Closed Circuit Ball Milling: Hydrocyclone Versus Sieve Oversize Methods

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ball Milling Technology Evolution and Objectives

Ball milling technology has evolved significantly since its inception in the early 20th century, transforming from simple grinding equipment to sophisticated processing systems. Initially developed for mineral processing, ball mills have become essential equipment in various industries including mining, cement production, pharmaceuticals, and advanced materials manufacturing. The fundamental principle of ball milling—utilizing the kinetic energy of cascading or tumbling grinding media to reduce particle size—has remained consistent, while the surrounding technology has advanced dramatically.

The evolution of closed circuit ball milling represents a significant milestone in this technological progression. Traditional open circuit milling suffered from inefficiencies including overgrinding, energy waste, and inconsistent product quality. The introduction of closed circuit systems in the mid-20th century addressed these limitations by incorporating classification devices to continuously separate adequately ground material from oversized particles, returning the latter for further processing.

Two primary classification methods emerged in closed circuit ball milling: hydrocyclone separation and sieve oversize methods. Hydrocyclones, introduced commercially in the 1940s, utilize centrifugal force to separate particles based on size and density, offering high throughput and relatively simple operation. Sieve classification systems, while older in concept, have evolved with modern materials and designs to provide precise particle size control in certain applications.

The technological objectives driving ball milling evolution have consistently focused on several key areas: energy efficiency, product quality consistency, throughput maximization, and operational flexibility. Energy consumption in grinding operations typically represents 30-50% of total processing costs in mineral processing, making efficiency improvements particularly valuable. Recent technological developments have emphasized intelligent control systems, advanced materials for grinding media and mill linings, and optimized circuit designs.

Current objectives in ball milling technology development include further reducing specific energy consumption, minimizing environmental impact through reduced water usage and dust generation, enabling finer grinding capabilities for complex ores, and integrating with downstream processes for holistic optimization. The comparison between hydrocyclone and sieve oversize methods represents an important aspect of this ongoing evolution, as each approach offers distinct advantages depending on specific application requirements.

The industry continues to pursue innovations that can address the inherent inefficiencies of ball milling, which typically converts less than 10% of input energy into actual size reduction. Research into hybrid systems, alternative grinding technologies, and advanced classification methods aims to overcome these fundamental limitations while building upon the established reliability of ball milling technology.

The evolution of closed circuit ball milling represents a significant milestone in this technological progression. Traditional open circuit milling suffered from inefficiencies including overgrinding, energy waste, and inconsistent product quality. The introduction of closed circuit systems in the mid-20th century addressed these limitations by incorporating classification devices to continuously separate adequately ground material from oversized particles, returning the latter for further processing.

Two primary classification methods emerged in closed circuit ball milling: hydrocyclone separation and sieve oversize methods. Hydrocyclones, introduced commercially in the 1940s, utilize centrifugal force to separate particles based on size and density, offering high throughput and relatively simple operation. Sieve classification systems, while older in concept, have evolved with modern materials and designs to provide precise particle size control in certain applications.

The technological objectives driving ball milling evolution have consistently focused on several key areas: energy efficiency, product quality consistency, throughput maximization, and operational flexibility. Energy consumption in grinding operations typically represents 30-50% of total processing costs in mineral processing, making efficiency improvements particularly valuable. Recent technological developments have emphasized intelligent control systems, advanced materials for grinding media and mill linings, and optimized circuit designs.

Current objectives in ball milling technology development include further reducing specific energy consumption, minimizing environmental impact through reduced water usage and dust generation, enabling finer grinding capabilities for complex ores, and integrating with downstream processes for holistic optimization. The comparison between hydrocyclone and sieve oversize methods represents an important aspect of this ongoing evolution, as each approach offers distinct advantages depending on specific application requirements.

The industry continues to pursue innovations that can address the inherent inefficiencies of ball milling, which typically converts less than 10% of input energy into actual size reduction. Research into hybrid systems, alternative grinding technologies, and advanced classification methods aims to overcome these fundamental limitations while building upon the established reliability of ball milling technology.

Market Demand Analysis for Efficient Grinding Systems

The global mineral processing industry is experiencing a significant shift towards more efficient grinding systems, driven by increasing demand for minerals and metals across various sectors. The market for closed circuit ball milling systems has been growing steadily at a compound annual growth rate of approximately 5-6% over the past five years, with particular acceleration in regions with intensive mining operations such as Australia, Chile, Canada, and South Africa.

Energy efficiency has become a primary market driver as grinding operations typically account for 30-40% of the total energy consumption in mineral processing plants. This has created substantial demand for optimized classification systems that can reduce overgrinding and improve throughput. Companies are increasingly willing to invest in advanced grinding technologies that offer demonstrable reductions in energy consumption per ton of processed material.

The market demand for hydrocyclone-based classification systems currently dominates with about 70% market share due to their lower capital costs and smaller footprint. However, sieve-based systems are gaining traction, particularly in applications requiring higher precision classification or when processing materials with specific gravity challenges that limit hydrocyclone efficiency.

Environmental regulations and sustainability initiatives are also reshaping market demands. Water conservation is becoming increasingly critical, with many mining operations located in water-stressed regions. This has boosted interest in closed circuit systems that optimize water usage and reduce waste generation, with some operations reporting water savings of up to 25% after implementing optimized classification systems.

The digital transformation of mining operations is creating new market opportunities for smart grinding systems equipped with sensors and automation capabilities. The market for digitally enhanced grinding systems is projected to grow twice as fast as conventional systems over the next decade, reflecting industry's willingness to pay premium prices for solutions that offer real-time optimization and predictive maintenance features.

Regional market analysis indicates that emerging economies, particularly in Asia and Africa, represent the fastest-growing markets for efficient grinding systems, with demand increasing by 8-10% annually. This growth is driven by rapid industrialization and infrastructure development projects that require substantial mineral resources.

Customer segmentation reveals distinct needs across different mining operations. Large-scale operations prioritize throughput and operational reliability, while medium-sized operations are more sensitive to capital expenditure and seek solutions with faster return on investment. Small-scale operations typically focus on versatility and ease of maintenance when selecting grinding and classification technologies.

Energy efficiency has become a primary market driver as grinding operations typically account for 30-40% of the total energy consumption in mineral processing plants. This has created substantial demand for optimized classification systems that can reduce overgrinding and improve throughput. Companies are increasingly willing to invest in advanced grinding technologies that offer demonstrable reductions in energy consumption per ton of processed material.

The market demand for hydrocyclone-based classification systems currently dominates with about 70% market share due to their lower capital costs and smaller footprint. However, sieve-based systems are gaining traction, particularly in applications requiring higher precision classification or when processing materials with specific gravity challenges that limit hydrocyclone efficiency.

Environmental regulations and sustainability initiatives are also reshaping market demands. Water conservation is becoming increasingly critical, with many mining operations located in water-stressed regions. This has boosted interest in closed circuit systems that optimize water usage and reduce waste generation, with some operations reporting water savings of up to 25% after implementing optimized classification systems.

The digital transformation of mining operations is creating new market opportunities for smart grinding systems equipped with sensors and automation capabilities. The market for digitally enhanced grinding systems is projected to grow twice as fast as conventional systems over the next decade, reflecting industry's willingness to pay premium prices for solutions that offer real-time optimization and predictive maintenance features.

Regional market analysis indicates that emerging economies, particularly in Asia and Africa, represent the fastest-growing markets for efficient grinding systems, with demand increasing by 8-10% annually. This growth is driven by rapid industrialization and infrastructure development projects that require substantial mineral resources.

Customer segmentation reveals distinct needs across different mining operations. Large-scale operations prioritize throughput and operational reliability, while medium-sized operations are more sensitive to capital expenditure and seek solutions with faster return on investment. Small-scale operations typically focus on versatility and ease of maintenance when selecting grinding and classification technologies.

Current State and Challenges in Closed Circuit Ball Milling

Closed circuit ball milling represents a cornerstone technology in mineral processing and materials engineering, with two predominant classification methods currently dominating the industry: hydrocyclone and sieve oversize techniques. The global implementation of these technologies varies significantly across regions, with hydrocyclones being more prevalent in North America and Australia, while sieve-based systems maintain stronger presence in parts of Europe and Asia.

The current technological landscape shows hydrocyclone systems achieving classification efficiencies of 40-70%, depending on operational parameters and material characteristics. These systems typically operate with pressure ranges of 40-100 kPa and can process 100-1000 tons per hour in industrial applications. In contrast, sieve oversize methods demonstrate classification efficiencies of 60-85% but with lower throughput capacities of 50-500 tons per hour.

Recent advancements in computational fluid dynamics (CFD) have significantly improved hydrocyclone design, with the latest models incorporating variable vortex finder configurations that can adapt to changing feed conditions. However, these systems continue to struggle with handling materials that have wide particle size distributions or those containing significant amounts of ultra-fine particles below 10 microns.

Sieve oversize methods have evolved with the introduction of high-frequency vibration technologies and wear-resistant materials, extending screen life by 30-50% compared to previous generations. Nevertheless, these systems face persistent challenges with blinding (screen clogging) when processing materials with high moisture content or those containing clay minerals.

A critical challenge facing both technologies is energy efficiency. Current closed circuit ball milling systems consume approximately 30-50 kWh per ton of processed material, representing a significant operational cost. Industry benchmarking indicates that theoretical minimum energy requirements could be 40% lower than current consumption levels, highlighting substantial room for improvement.

Water consumption presents another significant challenge, particularly in regions facing water scarcity. Hydrocyclone systems typically require 0.5-1.5 m³ of water per ton of processed material, while sieve systems generally consume 20-30% less water but may require additional washing stages for certain applications.

Maintenance requirements and system reliability continue to pose operational challenges. Hydrocyclones experience wear patterns that reduce classification efficiency over time, requiring replacement of components every 1000-3000 operating hours. Sieve systems typically require more frequent maintenance interventions, with screen replacements needed every 500-1500 hours depending on material abrasiveness.

The integration of real-time monitoring and control systems represents the current technological frontier, with advanced sensors and machine learning algorithms beginning to enable adaptive operation. However, implementation remains limited, with less than 15% of industrial installations currently utilizing fully automated control systems.

The current technological landscape shows hydrocyclone systems achieving classification efficiencies of 40-70%, depending on operational parameters and material characteristics. These systems typically operate with pressure ranges of 40-100 kPa and can process 100-1000 tons per hour in industrial applications. In contrast, sieve oversize methods demonstrate classification efficiencies of 60-85% but with lower throughput capacities of 50-500 tons per hour.

Recent advancements in computational fluid dynamics (CFD) have significantly improved hydrocyclone design, with the latest models incorporating variable vortex finder configurations that can adapt to changing feed conditions. However, these systems continue to struggle with handling materials that have wide particle size distributions or those containing significant amounts of ultra-fine particles below 10 microns.

Sieve oversize methods have evolved with the introduction of high-frequency vibration technologies and wear-resistant materials, extending screen life by 30-50% compared to previous generations. Nevertheless, these systems face persistent challenges with blinding (screen clogging) when processing materials with high moisture content or those containing clay minerals.

A critical challenge facing both technologies is energy efficiency. Current closed circuit ball milling systems consume approximately 30-50 kWh per ton of processed material, representing a significant operational cost. Industry benchmarking indicates that theoretical minimum energy requirements could be 40% lower than current consumption levels, highlighting substantial room for improvement.

Water consumption presents another significant challenge, particularly in regions facing water scarcity. Hydrocyclone systems typically require 0.5-1.5 m³ of water per ton of processed material, while sieve systems generally consume 20-30% less water but may require additional washing stages for certain applications.

Maintenance requirements and system reliability continue to pose operational challenges. Hydrocyclones experience wear patterns that reduce classification efficiency over time, requiring replacement of components every 1000-3000 operating hours. Sieve systems typically require more frequent maintenance interventions, with screen replacements needed every 500-1500 hours depending on material abrasiveness.

The integration of real-time monitoring and control systems represents the current technological frontier, with advanced sensors and machine learning algorithms beginning to enable adaptive operation. However, implementation remains limited, with less than 15% of industrial installations currently utilizing fully automated control systems.

Comparative Analysis of Hydrocyclone vs Sieve Methods

01 Closed circuit ball mill design with integrated classification systems

Closed circuit ball mills incorporate integrated classification systems to efficiently separate oversized particles from the milled product. These systems typically include screens, classifiers, or separators that continuously return oversized material back to the mill for further grinding while allowing properly sized particles to exit the circuit. This design significantly improves separation efficiency by ensuring only material meeting size specifications leaves the circuit, optimizing both energy consumption and product quality.- Closed circuit ball mill design with integrated classification systems: Closed circuit ball mills incorporate integrated classification systems that efficiently separate oversized particles from the milled product. These systems typically include screens, classifiers, or separators directly connected to the mill discharge, creating a continuous loop where oversized material is returned for further grinding. This integration improves overall grinding efficiency by ensuring only properly sized particles exit the circuit, while coarse particles undergo additional processing.

- Advanced separation technologies for oversize particle control: Various advanced separation technologies are employed to enhance oversize particle control in closed circuit ball milling. These include high-efficiency cyclones, dynamic air classifiers, and vibrating screens with specialized mesh configurations. These technologies utilize principles such as centrifugal force, air flow dynamics, and precise screening to achieve more accurate particle size separation, resulting in improved product quality and reduced energy consumption in the grinding process.

- Optimization of circuit parameters for improved separation efficiency: The separation efficiency in closed circuit ball milling can be significantly improved by optimizing various circuit parameters. These include adjusting the circulating load ratio, controlling the feed rate, optimizing the classifier cut point, and regulating the ball mill speed. Proper calibration of these parameters ensures that oversized particles are effectively identified and returned to the mill while preventing unnecessary recycling of properly sized material, thereby enhancing overall circuit efficiency.

- Sensor-based monitoring and control systems for separation processes: Modern closed circuit ball milling systems incorporate advanced sensor-based monitoring and control technologies to optimize separation efficiency. These systems utilize real-time particle size analyzers, load cells, acoustic sensors, and power draw monitors to continuously assess grinding and separation performance. The data collected enables automated adjustments to classification parameters, ensuring consistent separation of oversized particles and maintaining optimal circuit performance under varying operating conditions.

- Innovative structural designs for enhanced oversize separation: Innovative structural designs in closed circuit ball milling systems focus on enhancing oversize separation efficiency. These designs include specialized mill liners that improve material flow patterns, optimized classifier geometries that enhance particle separation, and novel circuit configurations that minimize short-circuiting of coarse particles. Some designs also incorporate multiple classification stages or hybrid separation technologies to achieve more precise particle size control and higher overall circuit efficiency.

02 Advanced separator technologies for improved oversize particle control

Various advanced separator technologies have been developed to enhance oversize particle control in closed circuit ball milling. These include dynamic classifiers, high-efficiency cyclones, and vibrating screens with specialized mesh designs. These technologies utilize principles such as centrifugal force, air classification, and precision screening to achieve more accurate particle size separation. The improved separation efficiency results in better product consistency, reduced energy consumption, and increased throughput in the milling process.Expand Specific Solutions03 Process parameter optimization for separation efficiency

Optimizing process parameters is crucial for maximizing separation efficiency in closed circuit ball milling. Key parameters include mill rotation speed, ball loading, feed rate, classifier speed, and air flow rates in pneumatic classification systems. By carefully adjusting these parameters based on material characteristics and desired product specifications, operators can significantly improve the separation of oversized particles. Advanced control systems that continuously monitor and adjust these parameters in real-time further enhance separation efficiency.Expand Specific Solutions04 Innovative feedback control systems for closed circuit operation

Innovative feedback control systems have been developed to optimize closed circuit ball milling operations. These systems utilize sensors to continuously monitor particle size distribution, mill load, and separation efficiency. The collected data is processed by advanced algorithms that automatically adjust operating parameters to maintain optimal separation efficiency. Some systems incorporate artificial intelligence and machine learning to predict and prevent separation inefficiencies before they occur, resulting in more consistent product quality and reduced energy consumption.Expand Specific Solutions05 Multi-stage classification for enhanced separation precision

Multi-stage classification systems provide enhanced separation precision in closed circuit ball milling operations. These systems employ sequential classification stages, each optimized for specific particle size ranges. Primary classifiers remove the coarsest particles, while secondary and tertiary stages handle progressively finer material. This approach allows for more precise control over particle size distribution and significantly improves the efficiency of oversize separation. The multi-stage design also reduces the load on individual classifiers, extending equipment life and improving overall system reliability.Expand Specific Solutions

Key Industry Players in Grinding and Classification Technology

The closed circuit ball milling market is currently in a growth phase, with increasing demand driven by efficiency requirements in mineral processing operations. The global market size is estimated to exceed $3 billion, expanding at a CAGR of approximately 5-7%. Technologically, hydrocyclone methods are more mature and widely adopted than sieve oversize methods, though both continue to evolve. Leading players include Weir Minerals Australia and NOV Inc., who offer advanced hydrocyclone solutions, while companies like CiDRA Corporate Services and Hosokawa Alpine AG focus on innovative monitoring and control systems. Chinese entities such as China ENFI Engineering Corp. and Anhui Masteel Mining are rapidly advancing their technological capabilities, particularly in hydrocyclone applications for iron ore processing, narrowing the gap with Western counterparts.

China University of Mining & Technology

Technical Solution: China University of Mining & Technology has developed innovative research solutions for closed circuit ball milling systems comparing hydrocyclone and sieve classification methods. Their research team has created a hybrid classification approach that utilizes a primary hydrocyclone stage with modified geometry featuring a double-vortex finder design that improves separation efficiency by creating distinct flow patterns for different particle size ranges[8]. For finer classification requirements, they've developed specialized high-frequency vibrating screens with composite deck materials that resist blinding while providing precise cut points down to 45 microns. Their research has demonstrated that this combined approach can reduce circulating load by up to 20% while improving grinding efficiency. The university's laboratory has also pioneered computational fluid dynamics (CFD) modeling techniques that accurately predict classification performance under varying operating conditions, allowing for virtual optimization of circuit design before implementation[9]. Their work includes development of sensor systems that provide real-time monitoring of particle size distribution in both hydrocyclone overflow and screen undersize streams.

Strengths: Cutting-edge research in classification efficiency; sophisticated modeling capabilities for circuit optimization; innovative hybrid classification designs. Weaknesses: Limited commercial-scale implementation experience; solutions may require adaptation for industrial environments; less focus on maintenance and operational aspects compared to equipment manufacturers.

NOV, Inc.

Technical Solution: NOV has developed the Brandt™ KING COBRA™ closed circuit ball milling system that integrates both hydrocyclone and screen classification technologies. Their approach features a primary hydrocyclone stage utilizing their patented VORTEX™ technology, which employs a variable geometry design that can be adjusted during operation to optimize separation efficiency across different feed conditions[5]. For applications requiring higher precision, their system incorporates secondary classification using their KING COBRA™ shaker screens with composite deck materials that resist blinding and provide longer service life in abrasive mineral processing environments. NOV's system is distinguished by its modular design philosophy, allowing operators to easily switch between hydrocyclone-dominant and screen-dominant configurations based on changing ore characteristics or product specifications. Their NOVOS™ process control system provides automated optimization of classification parameters including cyclone pressure, feed density, and screen deck angle to maintain target particle size distribution.

Strengths: Adaptable classification configuration allows optimization for different ore types; patented variable geometry hydrocyclone technology; modular design facilitates maintenance and upgrades. Weaknesses: System complexity requires specialized training for operators; higher initial capital cost compared to fixed-configuration systems; optimal performance depends on proper calibration of control systems.

Core Technical Innovations in Particle Classification

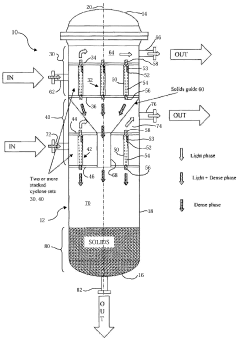

Compacted hydrocylone apparatus in vessels

PatentWO2011008432A1

Innovation

- A compact hydrocyclone separation assembly where multiple hydrocyclone groups are stacked within a single vessel, each with a tubular body having an inlet section and a separation section with smaller diameters, allowing for more efficient flow distribution and easier sealing, and enabling the use of smaller diameter vessels with improved turndown characteristics.

Apparatus for washing and grading sand and aggregate

PatentActiveUS20190247861A1

Innovation

- The apparatus employs a triple-deck aggregate washing and grading screen with multiple sand washing and grading units, each comprising a first and further hydrocyclone, and a vibratory screen, where the first hydrocyclone receives undersize material and water from the aggregate screen, and the further hydrocyclone's overflow is reused to reduce water consumption and enhance fines removal.

Energy Efficiency Considerations in Ball Milling Systems

Energy efficiency has become a critical consideration in mineral processing operations, particularly in ball milling systems where power consumption represents a significant operational cost. When comparing closed circuit ball milling configurations using hydrocyclones versus sieve oversize methods, energy efficiency emerges as a decisive factor in system selection and optimization.

Hydrocyclone-based circuits typically demonstrate higher throughput capabilities but may consume more energy per ton of material processed compared to sieve-based systems. This is primarily due to the additional pumping requirements needed to maintain proper pressure and flow rates for effective cyclone operation. Studies indicate that pumping energy can account for 15-25% of the total energy consumption in hydrocyclone circuits.

Sieve oversize methods, while generally operating at lower throughput rates, often exhibit better energy efficiency profiles for certain applications. The gravitational flow design of many sieve systems eliminates the need for slurry pumping between classification stages, resulting in direct energy savings. However, this advantage may be offset by the need for mechanical vibration systems to maintain screen efficiency.

The particle size distribution achieved by each method significantly impacts downstream energy requirements. Hydrocyclones typically produce a wider particle size distribution with potential for more fines generation, which may lead to overgrinding and wasted energy. Sieve systems generally provide sharper classification efficiency, potentially reducing overgrinding and associated energy losses.

Circuit configuration optimization presents substantial opportunities for energy conservation. Hybrid systems incorporating both technologies have demonstrated energy savings of 10-15% in certain applications. Advanced control systems that dynamically adjust mill operating parameters based on real-time classification performance can further reduce energy consumption by 5-8%.

Material characteristics play a crucial role in determining the most energy-efficient classification method. For harder ores requiring multiple grinding stages, hydrocyclones may offer better overall efficiency despite higher auxiliary power requirements. Conversely, softer materials with narrower target size ranges often benefit from the precision of sieve-based classification.

Recent technological innovations have focused on reducing the energy intensity of both systems. High-efficiency cyclones with improved vortex finder designs have demonstrated energy reductions of up to 20%, while advanced screen technologies utilizing composite materials and optimized aperture designs have achieved similar efficiency improvements in sieve-based circuits.

Hydrocyclone-based circuits typically demonstrate higher throughput capabilities but may consume more energy per ton of material processed compared to sieve-based systems. This is primarily due to the additional pumping requirements needed to maintain proper pressure and flow rates for effective cyclone operation. Studies indicate that pumping energy can account for 15-25% of the total energy consumption in hydrocyclone circuits.

Sieve oversize methods, while generally operating at lower throughput rates, often exhibit better energy efficiency profiles for certain applications. The gravitational flow design of many sieve systems eliminates the need for slurry pumping between classification stages, resulting in direct energy savings. However, this advantage may be offset by the need for mechanical vibration systems to maintain screen efficiency.

The particle size distribution achieved by each method significantly impacts downstream energy requirements. Hydrocyclones typically produce a wider particle size distribution with potential for more fines generation, which may lead to overgrinding and wasted energy. Sieve systems generally provide sharper classification efficiency, potentially reducing overgrinding and associated energy losses.

Circuit configuration optimization presents substantial opportunities for energy conservation. Hybrid systems incorporating both technologies have demonstrated energy savings of 10-15% in certain applications. Advanced control systems that dynamically adjust mill operating parameters based on real-time classification performance can further reduce energy consumption by 5-8%.

Material characteristics play a crucial role in determining the most energy-efficient classification method. For harder ores requiring multiple grinding stages, hydrocyclones may offer better overall efficiency despite higher auxiliary power requirements. Conversely, softer materials with narrower target size ranges often benefit from the precision of sieve-based classification.

Recent technological innovations have focused on reducing the energy intensity of both systems. High-efficiency cyclones with improved vortex finder designs have demonstrated energy reductions of up to 20%, while advanced screen technologies utilizing composite materials and optimized aperture designs have achieved similar efficiency improvements in sieve-based circuits.

Environmental Impact Assessment of Different Classification Methods

The environmental impact of classification methods in closed circuit ball milling systems represents a critical consideration for sustainable mineral processing operations. Hydrocyclones and sieve oversize methods differ significantly in their environmental footprints across multiple dimensions, necessitating comprehensive assessment for informed decision-making.

Water consumption patterns between these classification technologies show marked differences. Hydrocyclones typically require continuous water flow to maintain proper separation dynamics, resulting in higher overall water usage. In contrast, sieve-based systems often demonstrate more efficient water utilization, with potential for reduced consumption by 15-30% depending on implementation specifics and material characteristics.

Energy efficiency comparisons reveal that hydrocyclones generally operate with lower direct energy requirements due to their lack of moving parts, consuming approximately 0.3-0.5 kWh per ton of processed material. Sieve systems, while mechanically more complex, may require 0.5-0.8 kWh per ton. However, when considering the entire circuit efficiency, hydrocyclones can sometimes lead to overall energy savings by enabling more efficient mill operation.

Waste generation profiles differ substantially between methods. Hydrocyclones produce more diluted waste streams with finer particle distribution, potentially increasing the challenges associated with tailings management. Sieve-based classification typically generates more concentrated waste with coarser particle profiles, which may offer advantages for dewatering and storage stability.

Noise pollution represents another environmental consideration, with sieve systems generally producing higher operational noise levels (85-95 dB) compared to hydrocyclones (75-85 dB), necessitating additional noise mitigation measures in some regulatory environments.

Chemical usage also varies between systems. Hydrocyclone circuits often require additional flocculants and coagulants to manage the finer particles in their overflow, while sieve-based systems may require fewer chemical additives but more frequent screen replacement, creating different waste streams.

Life cycle assessment studies indicate that the environmental impact of both systems extends beyond operational considerations to include manufacturing and end-of-life disposal. Hydrocyclones, constructed primarily of metal and rubber components, present different recycling challenges compared to the metal and synthetic screen materials in sieve systems.

Greenhouse gas emissions, when calculated on a per-ton-processed basis and including both direct and indirect sources, typically favor hydrocyclones in large operations but may favor sieve systems in smaller installations where their simplicity and maintenance characteristics provide environmental advantages.

Water consumption patterns between these classification technologies show marked differences. Hydrocyclones typically require continuous water flow to maintain proper separation dynamics, resulting in higher overall water usage. In contrast, sieve-based systems often demonstrate more efficient water utilization, with potential for reduced consumption by 15-30% depending on implementation specifics and material characteristics.

Energy efficiency comparisons reveal that hydrocyclones generally operate with lower direct energy requirements due to their lack of moving parts, consuming approximately 0.3-0.5 kWh per ton of processed material. Sieve systems, while mechanically more complex, may require 0.5-0.8 kWh per ton. However, when considering the entire circuit efficiency, hydrocyclones can sometimes lead to overall energy savings by enabling more efficient mill operation.

Waste generation profiles differ substantially between methods. Hydrocyclones produce more diluted waste streams with finer particle distribution, potentially increasing the challenges associated with tailings management. Sieve-based classification typically generates more concentrated waste with coarser particle profiles, which may offer advantages for dewatering and storage stability.

Noise pollution represents another environmental consideration, with sieve systems generally producing higher operational noise levels (85-95 dB) compared to hydrocyclones (75-85 dB), necessitating additional noise mitigation measures in some regulatory environments.

Chemical usage also varies between systems. Hydrocyclone circuits often require additional flocculants and coagulants to manage the finer particles in their overflow, while sieve-based systems may require fewer chemical additives but more frequent screen replacement, creating different waste streams.

Life cycle assessment studies indicate that the environmental impact of both systems extends beyond operational considerations to include manufacturing and end-of-life disposal. Hydrocyclones, constructed primarily of metal and rubber components, present different recycling challenges compared to the metal and synthetic screen materials in sieve systems.

Greenhouse gas emissions, when calculated on a per-ton-processed basis and including both direct and indirect sources, typically favor hydrocyclones in large operations but may favor sieve systems in smaller installations where their simplicity and maintenance characteristics provide environmental advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!