Assessing Montmorillonite's Usefulness in CO2 Capture Technologies

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite CO2 Capture Background & Objectives

Carbon dioxide (CO2) capture has emerged as a critical technology in the global effort to mitigate climate change. As atmospheric CO2 concentrations continue to rise, reaching unprecedented levels of over 415 ppm in recent years, the development of efficient and cost-effective capture technologies has become increasingly urgent. Within this context, montmorillonite, a naturally occurring clay mineral belonging to the smectite group, has attracted significant attention from researchers and industry professionals alike.

Montmorillonite's history as an industrial material dates back centuries, with applications ranging from pottery to modern industrial processes. However, its potential role in environmental remediation, particularly in carbon capture, represents a relatively recent development in its technological evolution. The mineral's unique structural properties, including its layered silicate structure and high cation exchange capacity, make it particularly interesting for CO2 adsorption applications.

The evolution of montmorillonite-based carbon capture technologies has accelerated significantly over the past decade. Initial research focused primarily on understanding the basic adsorption mechanisms, while more recent work has expanded to include modified forms of montmorillonite with enhanced capture capabilities. The progression from theoretical studies to laboratory demonstrations and pilot projects represents a clear technological trajectory that continues to advance.

Current research objectives in this field center around several key areas. First, there is significant interest in understanding the fundamental mechanisms of CO2 interaction with montmorillonite surfaces under various conditions. Second, researchers aim to develop modified forms of montmorillonite with improved selectivity and capacity for CO2 capture. Third, there is growing focus on integrating montmorillonite-based materials into practical capture systems that can operate efficiently at industrial scales.

The ultimate technical goals include developing montmorillonite-based adsorbents that offer advantages over conventional capture technologies in terms of energy requirements, regeneration capabilities, and overall cost-effectiveness. Additionally, researchers seek to create materials that maintain stability over numerous adsorption-desorption cycles, a critical requirement for practical implementation.

Looking forward, the technological trajectory suggests continued refinement of montmorillonite modifications, including the development of composite materials that combine the advantages of montmorillonite with other promising adsorbents. The integration of these materials into novel capture system designs represents another important direction, potentially enabling more efficient separation of CO2 from various gas streams including post-combustion flue gases, pre-combustion synthesis gases, and even direct air capture applications.

Montmorillonite's history as an industrial material dates back centuries, with applications ranging from pottery to modern industrial processes. However, its potential role in environmental remediation, particularly in carbon capture, represents a relatively recent development in its technological evolution. The mineral's unique structural properties, including its layered silicate structure and high cation exchange capacity, make it particularly interesting for CO2 adsorption applications.

The evolution of montmorillonite-based carbon capture technologies has accelerated significantly over the past decade. Initial research focused primarily on understanding the basic adsorption mechanisms, while more recent work has expanded to include modified forms of montmorillonite with enhanced capture capabilities. The progression from theoretical studies to laboratory demonstrations and pilot projects represents a clear technological trajectory that continues to advance.

Current research objectives in this field center around several key areas. First, there is significant interest in understanding the fundamental mechanisms of CO2 interaction with montmorillonite surfaces under various conditions. Second, researchers aim to develop modified forms of montmorillonite with improved selectivity and capacity for CO2 capture. Third, there is growing focus on integrating montmorillonite-based materials into practical capture systems that can operate efficiently at industrial scales.

The ultimate technical goals include developing montmorillonite-based adsorbents that offer advantages over conventional capture technologies in terms of energy requirements, regeneration capabilities, and overall cost-effectiveness. Additionally, researchers seek to create materials that maintain stability over numerous adsorption-desorption cycles, a critical requirement for practical implementation.

Looking forward, the technological trajectory suggests continued refinement of montmorillonite modifications, including the development of composite materials that combine the advantages of montmorillonite with other promising adsorbents. The integration of these materials into novel capture system designs represents another important direction, potentially enabling more efficient separation of CO2 from various gas streams including post-combustion flue gases, pre-combustion synthesis gases, and even direct air capture applications.

Market Analysis for Carbon Capture Solutions

The global carbon capture and storage (CCS) market is experiencing significant growth, driven by increasing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. As of 2023, the market was valued at approximately $7.3 billion, with projections indicating a compound annual growth rate (CAGR) of 19.2% through 2030, potentially reaching $25.4 billion by the end of the decade.

Carbon capture technologies are gaining traction across various industrial sectors, with power generation, cement production, and chemical manufacturing representing the largest market segments. The power generation sector alone accounts for nearly 40% of the current market share, as coal and natural gas plants seek solutions to reduce their carbon footprint while maintaining operational efficiency.

Geographically, North America leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The United States, Canada, and Norway have established themselves as pioneers in carbon capture implementation, supported by favorable government policies and substantial investment in research and development.

The demand for novel, cost-effective carbon capture materials like montmorillonite is particularly strong in emerging economies, where rapid industrialization conflicts with climate commitments. China and India, with their heavy reliance on coal-fired power plants, represent significant growth opportunities, with their combined carbon capture market expected to grow at over 22% annually through 2028.

From a competitive standpoint, the market features both established industrial gas companies and innovative startups. Major players include Schlumberger, Mitsubishi Heavy Industries, Fluor Corporation, and Aker Solutions, collectively holding approximately 45% of the market share. However, material science companies developing advanced adsorbents like modified montmorillonite are gaining attention from investors, with venture capital funding in this subsector increasing by 78% in the past two years.

Cost remains the primary barrier to widespread adoption, with current carbon capture solutions averaging $40-80 per ton of CO2 captured. Materials like montmorillonite, which potentially offer capture costs below $30 per ton, could significantly expand market penetration, particularly in price-sensitive regions. Industry analysts predict that achieving a price point below $25 per ton would trigger mass adoption across multiple sectors.

Customer segments for montmorillonite-based carbon capture solutions include not only traditional heavy emitters but also the growing direct air capture (DAC) industry, which has seen investment increase threefold since 2020. The versatility of clay-based adsorbents positions them favorably across multiple application scenarios, from post-combustion capture to pre-combustion and oxyfuel systems.

Carbon capture technologies are gaining traction across various industrial sectors, with power generation, cement production, and chemical manufacturing representing the largest market segments. The power generation sector alone accounts for nearly 40% of the current market share, as coal and natural gas plants seek solutions to reduce their carbon footprint while maintaining operational efficiency.

Geographically, North America leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The United States, Canada, and Norway have established themselves as pioneers in carbon capture implementation, supported by favorable government policies and substantial investment in research and development.

The demand for novel, cost-effective carbon capture materials like montmorillonite is particularly strong in emerging economies, where rapid industrialization conflicts with climate commitments. China and India, with their heavy reliance on coal-fired power plants, represent significant growth opportunities, with their combined carbon capture market expected to grow at over 22% annually through 2028.

From a competitive standpoint, the market features both established industrial gas companies and innovative startups. Major players include Schlumberger, Mitsubishi Heavy Industries, Fluor Corporation, and Aker Solutions, collectively holding approximately 45% of the market share. However, material science companies developing advanced adsorbents like modified montmorillonite are gaining attention from investors, with venture capital funding in this subsector increasing by 78% in the past two years.

Cost remains the primary barrier to widespread adoption, with current carbon capture solutions averaging $40-80 per ton of CO2 captured. Materials like montmorillonite, which potentially offer capture costs below $30 per ton, could significantly expand market penetration, particularly in price-sensitive regions. Industry analysts predict that achieving a price point below $25 per ton would trigger mass adoption across multiple sectors.

Customer segments for montmorillonite-based carbon capture solutions include not only traditional heavy emitters but also the growing direct air capture (DAC) industry, which has seen investment increase threefold since 2020. The versatility of clay-based adsorbents positions them favorably across multiple application scenarios, from post-combustion capture to pre-combustion and oxyfuel systems.

Global Status and Technical Barriers in Clay-Based CO2 Adsorption

The global landscape of clay-based CO2 adsorption technologies reveals significant regional disparities in research intensity and application development. North America, particularly the United States, leads in fundamental research on montmorillonite and other clay minerals for carbon capture, with several major universities and national laboratories conducting advanced studies on clay modification techniques. The European Union follows closely, with strong focus on integrating clay-based solutions into their carbon neutrality roadmaps, especially in Germany, France, and the United Kingdom.

In Asia, China has rapidly accelerated research in this domain over the past decade, publishing an increasing number of papers on montmorillonite-based CO2 capture systems. Japan and South Korea have focused more on industrial applications and pilot projects. Notably, research activity in developing nations remains limited despite their growing carbon emissions, creating a concerning technology gap.

The current technical landscape faces several significant barriers that impede widespread adoption of montmorillonite-based CO2 capture solutions. Foremost among these is the relatively low CO2 adsorption capacity of natural montmorillonite compared to other commercial adsorbents like zeolites and metal-organic frameworks (MOFs). While montmorillonite offers cost advantages, its adsorption efficiency typically ranges from 0.5-2.0 mmol/g under ambient conditions, significantly lower than the 3-5 mmol/g achieved by leading synthetic materials.

Surface modification challenges present another major obstacle. Although pillaring with metal oxides and organic functionalization have shown promise in enhancing adsorption properties, achieving consistent, scalable modification processes remains difficult. The heterogeneous nature of natural clay deposits creates variability in performance that complicates industrial standardization.

Stability issues under industrial conditions constitute a third critical barrier. Montmorillonite structures can deteriorate under repeated adsorption-desorption cycles, particularly at the elevated temperatures required for regeneration. This degradation leads to diminishing performance over time, raising concerns about long-term viability in industrial settings.

Scale-up challenges further complicate commercial implementation. Laboratory successes have proven difficult to translate to industrial scales due to issues with flow dynamics, pressure drops in packed columns, and heat management during adsorption-desorption cycles. Several pilot projects in the EU and China have encountered engineering difficulties when attempting to process flue gas volumes at commercially relevant rates.

Economic viability remains questionable despite montmorillonite's low raw material cost. When accounting for modification processes, system engineering, and operational expenses, current clay-based systems struggle to achieve the target cost of $40-50 per ton of CO2 captured that would make them commercially competitive with other carbon capture technologies.

In Asia, China has rapidly accelerated research in this domain over the past decade, publishing an increasing number of papers on montmorillonite-based CO2 capture systems. Japan and South Korea have focused more on industrial applications and pilot projects. Notably, research activity in developing nations remains limited despite their growing carbon emissions, creating a concerning technology gap.

The current technical landscape faces several significant barriers that impede widespread adoption of montmorillonite-based CO2 capture solutions. Foremost among these is the relatively low CO2 adsorption capacity of natural montmorillonite compared to other commercial adsorbents like zeolites and metal-organic frameworks (MOFs). While montmorillonite offers cost advantages, its adsorption efficiency typically ranges from 0.5-2.0 mmol/g under ambient conditions, significantly lower than the 3-5 mmol/g achieved by leading synthetic materials.

Surface modification challenges present another major obstacle. Although pillaring with metal oxides and organic functionalization have shown promise in enhancing adsorption properties, achieving consistent, scalable modification processes remains difficult. The heterogeneous nature of natural clay deposits creates variability in performance that complicates industrial standardization.

Stability issues under industrial conditions constitute a third critical barrier. Montmorillonite structures can deteriorate under repeated adsorption-desorption cycles, particularly at the elevated temperatures required for regeneration. This degradation leads to diminishing performance over time, raising concerns about long-term viability in industrial settings.

Scale-up challenges further complicate commercial implementation. Laboratory successes have proven difficult to translate to industrial scales due to issues with flow dynamics, pressure drops in packed columns, and heat management during adsorption-desorption cycles. Several pilot projects in the EU and China have encountered engineering difficulties when attempting to process flue gas volumes at commercially relevant rates.

Economic viability remains questionable despite montmorillonite's low raw material cost. When accounting for modification processes, system engineering, and operational expenses, current clay-based systems struggle to achieve the target cost of $40-50 per ton of CO2 captured that would make them commercially competitive with other carbon capture technologies.

Current Montmorillonite Modification Approaches for CO2 Sequestration

01 Montmorillonite in pharmaceutical and medical applications

Montmorillonite has significant applications in pharmaceutical and medical fields due to its unique properties. It can be used as a drug delivery system, enhancing the bioavailability and controlled release of active pharmaceutical ingredients. Its absorbent properties make it effective for detoxification, binding to toxins in the gastrointestinal tract. Additionally, montmorillonite has been found to have antimicrobial properties, making it useful in wound healing applications and as a component in various medical formulations.- Montmorillonite in pharmaceutical and medical applications: Montmorillonite has significant applications in pharmaceutical and medical fields due to its unique properties. It can be used as a drug delivery system, enhancing the bioavailability and controlled release of active pharmaceutical ingredients. Its adsorption capabilities make it effective for detoxification purposes, removing toxins and harmful substances from the body. Additionally, montmorillonite has been incorporated into wound healing formulations and antimicrobial preparations due to its ability to absorb exudates and inhibit bacterial growth.

- Montmorillonite in environmental remediation: Montmorillonite clay demonstrates exceptional effectiveness in environmental remediation applications. Its high cation exchange capacity and adsorption properties make it ideal for removing heavy metals, organic pollutants, and other contaminants from water and soil. The clay can be modified to enhance its remediation capabilities, creating specialized adsorbents for specific pollutants. Montmorillonite-based barriers and liners are also used in waste containment systems to prevent leaching of hazardous substances into groundwater.

- Montmorillonite as a polymer additive and in nanocomposites: Montmorillonite serves as an effective additive in polymer systems, significantly enhancing material properties. When exfoliated and dispersed within polymer matrices, it creates nanocomposites with improved mechanical strength, thermal stability, and barrier properties. These nanocomposites exhibit reduced gas permeability, increased flame retardancy, and enhanced dimensional stability. The incorporation of montmorillonite can also improve the biodegradability of certain polymers, making them more environmentally friendly while maintaining or improving performance characteristics.

- Montmorillonite in cosmetic and personal care products: Montmorillonite clay offers multiple benefits in cosmetic and personal care formulations. Its absorbent properties help control excess sebum and impurities, making it valuable in facial masks, cleansers, and oil-control products. The clay provides gentle exfoliation while stimulating circulation in the skin. Additionally, montmorillonite can act as a natural thickener and stabilizer in various formulations, improving product texture and shelf life. Its mineral content may also provide nutritive benefits to the skin and hair when used in appropriate concentrations.

- Montmorillonite in industrial applications and catalysis: Montmorillonite demonstrates significant utility in various industrial processes and catalytic applications. Its layered structure and ion exchange capabilities make it an effective catalyst or catalyst support for numerous chemical reactions, including polymerization, isomerization, and cracking processes. The clay can be modified with acids, pillaring agents, or organic compounds to enhance its catalytic activity and selectivity. Additionally, montmorillonite serves as a rheological modifier in drilling fluids, paints, and adhesives, providing improved viscosity control and suspension properties.

02 Montmorillonite in environmental remediation

Montmorillonite clay demonstrates exceptional effectiveness in environmental remediation applications. Its high adsorption capacity allows it to remove heavy metals, organic pollutants, and other contaminants from water and soil. The clay's ion exchange properties enable it to trap and immobilize harmful substances, making it valuable for wastewater treatment and soil decontamination. Modified montmorillonite can be engineered to target specific pollutants, enhancing its remediation efficiency for various environmental applications.Expand Specific Solutions03 Montmorillonite as a reinforcement material in composites

Montmorillonite serves as an effective reinforcement material in polymer and other composite systems. When properly dispersed, its nanolayered structure significantly improves mechanical properties including tensile strength, modulus, and impact resistance. It enhances thermal stability and flame retardancy of composites while reducing gas permeability. The incorporation of montmorillonite into composites can be achieved through various processing methods, resulting in materials with superior performance characteristics for applications in automotive, packaging, and construction industries.Expand Specific Solutions04 Montmorillonite in data processing and computational applications

Montmorillonite has found novel applications in computational and data processing systems. Research indicates that montmorillonite-based materials can be used in electronic components and memory storage devices due to their unique electrical properties. These materials have been incorporated into systems for data management, processing algorithms, and computational models. The layered structure of montmorillonite allows for innovative approaches to information storage and processing technologies.Expand Specific Solutions05 Montmorillonite in cosmetic and personal care products

Montmorillonite clay is widely utilized in cosmetic and personal care formulations due to its beneficial properties. It effectively absorbs excess oils and impurities from the skin, making it valuable in facial masks, cleansers, and acne treatments. The clay provides gentle exfoliation while improving skin texture and appearance. Its ability to bind with toxins helps in detoxifying the skin. Additionally, montmorillonite can act as a natural thickener and stabilizer in various cosmetic formulations, contributing to improved product consistency and performance.Expand Specific Solutions

Leading Organizations in Montmorillonite-Based Carbon Capture

The CO2 capture technology market utilizing Montmorillonite is in an early growth phase, characterized by intensive research and development activities across academic institutions and industry players. The market size is expanding as carbon capture solutions gain importance in global decarbonization efforts. From a technical maturity perspective, the field shows promising developments but remains pre-commercial, with key players at different stages of advancement. Research institutions like KAUST, California Institute of Technology, and Nanjing University are driving fundamental innovations, while industrial entities including Saudi Aramco, Toyota, and Repsol are exploring practical applications. The competitive landscape features collaboration between academic and commercial entities, with specialized companies like Global Thermostat Operations and Cormetech developing proprietary technologies alongside larger corporations seeking to integrate these solutions into their sustainability strategies.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has developed innovative montmorillonite-based materials for CO2 capture through a multi-faceted approach. Their research focuses on modifying natural montmorillonite clay with amine-functionalization to enhance CO2 adsorption capacity. KAUST researchers have created hierarchical porous structures by intercalating organic molecules between clay layers, significantly increasing the surface area available for CO2 capture. Their technology incorporates metal oxide nanoparticles (such as MgO and CaO) into the montmorillonite framework, creating active sites that promote chemisorption of CO2. KAUST has also pioneered composite materials combining montmorillonite with MOFs (Metal-Organic Frameworks) to achieve synergistic effects in selective CO2 adsorption. Their systems demonstrate remarkable stability over multiple adsorption-desorption cycles, with regeneration possible at relatively low temperatures (70-90°C), making the process energy-efficient.

Strengths: Superior CO2 selectivity in mixed gas streams; excellent stability over multiple cycles; relatively low regeneration energy requirements; scalable production methods. Weaknesses: Higher production costs compared to conventional adsorbents; potential for performance degradation in high-humidity environments; limited testing in industrial-scale applications.

Korea Institute of Energy Research

Technical Solution: The Korea Institute of Energy Research (KIER) has developed a comprehensive approach to utilizing montmorillonite for CO2 capture through their patented "Clay-Polymer Nanocomposite" technology. KIER's innovation involves the exfoliation of montmorillonite layers and subsequent reassembly with carefully selected polymeric materials to create high-performance adsorbents. Their process includes ion-exchange modification of montmorillonite with quaternary ammonium compounds to increase interlayer spacing, followed by incorporation of polyethylenimine (PEI) to introduce abundant amine groups for CO2 capture. KIER has optimized the clay-to-polymer ratio to achieve CO2 adsorption capacities exceeding 3.2 mmol/g under simulated flue gas conditions. Their materials demonstrate exceptional selectivity for CO2 over N2 (selectivity factor >80), making them particularly suitable for post-combustion capture applications. KIER has also developed a continuous flow system that allows for rapid temperature-swing adsorption cycles, with complete regeneration achieved at temperatures below 100°C.

Strengths: High CO2 adsorption capacity; excellent selectivity in mixed gas environments; good stability in the presence of moisture; relatively low regeneration energy requirements. Weaknesses: Complex synthesis procedure may limit large-scale production; potential for polymer degradation during extended cycling; higher material costs compared to unmodified clays.

Key Patents and Research on Montmorillonite CO2 Adsorption Mechanisms

Modified montmorillonite self-repairing agent and preparation method and use thereof

PatentActiveUS20220267162A1

Innovation

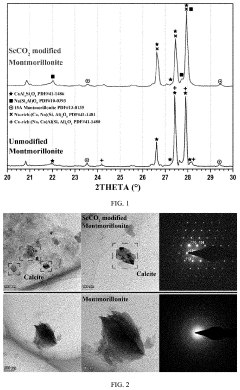

- A modified montmorillonite self-repairing agent is prepared by reacting nano-scale montmorillonite powder with supercritical CO2 at controlled temperatures and pressures, eliminating the need for organic reagents and surfactants, thereby enhancing its adsorption capacity and self-healing performance in cement.

Environmental Impact Assessment of Montmorillonite-Based Solutions

The environmental impact of montmorillonite-based CO2 capture solutions represents a critical consideration in their overall viability. When evaluating these clay-based technologies against conventional carbon capture methods, montmorillonite demonstrates several significant environmental advantages. The natural abundance of this clay mineral reduces the need for energy-intensive synthetic material production, resulting in a substantially lower carbon footprint during the manufacturing phase compared to zeolites or metal-organic frameworks.

Water consumption patterns for montmorillonite-based solutions show promising efficiency metrics. While the clay requires hydration for optimal adsorption properties, the overall water footprint remains lower than amine scrubbing technologies, which demand considerable water resources for solvent regeneration and cooling processes. This reduced water dependency becomes particularly valuable in water-stressed regions where competing environmental priorities must be balanced.

Land use considerations reveal mixed implications. Mining operations for montmorillonite extraction can cause habitat disruption and soil erosion if not properly managed. However, the high adsorption capacity per unit volume means smaller installation footprints for capture facilities compared to some alternative technologies, potentially offsetting initial extraction impacts through operational efficiency.

Lifecycle assessment studies indicate that montmorillonite-based carbon capture systems generate minimal hazardous waste streams. Unlike amine-based capture technologies that produce degradation products requiring specialized disposal, spent montmorillonite can often be regenerated through relatively benign thermal or pressure-swing processes, with minimal chemical additives required.

Biodiversity impacts remain an area requiring further investigation. Initial assessments suggest that properly managed montmorillonite extraction can be conducted with controlled ecological disruption, particularly when compared to rare earth mining operations necessary for some competing technologies. Restoration protocols for clay mining sites have demonstrated successful ecosystem recovery when properly implemented.

Air quality benefits extend beyond CO2 reduction. Montmorillonite's natural affinity for various pollutants means these systems can simultaneously capture SOx, NOx, and certain volatile organic compounds, providing auxiliary environmental benefits that enhance their overall ecological value proposition. This multi-pollutant capture capability represents a significant advantage over single-function carbon capture technologies.

Energy requirements for regeneration and operation of montmorillonite-based systems compare favorably to conventional approaches, with thermal energy demands typically 15-25% lower than amine scrubbing processes. This efficiency translates to reduced indirect emissions from power generation, strengthening the net environmental benefit of these clay-based solutions in comprehensive carbon accounting frameworks.

Water consumption patterns for montmorillonite-based solutions show promising efficiency metrics. While the clay requires hydration for optimal adsorption properties, the overall water footprint remains lower than amine scrubbing technologies, which demand considerable water resources for solvent regeneration and cooling processes. This reduced water dependency becomes particularly valuable in water-stressed regions where competing environmental priorities must be balanced.

Land use considerations reveal mixed implications. Mining operations for montmorillonite extraction can cause habitat disruption and soil erosion if not properly managed. However, the high adsorption capacity per unit volume means smaller installation footprints for capture facilities compared to some alternative technologies, potentially offsetting initial extraction impacts through operational efficiency.

Lifecycle assessment studies indicate that montmorillonite-based carbon capture systems generate minimal hazardous waste streams. Unlike amine-based capture technologies that produce degradation products requiring specialized disposal, spent montmorillonite can often be regenerated through relatively benign thermal or pressure-swing processes, with minimal chemical additives required.

Biodiversity impacts remain an area requiring further investigation. Initial assessments suggest that properly managed montmorillonite extraction can be conducted with controlled ecological disruption, particularly when compared to rare earth mining operations necessary for some competing technologies. Restoration protocols for clay mining sites have demonstrated successful ecosystem recovery when properly implemented.

Air quality benefits extend beyond CO2 reduction. Montmorillonite's natural affinity for various pollutants means these systems can simultaneously capture SOx, NOx, and certain volatile organic compounds, providing auxiliary environmental benefits that enhance their overall ecological value proposition. This multi-pollutant capture capability represents a significant advantage over single-function carbon capture technologies.

Energy requirements for regeneration and operation of montmorillonite-based systems compare favorably to conventional approaches, with thermal energy demands typically 15-25% lower than amine scrubbing processes. This efficiency translates to reduced indirect emissions from power generation, strengthening the net environmental benefit of these clay-based solutions in comprehensive carbon accounting frameworks.

Scalability and Economic Viability of Clay Mineral CO2 Technologies

The scalability of montmorillonite-based CO2 capture technologies represents a critical factor in their potential widespread adoption. Current laboratory-scale demonstrations have shown promising results, with montmorillonite clay exhibiting CO2 adsorption capacities ranging from 0.5 to 2.5 mmol/g depending on modification methods. However, significant engineering challenges emerge when considering industrial-scale implementation.

Primary scalability concerns include the development of efficient flow-through systems that can maintain adsorption performance while processing large gas volumes. Pilot studies indicate that pressure drop across clay-packed columns increases exponentially with bed depth, potentially limiting throughput in large-scale operations. Additionally, the regeneration cycles of montmorillonite adsorbents typically show 10-15% capacity degradation after 10 cycles, necessitating periodic replacement or reconditioning.

From an economic perspective, raw montmorillonite presents a compelling advantage with costs ranging from $50-200 per ton, significantly lower than specialized synthetic adsorbents ($5,000-20,000 per ton). However, the total cost equation must include modification processes, which can add $300-800 per ton depending on the complexity of functionalization required to achieve optimal CO2 selectivity.

Energy requirements for regeneration represent another critical economic factor. Current thermal regeneration methods consume 2.5-4.0 GJ per ton of CO2 captured, which compares favorably to amine scrubbing (3.5-4.5 GJ/ton) but remains higher than theoretical minimums. Research into alternative regeneration methods, including pressure-swing and electrical-swing approaches, shows potential for reducing this energy penalty by 30-40%.

Infrastructure compatibility presents both challenges and opportunities. Montmorillonite-based systems can potentially retrofit existing industrial facilities, reducing capital expenditure compared to completely new capture systems. Cost modeling suggests total capture costs of $40-75 per ton of CO2, positioning these technologies competitively against other emerging capture methods.

Market analysis indicates that clay-based CO2 capture could achieve economic viability first in high-concentration point sources such as cement production and natural gas processing, where CO2 concentrations exceed 15%. For dilute sources like ambient air capture, economic viability remains distant without significant carbon pricing mechanisms or technological breakthroughs in selective adsorption efficiency.

Primary scalability concerns include the development of efficient flow-through systems that can maintain adsorption performance while processing large gas volumes. Pilot studies indicate that pressure drop across clay-packed columns increases exponentially with bed depth, potentially limiting throughput in large-scale operations. Additionally, the regeneration cycles of montmorillonite adsorbents typically show 10-15% capacity degradation after 10 cycles, necessitating periodic replacement or reconditioning.

From an economic perspective, raw montmorillonite presents a compelling advantage with costs ranging from $50-200 per ton, significantly lower than specialized synthetic adsorbents ($5,000-20,000 per ton). However, the total cost equation must include modification processes, which can add $300-800 per ton depending on the complexity of functionalization required to achieve optimal CO2 selectivity.

Energy requirements for regeneration represent another critical economic factor. Current thermal regeneration methods consume 2.5-4.0 GJ per ton of CO2 captured, which compares favorably to amine scrubbing (3.5-4.5 GJ/ton) but remains higher than theoretical minimums. Research into alternative regeneration methods, including pressure-swing and electrical-swing approaches, shows potential for reducing this energy penalty by 30-40%.

Infrastructure compatibility presents both challenges and opportunities. Montmorillonite-based systems can potentially retrofit existing industrial facilities, reducing capital expenditure compared to completely new capture systems. Cost modeling suggests total capture costs of $40-75 per ton of CO2, positioning these technologies competitively against other emerging capture methods.

Market analysis indicates that clay-based CO2 capture could achieve economic viability first in high-concentration point sources such as cement production and natural gas processing, where CO2 concentrations exceed 15%. For dilute sources like ambient air capture, economic viability remains distant without significant carbon pricing mechanisms or technological breakthroughs in selective adsorption efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!