oxygen species generated during water splitting processes.

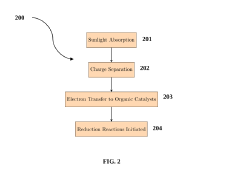

Light harvesting efficiency presents another significant challenge. Natural photosynthesis utilizes a complex antenna system to capture photons across the visible spectrum, whereas artificial systems typically absorb only narrow wavelength ranges. This limitation substantially reduces the theoretical maximum solar-to-fuel conversion efficiency, which currently stands at 4-5% for most laboratory systems, far below the 20-30% efficiency required for commercial viability.

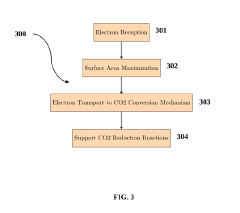

The integration of multiple components into a cohesive system introduces additional complications. Artificial photosynthesis requires precise spatial organization of light-harvesting units, electron transfer mediators, and catalytic centers. Achieving optimal electron transfer kinetics while minimizing recombination losses remains difficult, especially when scaling beyond laboratory demonstrations to practical device architectures.

Stability under operating conditions represents a persistent challenge. Many promising materials degrade rapidly under the oxidative conditions necessary for water splitting or lose activity when exposed to the complex mixture of intermediates formed during CO2 reduction. Most laboratory systems demonstrate significant performance degradation within hours or days, whereas commercial applications would require stability measured in years.

Scale-up and manufacturing considerations introduce further technical hurdles. Many current approaches rely on rare earth elements or precious metals that face supply constraints. Additionally, fabrication methods developed for laboratory-scale demonstrations often cannot be directly translated to mass production techniques, creating a significant barrier to commercialization.

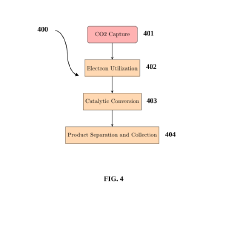

The management of reaction intermediates and products presents unique challenges. In CO2 reduction systems, product selectivity remains problematic, with many catalysts producing mixtures of carbon-based products rather than a single desired compound. Similarly, oxygen and hydrogen management in water splitting systems requires careful engineering to prevent explosive mixtures while maintaining system efficiency.

Addressing these technical challenges requires interdisciplinary approaches combining advances in materials science, nanotechnology, electrochemistry, and photophysics. Recent progress in earth-abundant catalysts, hierarchical nanostructured materials, and biomimetic approaches offers promising pathways forward, though significant breakthroughs are still needed to achieve commercially viable artificial photosynthesis systems.

Light harvesting efficiency presents another significant challenge. Natural photosynthesis utilizes a complex antenna system to capture photons across the visible spectrum, whereas artificial systems typically absorb only narrow wavelength ranges. This limitation substantially reduces the theoretical maximum solar-to-fuel conversion efficiency, which currently stands at 4-5% for most laboratory systems, far below the 20-30% efficiency required for commercial viability.

The integration of multiple components into a cohesive system introduces additional complications. Artificial photosynthesis requires precise spatial organization of light-harvesting units, electron transfer mediators, and catalytic centers. Achieving optimal electron transfer kinetics while minimizing recombination losses remains difficult, especially when scaling beyond laboratory demonstrations to practical device architectures.

Stability under operating conditions represents a persistent challenge. Many promising materials degrade rapidly under the oxidative conditions necessary for water splitting or lose activity when exposed to the complex mixture of intermediates formed during CO2 reduction. Most laboratory systems demonstrate significant performance degradation within hours or days, whereas commercial applications would require stability measured in years.

Scale-up and manufacturing considerations introduce further technical hurdles. Many current approaches rely on rare earth elements or precious metals that face supply constraints. Additionally, fabrication methods developed for laboratory-scale demonstrations often cannot be directly translated to mass production techniques, creating a significant barrier to commercialization.

The management of reaction intermediates and products presents unique challenges. In CO2 reduction systems, product selectivity remains problematic, with many catalysts producing mixtures of carbon-based products rather than a single desired compound. Similarly, oxygen and hydrogen management in water splitting systems requires careful engineering to prevent explosive mixtures while maintaining system efficiency.

Addressing these technical challenges requires interdisciplinary approaches combining advances in materials science, nanotechnology, electrochemistry, and photophysics. Recent progress in earth-abundant catalysts, hierarchical nanostructured materials, and biomimetic approaches offers promising pathways forward, though significant breakthroughs are still needed to achieve commercially viable artificial photosynthesis systems.

Current Artificial Photosynthesis Implementation Approaches

01 Photocatalytic systems for artificial photosynthesis

Photocatalytic systems are designed to mimic natural photosynthesis by converting light energy into chemical energy. These systems typically involve specialized catalysts that facilitate the conversion of water and carbon dioxide into useful fuels like hydrogen or hydrocarbons. The photocatalysts are often semiconductor materials that can absorb light and generate electron-hole pairs, which then drive redox reactions. Advanced designs incorporate co-catalysts and nanostructured materials to enhance efficiency and stability of the energy conversion process.- Photocatalytic systems for artificial photosynthesis: Photocatalytic systems are designed to mimic natural photosynthesis by converting light energy into chemical energy. These systems typically involve specialized catalysts that can split water into hydrogen and oxygen or reduce carbon dioxide to useful fuels. The photocatalysts are engineered to efficiently capture light energy and facilitate electron transfer reactions, enabling the storage of solar energy in chemical bonds for later use. Advanced materials and nanostructures are employed to enhance the efficiency and stability of these artificial photosynthesis systems.

- Electrochemical cells for energy conversion and storage: Electrochemical cells are utilized in artificial photosynthesis systems to convert and store energy. These cells contain electrodes where redox reactions occur, converting light energy into chemical energy that can be stored. The design of these cells often includes specialized membranes that separate reaction compartments while allowing ion transport. By optimizing the electrochemical interfaces and reaction conditions, these systems can achieve higher efficiency in converting solar energy to storable chemical fuels, providing a sustainable approach to energy storage.

- Carbon dioxide reduction for fuel production: Artificial photosynthesis systems can be designed to reduce carbon dioxide to produce valuable fuels and chemicals. These systems use specialized catalysts and electrode materials that can efficiently capture CO2 and convert it to products such as methanol, formic acid, or hydrocarbons. The process not only provides a method for energy storage but also offers a pathway for carbon capture and utilization, addressing both energy storage needs and climate change concerns. Various reactor designs and process conditions are optimized to enhance the selectivity and efficiency of CO2 conversion.

- Integrated systems combining light harvesting and energy storage: Integrated systems for artificial photosynthesis combine light harvesting components with energy storage mechanisms in a single device or closely coupled system. These designs may incorporate photovoltaic elements, catalytic surfaces, and storage media to create a seamless process from light absorption to energy storage. By integrating these components, system efficiency can be improved through reduced energy losses in transfer steps. These systems often employ advanced materials and architectures to optimize the flow of energy and electrons throughout the process, resulting in more efficient solar energy capture and storage.

- Novel materials and structures for enhanced efficiency: Research in artificial photosynthesis focuses on developing novel materials and structures to enhance energy conversion and storage efficiency. These include nanostructured catalysts, quantum dots, metal-organic frameworks, and biomimetic materials designed to improve light absorption, charge separation, and catalytic activity. Advanced fabrication techniques are employed to create precisely controlled structures with optimized interfaces between components. These materials innovations aim to overcome efficiency limitations of current systems and enable practical applications of artificial photosynthesis for sustainable energy storage.

02 Electrochemical cells for energy storage from artificial photosynthesis

Electrochemical cells serve as critical components in artificial photosynthesis systems for storing the generated energy. These cells typically consist of electrodes, electrolytes, and membranes that facilitate the conversion of solar energy into storable chemical energy. The designs focus on optimizing electron transfer processes, reducing overpotentials, and enhancing the stability of the system. Some advanced systems integrate photoelectrochemical cells with conventional batteries or capacitors to create hybrid energy storage solutions that can efficiently capture and release energy on demand.Expand Specific Solutions03 Biomimetic materials and structures for artificial photosynthesis

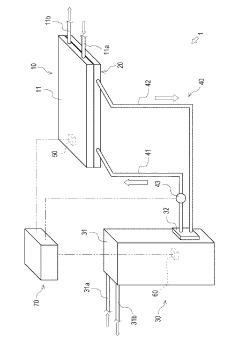

Biomimetic materials and structures are designed to replicate the efficiency of natural photosynthesis by mimicking the molecular architecture of plants. These materials often incorporate synthetic analogs of chlorophyll, enzyme-like catalysts, and self-assembling nanostructures that can harvest light and facilitate electron transfer. The biomimetic approach focuses on creating hierarchical structures that optimize light absorption, charge separation, and catalytic reactions. These systems typically employ porous frameworks, layered materials, or molecular assemblies that provide high surface areas for reactions while maintaining efficient energy transfer pathways.Expand Specific Solutions04 Integration of artificial photosynthesis with hydrogen production and storage

Systems that integrate artificial photosynthesis with hydrogen production and storage represent a complete energy cycle solution. These integrated systems typically split water into hydrogen and oxygen using solar energy, then store the hydrogen for later use as a clean fuel. The designs focus on optimizing the water-splitting reaction, hydrogen capture, and storage methods such as metal hydrides, chemical carriers, or pressurized tanks. Advanced systems incorporate selective membranes, pressure management components, and safety features to ensure efficient and safe operation of the hydrogen storage system.Expand Specific Solutions05 Carbon dioxide conversion and utilization systems

Carbon dioxide conversion and utilization systems capture CO2 and transform it into valuable chemicals or fuels through artificial photosynthesis processes. These systems typically employ specialized catalysts that can reduce CO2 to products like carbon monoxide, methanol, or formic acid using solar energy. The designs focus on optimizing CO2 capture, activation of the stable CO2 molecule, and selective conversion to desired products. Advanced systems incorporate multi-functional catalysts, reactor designs that maximize contact between CO2 and catalytic surfaces, and separation technologies that efficiently isolate the produced fuels or chemicals for storage and later use.Expand Specific Solutions

Leading Organizations in Artificial Photosynthesis Research

Artificial Photosynthesis in photochemical energy storage systems is currently in an early commercialization phase, with the global market expected to reach $25 billion by 2030. The technology is advancing from laboratory research to practical applications, with varying degrees of maturity across different approaches. Leading academic institutions (MIT, University of California, University of Tokyo) are driving fundamental research, while corporate players demonstrate different strategic focuses: FUJIFILM and Toshiba are developing materials and components; Toyota Central R&D and DENSO are exploring automotive applications; IBM and Panasonic are focusing on system integration. The field is characterized by international collaboration between academia and industry, with significant patent activity from both Asian and Western organizations indicating a competitive but collaborative innovation landscape.

University of Tokyo

Technical Solution: The University of Tokyo has developed sophisticated artificial photosynthesis systems focusing on molecular catalysts and novel semiconductor architectures. Their approach employs biomimetic molecular complexes that replicate the function of photosystem II in natural photosynthesis, achieving precise control over electron transfer processes. University researchers have created innovative metal-organic frameworks (MOFs) that serve as platforms for artificial photosynthesis, providing ordered structures with high surface areas that maximize catalytic activity. Their technology includes the development of specialized ruthenium and iridium complexes that can efficiently catalyze water oxidation with low overpotentials, addressing one of the key efficiency bottlenecks in artificial photosynthesis. The University of Tokyo has also pioneered the use of carbon nitride-based photocatalysts modified with metal nanoparticles that demonstrate enhanced visible light absorption and improved charge separation properties. Their systems incorporate advanced characterization techniques that allow for real-time monitoring of reaction intermediates, providing crucial insights for catalyst optimization and system design.

Strengths: Sophisticated molecular design approach allows for atomic-level control of catalytic processes; strong fundamental understanding of reaction mechanisms enables rational system improvement; innovative materials combinations provide pathways to higher efficiencies. Weaknesses: Some systems rely on precious metals with limited availability; complex molecular catalysts can face stability challenges under operating conditions; scaling from laboratory demonstrations to practical systems requires significant engineering development.

Toyota Central R&D Labs, Inc.

Technical Solution: Toyota Central R&D Labs has developed innovative artificial photosynthesis systems focused on practical energy storage applications for transportation and distributed energy. Their approach centers on photocatalytic water splitting using semiconductor materials modified with co-catalysts to enhance hydrogen production efficiency. Toyota's researchers have created specialized photocatalyst particles with core-shell structures that improve charge separation and reduce recombination losses, a common efficiency bottleneck in photocatalytic systems. Their technology employs Z-scheme photocatalytic systems that mimic the two-step excitation process in natural photosynthesis, allowing for more efficient utilization of solar energy across a broader spectrum. Toyota has also developed novel reactor designs that optimize light distribution and mass transfer within the photocatalytic system, addressing scaling challenges that often limit laboratory technologies. Their research includes integration pathways with Toyota's hydrogen fuel cell technology, creating a potential closed-loop system where artificial photosynthesis produces hydrogen that can be used in fuel cell vehicles.

Strengths: Strong focus on practical implementation and integration with existing hydrogen infrastructure; robust engineering approach to reactor design and system optimization; potential for direct application in transportation sector. Weaknesses: Current efficiencies still below commercial viability thresholds; requires further development for cost-effective large-scale deployment; dependent on advances in hydrogen storage and distribution infrastructure.

Key Patents and Breakthroughs in Photochemical Catalysts

Solar energy utilization system

PatentActiveJP2015214469A

Innovation

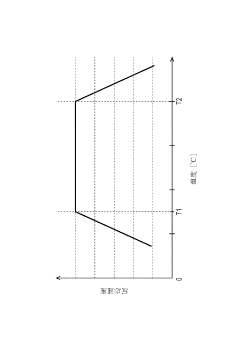

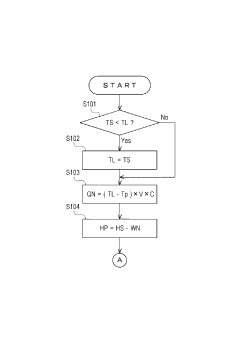

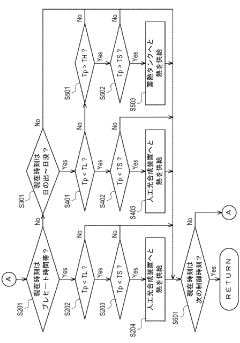

- A solar energy utilization system incorporating an artificial photosynthesis device with a catalyst, a heat exchange device, a heat storage device, and a heat medium circulation system to adjust the temperature of the catalyst within an optimal range for enhanced efficiency.

Artificial photosynthesis system

PatentPendingIN202411020292A

Innovation

- An artificial photosynthesis system utilizing a photocatalytic material composed of semiconductor nanoparticles and organic catalysts, nanostructured electrodes, and a CO2 conversion medium with enzymatic and chemical catalysts, integrated in a modular design for enhanced solar energy conversion, CO2 reduction, and production of clean energy and chemicals.

Environmental Impact and Sustainability Assessment

Artificial photosynthesis systems represent a significant advancement in sustainable energy technology, offering potential environmental benefits that extend beyond traditional renewable energy sources. These systems mimic natural photosynthetic processes to convert solar energy into chemical energy, providing a carbon-neutral pathway for energy production and storage. When properly implemented, artificial photosynthesis can contribute to carbon dioxide reduction by consuming CO2 as a feedstock, effectively serving as a carbon capture technology while simultaneously producing valuable fuels or chemicals.

The life cycle assessment (LCA) of artificial photosynthesis systems reveals favorable environmental profiles compared to fossil fuel-based energy systems. Studies indicate potential reductions in greenhouse gas emissions by 40-60% when replacing conventional energy production methods. However, these assessments must consider the full production chain, including raw material extraction, manufacturing processes, operational lifetime, and end-of-life disposal or recycling. Current research indicates that the environmental payback period for these systems ranges from 1-3 years, depending on system design and deployment location.

Water consumption represents both a challenge and an opportunity for artificial photosynthesis technologies. While some systems require significant water inputs, advanced designs can operate with non-potable or even saline water sources, reducing pressure on freshwater resources. Additionally, certain artificial photosynthesis approaches can be integrated with wastewater treatment processes, creating synergistic environmental benefits through simultaneous energy production and water purification.

Land use considerations for artificial photosynthesis systems are generally favorable compared to biofuel production or large-scale solar farms. These systems can achieve higher energy conversion efficiencies per unit area, potentially reducing land footprint by 70-80% compared to first-generation biofuels. Furthermore, modular designs enable integration into existing infrastructure and urban environments, minimizing additional land requirements.

Material sustainability presents ongoing challenges, particularly regarding the use of rare earth elements and precious metals as catalysts. Current research focuses on developing earth-abundant alternatives and reducing material intensity while maintaining system performance. Recycling pathways for system components are being established, with potential recovery rates exceeding 85% for key materials, enhancing the long-term sustainability of these technologies.

The integration of artificial photosynthesis into existing energy systems offers pathways for gradual decarbonization without requiring immediate wholesale infrastructure replacement. This transitional capability, combined with the technology's potential for distributed implementation, provides flexibility in addressing environmental challenges across diverse geographical and economic contexts.

The life cycle assessment (LCA) of artificial photosynthesis systems reveals favorable environmental profiles compared to fossil fuel-based energy systems. Studies indicate potential reductions in greenhouse gas emissions by 40-60% when replacing conventional energy production methods. However, these assessments must consider the full production chain, including raw material extraction, manufacturing processes, operational lifetime, and end-of-life disposal or recycling. Current research indicates that the environmental payback period for these systems ranges from 1-3 years, depending on system design and deployment location.

Water consumption represents both a challenge and an opportunity for artificial photosynthesis technologies. While some systems require significant water inputs, advanced designs can operate with non-potable or even saline water sources, reducing pressure on freshwater resources. Additionally, certain artificial photosynthesis approaches can be integrated with wastewater treatment processes, creating synergistic environmental benefits through simultaneous energy production and water purification.

Land use considerations for artificial photosynthesis systems are generally favorable compared to biofuel production or large-scale solar farms. These systems can achieve higher energy conversion efficiencies per unit area, potentially reducing land footprint by 70-80% compared to first-generation biofuels. Furthermore, modular designs enable integration into existing infrastructure and urban environments, minimizing additional land requirements.

Material sustainability presents ongoing challenges, particularly regarding the use of rare earth elements and precious metals as catalysts. Current research focuses on developing earth-abundant alternatives and reducing material intensity while maintaining system performance. Recycling pathways for system components are being established, with potential recovery rates exceeding 85% for key materials, enhancing the long-term sustainability of these technologies.

The integration of artificial photosynthesis into existing energy systems offers pathways for gradual decarbonization without requiring immediate wholesale infrastructure replacement. This transitional capability, combined with the technology's potential for distributed implementation, provides flexibility in addressing environmental challenges across diverse geographical and economic contexts.

Scalability and Commercialization Roadmap

The commercialization of artificial photosynthesis technologies faces significant scaling challenges that must be addressed systematically. Current laboratory-scale demonstrations, while promising, operate at efficiencies and volumes insufficient for commercial viability. A phased approach to scaling is essential, beginning with pilot plants processing 1-10 kg of CO2 daily, followed by demonstration facilities handling 100-1000 kg daily, before reaching commercial scale operations of multiple tons per day.

Material costs represent a critical barrier to commercialization. Precious metal catalysts like platinum and ruthenium currently dominate research prototypes but are economically prohibitive at scale. Research priorities must focus on developing earth-abundant alternatives such as nickel-iron compounds and carbon-based catalysts that maintain performance while dramatically reducing costs. Parallel efforts should target reducing semiconductor material requirements through nanostructuring and thin-film technologies.

Manufacturing processes require substantial innovation to transition from laboratory batch production to continuous industrial processes. Roll-to-roll manufacturing techniques show particular promise for photoelectrochemical devices, potentially reducing production costs by 60-80% compared to current methods. Standardization of components and modular design approaches will further accelerate scaling while reducing integration complexity.

Market entry strategies should prioritize high-value niche applications initially. Specialty chemicals production represents an attractive early market where artificial photosynthesis can compete despite higher costs. As scale increases and costs decrease, expansion into fuel production becomes viable, particularly in regions with favorable renewable energy profiles and carbon pricing mechanisms.

Policy support mechanisms will be crucial during the scaling journey. Carbon pricing, production tax credits, and government procurement programs can bridge the cost gap during early commercialization phases. Regulatory frameworks must evolve to recognize and value the environmental benefits of artificial photosynthesis systems, particularly their potential for carbon-negative operation when integrated with carbon capture technologies.

Investment requirements follow a typical emerging technology curve, with approximately $50-100 million needed for pilot scale demonstrations, $200-500 million for initial commercial facilities, and $1-5 billion for widespread deployment. Return on investment timelines suggest 3-5 years for specialty chemical applications and 7-10 years for energy storage applications, contingent upon supportive policy environments and continued technical progress in efficiency and durability metrics.

Material costs represent a critical barrier to commercialization. Precious metal catalysts like platinum and ruthenium currently dominate research prototypes but are economically prohibitive at scale. Research priorities must focus on developing earth-abundant alternatives such as nickel-iron compounds and carbon-based catalysts that maintain performance while dramatically reducing costs. Parallel efforts should target reducing semiconductor material requirements through nanostructuring and thin-film technologies.

Manufacturing processes require substantial innovation to transition from laboratory batch production to continuous industrial processes. Roll-to-roll manufacturing techniques show particular promise for photoelectrochemical devices, potentially reducing production costs by 60-80% compared to current methods. Standardization of components and modular design approaches will further accelerate scaling while reducing integration complexity.

Market entry strategies should prioritize high-value niche applications initially. Specialty chemicals production represents an attractive early market where artificial photosynthesis can compete despite higher costs. As scale increases and costs decrease, expansion into fuel production becomes viable, particularly in regions with favorable renewable energy profiles and carbon pricing mechanisms.

Policy support mechanisms will be crucial during the scaling journey. Carbon pricing, production tax credits, and government procurement programs can bridge the cost gap during early commercialization phases. Regulatory frameworks must evolve to recognize and value the environmental benefits of artificial photosynthesis systems, particularly their potential for carbon-negative operation when integrated with carbon capture technologies.

Investment requirements follow a typical emerging technology curve, with approximately $50-100 million needed for pilot scale demonstrations, $200-500 million for initial commercial facilities, and $1-5 billion for widespread deployment. Return on investment timelines suggest 3-5 years for specialty chemical applications and 7-10 years for energy storage applications, contingent upon supportive policy environments and continued technical progress in efficiency and durability metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!