Ball Mill Troubleshooting: Vibration, Low Throughput, And Segregation

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ball Mill Technology Evolution and Objectives

Ball mills have evolved significantly since their inception in the late 19th century. Initially designed as simple rotating drums with metal balls, these machines have transformed into sophisticated grinding equipment essential for various industries including mining, cement production, and pharmaceuticals. The evolution trajectory shows a clear shift from purely mechanical systems to integrated electromechanical solutions with advanced control mechanisms, reflecting the growing demands for efficiency, precision, and reliability.

The 1950s marked a significant turning point with the introduction of automated control systems, allowing for better monitoring of mill operations. By the 1970s, computational models began informing ball mill design, leading to optimized chamber geometries and ball size distributions. The 1990s witnessed the integration of digital control systems and real-time monitoring capabilities, fundamentally changing how operators could identify and address issues like vibration and throughput problems.

Recent technological advancements have focused on energy efficiency and grinding precision. Modern ball mills incorporate variable speed drives, advanced liner designs, and sophisticated bearing systems that collectively minimize vibration issues while maximizing throughput. The development of specialized sensors and monitoring equipment has enabled predictive maintenance approaches, reducing downtime and extending equipment lifespan.

The primary objectives of contemporary ball mill technology center around four key areas: operational efficiency, product quality consistency, energy consumption reduction, and maintenance optimization. Vibration control represents a critical technical objective, as excessive vibration not only reduces grinding efficiency but also accelerates wear on mill components. Throughput maximization while maintaining product quality specifications remains another central goal, particularly challenging when dealing with variable feed materials.

Material segregation, a common issue in ball milling operations, has driven the development of specialized internal components and operational protocols. The technical objective of minimizing segregation focuses on achieving homogeneous particle size distribution, which directly impacts downstream processes and final product quality.

Looking forward, the ball mill technology roadmap aims to incorporate artificial intelligence for autonomous operation, advanced materials for extended component life, and improved energy recovery systems. These developments align with broader industry trends toward sustainability and digitalization, with particular emphasis on reducing the environmental footprint of grinding operations while enhancing productivity and reliability.

The 1950s marked a significant turning point with the introduction of automated control systems, allowing for better monitoring of mill operations. By the 1970s, computational models began informing ball mill design, leading to optimized chamber geometries and ball size distributions. The 1990s witnessed the integration of digital control systems and real-time monitoring capabilities, fundamentally changing how operators could identify and address issues like vibration and throughput problems.

Recent technological advancements have focused on energy efficiency and grinding precision. Modern ball mills incorporate variable speed drives, advanced liner designs, and sophisticated bearing systems that collectively minimize vibration issues while maximizing throughput. The development of specialized sensors and monitoring equipment has enabled predictive maintenance approaches, reducing downtime and extending equipment lifespan.

The primary objectives of contemporary ball mill technology center around four key areas: operational efficiency, product quality consistency, energy consumption reduction, and maintenance optimization. Vibration control represents a critical technical objective, as excessive vibration not only reduces grinding efficiency but also accelerates wear on mill components. Throughput maximization while maintaining product quality specifications remains another central goal, particularly challenging when dealing with variable feed materials.

Material segregation, a common issue in ball milling operations, has driven the development of specialized internal components and operational protocols. The technical objective of minimizing segregation focuses on achieving homogeneous particle size distribution, which directly impacts downstream processes and final product quality.

Looking forward, the ball mill technology roadmap aims to incorporate artificial intelligence for autonomous operation, advanced materials for extended component life, and improved energy recovery systems. These developments align with broader industry trends toward sustainability and digitalization, with particular emphasis on reducing the environmental footprint of grinding operations while enhancing productivity and reliability.

Market Demand Analysis for Grinding Efficiency

The global grinding efficiency market is experiencing significant growth driven by increasing demands across multiple industries. Mining and mineral processing sectors represent the largest market segment, with an estimated annual growth rate of 5.7% through 2028. This growth is primarily fueled by the rising global demand for metals and minerals, particularly in developing economies where infrastructure development continues at a rapid pace.

Energy consumption optimization has become a critical factor in market demand for improved grinding efficiency. Ball mills typically consume 30-40% of the total energy in mineral processing operations, making efficiency improvements a top priority for operators seeking to reduce operational costs. Recent industry surveys indicate that companies are willing to invest in solutions that can reduce energy consumption by at least 15%, with potential market value for such solutions exceeding $2.5 billion globally.

Environmental regulations and sustainability initiatives are creating additional market pressure for grinding efficiency solutions. Regulations limiting carbon emissions have forced companies to seek more energy-efficient grinding technologies, with carbon taxation directly impacting operational costs in many regions. This regulatory landscape has expanded the market for grinding efficiency solutions beyond traditional cost-saving motivations.

Maintenance cost reduction represents another significant market driver. Unplanned downtime due to vibration issues and other mechanical failures costs the mining industry billions annually. Solutions addressing vibration problems in ball mills can capture a substantial portion of this market, with preventative maintenance technologies showing a compound annual growth rate of 8.3% since 2020.

The throughput optimization segment shows particularly strong growth potential, as production capacity directly impacts revenue generation. Market analysis reveals that a 10% increase in grinding throughput can translate to millions in additional annual revenue for large mining operations. This economic incentive has created a premium market for solutions that can reliably increase throughput without compromising product quality.

Material segregation solutions represent an emerging market niche with significant growth potential. As processing operations handle increasingly complex ore bodies with variable characteristics, technologies that can address segregation issues are gaining market traction. This segment is projected to grow at 9.2% annually through 2027, outpacing the overall grinding efficiency market.

Digital transformation is reshaping market demands, with increasing interest in sensor-based monitoring systems, predictive maintenance solutions, and AI-driven optimization tools. The digital solutions segment for grinding efficiency has doubled in market size over the past five years, indicating strong future growth potential as Industry 4.0 adoption accelerates across the mining and processing sectors.

Energy consumption optimization has become a critical factor in market demand for improved grinding efficiency. Ball mills typically consume 30-40% of the total energy in mineral processing operations, making efficiency improvements a top priority for operators seeking to reduce operational costs. Recent industry surveys indicate that companies are willing to invest in solutions that can reduce energy consumption by at least 15%, with potential market value for such solutions exceeding $2.5 billion globally.

Environmental regulations and sustainability initiatives are creating additional market pressure for grinding efficiency solutions. Regulations limiting carbon emissions have forced companies to seek more energy-efficient grinding technologies, with carbon taxation directly impacting operational costs in many regions. This regulatory landscape has expanded the market for grinding efficiency solutions beyond traditional cost-saving motivations.

Maintenance cost reduction represents another significant market driver. Unplanned downtime due to vibration issues and other mechanical failures costs the mining industry billions annually. Solutions addressing vibration problems in ball mills can capture a substantial portion of this market, with preventative maintenance technologies showing a compound annual growth rate of 8.3% since 2020.

The throughput optimization segment shows particularly strong growth potential, as production capacity directly impacts revenue generation. Market analysis reveals that a 10% increase in grinding throughput can translate to millions in additional annual revenue for large mining operations. This economic incentive has created a premium market for solutions that can reliably increase throughput without compromising product quality.

Material segregation solutions represent an emerging market niche with significant growth potential. As processing operations handle increasingly complex ore bodies with variable characteristics, technologies that can address segregation issues are gaining market traction. This segment is projected to grow at 9.2% annually through 2027, outpacing the overall grinding efficiency market.

Digital transformation is reshaping market demands, with increasing interest in sensor-based monitoring systems, predictive maintenance solutions, and AI-driven optimization tools. The digital solutions segment for grinding efficiency has doubled in market size over the past five years, indicating strong future growth potential as Industry 4.0 adoption accelerates across the mining and processing sectors.

Current Challenges in Ball Mill Operations

Ball mill operations face several persistent challenges that impact efficiency, product quality, and operational costs. Vibration stands as one of the most significant issues, often resulting from imbalanced loads, worn bearings, or improper foundation support. These vibrations not only accelerate equipment wear but also compromise grinding efficiency and potentially damage peripheral systems. Monitoring vibration patterns through advanced sensors has become essential for predictive maintenance strategies, yet many facilities still struggle with implementing effective vibration analysis protocols.

Low throughput represents another critical challenge, typically manifesting as reduced grinding capacity despite unchanged operational parameters. This issue frequently stems from media wear, improper ball charge distribution, or suboptimal mill speed settings. The relationship between mill loading, rotation speed, and grinding efficiency follows complex non-linear patterns that require sophisticated modeling approaches. Industry data indicates that even minor deviations from optimal operating conditions can reduce throughput by 15-25%, significantly impacting production economics.

Material segregation within ball mills creates inconsistent particle size distribution in the final product, a particularly problematic issue in industries requiring precise specifications such as pharmaceuticals and advanced ceramics. Segregation occurs due to differential settling rates of particles with varying densities and sizes, often exacerbated by improper feed rate control or liner wear patterns. Recent studies have demonstrated that segregation can increase product rejection rates by up to 30% in precision applications.

Liner wear presents an ongoing operational challenge, with uneven wear patterns creating inefficient grinding zones and potentially dangerous operating conditions. Modern composite liners offer improved wear resistance but at significantly higher initial costs, creating difficult economic trade-offs for operators. The industry still lacks reliable methods for real-time liner condition monitoring without mill shutdown.

Energy efficiency remains a persistent concern, with ball mills typically converting only 3-5% of input energy into actual grinding work. The remainder dissipates as heat, noise, and mechanical losses. Despite decades of research, fundamental improvements in energy efficiency have been incremental rather than transformative. Recent innovations in mill design and control systems have achieved modest gains of 5-10% in energy efficiency, but revolutionary approaches remain elusive.

Water management challenges have intensified with growing environmental regulations and water scarcity concerns. Wet grinding operations must balance water conservation with maintaining optimal slurry density for efficient grinding. Closed-loop water systems introduce additional complexities related to contaminant buildup and corrosion management that require sophisticated treatment technologies.

Low throughput represents another critical challenge, typically manifesting as reduced grinding capacity despite unchanged operational parameters. This issue frequently stems from media wear, improper ball charge distribution, or suboptimal mill speed settings. The relationship between mill loading, rotation speed, and grinding efficiency follows complex non-linear patterns that require sophisticated modeling approaches. Industry data indicates that even minor deviations from optimal operating conditions can reduce throughput by 15-25%, significantly impacting production economics.

Material segregation within ball mills creates inconsistent particle size distribution in the final product, a particularly problematic issue in industries requiring precise specifications such as pharmaceuticals and advanced ceramics. Segregation occurs due to differential settling rates of particles with varying densities and sizes, often exacerbated by improper feed rate control or liner wear patterns. Recent studies have demonstrated that segregation can increase product rejection rates by up to 30% in precision applications.

Liner wear presents an ongoing operational challenge, with uneven wear patterns creating inefficient grinding zones and potentially dangerous operating conditions. Modern composite liners offer improved wear resistance but at significantly higher initial costs, creating difficult economic trade-offs for operators. The industry still lacks reliable methods for real-time liner condition monitoring without mill shutdown.

Energy efficiency remains a persistent concern, with ball mills typically converting only 3-5% of input energy into actual grinding work. The remainder dissipates as heat, noise, and mechanical losses. Despite decades of research, fundamental improvements in energy efficiency have been incremental rather than transformative. Recent innovations in mill design and control systems have achieved modest gains of 5-10% in energy efficiency, but revolutionary approaches remain elusive.

Water management challenges have intensified with growing environmental regulations and water scarcity concerns. Wet grinding operations must balance water conservation with maintaining optimal slurry density for efficient grinding. Closed-loop water systems introduce additional complexities related to contaminant buildup and corrosion management that require sophisticated treatment technologies.

Existing Solutions for Ball Mill Performance Issues

01 Vibration reduction mechanisms in ball mills

Various mechanisms can be implemented to reduce vibration in ball mills, which improves operational stability and extends equipment lifespan. These include damping systems, vibration isolators, and specialized mounting structures that absorb and dissipate vibrational energy. Reducing vibration helps maintain consistent grinding performance, prevents structural damage, and minimizes noise pollution in industrial environments.- Vibration control mechanisms in ball mills: Various mechanisms can be implemented to control and reduce vibrations in ball mills, which can improve operational stability and extend equipment life. These include vibration dampening systems, specialized bearings, and structural reinforcements. By minimizing harmful vibrations, these mechanisms help maintain consistent grinding performance and prevent damage to mill components, ultimately enhancing overall efficiency and reducing maintenance requirements.

- Throughput optimization techniques: Ball mill throughput can be optimized through various techniques including feed rate control, grinding media selection, and operational parameter adjustments. Advanced monitoring systems can provide real-time data on mill performance, allowing for dynamic adjustments to maximize material processing rates. Optimized liner designs and improved classification systems also contribute to enhanced throughput by improving grinding efficiency and material flow through the mill.

- Material segregation prevention methods: Preventing material segregation in ball mills is crucial for consistent product quality. This can be achieved through specialized feeding mechanisms, optimized mill geometry, and controlled rotation speeds. Some designs incorporate internal baffles or lifters that promote uniform mixing of materials during grinding. Advanced monitoring systems can detect early signs of segregation, allowing for timely intervention to maintain homogeneous grinding conditions.

- Innovative ball mill structural designs: Novel structural designs for ball mills can address issues of vibration, throughput, and segregation simultaneously. These include modular construction approaches, specialized chamber configurations, and innovative material selection for mill components. Some designs feature adjustable internal components that can be optimized for different grinding requirements. Advanced computational modeling is often used to develop these designs, ensuring optimal performance across various operational parameters.

- Monitoring and control systems for mill performance: Advanced monitoring and control systems can significantly improve ball mill performance by providing real-time data on vibration levels, throughput rates, and material distribution. These systems often incorporate sensors, data analytics, and automated control mechanisms to maintain optimal operating conditions. Some implementations use artificial intelligence to predict maintenance needs and prevent operational issues before they occur, maximizing mill availability and consistency of output quality.

02 Throughput optimization techniques

Ball mill throughput can be optimized through various techniques including feed rate control, grinding media selection, and operational parameter adjustments. Advanced monitoring systems can analyze mill performance in real-time to maintain optimal processing conditions. Proper sizing of mill components and strategic placement of lifters and liners also contribute to maximizing material processing capacity while maintaining product quality.Expand Specific Solutions03 Material segregation prevention methods

Preventing material segregation in ball mills involves specialized design features and operational strategies. These include optimized feed distribution systems, controlled rotation speeds, and strategic placement of internal components. Some designs incorporate baffles or deflectors to promote uniform mixing and prevent particle separation based on size or density. Maintaining proper mill loading and moisture content also helps minimize segregation issues during grinding operations.Expand Specific Solutions04 Monitoring and control systems for ball mills

Advanced monitoring and control systems for ball mills utilize sensors, data analytics, and automation to optimize performance. These systems can detect abnormal vibration patterns, monitor throughput variations, and identify potential segregation issues in real-time. Implementing closed-loop control algorithms allows for automatic adjustments to operational parameters, ensuring consistent product quality and preventing equipment damage while maximizing processing efficiency.Expand Specific Solutions05 Innovative ball mill designs addressing multiple performance factors

Novel ball mill designs incorporate features that simultaneously address vibration, throughput, and segregation challenges. These innovations include specialized liner configurations, optimized chamber geometries, and hybrid grinding mechanisms. Some designs feature modular components that can be adjusted based on specific material properties and processing requirements. These integrated approaches result in more efficient grinding operations with improved energy utilization and product consistency.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The ball mill troubleshooting market is currently in a mature growth phase, with an estimated global value exceeding $5 billion. Technical maturity varies across solutions addressing vibration, throughput, and segregation issues. Leading players include established European manufacturers like Netzsch Feinmahltechnik, Bühler AG, and Fritsch GmbH, who dominate with advanced diagnostic technologies and comprehensive service offerings. Asian competitors such as Kobe Steel and emerging players like Shenzhen Keli Nano Engineering are gaining market share through cost-effective solutions. The competitive landscape is further shaped by specialized monitoring solution providers like SPM Instrument AB and research collaborations with institutions like Zhejiang University, driving innovation in predictive maintenance and efficiency optimization technologies.

Netzsch Feinmahltechnik GmbH

Technical Solution: Netzsch has developed the ZETA® grinding system specifically designed to address common ball mill issues. Their vibration management technology incorporates a multi-level approach: mechanical isolation through specialized mounting systems and electronic monitoring via their NETZSCH ContiTech® vibration analysis platform. This system employs accelerometers at critical points to detect abnormal vibration patterns across different frequency ranges, allowing for early identification of bearing issues, unbalanced loads, or structural problems. For throughput optimization, Netzsch utilizes their patented NETZSCH-BEADS® grinding media combined with the ZETA® circulation system that enhances grinding efficiency by optimizing media movement patterns. Their segregation prevention technology includes the ZETA® rotor-stator design that creates controlled turbulence within the grinding chamber, ensuring homogeneous particle distribution. Additionally, their NEMO® pump technology provides precise control over material flow rates, preventing overloading while maintaining optimal grinding conditions.

Strengths: Superior fine grinding capabilities with exceptional particle size distribution control; highly energy-efficient compared to conventional ball mills; comprehensive process monitoring capabilities. Weaknesses: Higher initial investment cost; requires specialized maintenance expertise; optimal performance depends on proper media selection and regular system calibration.

Bühler AG

Technical Solution: Bühler AG has developed the DiaPerf™ ball mill system with advanced troubleshooting capabilities. Their vibration management approach combines mechanical solutions with digital monitoring through their DiaMon™ predictive maintenance platform. The system employs strategically placed sensors that continuously monitor vibration signatures across multiple frequency bands, enabling early detection of bearing failures, unbalanced loads, or liner wear. For throughput optimization, Bühler has implemented their AutoGrind™ control system that automatically adjusts mill parameters based on feed characteristics and operational conditions. The system incorporates load cells and power consumption monitoring to maintain optimal filling levels and prevent overloading. Their anti-segregation technology includes the DiaMix™ lifter design that creates optimized cascading patterns within the mill, ensuring uniform material distribution. Additionally, their patented ball charge gradation methodology maintains proper grinding media distribution throughout the mill, preventing segregation zones and ensuring consistent grinding performance across the entire chamber.

Strengths: Comprehensive digital integration with IoT capabilities for remote monitoring and troubleshooting; excellent energy efficiency through optimized grinding parameters; proven reliability in food and industrial mineral applications. Weaknesses: Complex system requires specialized training for maintenance personnel; higher initial investment compared to basic mill systems; optimal performance depends on proper integration with upstream and downstream processes.

Key Technical Innovations in Vibration Control

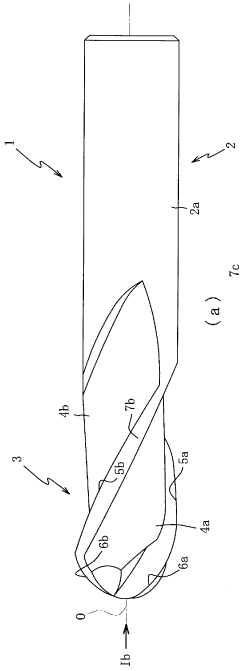

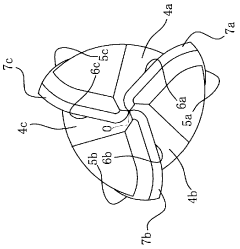

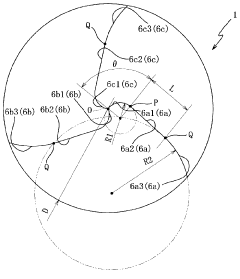

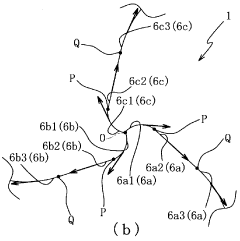

Ball end mill

PatentWO2007046132A1

Innovation

- The ball end mill features a cylindrical tool body with a ball edge having multiple blade portions with varying curvature radii and angles, dispersing cutting force direction to reduce vibration, allowing for increased feed rate and depth of cut.

Ball mill having spatial unbalance compensation

PatentActiveEP2861350A1

Innovation

- The grinding bowl holders are set in a forcibly guided circular movement using eccentric shafts with counterweights, and additional mass balances are implemented to compensate for imbalance forces and moments, ensuring a precise and repeatable movement regime with controlled impact and friction components.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical considerations in ball mill operations, particularly as industries face increasing pressure to reduce environmental footprints and operational costs. Ball mills are notorious energy consumers, typically operating at energy efficiency rates of only 1-5%, with the majority of input energy dissipated as heat, noise, and vibration rather than contributing to the grinding process.

Addressing vibration issues in ball mills not only improves operational stability but significantly reduces energy waste. Excessive vibration indicates mechanical inefficiencies that directly translate to higher power consumption. Studies indicate that properly balanced mills with optimized liner designs can achieve energy savings of 10-15% compared to mills experiencing vibration problems.

Low throughput scenarios present dual sustainability challenges: they reduce production efficiency while maintaining similar energy consumption levels, effectively increasing the energy footprint per ton of processed material. Modern variable speed drives and advanced control systems can optimize mill performance based on load conditions, potentially reducing energy consumption by 15-20% during partial loading scenarios.

Material segregation issues similarly impact sustainability metrics by necessitating rework of improperly ground materials. This rework cycle multiplies the energy footprint of affected batches, sometimes doubling the effective energy consumption per unit of final product. Implementing proper classification systems and optimized ball charge distributions can minimize segregation while reducing unnecessary overgrinding.

Water consumption represents another critical sustainability factor in wet grinding operations. Mills experiencing operational issues often require additional water to compensate for inefficiencies, increasing resource consumption and subsequent water treatment requirements. Advanced water recycling systems integrated with properly functioning mills can reduce freshwater requirements by up to 60%.

Carbon footprint considerations extend beyond direct energy consumption to include maintenance activities. Mills experiencing chronic vibration issues require more frequent part replacements and maintenance interventions, each carrying embedded carbon costs in manufacturing, transportation, and installation of replacement components.

Recent technological innovations offer promising pathways toward more sustainable ball mill operations. These include advanced composite liner materials that reduce weight while extending service life, high-efficiency motors with energy recovery capabilities, and AI-driven predictive maintenance systems that optimize performance while minimizing resource consumption. Combined implementation of these technologies in properly functioning mills can reduce overall environmental impact by 25-30% compared to traditional operations experiencing troubleshooting issues.

Addressing vibration issues in ball mills not only improves operational stability but significantly reduces energy waste. Excessive vibration indicates mechanical inefficiencies that directly translate to higher power consumption. Studies indicate that properly balanced mills with optimized liner designs can achieve energy savings of 10-15% compared to mills experiencing vibration problems.

Low throughput scenarios present dual sustainability challenges: they reduce production efficiency while maintaining similar energy consumption levels, effectively increasing the energy footprint per ton of processed material. Modern variable speed drives and advanced control systems can optimize mill performance based on load conditions, potentially reducing energy consumption by 15-20% during partial loading scenarios.

Material segregation issues similarly impact sustainability metrics by necessitating rework of improperly ground materials. This rework cycle multiplies the energy footprint of affected batches, sometimes doubling the effective energy consumption per unit of final product. Implementing proper classification systems and optimized ball charge distributions can minimize segregation while reducing unnecessary overgrinding.

Water consumption represents another critical sustainability factor in wet grinding operations. Mills experiencing operational issues often require additional water to compensate for inefficiencies, increasing resource consumption and subsequent water treatment requirements. Advanced water recycling systems integrated with properly functioning mills can reduce freshwater requirements by up to 60%.

Carbon footprint considerations extend beyond direct energy consumption to include maintenance activities. Mills experiencing chronic vibration issues require more frequent part replacements and maintenance interventions, each carrying embedded carbon costs in manufacturing, transportation, and installation of replacement components.

Recent technological innovations offer promising pathways toward more sustainable ball mill operations. These include advanced composite liner materials that reduce weight while extending service life, high-efficiency motors with energy recovery capabilities, and AI-driven predictive maintenance systems that optimize performance while minimizing resource consumption. Combined implementation of these technologies in properly functioning mills can reduce overall environmental impact by 25-30% compared to traditional operations experiencing troubleshooting issues.

Predictive Maintenance Strategies for Ball Mills

Predictive maintenance strategies for ball mills represent a significant advancement in industrial operations, leveraging data analytics and machine learning to anticipate equipment failures before they occur. These strategies are particularly valuable for addressing common ball mill issues such as vibration, low throughput, and material segregation, which can significantly impact production efficiency and quality.

The foundation of predictive maintenance lies in continuous monitoring systems that collect real-time data from various sensors strategically placed throughout the ball mill. These sensors track critical parameters including vibration patterns, motor current, temperature fluctuations, acoustic emissions, and load variations. Advanced vibration analysis techniques can detect subtle changes in equipment behavior that often precede mechanical failures, allowing maintenance teams to intervene before catastrophic breakdowns occur.

Machine learning algorithms play a crucial role in predictive maintenance by establishing baseline operational patterns and identifying anomalies that may indicate developing problems. These algorithms become increasingly accurate over time as they process more historical data, enabling them to distinguish between normal operational variations and genuine fault indicators. For ball mills specifically, these systems can recognize vibration signatures associated with bearing wear, liner damage, or imbalanced loads.

Digital twin technology represents the cutting edge of predictive maintenance strategies. By creating a virtual replica of the physical ball mill that simulates its operation in real-time, engineers can conduct scenario testing and predict how different maintenance interventions might affect performance. This approach allows for optimization of maintenance schedules and procedures without disrupting actual production.

Implementation of condition-based maintenance protocols, guided by predictive analytics, enables maintenance to be performed only when necessary rather than on arbitrary schedules. This approach minimizes unnecessary downtime while preventing unexpected failures, striking an optimal balance between equipment reliability and maintenance costs. For issues like material segregation and low throughput, predictive systems can identify early indicators of grinding inefficiency and recommend timely adjustments.

Return on investment for predictive maintenance systems typically manifests through extended equipment lifespan, reduced energy consumption, decreased maintenance costs, and minimized production losses due to unexpected downtime. While initial implementation requires significant investment in sensors, software, and training, the long-term operational benefits generally outweigh these costs, particularly for critical equipment like ball mills where failures can halt entire production lines.

The foundation of predictive maintenance lies in continuous monitoring systems that collect real-time data from various sensors strategically placed throughout the ball mill. These sensors track critical parameters including vibration patterns, motor current, temperature fluctuations, acoustic emissions, and load variations. Advanced vibration analysis techniques can detect subtle changes in equipment behavior that often precede mechanical failures, allowing maintenance teams to intervene before catastrophic breakdowns occur.

Machine learning algorithms play a crucial role in predictive maintenance by establishing baseline operational patterns and identifying anomalies that may indicate developing problems. These algorithms become increasingly accurate over time as they process more historical data, enabling them to distinguish between normal operational variations and genuine fault indicators. For ball mills specifically, these systems can recognize vibration signatures associated with bearing wear, liner damage, or imbalanced loads.

Digital twin technology represents the cutting edge of predictive maintenance strategies. By creating a virtual replica of the physical ball mill that simulates its operation in real-time, engineers can conduct scenario testing and predict how different maintenance interventions might affect performance. This approach allows for optimization of maintenance schedules and procedures without disrupting actual production.

Implementation of condition-based maintenance protocols, guided by predictive analytics, enables maintenance to be performed only when necessary rather than on arbitrary schedules. This approach minimizes unnecessary downtime while preventing unexpected failures, striking an optimal balance between equipment reliability and maintenance costs. For issues like material segregation and low throughput, predictive systems can identify early indicators of grinding inefficiency and recommend timely adjustments.

Return on investment for predictive maintenance systems typically manifests through extended equipment lifespan, reduced energy consumption, decreased maintenance costs, and minimized production losses due to unexpected downtime. While initial implementation requires significant investment in sensors, software, and training, the long-term operational benefits generally outweigh these costs, particularly for critical equipment like ball mills where failures can halt entire production lines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!