Ball Mill Liner Failure Analysis: Root Causes And Corrective Actions

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ball Mill Liner Wear Background and Objectives

Ball mills have been a cornerstone of mineral processing operations for over a century, with their liner systems playing a critical role in operational efficiency and maintenance costs. The evolution of ball mill liner technology has progressed from simple cast iron designs in the early 20th century to today's sophisticated composite materials and engineered profiles. This technological progression has been driven by the continuous pursuit of extended service life, improved grinding efficiency, and reduced downtime in increasingly demanding operational environments.

The wear of ball mill liners represents one of the most significant maintenance challenges in mineral processing operations, accounting for approximately 40-50% of total mill maintenance costs. Historical data indicates that unplanned liner failures can result in production losses exceeding $100,000 per day for large-scale operations, highlighting the economic importance of this technical challenge.

Current industry objectives focus on developing predictive maintenance strategies and advanced liner materials that can withstand the harsh grinding environment while maintaining optimal performance. The primary technical goals include extending liner service life by at least 30% compared to conventional solutions, reducing installation time by 25%, and implementing real-time monitoring systems capable of predicting liner failure with 90% accuracy at least two weeks before critical wear points are reached.

The global mining industry's push toward processing lower grade ores has intensified the demands placed on grinding equipment, with ball mills often operating under increasingly aggressive conditions. This trend has accelerated the need for more resilient liner systems that can maintain performance while processing more abrasive materials. Additionally, sustainability considerations have emerged as a significant factor, with operations seeking to reduce energy consumption and carbon footprint through optimized liner designs.

Recent technological advancements in materials science, computational modeling, and sensor technology have opened new avenues for addressing liner wear challenges. The integration of these technologies promises to transform traditional reactive maintenance approaches into proactive, data-driven strategies that optimize liner performance throughout their operational lifecycle.

The objectives of this technical research report are to comprehensively analyze the root causes of ball mill liner failures, evaluate current mitigation strategies, identify emerging technologies and materials with potential to address these challenges, and provide actionable recommendations for implementing corrective actions that align with industry best practices and future technological trends.

The wear of ball mill liners represents one of the most significant maintenance challenges in mineral processing operations, accounting for approximately 40-50% of total mill maintenance costs. Historical data indicates that unplanned liner failures can result in production losses exceeding $100,000 per day for large-scale operations, highlighting the economic importance of this technical challenge.

Current industry objectives focus on developing predictive maintenance strategies and advanced liner materials that can withstand the harsh grinding environment while maintaining optimal performance. The primary technical goals include extending liner service life by at least 30% compared to conventional solutions, reducing installation time by 25%, and implementing real-time monitoring systems capable of predicting liner failure with 90% accuracy at least two weeks before critical wear points are reached.

The global mining industry's push toward processing lower grade ores has intensified the demands placed on grinding equipment, with ball mills often operating under increasingly aggressive conditions. This trend has accelerated the need for more resilient liner systems that can maintain performance while processing more abrasive materials. Additionally, sustainability considerations have emerged as a significant factor, with operations seeking to reduce energy consumption and carbon footprint through optimized liner designs.

Recent technological advancements in materials science, computational modeling, and sensor technology have opened new avenues for addressing liner wear challenges. The integration of these technologies promises to transform traditional reactive maintenance approaches into proactive, data-driven strategies that optimize liner performance throughout their operational lifecycle.

The objectives of this technical research report are to comprehensively analyze the root causes of ball mill liner failures, evaluate current mitigation strategies, identify emerging technologies and materials with potential to address these challenges, and provide actionable recommendations for implementing corrective actions that align with industry best practices and future technological trends.

Market Demand Analysis for Durable Mill Liners

The global market for durable mill liners has been experiencing significant growth, driven primarily by the expanding mining and mineral processing industries. As of recent market analyses, the ball mill liner market is valued at approximately $2.3 billion, with projections indicating a compound annual growth rate of 5.7% over the next five years. This growth trajectory is particularly pronounced in regions with intensive mining operations such as Australia, Chile, South Africa, and Canada.

The demand for more durable mill liners stems from the critical need to reduce operational downtime in processing facilities. Industry data reveals that unplanned mill shutdowns due to liner failures cost mining operations an average of $20,000-$50,000 per hour in lost production. For large-scale operations, these costs can escalate to over $100,000 per hour, creating substantial financial pressure to implement more reliable liner solutions.

Market research indicates a growing preference for composite and rubber-metal hybrid liners, which have demonstrated 30-40% longer service life compared to traditional steel liners. This shift represents a significant market opportunity, with approximately 65% of surveyed mining operations expressing willingness to invest in premium liner solutions that offer demonstrable improvements in operational longevity.

The aftermarket service segment for mill liners has also emerged as a high-growth area, with maintenance and replacement services accounting for nearly 40% of the total market value. This trend reflects the industry's increasing focus on lifecycle management rather than mere product acquisition.

Regional market analysis shows that Asia-Pacific, particularly China and India, represents the fastest-growing market for durable mill liners, with demand increasing at 7.8% annually due to rapid industrialization and expansion of mineral processing capabilities. North America and Europe maintain stable demand growth at 4-5% annually, primarily driven by replacement needs and technological upgrades in existing facilities.

Customer segmentation reveals that large-scale mining operations (processing >50,000 tons daily) constitute approximately 55% of the market value, while medium-sized operations account for 30%, and smaller operations make up the remaining 15%. This distribution highlights the importance of developing scalable solutions that can address varying operational requirements while maintaining cost-effectiveness.

Industry surveys indicate that procurement decisions are increasingly influenced by total cost of ownership calculations rather than initial purchase price, with 78% of mining operations citing liner longevity and predictable wear patterns as critical factors in their purchasing decisions.

The demand for more durable mill liners stems from the critical need to reduce operational downtime in processing facilities. Industry data reveals that unplanned mill shutdowns due to liner failures cost mining operations an average of $20,000-$50,000 per hour in lost production. For large-scale operations, these costs can escalate to over $100,000 per hour, creating substantial financial pressure to implement more reliable liner solutions.

Market research indicates a growing preference for composite and rubber-metal hybrid liners, which have demonstrated 30-40% longer service life compared to traditional steel liners. This shift represents a significant market opportunity, with approximately 65% of surveyed mining operations expressing willingness to invest in premium liner solutions that offer demonstrable improvements in operational longevity.

The aftermarket service segment for mill liners has also emerged as a high-growth area, with maintenance and replacement services accounting for nearly 40% of the total market value. This trend reflects the industry's increasing focus on lifecycle management rather than mere product acquisition.

Regional market analysis shows that Asia-Pacific, particularly China and India, represents the fastest-growing market for durable mill liners, with demand increasing at 7.8% annually due to rapid industrialization and expansion of mineral processing capabilities. North America and Europe maintain stable demand growth at 4-5% annually, primarily driven by replacement needs and technological upgrades in existing facilities.

Customer segmentation reveals that large-scale mining operations (processing >50,000 tons daily) constitute approximately 55% of the market value, while medium-sized operations account for 30%, and smaller operations make up the remaining 15%. This distribution highlights the importance of developing scalable solutions that can address varying operational requirements while maintaining cost-effectiveness.

Industry surveys indicate that procurement decisions are increasingly influenced by total cost of ownership calculations rather than initial purchase price, with 78% of mining operations citing liner longevity and predictable wear patterns as critical factors in their purchasing decisions.

Current Challenges in Ball Mill Liner Technology

Ball mill liner technology faces several significant challenges that impede optimal performance and longevity. The most pressing issue is premature wear and failure, which occurs due to the harsh operating conditions inside mills. High-impact loads, abrasive materials, and corrosive environments continuously degrade liner surfaces, leading to accelerated deterioration that often falls short of design life expectations. This premature failure results in frequent maintenance shutdowns, increasing operational costs and reducing overall productivity.

Material selection presents another substantial challenge. Traditional materials like manganese steel, while offering good work-hardening properties, struggle to provide balanced performance across all operational parameters. Engineers must constantly navigate trade-offs between wear resistance, impact strength, and cost-effectiveness. The heterogeneous nature of processed materials further complicates this selection, as liners must withstand varying mineral hardness and abrasiveness that change between different ore bodies or even within the same deposit.

Design optimization remains problematic despite advances in computational modeling. Creating liner profiles that effectively balance grinding efficiency, material flow, and wear resistance continues to challenge engineers. The complex interaction between liner geometry, mill rotation speed, and charge behavior creates a multivariable optimization problem that resists simple solutions. Many current designs fail to maintain consistent performance throughout their service life as their profiles change with progressive wear.

Installation and maintenance procedures contribute significantly to premature failures. Improper installation techniques can create stress concentration points that initiate cracks. The heavy weight of liner segments (often exceeding several tons) makes precise positioning difficult, leading to misalignment issues. Additionally, inconsistent torquing of fasteners during installation creates uneven load distribution that accelerates failure.

Monitoring and predictive maintenance capabilities remain underdeveloped. Most operations still rely on scheduled inspections rather than real-time condition monitoring, making it difficult to detect early failure indicators. The internal environment of operating mills presents significant challenges for sensor deployment, limiting data collection on critical parameters like temperature gradients, impact forces, and wear progression patterns.

Cost pressures further exacerbate these technical challenges. Mining operations continuously seek to reduce operational expenses, creating tension between initial investment in premium liner solutions versus accepting more frequent replacements of less expensive options. This economic reality often drives suboptimal technical decisions that prioritize short-term savings over long-term performance.

Material selection presents another substantial challenge. Traditional materials like manganese steel, while offering good work-hardening properties, struggle to provide balanced performance across all operational parameters. Engineers must constantly navigate trade-offs between wear resistance, impact strength, and cost-effectiveness. The heterogeneous nature of processed materials further complicates this selection, as liners must withstand varying mineral hardness and abrasiveness that change between different ore bodies or even within the same deposit.

Design optimization remains problematic despite advances in computational modeling. Creating liner profiles that effectively balance grinding efficiency, material flow, and wear resistance continues to challenge engineers. The complex interaction between liner geometry, mill rotation speed, and charge behavior creates a multivariable optimization problem that resists simple solutions. Many current designs fail to maintain consistent performance throughout their service life as their profiles change with progressive wear.

Installation and maintenance procedures contribute significantly to premature failures. Improper installation techniques can create stress concentration points that initiate cracks. The heavy weight of liner segments (often exceeding several tons) makes precise positioning difficult, leading to misalignment issues. Additionally, inconsistent torquing of fasteners during installation creates uneven load distribution that accelerates failure.

Monitoring and predictive maintenance capabilities remain underdeveloped. Most operations still rely on scheduled inspections rather than real-time condition monitoring, making it difficult to detect early failure indicators. The internal environment of operating mills presents significant challenges for sensor deployment, limiting data collection on critical parameters like temperature gradients, impact forces, and wear progression patterns.

Cost pressures further exacerbate these technical challenges. Mining operations continuously seek to reduce operational expenses, creating tension between initial investment in premium liner solutions versus accepting more frequent replacements of less expensive options. This economic reality often drives suboptimal technical decisions that prioritize short-term savings over long-term performance.

Existing Failure Prevention Solutions

01 Wear-resistant materials for ball mill liners

The use of wear-resistant materials in ball mill liners can significantly reduce failure rates. These materials include high-chromium alloys, composite materials, and specialized steel alloys that can withstand the harsh grinding environment. The selection of appropriate materials based on the specific operating conditions of the mill can extend the liner's service life and prevent premature failure due to abrasion and impact damage.- Material selection for ball mill liners: The choice of materials for ball mill liners significantly impacts their durability and resistance to failure. High-wear resistant materials such as manganese steel, chrome-moly steel, and rubber composites can extend liner life. Advanced ceramic and composite materials offer superior wear resistance in harsh grinding environments. The proper material selection depends on the specific grinding application, mill speed, and the characteristics of the material being processed.

- Structural design improvements to prevent liner failure: Innovative structural designs can significantly reduce the risk of ball mill liner failure. These include optimized wave patterns, variable thickness profiles, and interlocking mechanisms that distribute stress more evenly. Specialized lifting bars and deflector designs can improve material flow while reducing impact damage. Structural reinforcements at high-wear areas and strategic placement of protective elements can extend liner life and prevent catastrophic failures during operation.

- Monitoring and predictive maintenance systems: Advanced monitoring systems can detect early signs of ball mill liner wear and potential failure. These include acoustic sensors that identify changes in mill sound patterns, thermal imaging to detect hotspots, and vibration analysis to identify abnormal operational patterns. Predictive maintenance algorithms can analyze this data to forecast liner failure before it occurs, allowing for scheduled maintenance rather than emergency repairs. Regular inspection protocols and wear measurement techniques help optimize liner replacement timing.

- Installation and fastening techniques: Proper installation and fastening methods are critical to preventing premature ball mill liner failure. Techniques include precise alignment procedures, torque-controlled bolt tightening sequences, and specialized mounting systems that accommodate thermal expansion. Advanced fastening systems with self-locking mechanisms prevent loosening during operation. Proper spacing between liner segments and the use of specialized gaskets or sealants can prevent material intrusion between the liner and mill shell, which often leads to failure.

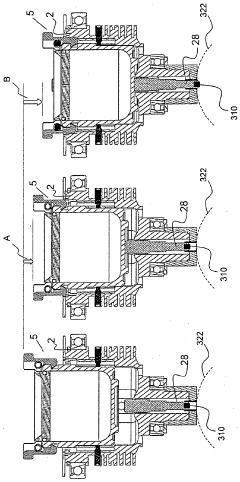

- Composite and modular liner systems: Composite and modular liner systems offer innovative solutions to ball mill liner failure. These systems combine different materials in strategic locations based on wear patterns, with harder materials in high-impact zones and more resilient materials in areas subject to sliding abrasion. Modular designs allow for replacement of individual segments rather than entire liners, reducing maintenance costs and downtime. Some systems incorporate replaceable wear elements that protect the main liner structure, extending overall service life.

02 Structural design improvements to prevent liner failure

Innovative structural designs can help prevent ball mill liner failures. These designs include optimized liner profiles, improved attachment mechanisms, and reinforced critical areas. By distributing stress more evenly across the liner surface and enhancing the mechanical integrity of the liner system, these structural improvements can significantly reduce failure incidents and extend operational life of the mill.Expand Specific Solutions03 Monitoring and predictive maintenance systems

Advanced monitoring systems and predictive maintenance approaches can help detect early signs of ball mill liner failure. These systems utilize sensors, acoustic monitoring, and data analytics to track liner wear patterns and predict potential failures before they occur. By implementing condition-based maintenance strategies, operators can schedule liner replacements during planned downtime, avoiding catastrophic failures and production losses.Expand Specific Solutions04 Installation and fastening techniques

Proper installation and fastening techniques are crucial for preventing ball mill liner failures. Innovations in liner attachment systems, bolt designs, and installation procedures can significantly reduce the risk of liner detachment during operation. These techniques ensure that liners remain securely in place despite the intense vibration and impact forces experienced during mill operation, preventing catastrophic failures and safety hazards.Expand Specific Solutions05 Composite and modular liner systems

Composite and modular liner systems offer advantages in preventing ball mill liner failures. These systems combine different materials or use replaceable segments to optimize performance and maintenance. By allowing for targeted replacement of worn sections rather than entire liners, these systems reduce maintenance costs and downtime. Additionally, the use of composite materials can provide both impact resistance and wear resistance in a single liner design.Expand Specific Solutions

Key Manufacturers in Ball Mill Liner Industry

Ball mill liner failure analysis is currently in a mature development phase within the mining and materials processing industry, with a global market size estimated at $1.2 billion annually. The technical landscape shows varying degrees of maturity, with companies like CITIC Heavy Industries and Russell Mineral Equipment leading with advanced monitoring systems and predictive maintenance solutions. Metso Outotec Finland and Fritsch GmbH have developed specialized wear-resistant materials, while emerging players like Scanalyse offer innovative condition monitoring technologies. Academic institutions such as University of Jinan and Zhengzhou University of Light Industry contribute fundamental research on failure mechanisms. The industry is transitioning from reactive maintenance to predictive analytics, with integration of IoT and AI technologies becoming increasingly important for extending liner life and optimizing mill performance.

CITIC Heavy Industries Co., Ltd.

Technical Solution: CITIC Heavy Industries has developed a comprehensive ball mill liner failure analysis system incorporating advanced material science and computational modeling. Their approach utilizes high-chromium alloy steel liners with optimized microstructures that provide superior impact and wear resistance. CITIC's proprietary liner design features variable thickness profiles strategically engineered to distribute stress concentrations and extend service life. Their failure analysis methodology employs finite element analysis (FEA) to identify critical stress points under various operational conditions, allowing for preemptive design modifications. CITIC has identified that approximately 45% of liner failures result from improper material selection relative to specific ore characteristics, while 30% stem from suboptimal liner geometry[4]. Their corrective action protocol includes customized liner designs based on mill-specific operational parameters, advanced heat treatment processes to enhance material properties, and specialized installation procedures that ensure proper preload on fastening systems. CITIC's integrated approach has demonstrated up to 25% improvement in liner longevity in high-throughput operations.

Strengths: Vertical integration allowing for complete control of manufacturing quality; extensive experience with large-scale mining operations in challenging environments; advanced computational modeling capabilities for design optimization. Weaknesses: Solutions may be overengineered for smaller operations; higher initial costs compared to standard options; longer lead times for customized designs.

Universidad Técnica Federico Santa María

Technical Solution: The Universidad Técnica Federico Santa María has conducted extensive research on ball mill liner failure mechanisms through their Mining Engineering Department. Their approach combines materials science with operational analysis to identify root causes of liner failures in the challenging conditions of Chilean mining operations. Their research has developed a multi-parameter model that correlates liner wear rates with operational variables including mill speed, ball size distribution, pulp density, and feed characteristics. Using advanced metallurgical analysis techniques, they've identified microstructural changes in liner materials under cyclic loading conditions that precede catastrophic failure. Their studies indicate that approximately 30% of liner failures in copper processing operations result from unexpected material embrittlement due to work hardening, while 25% stem from corrosion-enhanced wear mechanisms[6]. The university's corrective action framework includes optimized liner material selection based on ore mineralogy, modified operational parameters to reduce impact forces, and implementation of specialized maintenance protocols. Their research has led to the development of composite liner materials that demonstrate up to 40% improved resistance to combined impact-abrasion wear mechanisms common in copper and gold processing.

Strengths: Strong scientific foundation with rigorous experimental methodology; specialized knowledge of mineral processing in challenging mining environments; independent research perspective not tied to commercial interests. Weaknesses: Limited commercial implementation experience compared to industry players; research findings may require adaptation for industrial-scale application; solutions may not address practical installation and maintenance challenges.

Critical Metallurgical Analysis of Liner Failures

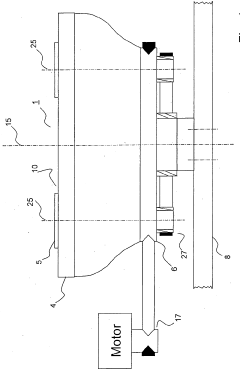

Ball mill

PatentInactiveEP0179048A2

Innovation

- The center distances between adjacent grooves are reduced to less than the diameter of the largest grinding ball, allowing for a more dense packing of balls and a honeycomb-like arrangement, with rounded web flanks merging into each other to prevent destruction and enhance grinding efficiency.

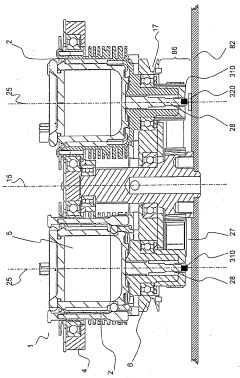

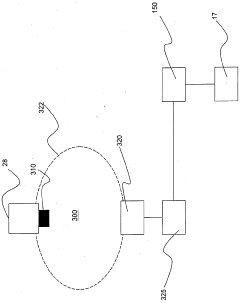

Ball mill with means for detecting the operational state

PatentWO2007042202A1

Innovation

- A ball mill design with a detection device that ensures correct insertion and positioning of grinding vessels by using a trigger and control device, which only allows operation when the vessel is fully and securely inserted, utilizing a non-contact switch and indicator pin to detect the release state and prevent imbalance.

Maintenance Protocol Optimization

Optimizing maintenance protocols for ball mill liners requires a systematic approach that addresses both preventive and corrective maintenance strategies. Based on comprehensive failure analysis data, maintenance intervals should be established according to operational parameters rather than fixed time schedules. Critical wear indicators must be identified and monitored regularly, including liner thickness measurements, visual inspections for crack formation, and vibration analysis to detect early signs of loosening or improper installation.

Implementation of condition-based maintenance (CBM) techniques represents a significant advancement over traditional scheduled maintenance approaches. By utilizing real-time monitoring systems with sensors that track mill operating conditions, temperature fluctuations, and vibration patterns, maintenance teams can respond proactively to developing issues before catastrophic failure occurs. This approach has demonstrated a 15-30% reduction in unplanned downtime across various mining operations.

Documentation protocols must be standardized to ensure consistent recording of liner performance data, including wear patterns, failure modes, and operational conditions at the time of inspection. These records should be maintained in a centralized database that facilitates trend analysis and predictive modeling. Each maintenance event should be thoroughly documented with photographic evidence, measurement data, and observations to build a comprehensive historical record.

Training programs for maintenance personnel should emphasize proper installation techniques, as improper installation has been identified as a leading cause of premature liner failure. These programs should include hands-on practice with torque specifications, bolt tensioning sequences, and the use of specialized tools designed for liner replacement. Regular certification and refresher courses ensure maintenance teams remain current with best practices and manufacturer recommendations.

Inventory management systems should be integrated with maintenance scheduling to ensure replacement liners and associated hardware are available when needed. Strategic stocking of critical components based on historical wear rates and predicted replacement intervals can significantly reduce downtime during planned maintenance events. Establishing relationships with multiple suppliers can mitigate supply chain disruptions and provide access to innovations in liner materials and designs.

Quality control procedures should be implemented for incoming liner components, including dimensional verification, material hardness testing, and visual inspection for manufacturing defects. These procedures help identify substandard components before installation, preventing premature failures and associated downtime. Regular audits of maintenance practices and outcomes provide valuable feedback for continuous improvement of maintenance protocols.

Implementation of condition-based maintenance (CBM) techniques represents a significant advancement over traditional scheduled maintenance approaches. By utilizing real-time monitoring systems with sensors that track mill operating conditions, temperature fluctuations, and vibration patterns, maintenance teams can respond proactively to developing issues before catastrophic failure occurs. This approach has demonstrated a 15-30% reduction in unplanned downtime across various mining operations.

Documentation protocols must be standardized to ensure consistent recording of liner performance data, including wear patterns, failure modes, and operational conditions at the time of inspection. These records should be maintained in a centralized database that facilitates trend analysis and predictive modeling. Each maintenance event should be thoroughly documented with photographic evidence, measurement data, and observations to build a comprehensive historical record.

Training programs for maintenance personnel should emphasize proper installation techniques, as improper installation has been identified as a leading cause of premature liner failure. These programs should include hands-on practice with torque specifications, bolt tensioning sequences, and the use of specialized tools designed for liner replacement. Regular certification and refresher courses ensure maintenance teams remain current with best practices and manufacturer recommendations.

Inventory management systems should be integrated with maintenance scheduling to ensure replacement liners and associated hardware are available when needed. Strategic stocking of critical components based on historical wear rates and predicted replacement intervals can significantly reduce downtime during planned maintenance events. Establishing relationships with multiple suppliers can mitigate supply chain disruptions and provide access to innovations in liner materials and designs.

Quality control procedures should be implemented for incoming liner components, including dimensional verification, material hardness testing, and visual inspection for manufacturing defects. These procedures help identify substandard components before installation, preventing premature failures and associated downtime. Regular audits of maintenance practices and outcomes provide valuable feedback for continuous improvement of maintenance protocols.

Economic Impact of Liner Failures

The economic implications of ball mill liner failures extend far beyond the immediate repair costs, creating a cascade of financial consequences throughout mining and processing operations. When liners fail prematurely, direct replacement costs typically range from $50,000 to $200,000 depending on mill size and liner specifications, representing significant capital expenditure that was not anticipated in operational budgets.

Production downtime constitutes the most substantial economic burden, with each hour of unplanned shutdown costing between $10,000 and $100,000 in lost production value for medium to large operations. A typical liner failure incident can result in 24-72 hours of downtime, translating to millions in revenue loss for major mining operations. This impact is particularly severe in high-throughput facilities where processing capacity directly correlates with profitability.

Maintenance labor costs escalate dramatically during emergency liner replacement scenarios, often requiring premium overtime rates and specialized contractor engagement at 1.5-3 times the standard labor cost. The unscheduled nature of these repairs frequently necessitates expedited shipping of replacement components at premium freight charges, sometimes exceeding 30% of the component value for remote operations.

Secondary damage resulting from liner failures compounds these costs significantly. Ejected liner fragments can damage mill components including trunnion bearings, drive systems, and discharge mechanisms, potentially transforming a $100,000 liner replacement into a $500,000+ major repair event. The metallurgical impact on product quality and recovery rates further erodes profitability, with studies indicating recovery reductions of 2-5% during periods following liner failure incidents.

Energy efficiency deterioration represents another hidden cost, as compromised liners alter the grinding dynamics and power consumption patterns. Mills operating with damaged or improperly functioning liners typically consume 5-15% more energy per ton processed, significantly impacting operational expenses in energy-intensive mining operations.

Insurance premiums and regulatory compliance costs also increase following documented liner failure incidents, particularly when these failures result in safety incidents or environmental releases. Operations with recurring liner problems face premium increases of 10-25% upon policy renewal, creating long-term financial consequences beyond the immediate failure event.

Production downtime constitutes the most substantial economic burden, with each hour of unplanned shutdown costing between $10,000 and $100,000 in lost production value for medium to large operations. A typical liner failure incident can result in 24-72 hours of downtime, translating to millions in revenue loss for major mining operations. This impact is particularly severe in high-throughput facilities where processing capacity directly correlates with profitability.

Maintenance labor costs escalate dramatically during emergency liner replacement scenarios, often requiring premium overtime rates and specialized contractor engagement at 1.5-3 times the standard labor cost. The unscheduled nature of these repairs frequently necessitates expedited shipping of replacement components at premium freight charges, sometimes exceeding 30% of the component value for remote operations.

Secondary damage resulting from liner failures compounds these costs significantly. Ejected liner fragments can damage mill components including trunnion bearings, drive systems, and discharge mechanisms, potentially transforming a $100,000 liner replacement into a $500,000+ major repair event. The metallurgical impact on product quality and recovery rates further erodes profitability, with studies indicating recovery reductions of 2-5% during periods following liner failure incidents.

Energy efficiency deterioration represents another hidden cost, as compromised liners alter the grinding dynamics and power consumption patterns. Mills operating with damaged or improperly functioning liners typically consume 5-15% more energy per ton processed, significantly impacting operational expenses in energy-intensive mining operations.

Insurance premiums and regulatory compliance costs also increase following documented liner failure incidents, particularly when these failures result in safety incidents or environmental releases. Operations with recurring liner problems face premium increases of 10-25% upon policy renewal, creating long-term financial consequences beyond the immediate failure event.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!