Ball Mill Throughput Optimization: Case Studies And KPI Tracking

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ball Mill Technology Evolution and Optimization Goals

Ball mill technology has evolved significantly since its inception in the late 19th century. Initially designed as simple rotating cylinders with metal balls, these mills primarily served the mining industry for ore grinding. The early 20th century witnessed the first major technological advancement with the introduction of grate discharge systems, which improved material flow and prevented overgrinding. By mid-century, manufacturers began incorporating rubber and polyurethane linings to reduce noise, energy consumption, and wear, marking a significant step in operational efficiency.

The 1970s and 1980s brought computerized control systems that enabled real-time monitoring of mill operations, laying the groundwork for modern optimization techniques. During this period, the development of advanced grinding media with specialized metallurgical compositions substantially improved grinding efficiency and media longevity. The 1990s saw the emergence of variable speed drives, allowing operators to adjust mill rotation speeds according to changing feed characteristics and production requirements.

In recent decades, ball mill technology has embraced Industry 4.0 principles, incorporating IoT sensors, machine learning algorithms, and advanced analytics platforms. These technologies enable predictive maintenance, real-time performance optimization, and adaptive control strategies that respond to changing ore characteristics. Modern mills now feature sophisticated liner designs that optimize the cascading and cataracting motion of the grinding media, significantly improving energy efficiency and grinding performance.

The primary optimization goals in contemporary ball mill operations focus on maximizing throughput while minimizing energy consumption, which typically represents 30-40% of mineral processing operational costs. Achieving optimal particle size distribution remains a critical objective, as it directly impacts downstream processes such as flotation, leaching, and concentration. Reducing media and liner wear rates constitutes another key goal, as replacement costs and associated downtime significantly affect operational economics.

Environmental sustainability has emerged as an increasingly important optimization target, with efforts directed toward reducing water consumption, minimizing dust emissions, and lowering the overall carbon footprint of grinding operations. Additionally, modern optimization strategies aim to enhance operational flexibility, enabling mills to process varying ore types and grades without sacrificing efficiency or product quality.

The evolution of ball mill technology continues to be driven by the mining industry's pursuit of processing lower-grade ores economically, necessitating higher throughput and greater energy efficiency. Future development trajectories point toward fully autonomous grinding circuits that self-optimize based on comprehensive sensor data and advanced control algorithms, representing the next frontier in ball mill technology.

The 1970s and 1980s brought computerized control systems that enabled real-time monitoring of mill operations, laying the groundwork for modern optimization techniques. During this period, the development of advanced grinding media with specialized metallurgical compositions substantially improved grinding efficiency and media longevity. The 1990s saw the emergence of variable speed drives, allowing operators to adjust mill rotation speeds according to changing feed characteristics and production requirements.

In recent decades, ball mill technology has embraced Industry 4.0 principles, incorporating IoT sensors, machine learning algorithms, and advanced analytics platforms. These technologies enable predictive maintenance, real-time performance optimization, and adaptive control strategies that respond to changing ore characteristics. Modern mills now feature sophisticated liner designs that optimize the cascading and cataracting motion of the grinding media, significantly improving energy efficiency and grinding performance.

The primary optimization goals in contemporary ball mill operations focus on maximizing throughput while minimizing energy consumption, which typically represents 30-40% of mineral processing operational costs. Achieving optimal particle size distribution remains a critical objective, as it directly impacts downstream processes such as flotation, leaching, and concentration. Reducing media and liner wear rates constitutes another key goal, as replacement costs and associated downtime significantly affect operational economics.

Environmental sustainability has emerged as an increasingly important optimization target, with efforts directed toward reducing water consumption, minimizing dust emissions, and lowering the overall carbon footprint of grinding operations. Additionally, modern optimization strategies aim to enhance operational flexibility, enabling mills to process varying ore types and grades without sacrificing efficiency or product quality.

The evolution of ball mill technology continues to be driven by the mining industry's pursuit of processing lower-grade ores economically, necessitating higher throughput and greater energy efficiency. Future development trajectories point toward fully autonomous grinding circuits that self-optimize based on comprehensive sensor data and advanced control algorithms, representing the next frontier in ball mill technology.

Market Demand Analysis for Enhanced Mill Throughput

The global mining and cement industries are experiencing significant market pressure to optimize ball mill throughput, driven primarily by increasing energy costs and environmental regulations. Current market analysis indicates that ball mill operations typically consume between 30-40% of total plant energy in mineral processing facilities, representing a substantial operational expense. This has created a growing demand for throughput optimization solutions that can reduce specific energy consumption while maintaining or improving product quality.

Market research reveals that the global ball mill optimization market was valued at approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028. This growth is particularly pronounced in regions with established mining operations such as Australia, Chile, Canada, and South Africa, where rising operational costs are compelling operators to seek efficiency improvements.

The demand for enhanced mill throughput is further intensified by the global transition toward lower-grade ore bodies, which require more intensive grinding to achieve mineral liberation. Industry surveys indicate that a 5% improvement in mill throughput can translate to annual savings of $2-5 million for a medium-sized operation, creating a compelling business case for optimization investments.

Key market segments driving demand include large-scale copper and gold mining operations, iron ore processing facilities, and cement manufacturers. These sectors collectively represent over 70% of the current market for ball mill optimization solutions. The cement industry, in particular, has shown accelerated interest due to carbon pricing mechanisms that penalize energy-intensive operations.

Customer requirements have evolved beyond simple throughput increases to include comprehensive performance monitoring systems that track multiple KPIs simultaneously. Market analysis shows that solutions offering real-time analytics and predictive maintenance capabilities command premium pricing, with customers willing to pay 15-25% more for systems that provide actionable intelligence rather than raw data alone.

Geographically, the Asia-Pacific region represents the fastest-growing market segment, with China and India leading adoption rates as they modernize aging industrial infrastructure. North American and European markets, while more mature, are increasingly focused on digital integration capabilities that connect mill optimization with broader plant management systems.

The competitive landscape is characterized by both established equipment manufacturers expanding into digital services and specialized software providers offering advanced analytics platforms. This market convergence is creating new partnership opportunities and business models, including performance-based contracts where vendors share in the documented efficiency gains.

Market research reveals that the global ball mill optimization market was valued at approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028. This growth is particularly pronounced in regions with established mining operations such as Australia, Chile, Canada, and South Africa, where rising operational costs are compelling operators to seek efficiency improvements.

The demand for enhanced mill throughput is further intensified by the global transition toward lower-grade ore bodies, which require more intensive grinding to achieve mineral liberation. Industry surveys indicate that a 5% improvement in mill throughput can translate to annual savings of $2-5 million for a medium-sized operation, creating a compelling business case for optimization investments.

Key market segments driving demand include large-scale copper and gold mining operations, iron ore processing facilities, and cement manufacturers. These sectors collectively represent over 70% of the current market for ball mill optimization solutions. The cement industry, in particular, has shown accelerated interest due to carbon pricing mechanisms that penalize energy-intensive operations.

Customer requirements have evolved beyond simple throughput increases to include comprehensive performance monitoring systems that track multiple KPIs simultaneously. Market analysis shows that solutions offering real-time analytics and predictive maintenance capabilities command premium pricing, with customers willing to pay 15-25% more for systems that provide actionable intelligence rather than raw data alone.

Geographically, the Asia-Pacific region represents the fastest-growing market segment, with China and India leading adoption rates as they modernize aging industrial infrastructure. North American and European markets, while more mature, are increasingly focused on digital integration capabilities that connect mill optimization with broader plant management systems.

The competitive landscape is characterized by both established equipment manufacturers expanding into digital services and specialized software providers offering advanced analytics platforms. This market convergence is creating new partnership opportunities and business models, including performance-based contracts where vendors share in the documented efficiency gains.

Current Challenges in Ball Mill Performance

Despite significant technological advancements in mineral processing, ball mills continue to face several persistent challenges that impact their throughput optimization. Energy efficiency remains a primary concern, with ball mills typically operating at only 3-5% mechanical efficiency. This inefficiency translates to substantial power consumption, making ball mills one of the most energy-intensive equipment in mineral processing plants, often accounting for 30-40% of total plant energy usage.

Grinding media wear presents another significant challenge, as the continuous impact and abrasion between steel balls and ore particles results in gradual degradation of grinding media. This wear not only increases operational costs through frequent media replacement but also affects grinding efficiency as worn media provides suboptimal size reduction performance.

Process variability continues to plague ball mill operations, with fluctuations in ore hardness, feed size distribution, and mineralogical composition creating inconsistent grinding conditions. These variations make it difficult to maintain stable throughput rates and product quality, often requiring frequent adjustments to operational parameters that may not be implemented quickly enough to prevent efficiency losses.

Monitoring limitations further complicate optimization efforts. Traditional ball mill monitoring systems often provide delayed or incomplete data about internal conditions. The harsh environment inside mills makes real-time measurement challenging, creating a significant lag between process changes and operator awareness, which hinders proactive optimization.

Circulating load management presents ongoing difficulties, as improper control of the circulating load can lead to overgrinding or undergrinding. Finding the optimal balance that maximizes throughput while maintaining product quality specifications requires sophisticated control strategies that many operations struggle to implement effectively.

Water management issues also impact performance, with pulp density fluctuations affecting grinding efficiency and classification performance. Maintaining optimal slurry rheology becomes particularly challenging when processing ores with varying clay content or when water availability is constrained.

Finally, liner design and maintenance continue to present technical challenges. Liner profiles significantly impact grinding efficiency and wear rates, but optimizing designs for specific ore types while maximizing intervals between maintenance shutdowns remains difficult. The trade-off between liner longevity and grinding performance represents a complex optimization problem that varies with each operation's specific conditions and economic constraints.

Grinding media wear presents another significant challenge, as the continuous impact and abrasion between steel balls and ore particles results in gradual degradation of grinding media. This wear not only increases operational costs through frequent media replacement but also affects grinding efficiency as worn media provides suboptimal size reduction performance.

Process variability continues to plague ball mill operations, with fluctuations in ore hardness, feed size distribution, and mineralogical composition creating inconsistent grinding conditions. These variations make it difficult to maintain stable throughput rates and product quality, often requiring frequent adjustments to operational parameters that may not be implemented quickly enough to prevent efficiency losses.

Monitoring limitations further complicate optimization efforts. Traditional ball mill monitoring systems often provide delayed or incomplete data about internal conditions. The harsh environment inside mills makes real-time measurement challenging, creating a significant lag between process changes and operator awareness, which hinders proactive optimization.

Circulating load management presents ongoing difficulties, as improper control of the circulating load can lead to overgrinding or undergrinding. Finding the optimal balance that maximizes throughput while maintaining product quality specifications requires sophisticated control strategies that many operations struggle to implement effectively.

Water management issues also impact performance, with pulp density fluctuations affecting grinding efficiency and classification performance. Maintaining optimal slurry rheology becomes particularly challenging when processing ores with varying clay content or when water availability is constrained.

Finally, liner design and maintenance continue to present technical challenges. Liner profiles significantly impact grinding efficiency and wear rates, but optimizing designs for specific ore types while maximizing intervals between maintenance shutdowns remains difficult. The trade-off between liner longevity and grinding performance represents a complex optimization problem that varies with each operation's specific conditions and economic constraints.

Current Throughput Optimization Methodologies

01 Optimization of mill parameters for increased throughput

Various parameters of ball mills can be optimized to increase throughput, including rotation speed, ball loading, and mill dimensions. By adjusting these parameters, the efficiency of the grinding process can be significantly improved, leading to higher throughput rates. Proper selection of operating parameters ensures optimal energy utilization and maximizes the processing capacity of the mill.- Ball mill design optimization for increased throughput: Optimizing the design of ball mills can significantly increase throughput capacity. This includes modifications to the mill structure, liner configurations, and overall dimensions. Advanced design features such as improved grinding chamber geometry, optimized lifting liner profiles, and enhanced discharge systems can reduce material retention time while maintaining grinding efficiency. These design improvements allow for processing larger volumes of material without compromising the quality of the ground product.

- Control systems for ball mill throughput enhancement: Automated control systems can be implemented to monitor and adjust ball mill operations in real-time, optimizing throughput. These systems utilize sensors to measure parameters such as load levels, rotational speed, feed rate, and product fineness. Advanced algorithms process this data to make automatic adjustments to operational parameters, maintaining optimal grinding conditions. Implementation of such control systems results in consistent throughput rates, reduced energy consumption, and prevention of overgrinding or undergrinding issues.

- Feed material preparation techniques for improved throughput: Proper preparation of feed materials before entering the ball mill can significantly enhance throughput. This includes pre-crushing, screening, and classification of materials to ensure optimal size distribution. Techniques such as pre-drying wet materials, removing contaminants, and blending different material types can improve grinding efficiency. Additionally, controlled feeding systems that maintain consistent material flow rates help prevent mill overloading and ensure stable operation, resulting in higher overall throughput.

- Grinding media optimization for enhanced throughput: Selection and optimization of grinding media significantly impacts ball mill throughput. This includes choosing appropriate ball size distribution, material composition, and ball charge volume. Using a combination of different ball sizes creates more efficient grinding action for various particle sizes. Regular replacement schedules for worn media and maintaining optimal ball charge levels prevent inefficient grinding. Advanced grinding media materials with improved wear resistance and impact properties can extend operational time between maintenance intervals.

- Circuit configuration and multi-stage grinding for throughput maximization: Implementing optimized circuit configurations and multi-stage grinding processes can maximize ball mill throughput. This includes closed-circuit operations with classifiers that return oversized particles for regrinding, reducing mill overloading. Combining ball mills with other grinding equipment in series or parallel arrangements distributes the grinding load more efficiently. Pre-grinding stages reduce the work required by the main ball mill, while post-grinding stages can handle specific size fractions, collectively increasing the overall system throughput.

02 Advanced control systems for ball mill operation

Implementation of advanced control systems can enhance ball mill throughput by continuously monitoring and adjusting operating conditions. These systems may include automated load sensing, predictive maintenance algorithms, and real-time optimization of grinding parameters. By maintaining optimal operating conditions, these control systems minimize downtime and maximize processing efficiency, resulting in improved throughput.Expand Specific Solutions03 Innovative ball mill design modifications

Structural modifications to traditional ball mill designs can significantly increase throughput capacity. These innovations may include improved liner configurations, optimized chamber geometry, and enhanced discharge systems. Such design modifications reduce material retention time while maintaining grinding efficiency, allowing for greater volumes of material to be processed in the same timeframe.Expand Specific Solutions04 Material feed optimization techniques

The method and consistency of material feeding into ball mills significantly impacts throughput. Techniques such as pre-classification of feed materials, controlled feed rates, and optimized particle size distribution can enhance grinding efficiency. By ensuring consistent and appropriate material input, these techniques prevent overloading and underutilization of the mill, leading to maximized throughput rates.Expand Specific Solutions05 Grinding media selection and management

The selection and management of grinding media (balls) plays a crucial role in determining ball mill throughput. Factors such as ball size distribution, material composition, and replacement strategies significantly affect grinding efficiency. Optimized grinding media configurations ensure effective energy transfer to the material being ground, reducing processing time and increasing overall throughput capacity.Expand Specific Solutions

Leading Manufacturers and Industry Competitors

Ball mill throughput optimization is currently in a mature development stage with a growing market driven by increasing demand for efficient mineral processing. The global market size is estimated to reach $3.5 billion by 2025, with a CAGR of 4.8%. Technologically, the field has evolved from basic mechanical solutions to sophisticated digital monitoring systems. Leading players include Metso Outotec Finland Oy, which specializes in advanced grinding technologies; thyssenkrupp Industrial Solutions AG, offering comprehensive mill optimization solutions; and CiDRA Corporate Services, providing innovative measurement systems. Other significant contributors include Siemens AG with automation solutions, LOESCHE GmbH with specialized grinding equipment, and Bühler AG with process optimization technologies. Academic institutions like Wuhan University and Yanshan University are advancing theoretical research in this domain.

Metso Outotec Finland Oy

Technical Solution: Metso Outotec has developed an advanced SmartMill™ optimization system for ball mill throughput enhancement. This technology integrates real-time process monitoring with predictive analytics to optimize grinding performance. Their solution employs multiple sensors throughout the grinding circuit that continuously measure critical parameters including particle size distribution, mill load, bearing pressure, and power draw. The system utilizes digital twin modeling to simulate mill performance under varying conditions, allowing for predictive maintenance and proactive optimization. Metso's Grinding Optimization System incorporates machine learning algorithms that adapt to changing ore characteristics, automatically adjusting mill operating parameters to maintain optimal throughput. Their case studies have demonstrated throughput increases of 5-15% while reducing specific energy consumption by up to 10%. The system also features advanced KPI dashboards that track performance metrics including throughput, energy efficiency, and product quality in real-time, enabling operators to make data-driven decisions.

Strengths: Comprehensive integration of sensors, analytics and control systems provides holistic optimization. Their extensive global installation base provides rich comparative data for benchmarking. Weaknesses: Implementation requires significant capital investment and specialized technical expertise for configuration and maintenance. System complexity may present challenges for operations with limited technical resources.

Asea Brown Boveri Ltd

Technical Solution: ABB has developed the Expert Optimizer system specifically tailored for ball mill throughput optimization. This advanced solution combines model predictive control with artificial intelligence to continuously optimize grinding circuit performance. The system employs a multi-layered approach that includes basic process control, advanced regulatory control, and expert systems that adapt to changing operational conditions. ABB's solution incorporates their proprietary OptimizeIT platform which uses neural networks to learn from historical data and predict optimal operating parameters. The technology includes specialized mill power models that accurately predict energy requirements based on ore characteristics and desired product specifications. Their implementation includes comprehensive KPI tracking through the ABB Ability™ System 800xA platform, which provides real-time visualization of critical performance metrics. Case studies from implementations across various mining operations have demonstrated throughput increases of 4-12% while reducing specific energy consumption. The system also features advanced fault detection capabilities that identify potential issues before they impact production, significantly improving overall equipment effectiveness (OEE).

Strengths: Seamless integration with existing ABB control systems provides comprehensive plant-wide optimization. Advanced AI capabilities enable continuous learning and adaptation to changing conditions. Weaknesses: May require significant customization for non-ABB control environments. Higher complexity compared to simpler optimization solutions may increase implementation time.

Key Performance Indicators and Measurement Techniques

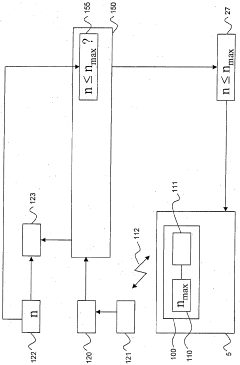

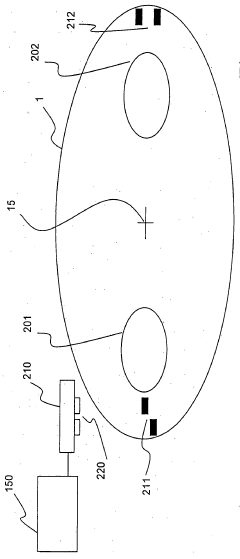

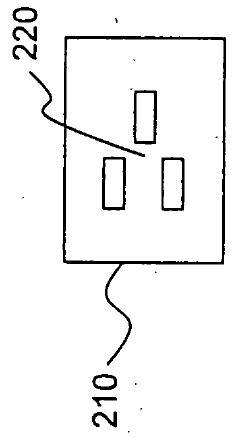

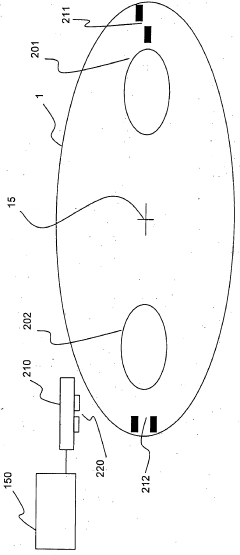

Ball mill comprising means for identifying milling vessels

PatentActiveEP1945364A1

Innovation

- A ball mill system that includes a readable storage medium on the grinding vessel providing information about its volume, material properties, and maximum speed, coupled with a controller that adjusts operational parameters to prevent excessive kinetic energy input, ensuring safe and efficient operation by limiting rotational speed based on the grinding tools used.

Ball mill comprising means for identifying milling vessels

PatentWO2007042200A1

Innovation

- A ball mill system with a housing, carrier device, receiving device, and grinding vessel that includes a readable storage medium for information about the vessel's volume, material properties, and maximum speed, allowing for automatic control of the mill's operation to prevent excessive speed and ensure safe grinding conditions.

Energy Consumption and Sustainability Considerations

Energy efficiency represents a critical dimension in ball mill optimization, with modern operations increasingly focused on balancing productivity with sustainability objectives. Ball mills typically consume between 30-40% of the total energy in mineral processing operations, making them prime targets for efficiency improvements. Recent case studies demonstrate that optimized ball mills can achieve energy savings of 10-15% through strategic interventions in grinding media selection, mill speed adjustments, and feed characteristics optimization.

Key performance indicators for energy consumption include kWh/ton of material processed, specific energy consumption (SEC), and energy utilization efficiency. These metrics provide quantifiable measures to track improvements and benchmark performance against industry standards. Advanced monitoring systems now enable real-time energy consumption tracking, allowing operators to identify inefficiencies promptly and implement corrective actions.

The environmental impact of ball mill operations extends beyond energy consumption to include carbon emissions, water usage, and waste generation. Case studies from leading mining operations in Australia and Canada have demonstrated that optimized ball mills contribute significantly to reduced carbon footprints, with some operations reporting CO2 emission reductions of up to 12% following comprehensive optimization programs.

Water conservation represents another sustainability consideration, with recirculation systems and advanced water management techniques becoming standard practice in modern ball mill operations. Facilities implementing closed-loop water systems have reported water consumption reductions of 20-30%, significantly enhancing their environmental performance while reducing operational costs.

Lifecycle assessment (LCA) methodologies are increasingly being applied to ball mill operations, providing comprehensive evaluations of environmental impacts from raw material extraction through processing and disposal. These assessments reveal that optimization efforts focused on extending equipment lifespan and reducing maintenance requirements deliver substantial sustainability benefits beyond immediate energy savings.

Regulatory compliance and corporate sustainability commitments are driving innovation in ball mill technology, with manufacturers developing energy-efficient designs incorporating variable speed drives, advanced liner materials, and optimized lifting mechanisms. These technological advancements, when properly implemented and monitored through robust KPI tracking systems, enable operations to meet increasingly stringent environmental standards while maintaining competitive production costs.

Return on investment analyses from multiple case studies indicate that energy efficiency improvements in ball mills typically achieve payback periods of 12-24 months, making them financially attractive while supporting broader sustainability objectives. This convergence of economic and environmental benefits underscores the strategic importance of energy-focused optimization initiatives in modern mineral processing operations.

Key performance indicators for energy consumption include kWh/ton of material processed, specific energy consumption (SEC), and energy utilization efficiency. These metrics provide quantifiable measures to track improvements and benchmark performance against industry standards. Advanced monitoring systems now enable real-time energy consumption tracking, allowing operators to identify inefficiencies promptly and implement corrective actions.

The environmental impact of ball mill operations extends beyond energy consumption to include carbon emissions, water usage, and waste generation. Case studies from leading mining operations in Australia and Canada have demonstrated that optimized ball mills contribute significantly to reduced carbon footprints, with some operations reporting CO2 emission reductions of up to 12% following comprehensive optimization programs.

Water conservation represents another sustainability consideration, with recirculation systems and advanced water management techniques becoming standard practice in modern ball mill operations. Facilities implementing closed-loop water systems have reported water consumption reductions of 20-30%, significantly enhancing their environmental performance while reducing operational costs.

Lifecycle assessment (LCA) methodologies are increasingly being applied to ball mill operations, providing comprehensive evaluations of environmental impacts from raw material extraction through processing and disposal. These assessments reveal that optimization efforts focused on extending equipment lifespan and reducing maintenance requirements deliver substantial sustainability benefits beyond immediate energy savings.

Regulatory compliance and corporate sustainability commitments are driving innovation in ball mill technology, with manufacturers developing energy-efficient designs incorporating variable speed drives, advanced liner materials, and optimized lifting mechanisms. These technological advancements, when properly implemented and monitored through robust KPI tracking systems, enable operations to meet increasingly stringent environmental standards while maintaining competitive production costs.

Return on investment analyses from multiple case studies indicate that energy efficiency improvements in ball mills typically achieve payback periods of 12-24 months, making them financially attractive while supporting broader sustainability objectives. This convergence of economic and environmental benefits underscores the strategic importance of energy-focused optimization initiatives in modern mineral processing operations.

Economic Impact of Throughput Optimization

The economic implications of ball mill throughput optimization extend far beyond operational efficiency, directly impacting the financial performance of mining and processing operations. Optimized throughput translates to increased production capacity without additional capital expenditure, effectively lowering the cost per ton of processed material. Industry data suggests that even modest throughput improvements of 5-10% can yield annual revenue increases of millions of dollars for medium to large operations, with ROI often realized within 6-12 months of implementation.

Cost reduction represents another significant economic benefit. Enhanced throughput efficiency reduces energy consumption per ton of processed material, with case studies demonstrating energy savings of 8-15% following optimization initiatives. Labor costs per unit of production decrease proportionally as throughput increases, while maintenance expenses often decline due to more stable mill operation and reduced mechanical stress from optimal loading conditions.

The market competitiveness factor cannot be overlooked. Operations with optimized ball mill throughput gain substantial advantages in commodity markets where price fluctuations are common. During periods of high commodity prices, maximized throughput allows companies to capitalize on favorable market conditions. Conversely, during market downturns, the lower production costs achieved through optimization provide critical margin protection that can determine operational viability.

Environmental compliance costs also factor into the economic equation. Optimized mills typically generate less waste per ton of processed material and consume fewer resources, potentially reducing environmental compliance costs and minimizing exposure to carbon taxation or emissions penalties. Several mining operations have reported 10-20% reductions in water usage following comprehensive throughput optimization programs.

Investment analysts increasingly recognize throughput optimization as a key performance indicator when evaluating mining companies. Operations demonstrating consistent throughput improvements typically command higher valuations, with enhanced investor confidence reflected in share price performance. Analysis of publicly traded mining companies shows that those implementing systematic throughput optimization programs outperformed industry averages by 7-12% in terms of EBITDA margins over a five-year period.

The economic ripple effects extend to supply chain partners and local economies. Suppliers benefit from increased demand for consumables, while local communities experience economic stimulus through increased employment stability and tax revenues. This broader economic impact underscores why throughput optimization has evolved from a purely technical consideration to a strategic business imperative across the mining and mineral processing sectors.

Cost reduction represents another significant economic benefit. Enhanced throughput efficiency reduces energy consumption per ton of processed material, with case studies demonstrating energy savings of 8-15% following optimization initiatives. Labor costs per unit of production decrease proportionally as throughput increases, while maintenance expenses often decline due to more stable mill operation and reduced mechanical stress from optimal loading conditions.

The market competitiveness factor cannot be overlooked. Operations with optimized ball mill throughput gain substantial advantages in commodity markets where price fluctuations are common. During periods of high commodity prices, maximized throughput allows companies to capitalize on favorable market conditions. Conversely, during market downturns, the lower production costs achieved through optimization provide critical margin protection that can determine operational viability.

Environmental compliance costs also factor into the economic equation. Optimized mills typically generate less waste per ton of processed material and consume fewer resources, potentially reducing environmental compliance costs and minimizing exposure to carbon taxation or emissions penalties. Several mining operations have reported 10-20% reductions in water usage following comprehensive throughput optimization programs.

Investment analysts increasingly recognize throughput optimization as a key performance indicator when evaluating mining companies. Operations demonstrating consistent throughput improvements typically command higher valuations, with enhanced investor confidence reflected in share price performance. Analysis of publicly traded mining companies shows that those implementing systematic throughput optimization programs outperformed industry averages by 7-12% in terms of EBITDA margins over a five-year period.

The economic ripple effects extend to supply chain partners and local economies. Suppliers benefit from increased demand for consumables, while local communities experience economic stimulus through increased employment stability and tax revenues. This broader economic impact underscores why throughput optimization has evolved from a purely technical consideration to a strategic business imperative across the mining and mineral processing sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!