Ball Mill Retrofit Guide: Variable Speed Drives And Advanced Controls

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ball Mill Retrofit Technology Background and Objectives

Ball mills have been a cornerstone of mineral processing operations for over a century, with their origins dating back to the late 19th century. These robust grinding devices operate on a simple yet effective principle: rotating cylindrical shells filled with grinding media that crush and grind materials through impact and attrition. Traditionally, ball mills operated at fixed speeds determined by their motor and gearing configurations, offering limited flexibility in operational parameters.

The evolution of ball mill technology has been marked by incremental improvements in mechanical design, materials, and operational efficiency. However, a significant paradigm shift began in the 1980s with the introduction of variable speed drives (VSDs) in industrial applications, though their widespread adoption in ball mill operations came much later due to technical and economic constraints.

Recent technological advancements in power electronics, digital control systems, and industrial automation have created new opportunities for enhancing the performance of existing ball mill installations through retrofitting. The integration of VSDs and advanced control systems represents a transformative approach to modernizing legacy equipment without the capital expenditure of complete replacement.

The primary objective of ball mill retrofitting with VSDs and advanced controls is to optimize grinding efficiency while reducing energy consumption, which typically accounts for 30-40% of mineral processing operational costs. Additional goals include extending equipment lifespan, improving process stability, enhancing product quality consistency, and reducing maintenance requirements.

Current industry trends indicate a growing focus on sustainability and operational excellence, driving interest in technologies that can improve energy efficiency and reduce the environmental footprint of mineral processing operations. The mining and cement industries, in particular, face increasing pressure to reduce carbon emissions while maintaining competitive production costs.

The technological trajectory points toward increasingly sophisticated control algorithms, integration with plant-wide automation systems, and the incorporation of machine learning and artificial intelligence for predictive maintenance and real-time optimization. These advancements are expected to further enhance the value proposition of ball mill retrofits.

The convergence of Industry 4.0 principles with traditional mineral processing equipment creates a compelling case for modernization through retrofitting. By understanding the historical context and technological evolution of ball mills, we can better appreciate the transformative potential of VSD and advanced control retrofits in meeting current and future industry challenges.

The evolution of ball mill technology has been marked by incremental improvements in mechanical design, materials, and operational efficiency. However, a significant paradigm shift began in the 1980s with the introduction of variable speed drives (VSDs) in industrial applications, though their widespread adoption in ball mill operations came much later due to technical and economic constraints.

Recent technological advancements in power electronics, digital control systems, and industrial automation have created new opportunities for enhancing the performance of existing ball mill installations through retrofitting. The integration of VSDs and advanced control systems represents a transformative approach to modernizing legacy equipment without the capital expenditure of complete replacement.

The primary objective of ball mill retrofitting with VSDs and advanced controls is to optimize grinding efficiency while reducing energy consumption, which typically accounts for 30-40% of mineral processing operational costs. Additional goals include extending equipment lifespan, improving process stability, enhancing product quality consistency, and reducing maintenance requirements.

Current industry trends indicate a growing focus on sustainability and operational excellence, driving interest in technologies that can improve energy efficiency and reduce the environmental footprint of mineral processing operations. The mining and cement industries, in particular, face increasing pressure to reduce carbon emissions while maintaining competitive production costs.

The technological trajectory points toward increasingly sophisticated control algorithms, integration with plant-wide automation systems, and the incorporation of machine learning and artificial intelligence for predictive maintenance and real-time optimization. These advancements are expected to further enhance the value proposition of ball mill retrofits.

The convergence of Industry 4.0 principles with traditional mineral processing equipment creates a compelling case for modernization through retrofitting. By understanding the historical context and technological evolution of ball mills, we can better appreciate the transformative potential of VSD and advanced control retrofits in meeting current and future industry challenges.

Market Demand Analysis for Mill Modernization

The global ball mill modernization market is experiencing significant growth, driven by increasing demands for energy efficiency, productivity improvements, and sustainability in mining and cement industries. Current market analysis indicates that approximately 60% of existing ball mills worldwide are operating with outdated control systems and fixed-speed drives, presenting a substantial retrofit opportunity valued at over $3.5 billion annually.

Energy consumption represents 30-40% of operational costs in mineral processing facilities, with ball mills accounting for up to 70% of the total energy used in grinding operations. This economic pressure is compelling operators to seek modernization solutions, particularly as electricity costs continue to rise globally at an average rate of 4-6% annually in major mining regions.

Market research reveals that facilities implementing variable speed drives (VSDs) and advanced controls in ball mill operations typically achieve energy savings between 15-30%, with payback periods averaging 12-24 months depending on facility size and operational parameters. This compelling return on investment is accelerating adoption rates, with the market for ball mill retrofits growing at approximately 8.7% CAGR.

Regulatory factors are also driving market demand, as countries implement increasingly stringent energy efficiency standards and carbon reduction targets. The European Union's Energy Efficiency Directive, China's industrial energy efficiency policies, and similar regulations in Australia and Canada have created compliance pressures that further stimulate retrofit investments.

Geographically, the highest demand concentration appears in established mining regions with aging infrastructure, particularly in North America, Australia, and parts of South America, where approximately 65% of ball mills are over 15 years old. Emerging markets in Africa and Southeast Asia are showing accelerated growth rates as these regions expand mineral processing capabilities while seeking to implement modern technologies from the outset.

Customer surveys indicate that beyond energy savings, facilities are increasingly valuing additional benefits of modernization, including extended equipment life (valued by 78% of respondents), reduced maintenance costs (82%), improved process stability (91%), and enhanced production quality (74%). This multi-benefit value proposition is expanding the market beyond purely cost-driven decisions.

Industry forecasts project that by 2028, over 70% of large-scale mining and cement operations will have implemented some form of variable speed technology and advanced controls in their grinding circuits, representing a significant market opportunity for retrofit solution providers who can demonstrate proven expertise and measurable performance improvements.

Energy consumption represents 30-40% of operational costs in mineral processing facilities, with ball mills accounting for up to 70% of the total energy used in grinding operations. This economic pressure is compelling operators to seek modernization solutions, particularly as electricity costs continue to rise globally at an average rate of 4-6% annually in major mining regions.

Market research reveals that facilities implementing variable speed drives (VSDs) and advanced controls in ball mill operations typically achieve energy savings between 15-30%, with payback periods averaging 12-24 months depending on facility size and operational parameters. This compelling return on investment is accelerating adoption rates, with the market for ball mill retrofits growing at approximately 8.7% CAGR.

Regulatory factors are also driving market demand, as countries implement increasingly stringent energy efficiency standards and carbon reduction targets. The European Union's Energy Efficiency Directive, China's industrial energy efficiency policies, and similar regulations in Australia and Canada have created compliance pressures that further stimulate retrofit investments.

Geographically, the highest demand concentration appears in established mining regions with aging infrastructure, particularly in North America, Australia, and parts of South America, where approximately 65% of ball mills are over 15 years old. Emerging markets in Africa and Southeast Asia are showing accelerated growth rates as these regions expand mineral processing capabilities while seeking to implement modern technologies from the outset.

Customer surveys indicate that beyond energy savings, facilities are increasingly valuing additional benefits of modernization, including extended equipment life (valued by 78% of respondents), reduced maintenance costs (82%), improved process stability (91%), and enhanced production quality (74%). This multi-benefit value proposition is expanding the market beyond purely cost-driven decisions.

Industry forecasts project that by 2028, over 70% of large-scale mining and cement operations will have implemented some form of variable speed technology and advanced controls in their grinding circuits, representing a significant market opportunity for retrofit solution providers who can demonstrate proven expertise and measurable performance improvements.

Current State and Challenges in Mill Control Systems

The current state of ball mill control systems in the mining and cement industries reveals a landscape in transition. Traditional control systems predominantly rely on fixed-speed operations with basic PID (Proportional-Integral-Derivative) controllers that maintain predetermined parameters such as feed rate, mill weight, and power draw. These conventional systems, while reliable, offer limited flexibility and efficiency, particularly when processing materials with varying hardness or when energy optimization becomes critical.

Most existing installations feature outdated relay-based control panels or early-generation PLCs (Programmable Logic Controllers) that lack the computational power and connectivity required for advanced analytics and optimization. Industry surveys indicate that approximately 65% of operational ball mills globally still utilize fixed-speed drives with limited or no variable speed capabilities, resulting in significant energy inefficiencies and production inflexibility.

A primary challenge in current mill control systems is the inability to dynamically respond to changing ore characteristics. Without real-time adjustment capabilities, mills often operate at suboptimal conditions, leading to excessive energy consumption, inconsistent product quality, and accelerated equipment wear. The absence of advanced sensing technologies further compounds this issue, as operators lack accurate, real-time data on critical parameters such as particle size distribution, mill filling levels, and material flow dynamics.

Integration challenges present another significant hurdle. Many facilities operate with siloed systems where mill controls remain disconnected from broader plant management systems. This fragmentation prevents holistic optimization and creates operational blind spots that impact overall plant efficiency. Legacy communication protocols and proprietary systems further complicate integration efforts, making comprehensive retrofits technically challenging and potentially disruptive to ongoing operations.

Maintenance complexities also plague current systems. As original equipment manufacturers phase out support for older control platforms, facilities face increasing difficulty sourcing replacement parts and technical expertise. This obsolescence risk is particularly acute for mills installed in the 1990s and early 2000s, which represent a substantial portion of the global installed base.

Energy efficiency remains perhaps the most pressing challenge. Ball mills typically consume 30-40% of a mineral processing plant's total energy budget, yet most operate at fixed speeds regardless of varying load conditions. This inflexibility results in energy wastage estimated at 15-25% compared to optimized variable speed operations, representing both a significant environmental impact and a substantial operational cost burden for plant operators.

Most existing installations feature outdated relay-based control panels or early-generation PLCs (Programmable Logic Controllers) that lack the computational power and connectivity required for advanced analytics and optimization. Industry surveys indicate that approximately 65% of operational ball mills globally still utilize fixed-speed drives with limited or no variable speed capabilities, resulting in significant energy inefficiencies and production inflexibility.

A primary challenge in current mill control systems is the inability to dynamically respond to changing ore characteristics. Without real-time adjustment capabilities, mills often operate at suboptimal conditions, leading to excessive energy consumption, inconsistent product quality, and accelerated equipment wear. The absence of advanced sensing technologies further compounds this issue, as operators lack accurate, real-time data on critical parameters such as particle size distribution, mill filling levels, and material flow dynamics.

Integration challenges present another significant hurdle. Many facilities operate with siloed systems where mill controls remain disconnected from broader plant management systems. This fragmentation prevents holistic optimization and creates operational blind spots that impact overall plant efficiency. Legacy communication protocols and proprietary systems further complicate integration efforts, making comprehensive retrofits technically challenging and potentially disruptive to ongoing operations.

Maintenance complexities also plague current systems. As original equipment manufacturers phase out support for older control platforms, facilities face increasing difficulty sourcing replacement parts and technical expertise. This obsolescence risk is particularly acute for mills installed in the 1990s and early 2000s, which represent a substantial portion of the global installed base.

Energy efficiency remains perhaps the most pressing challenge. Ball mills typically consume 30-40% of a mineral processing plant's total energy budget, yet most operate at fixed speeds regardless of varying load conditions. This inflexibility results in energy wastage estimated at 15-25% compared to optimized variable speed operations, representing both a significant environmental impact and a substantial operational cost burden for plant operators.

Current Variable Speed Drive Implementation Solutions

01 Variable Speed Drive Integration for Ball Mills

Variable speed drives can be retrofitted to existing ball mills to improve operational efficiency and control. These drives allow for adjustable mill rotation speeds based on process requirements, leading to optimized grinding performance. The implementation of variable speed technology enables energy savings, reduced wear on mechanical components, and better adaptation to changing material characteristics during the grinding process.- Variable Speed Drive Integration for Ball Mills: Variable speed drives can be retrofitted to existing ball mills to improve operational efficiency and control. These drives allow for precise adjustment of mill speed according to process requirements, resulting in optimized grinding performance, reduced energy consumption, and extended equipment life. The implementation of variable speed technology enables mills to operate at their most efficient speed for different materials and grinding conditions.

- Advanced Control Systems for Ball Mill Operation: Advanced control systems incorporate sensors, monitoring equipment, and intelligent algorithms to optimize ball mill performance. These systems can automatically adjust operational parameters based on real-time data, including load conditions, material properties, and power consumption. By implementing advanced controls, mills can maintain consistent product quality while maximizing throughput and minimizing energy usage. These systems often include predictive maintenance capabilities to reduce downtime.

- Energy Efficiency Improvements in Retrofitted Ball Mills: Retrofitting ball mills with modern drive systems and controls significantly improves energy efficiency. By implementing variable frequency drives, power consumption can be reduced by adjusting motor speed to match grinding requirements. Advanced control algorithms optimize the grinding process by maintaining ideal operating conditions, reducing overgrinding, and minimizing idle running. These energy-saving technologies can result in substantial cost reductions while also decreasing the environmental impact of grinding operations.

- Monitoring and Diagnostic Systems for Ball Mills: Modern ball mill retrofits incorporate comprehensive monitoring and diagnostic systems that track critical operational parameters. These systems collect data on vibration, temperature, pressure, and power consumption to identify potential issues before they lead to failures. Real-time monitoring enables operators to make informed decisions about maintenance needs and process adjustments. Advanced diagnostic capabilities can detect abnormal operating conditions, predict component failures, and recommend corrective actions to prevent unplanned downtime.

- Automation and Integration with Plant Control Systems: Ball mill retrofits often include automation features that integrate with broader plant control systems. These integrations allow for coordinated operation with upstream and downstream processes, optimizing the entire production line. Automated control systems can adjust mill parameters based on feed characteristics and product requirements without operator intervention. The integration with plant-wide systems enables comprehensive data collection for process optimization, quality control, and production planning, resulting in improved overall plant efficiency.

02 Advanced Control Systems for Ball Mill Operation

Modern ball mills can be equipped with advanced control systems that monitor and adjust operational parameters in real-time. These systems utilize sensors and algorithms to optimize grinding efficiency based on load conditions, material properties, and production requirements. Advanced controls can implement predictive maintenance strategies, fault detection, and automated process adjustments to maintain optimal performance while minimizing downtime.Expand Specific Solutions03 Energy Efficiency Improvements in Retrofitted Ball Mills

Retrofitting ball mills with modern drive and control technologies significantly improves energy efficiency. By implementing precise speed control and load monitoring, the mill can operate at optimal energy consumption levels. These retrofits often include power monitoring systems, regenerative braking capabilities, and intelligent load management algorithms that reduce overall power consumption while maintaining or improving production output.Expand Specific Solutions04 Automation and Remote Monitoring Solutions

Ball mill retrofits often incorporate automation and remote monitoring capabilities that allow for centralized control and reduced operator intervention. These systems enable remote adjustment of operational parameters, continuous performance monitoring, and data collection for analysis. The integration of these technologies facilitates better decision-making, improves safety by reducing manual interventions, and enables integration with broader plant management systems.Expand Specific Solutions05 Mechanical Modifications for Variable Speed Implementation

Implementing variable speed drives in ball mill retrofits often requires specific mechanical modifications to ensure compatibility and optimal performance. These modifications may include reinforced bearing systems, improved lubrication methods, enhanced coupling designs, and structural reinforcements to handle variable operational stresses. The mechanical adaptations work in conjunction with the electronic control systems to ensure reliable operation across the expanded speed range.Expand Specific Solutions

Key Industry Players in Mill Automation

The ball mill retrofit market is currently in a growth phase, characterized by increasing adoption of variable speed drives and advanced controls to enhance efficiency and productivity. The global market size for industrial mill retrofits is expanding, driven by demand for energy efficiency and operational optimization. Technologically, the field is maturing rapidly with companies like LOESCHE GmbH and Fritsch GmbH leading innovation in grinding technology, while Toshiba Mitsubishi-Electric Industrial Systems Corp. and Hitachi Ltd. dominate the variable speed drive segment. Automation leaders including Yanmar Power Technology and Alstom SA are advancing control systems integration. The competitive landscape features specialized mill manufacturers collaborating with electronics and automation giants to deliver comprehensive retrofit solutions that balance mechanical engineering with digital control capabilities.

LOESCHE GmbH

Technical Solution: LOESCHE has developed comprehensive ball mill retrofit solutions centered around their LM Master variable speed drive system. Their technology integrates advanced PLC-based control systems with high-efficiency motors and sophisticated frequency converters specifically designed for grinding applications. The system features real-time monitoring capabilities that analyze mill load, material properties, and energy consumption patterns to dynamically adjust mill speed. LOESCHE's retrofit package includes proprietary algorithms that optimize grinding efficiency by maintaining the ideal cascade/cataract motion of the grinding media across varying operational conditions. Their solution incorporates predictive maintenance functionality through continuous vibration analysis and bearing temperature monitoring, allowing for condition-based maintenance scheduling rather than fixed intervals.

Strengths: Specialized expertise in grinding technology with over 100 years of experience; comprehensive integration with existing plant control systems; documented energy savings of 15-30% in retrofitted installations. Weaknesses: Higher initial investment cost compared to basic VFD solutions; requires more extensive installation downtime; system complexity may necessitate specialized training for maintenance personnel.

Hitachi Ltd.

Technical Solution: Hitachi has developed an advanced ball mill retrofit solution centered around their HDRIVE-VG series variable frequency drives integrated with their Lumada IoT platform. Their system employs sophisticated digital twin modeling that creates a virtual representation of the mill to predict optimal operating parameters in real-time. Hitachi's solution incorporates adaptive control algorithms that continuously learn from operational data to optimize mill performance across varying conditions. The system features high-precision torque control that maintains optimal ball trajectory regardless of mill loading conditions, while their proprietary EcoMonitor power analyzers provide detailed energy consumption metrics. Hitachi's retrofit package includes advanced vibration analysis tools that detect early signs of mechanical issues, allowing for predictive maintenance scheduling. Their solution integrates seamlessly with existing plant control systems through standardized communication protocols and offers cloud-based analytics for remote monitoring and optimization.

Strengths: Comprehensive integration with broader plant systems through IoT platform; sophisticated analytics capabilities providing actionable insights; documented energy efficiency improvements of up to 25%. Weaknesses: Higher initial investment compared to basic VFD solutions; complex implementation requiring specialized expertise; potential cybersecurity concerns with cloud-connected industrial systems.

Core Technologies in Advanced Mill Control Systems

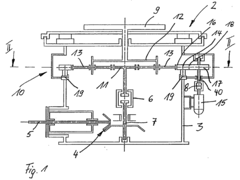

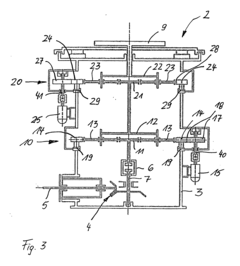

Variable speed drive having intermediate alternating movements

PatentInactiveEP0760914A1

Innovation

- A variable speed drive with at least two inclined bearings, each comprising an outer and inner cage, where the axis orientation is adjustable to control the transmission ratio, using mechanical storage means like torsion springs to modify inclination during non-engagement phases, and unidirectional link devices for smooth operation in motor, retrograde, and neutral modes, eliminating the need for hydraulic couplers and flywheels.

Variable rotation speed mill transmission system

PatentInactiveEP1982769A1

Innovation

- A variable-speed mill gear design using a separately mounted and driven ring gear within a planetary gear set, allowing for continuous speed adjustment by rotating the ring gear in the same or opposite direction of the output flange, enabling a +/- 25% stepless speed adjustment range.

Energy Efficiency and Sustainability Considerations

The implementation of variable speed drives and advanced controls in ball mill retrofits presents significant opportunities for energy efficiency improvements and sustainability advancements. Traditional ball mills typically operate at fixed speeds regardless of load conditions, resulting in substantial energy wastage during periods of lower throughput. Variable speed technology enables mills to adjust their operational parameters according to actual processing requirements, potentially reducing energy consumption by 15-30% compared to conventional fixed-speed systems.

Energy efficiency gains from VSD retrofits manifest primarily through optimized grinding efficiency and reduced no-load power consumption. When material load decreases, the mill can automatically reduce its rotational speed while maintaining optimal ball trajectory and grinding performance. This adaptive operation eliminates the energy losses associated with over-grinding and mechanical friction during partial loading conditions.

Carbon footprint reduction represents another critical sustainability benefit of ball mill retrofits. The mining and mineral processing industries collectively account for approximately 4-7% of global energy consumption, with grinding operations responsible for up to 60% of a processing plant's energy usage. By implementing advanced control systems and VSDs, facilities can achieve measurable reductions in greenhouse gas emissions, supporting corporate sustainability goals and compliance with increasingly stringent environmental regulations.

The economic sustainability aspects of these retrofits are equally compelling. While initial capital investment for VSD implementation ranges from $200,000 to $1,000,000 depending on mill size and complexity, the payback period typically falls between 12-36 months based on current energy pricing models. This favorable return on investment makes retrofitting an attractive option compared to complete equipment replacement.

Water conservation benefits also emerge from advanced control implementations. Optimized grinding efficiency leads to more precise particle size distribution, which can improve downstream processes such as flotation and leaching. This optimization often results in reduced water consumption per ton of processed material, addressing growing concerns about water scarcity in many mining regions.

Lifecycle assessment studies indicate that retrofitted ball mills with variable speed capabilities demonstrate extended equipment longevity due to reduced mechanical stress during operation. This extension of useful life represents a significant sustainability advantage by delaying the resource-intensive processes of manufacturing and installing replacement equipment.

Energy efficiency gains from VSD retrofits manifest primarily through optimized grinding efficiency and reduced no-load power consumption. When material load decreases, the mill can automatically reduce its rotational speed while maintaining optimal ball trajectory and grinding performance. This adaptive operation eliminates the energy losses associated with over-grinding and mechanical friction during partial loading conditions.

Carbon footprint reduction represents another critical sustainability benefit of ball mill retrofits. The mining and mineral processing industries collectively account for approximately 4-7% of global energy consumption, with grinding operations responsible for up to 60% of a processing plant's energy usage. By implementing advanced control systems and VSDs, facilities can achieve measurable reductions in greenhouse gas emissions, supporting corporate sustainability goals and compliance with increasingly stringent environmental regulations.

The economic sustainability aspects of these retrofits are equally compelling. While initial capital investment for VSD implementation ranges from $200,000 to $1,000,000 depending on mill size and complexity, the payback period typically falls between 12-36 months based on current energy pricing models. This favorable return on investment makes retrofitting an attractive option compared to complete equipment replacement.

Water conservation benefits also emerge from advanced control implementations. Optimized grinding efficiency leads to more precise particle size distribution, which can improve downstream processes such as flotation and leaching. This optimization often results in reduced water consumption per ton of processed material, addressing growing concerns about water scarcity in many mining regions.

Lifecycle assessment studies indicate that retrofitted ball mills with variable speed capabilities demonstrate extended equipment longevity due to reduced mechanical stress during operation. This extension of useful life represents a significant sustainability advantage by delaying the resource-intensive processes of manufacturing and installing replacement equipment.

ROI Analysis and Implementation Roadmap

Implementing variable speed drives (VSDs) and advanced controls in ball mill operations represents a significant capital investment that requires thorough financial analysis. The return on investment (ROI) for ball mill retrofits typically ranges from 12-24 months, depending on existing infrastructure, operational conditions, and energy costs. Energy savings of 15-30% are commonly achieved through optimized mill speed control, which translates to substantial cost reductions for energy-intensive mining and cement operations.

A comprehensive ROI analysis should begin with baseline measurements of current power consumption, production rates, and maintenance costs. This establishes clear metrics against which post-implementation performance can be measured. Capital expenditure considerations must include not only the VSD and control system hardware but also installation costs, potential downtime during implementation, and staff training requirements.

The implementation roadmap should follow a phased approach to minimize operational disruption while maximizing early benefits. Phase one typically involves conducting a detailed site assessment and energy audit to identify specific opportunities and constraints. This includes evaluating existing electrical infrastructure to determine if upgrades are necessary to support VSD installation.

Phase two encompasses system design and procurement, where specifications are finalized based on mill characteristics and operational requirements. Vendor selection should prioritize suppliers with proven experience in similar applications and robust technical support capabilities. During this phase, establishing clear performance metrics and success criteria is essential for post-implementation evaluation.

The installation and commissioning phase requires careful planning to minimize production downtime. Many facilities opt for implementation during scheduled maintenance shutdowns. This phase should include comprehensive testing of all control systems and integration with existing plant automation infrastructure. Operator and maintenance staff training must be conducted before the system goes live to ensure smooth transition.

Post-implementation monitoring represents a critical final phase, where actual performance is measured against projected benefits. This should include continuous data collection on energy consumption, production rates, and product quality. Many modern systems include advanced analytics capabilities that can identify further optimization opportunities beyond the initial implementation.

For maximum ROI, the implementation plan should also incorporate ongoing optimization strategies. As operators become more familiar with the new system capabilities, additional fine-tuning of control parameters can yield incremental efficiency improvements. Establishing a regular review process ensures that the system continues to deliver optimal performance as operational conditions evolve over time.

A comprehensive ROI analysis should begin with baseline measurements of current power consumption, production rates, and maintenance costs. This establishes clear metrics against which post-implementation performance can be measured. Capital expenditure considerations must include not only the VSD and control system hardware but also installation costs, potential downtime during implementation, and staff training requirements.

The implementation roadmap should follow a phased approach to minimize operational disruption while maximizing early benefits. Phase one typically involves conducting a detailed site assessment and energy audit to identify specific opportunities and constraints. This includes evaluating existing electrical infrastructure to determine if upgrades are necessary to support VSD installation.

Phase two encompasses system design and procurement, where specifications are finalized based on mill characteristics and operational requirements. Vendor selection should prioritize suppliers with proven experience in similar applications and robust technical support capabilities. During this phase, establishing clear performance metrics and success criteria is essential for post-implementation evaluation.

The installation and commissioning phase requires careful planning to minimize production downtime. Many facilities opt for implementation during scheduled maintenance shutdowns. This phase should include comprehensive testing of all control systems and integration with existing plant automation infrastructure. Operator and maintenance staff training must be conducted before the system goes live to ensure smooth transition.

Post-implementation monitoring represents a critical final phase, where actual performance is measured against projected benefits. This should include continuous data collection on energy consumption, production rates, and product quality. Many modern systems include advanced analytics capabilities that can identify further optimization opportunities beyond the initial implementation.

For maximum ROI, the implementation plan should also incorporate ongoing optimization strategies. As operators become more familiar with the new system capabilities, additional fine-tuning of control parameters can yield incremental efficiency improvements. Establishing a regular review process ensures that the system continues to deliver optimal performance as operational conditions evolve over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!