Ball Mill Process Control: Feed, Pulp Density, And Classified Circuit Tips

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ball Mill Technology Background and Objectives

Ball mill technology has evolved significantly since its inception in the early 20th century, transforming from simple grinding equipment into sophisticated processing systems. The fundamental principle remains unchanged—utilizing rotating cylinders filled with grinding media to reduce material size—but advancements in design, materials, and control systems have dramatically improved efficiency and output quality. Recent technological developments have focused on optimizing energy consumption, as ball mills traditionally consume approximately 3-5% of all electricity generated globally in mining operations.

The evolution trajectory shows a clear shift from manual control systems to semi-automated processes in the 1980s, followed by fully automated digital control systems in the 2000s. Modern ball mills incorporate real-time monitoring capabilities, predictive maintenance algorithms, and adaptive control mechanisms that respond to variations in feed characteristics and operational conditions.

Process control represents the frontier of ball mill technology advancement, with feed rate management, pulp density optimization, and classified circuit integration emerging as critical factors for operational excellence. Effective feed control ensures consistent mill loading, preventing overgrinding or underprocessing. Pulp density management directly impacts grinding efficiency, media wear rates, and energy consumption, while properly designed classification circuits determine the final product quality and throughput capacity.

The primary technological objective in this field is to develop integrated control systems that simultaneously optimize these three interdependent variables—feed rate, pulp density, and classification parameters—to maximize throughput while minimizing energy consumption and maintaining product quality specifications. This requires advanced sensing technologies, sophisticated modeling algorithms, and robust control architectures capable of handling the inherent variability of mineral processing operations.

Secondary objectives include reducing environmental impact through water conservation and chemical usage optimization, extending equipment lifespan through improved wear prediction and prevention, and enhancing operator decision-making through intuitive interfaces and actionable intelligence derived from process data.

The convergence of traditional mineral processing expertise with emerging technologies such as machine learning, digital twins, and industrial IoT presents unprecedented opportunities for ball mill process control advancement. Industry leaders are increasingly focusing on developing holistic solutions that address the entire grinding circuit as an integrated system rather than optimizing individual components in isolation.

The evolution trajectory shows a clear shift from manual control systems to semi-automated processes in the 1980s, followed by fully automated digital control systems in the 2000s. Modern ball mills incorporate real-time monitoring capabilities, predictive maintenance algorithms, and adaptive control mechanisms that respond to variations in feed characteristics and operational conditions.

Process control represents the frontier of ball mill technology advancement, with feed rate management, pulp density optimization, and classified circuit integration emerging as critical factors for operational excellence. Effective feed control ensures consistent mill loading, preventing overgrinding or underprocessing. Pulp density management directly impacts grinding efficiency, media wear rates, and energy consumption, while properly designed classification circuits determine the final product quality and throughput capacity.

The primary technological objective in this field is to develop integrated control systems that simultaneously optimize these three interdependent variables—feed rate, pulp density, and classification parameters—to maximize throughput while minimizing energy consumption and maintaining product quality specifications. This requires advanced sensing technologies, sophisticated modeling algorithms, and robust control architectures capable of handling the inherent variability of mineral processing operations.

Secondary objectives include reducing environmental impact through water conservation and chemical usage optimization, extending equipment lifespan through improved wear prediction and prevention, and enhancing operator decision-making through intuitive interfaces and actionable intelligence derived from process data.

The convergence of traditional mineral processing expertise with emerging technologies such as machine learning, digital twins, and industrial IoT presents unprecedented opportunities for ball mill process control advancement. Industry leaders are increasingly focusing on developing holistic solutions that address the entire grinding circuit as an integrated system rather than optimizing individual components in isolation.

Market Demand Analysis for Advanced Grinding Solutions

The global mineral processing industry is experiencing a significant shift towards advanced grinding solutions, driven by multiple market factors. Mining operations worldwide are facing increasing pressure to optimize their ball mill processes due to declining ore grades, which necessitate processing larger volumes of material to maintain production levels. This trend is particularly evident in copper, gold, and iron ore sectors, where the average ore grade has decreased by approximately 30% over the past decade.

Energy efficiency has become a paramount concern as grinding operations typically account for 30-40% of a mine's total energy consumption. With rising energy costs and stricter environmental regulations, the demand for solutions that can reduce power consumption while maintaining throughput has intensified. Companies are actively seeking technologies that can optimize feed rates, pulp density, and classification circuits to achieve energy savings of 15-20% without compromising production targets.

The market for advanced grinding control systems is projected to grow substantially, with particular emphasis on real-time monitoring and automated adjustment capabilities. Mining companies are increasingly recognizing that precise control of pulp density can lead to grinding efficiency improvements of up to 25%, directly impacting their operational costs and productivity. This has created a robust demand for sensors, analyzers, and control systems specifically designed for pulp density management.

Classification circuit optimization represents another high-demand segment, as inefficient classification can reduce overall mill efficiency by 10-15%. Solutions that can minimize circulating loads while maintaining product quality specifications are highly sought after, especially in regions with water scarcity where optimizing water usage in grinding circuits is critical.

Geographically, the strongest market demand is observed in established mining regions such as Australia, Chile, Canada, and South Africa, where aging infrastructure necessitates modernization. However, emerging markets in Central Asia, West Africa, and parts of South America are showing accelerated growth rates as new mining operations adopt advanced technologies from inception rather than retrofitting.

The aftermarket service sector for grinding optimization solutions is expanding rapidly, with an increasing preference for subscription-based monitoring and optimization services rather than one-time capital investments. This shift reflects mining companies' desire to convert capital expenditures to operational expenses while ensuring continuous technological updates and expert support.

Energy efficiency has become a paramount concern as grinding operations typically account for 30-40% of a mine's total energy consumption. With rising energy costs and stricter environmental regulations, the demand for solutions that can reduce power consumption while maintaining throughput has intensified. Companies are actively seeking technologies that can optimize feed rates, pulp density, and classification circuits to achieve energy savings of 15-20% without compromising production targets.

The market for advanced grinding control systems is projected to grow substantially, with particular emphasis on real-time monitoring and automated adjustment capabilities. Mining companies are increasingly recognizing that precise control of pulp density can lead to grinding efficiency improvements of up to 25%, directly impacting their operational costs and productivity. This has created a robust demand for sensors, analyzers, and control systems specifically designed for pulp density management.

Classification circuit optimization represents another high-demand segment, as inefficient classification can reduce overall mill efficiency by 10-15%. Solutions that can minimize circulating loads while maintaining product quality specifications are highly sought after, especially in regions with water scarcity where optimizing water usage in grinding circuits is critical.

Geographically, the strongest market demand is observed in established mining regions such as Australia, Chile, Canada, and South Africa, where aging infrastructure necessitates modernization. However, emerging markets in Central Asia, West Africa, and parts of South America are showing accelerated growth rates as new mining operations adopt advanced technologies from inception rather than retrofitting.

The aftermarket service sector for grinding optimization solutions is expanding rapidly, with an increasing preference for subscription-based monitoring and optimization services rather than one-time capital investments. This shift reflects mining companies' desire to convert capital expenditures to operational expenses while ensuring continuous technological updates and expert support.

Current Challenges in Ball Mill Process Control

Despite significant advancements in ball mill technology, several persistent challenges continue to impact optimal process control in modern mineral processing operations. The primary challenge remains achieving consistent feed rate control, as fluctuations in ore characteristics such as hardness, size distribution, and mineralogy create unpredictable grinding behavior. These variations often occur within the same ore body, making real-time adjustments difficult even with advanced control systems.

Pulp density management presents another critical challenge, with operators struggling to maintain the optimal solid-to-liquid ratio throughout the grinding circuit. Deviations from target density values directly impact grinding efficiency, classification performance, and downstream processes. The complex relationship between pulp density and mill performance is further complicated by variations in ore type and changing operational conditions.

Classification circuit control remains problematic due to the inherent difficulties in accurately measuring particle size distribution in real-time. Most operations still rely on indirect measurements or periodic sampling, creating significant time lags between process changes and corrective actions. This delay often results in suboptimal separation efficiency and circulating loads that deviate from target values.

Energy efficiency concerns have become increasingly prominent as processing facilities face rising power costs and sustainability pressures. Ball mills typically operate at 30-40% efficiency, with significant energy losses occurring as heat, noise, and mechanical wear. Optimizing energy utilization while maintaining product quality specifications represents a delicate balance that many operations struggle to achieve consistently.

Instrumentation limitations continue to hinder effective process control, as harsh operating environments damage sensors and measurement devices. The lack of reliable, continuous monitoring for critical parameters such as ball charge levels, liner wear conditions, and internal material flow patterns forces operators to rely on experience and periodic inspections rather than data-driven decision making.

Integration challenges between different control systems further complicate mill operation, with many facilities utilizing disparate systems for different aspects of the grinding circuit. The lack of seamless communication between feed control, mill operation, and classification systems creates coordination problems and prevents truly optimized circuit performance.

Workforce expertise presents an ongoing challenge as experienced operators retire and new personnel require extensive training to develop the necessary skills for effective mill management. The combination of complex equipment, variable ore characteristics, and intricate process relationships demands both theoretical knowledge and practical experience that is increasingly difficult to maintain within operations teams.

Pulp density management presents another critical challenge, with operators struggling to maintain the optimal solid-to-liquid ratio throughout the grinding circuit. Deviations from target density values directly impact grinding efficiency, classification performance, and downstream processes. The complex relationship between pulp density and mill performance is further complicated by variations in ore type and changing operational conditions.

Classification circuit control remains problematic due to the inherent difficulties in accurately measuring particle size distribution in real-time. Most operations still rely on indirect measurements or periodic sampling, creating significant time lags between process changes and corrective actions. This delay often results in suboptimal separation efficiency and circulating loads that deviate from target values.

Energy efficiency concerns have become increasingly prominent as processing facilities face rising power costs and sustainability pressures. Ball mills typically operate at 30-40% efficiency, with significant energy losses occurring as heat, noise, and mechanical wear. Optimizing energy utilization while maintaining product quality specifications represents a delicate balance that many operations struggle to achieve consistently.

Instrumentation limitations continue to hinder effective process control, as harsh operating environments damage sensors and measurement devices. The lack of reliable, continuous monitoring for critical parameters such as ball charge levels, liner wear conditions, and internal material flow patterns forces operators to rely on experience and periodic inspections rather than data-driven decision making.

Integration challenges between different control systems further complicate mill operation, with many facilities utilizing disparate systems for different aspects of the grinding circuit. The lack of seamless communication between feed control, mill operation, and classification systems creates coordination problems and prevents truly optimized circuit performance.

Workforce expertise presents an ongoing challenge as experienced operators retire and new personnel require extensive training to develop the necessary skills for effective mill management. The combination of complex equipment, variable ore characteristics, and intricate process relationships demands both theoretical knowledge and practical experience that is increasingly difficult to maintain within operations teams.

Current Process Control Solutions for Ball Mills

01 Feed Control Systems for Ball Mills

Advanced feed control systems are essential for optimizing ball mill operations. These systems monitor and adjust the feed rate to maintain optimal grinding efficiency. By implementing automated feed control mechanisms, operators can ensure consistent particle size distribution and prevent overloading or underutilization of the mill. These systems often incorporate sensors that measure parameters such as power draw, sound emissions, and bearing pressure to determine the optimal feed rate in real-time.- Feed control systems for ball mills: Advanced feed control systems are essential for optimizing ball mill operations. These systems monitor and adjust the feed rate to maintain optimal grinding efficiency and prevent overloading or underutilization of the mill. By implementing automated feed control mechanisms, operators can achieve consistent particle size distribution and maximize throughput while minimizing energy consumption. These systems often incorporate sensors that measure parameters such as power draw, sound emissions, and bearing pressure to determine the optimal feed rate in real-time.

- Pulp density monitoring and control: Maintaining optimal pulp density is crucial for efficient ball mill operation. Control systems that continuously monitor and adjust pulp density help achieve consistent grinding performance and prevent issues such as overgrinding or inadequate particle reduction. These systems typically use density meters, flow meters, and automated valves to regulate the addition of water or solids to the mill. By maintaining the ideal pulp density, operators can optimize mineral liberation, reduce energy consumption, and extend the lifespan of grinding media and mill liners.

- Classified circuit optimization: Optimization of classified circuits in ball mill operations involves the strategic arrangement and control of classifiers to separate adequately ground material from coarse particles that require further grinding. Advanced classified circuit designs incorporate feedback loops that continuously monitor particle size distribution and adjust classifier parameters accordingly. These systems may include hydrocyclones, screens, or other separation devices that work in conjunction with the ball mill to achieve the desired product specifications. Proper classified circuit design and control can significantly improve grinding efficiency and reduce energy consumption.

- Integrated process control systems: Integrated process control systems for ball mills combine multiple control parameters including feed rate, pulp density, and classifier performance into a unified control strategy. These comprehensive systems often utilize advanced algorithms, machine learning, or artificial intelligence to optimize the entire grinding circuit. By simultaneously monitoring and adjusting multiple variables, these systems can adapt to changing ore characteristics, equipment conditions, and production requirements. Integrated control approaches typically result in more stable operation, improved product quality, and reduced operational costs compared to controlling individual parameters separately.

- Sensor technology and real-time monitoring: Advanced sensor technology enables real-time monitoring of critical ball mill parameters, providing operators with immediate feedback on mill performance. These sensors measure variables such as acoustic emissions, vibration patterns, temperature, power draw, and load levels to assess grinding efficiency and equipment condition. Modern systems may incorporate wireless sensors, digital twins, and cloud-based analytics to process the data and generate actionable insights. Real-time monitoring allows for predictive maintenance, early detection of operational issues, and continuous optimization of the grinding process, resulting in improved productivity and reduced downtime.

02 Pulp Density Monitoring and Regulation

Maintaining optimal pulp density is crucial for efficient ball mill operation. Systems for continuous monitoring and automatic adjustment of pulp density help achieve consistent grinding performance. These technologies use various sensors to measure the solids concentration in the slurry and adjust water addition accordingly. Proper pulp density control ensures efficient energy utilization, reduces wear on mill components, and improves the overall grinding efficiency by maintaining the optimal rheological properties of the slurry.Expand Specific Solutions03 Closed Circuit Classification Systems

Closed circuit grinding systems with integrated classifiers improve ball mill efficiency by continuously separating adequately ground material from coarse particles. These systems return oversized particles to the mill for further grinding while allowing properly sized particles to proceed to the next processing stage. Advanced classification technologies incorporate hydrocyclones, screens, or other separation devices that can be adjusted based on process requirements. This approach optimizes energy consumption, increases throughput, and ensures consistent product quality.Expand Specific Solutions04 Integrated Process Control and Automation

Integrated control systems that simultaneously manage feed rate, pulp density, and classification parameters provide comprehensive ball mill process optimization. These systems use advanced algorithms and machine learning techniques to analyze multiple process variables and make coordinated adjustments. By implementing such integrated automation solutions, operators can achieve stable operation under varying conditions, reduce operator intervention, and optimize the entire grinding circuit for maximum efficiency and product quality.Expand Specific Solutions05 Sensor Technologies and Process Monitoring

Advanced sensor technologies enable real-time monitoring of critical ball mill parameters including load levels, particle size distribution, and grinding efficiency. These sensors provide data for both immediate control decisions and long-term process optimization. Modern monitoring systems incorporate acoustic sensors, power draw measurements, vibration analysis, and image processing to assess mill performance. The integration of these diverse data sources allows for predictive maintenance, early detection of process deviations, and continuous optimization of grinding parameters.Expand Specific Solutions

Major Industry Players in Grinding Technology

The ball mill process control market is currently in a growth phase, with increasing demand for efficient grinding solutions across mining, ceramics, and pulp industries. The market size is expanding due to rising automation needs in mineral processing and industrial manufacturing. Technologically, the field is moderately mature but evolving toward more sophisticated control systems. Leading players include established industrial equipment providers like Andritz, Valmet, FLSmidth, and Netzsch Feinmahltechnik offering comprehensive solutions, while specialized companies such as CiDRA Corporate Services and PUHLER focus on niche innovations in measurement and intelligent equipment. Chinese manufacturers like Guangdong Jiamei Ceramics and Weimei Group companies are rapidly gaining market share by combining traditional manufacturing with emerging automation technologies.

CiDRA Corporate Services, Inc.

Technical Solution: CiDRA has developed specialized SONARtrac® flow and entrained air measurement technology specifically optimized for ball mill circuits. Their non-invasive clamp-on sensors provide real-time monitoring of volumetric flow, entrained air, and density without contacting the slurry, eliminating wear concerns in abrasive environments. For pulp density control, CiDRA's CYCLONEtrac™ PST system monitors individual hydrocyclone performance in real-time, detecting deviations in classification efficiency and enabling immediate corrective actions. Their integrated solution connects to distributed control systems to provide automated feed rate adjustments based on measured parameters throughout the grinding circuit. CiDRA's technology employs advanced signal processing algorithms that can distinguish between process variations and measurement noise, providing stable control inputs even in highly turbulent flow conditions. Implementation of their systems has demonstrated up to 4% throughput improvements while maintaining or improving grind size consistency.

Strengths: Non-invasive measurement technology eliminates maintenance concerns associated with in-stream sensors; specialized focus on grinding circuit measurements provides highly relevant data. Weaknesses: Primarily focused on measurement rather than comprehensive control solutions; may require integration with third-party control systems for complete implementation.

FLSmidth A/S

Technical Solution: FLSmidth has developed advanced SmartCyclone™ technology for ball mill circuits that utilizes wireless sensors to monitor and control cyclone performance in real-time. Their ECS/ProcessExpert® platform integrates with ball mill circuits to provide comprehensive control of feed rates, pulp density, and classification efficiency. The system employs model predictive control algorithms that continuously adjust mill parameters based on ore characteristics and process conditions. FLSmidth's solution includes specialized MillMaster™ technology that optimizes grinding efficiency by maintaining optimal ball charge levels and pulp density through automated control loops. Their systems can detect process deviations within seconds and make immediate adjustments to prevent circuit instabilities, resulting in up to 6% throughput improvements while maintaining product quality specifications.

Strengths: Comprehensive integration of sensors and control systems across the entire grinding circuit; proven implementation in large-scale mining operations with documented efficiency gains. Weaknesses: Higher initial implementation costs compared to basic control systems; requires significant technical expertise for optimal configuration and maintenance.

Key Technical Innovations in Feed and Pulp Density Control

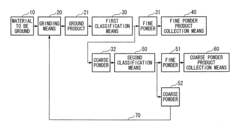

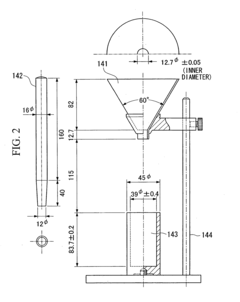

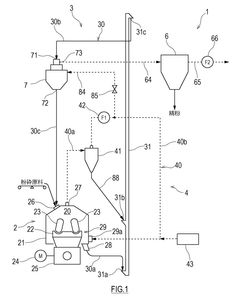

Dry grinding system and dry grinding method

PatentInactiveUS20060255192A1

Innovation

- A dry grinding system employing multiple classification stages, including grinding means like ball mills and classification means such as air classifiers and sieves, to achieve precise particle size distribution, with returning mechanisms to optimize the grinding process and collection means for iron removal.

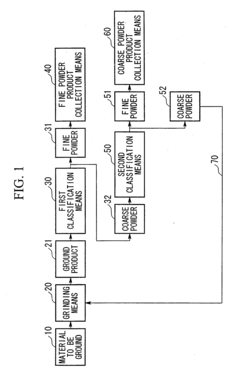

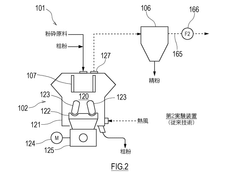

Method for operating pulverizing system, and method for manufacturing powder

PatentWO2021006154A1

Innovation

- A method that includes a vertical pulverizer with a classifier and a dust collector, where the air bleed volume from the pulverizer is adjusted to control the fineness of the fine powder, allowing for the separation and re-pulverization of coarse powder, and the correlation between air extraction and fineness is determined to set the optimal bleed air volume for desired powder quality.

Energy Efficiency Considerations in Ball Mill Operations

Energy efficiency has become a critical consideration in ball mill operations due to the significant power consumption associated with grinding processes. Ball mills typically consume between 30-40% of the total energy in mineral processing plants, making them prime targets for efficiency improvements. The relationship between process control parameters and energy consumption is complex but vital to understand for optimizing operations.

Feed rate management directly impacts energy efficiency in ball mills. Overfeeding leads to inefficient grinding and potential mill overload, while underfeeding results in media-to-media contact that wastes energy and accelerates liner and media wear. Maintaining optimal mill loading through precise feed control systems can reduce specific energy consumption by 5-15% in typical operations.

Pulp density control represents another crucial factor affecting energy efficiency. Higher pulp densities generally improve grinding efficiency up to an optimal point, beyond which efficiency decreases rapidly. Research indicates that maintaining pulp density within 2-3% of the optimal range can yield energy savings of 7-10%. Modern density control systems utilizing real-time measurements and automated reagent addition have demonstrated significant improvements in consistency.

The classification circuit's efficiency directly influences the overall energy consumption of grinding operations. Inefficient classification leads to recirculation of already adequately ground material, wasting energy in unnecessary regrinding. Studies show that optimizing classifier cut points and reducing bypass can decrease specific energy consumption by 8-12% while maintaining product specifications.

Advanced control strategies incorporating machine learning algorithms have emerged as powerful tools for energy optimization. These systems continuously adjust operating parameters based on changing ore characteristics and operational conditions. Implementations at several mining operations have demonstrated energy savings of 3-7% without capital-intensive equipment modifications.

Heat recovery systems represent an emerging approach to improving overall energy efficiency. The significant thermal energy generated during grinding can be captured and repurposed for other processes within the plant. Pilot installations have shown potential for recovering 10-15% of input energy, though implementation challenges related to integration with existing systems remain.

Return on investment calculations for energy efficiency improvements in ball mill operations typically show payback periods of 6-18 months for control system optimizations, making them attractive even in challenging economic environments. The combined implementation of multiple efficiency measures can reduce overall grinding energy consumption by 15-25%, representing significant cost savings and environmental benefits for mining operations.

Feed rate management directly impacts energy efficiency in ball mills. Overfeeding leads to inefficient grinding and potential mill overload, while underfeeding results in media-to-media contact that wastes energy and accelerates liner and media wear. Maintaining optimal mill loading through precise feed control systems can reduce specific energy consumption by 5-15% in typical operations.

Pulp density control represents another crucial factor affecting energy efficiency. Higher pulp densities generally improve grinding efficiency up to an optimal point, beyond which efficiency decreases rapidly. Research indicates that maintaining pulp density within 2-3% of the optimal range can yield energy savings of 7-10%. Modern density control systems utilizing real-time measurements and automated reagent addition have demonstrated significant improvements in consistency.

The classification circuit's efficiency directly influences the overall energy consumption of grinding operations. Inefficient classification leads to recirculation of already adequately ground material, wasting energy in unnecessary regrinding. Studies show that optimizing classifier cut points and reducing bypass can decrease specific energy consumption by 8-12% while maintaining product specifications.

Advanced control strategies incorporating machine learning algorithms have emerged as powerful tools for energy optimization. These systems continuously adjust operating parameters based on changing ore characteristics and operational conditions. Implementations at several mining operations have demonstrated energy savings of 3-7% without capital-intensive equipment modifications.

Heat recovery systems represent an emerging approach to improving overall energy efficiency. The significant thermal energy generated during grinding can be captured and repurposed for other processes within the plant. Pilot installations have shown potential for recovering 10-15% of input energy, though implementation challenges related to integration with existing systems remain.

Return on investment calculations for energy efficiency improvements in ball mill operations typically show payback periods of 6-18 months for control system optimizations, making them attractive even in challenging economic environments. The combined implementation of multiple efficiency measures can reduce overall grinding energy consumption by 15-25%, representing significant cost savings and environmental benefits for mining operations.

Environmental Impact and Sustainability Measures

Ball mill operations have significant environmental implications that require careful consideration and management. The energy-intensive nature of grinding processes contributes substantially to the carbon footprint of mineral processing operations, with ball mills typically consuming between 30-40% of a processing plant's total energy. This high energy demand translates directly into greenhouse gas emissions when power is derived from fossil fuel sources. Additionally, the grinding media wear generates metal particulates that can contaminate tailings and potentially leach into surrounding ecosystems if not properly managed.

Water usage represents another critical environmental concern, as ball mill circuits typically require substantial volumes for slurry formation and density control. In regions facing water scarcity, this consumption pattern creates competition with agricultural and community needs. The chemical reagents used in the classified circuit, including flocculants and pH modifiers, may also introduce potential contaminants into the environment if discharge streams are not adequately treated.

Progressive mining operations are implementing various sustainability measures to address these environmental challenges. Energy efficiency improvements include the installation of variable speed drives that optimize mill rotation based on load conditions, reducing unnecessary power consumption by up to 15%. Advanced control systems that maintain optimal pulp density and feed rates not only enhance recovery but also minimize energy waste. Some operations have begun incorporating renewable energy sources, particularly solar and wind power, to reduce the carbon intensity of their grinding circuits.

Water conservation strategies have become increasingly sophisticated, with closed-loop water systems now standard in modern operations. These systems can achieve water recycling rates exceeding 85%, significantly reducing freshwater withdrawal requirements. Advanced thickeners and filter technologies enable more efficient water recovery from tailings, while also producing drier waste material that requires less storage area and poses reduced risk of containment failure.

Grinding media selection has evolved to include more durable materials that reduce wear rates and subsequent waste generation. Some operations have implemented programs to recover and recycle worn grinding media, creating a circular materials flow that reduces both waste and raw material demand. Noise and vibration dampening technologies have also been deployed to minimize impacts on surrounding communities and wildlife.

The industry is increasingly adopting life cycle assessment methodologies to quantify the environmental footprint of ball mill operations and identify improvement opportunities. This holistic approach enables operators to make informed decisions that balance production requirements with environmental stewardship goals, supporting both regulatory compliance and corporate sustainability commitments.

Water usage represents another critical environmental concern, as ball mill circuits typically require substantial volumes for slurry formation and density control. In regions facing water scarcity, this consumption pattern creates competition with agricultural and community needs. The chemical reagents used in the classified circuit, including flocculants and pH modifiers, may also introduce potential contaminants into the environment if discharge streams are not adequately treated.

Progressive mining operations are implementing various sustainability measures to address these environmental challenges. Energy efficiency improvements include the installation of variable speed drives that optimize mill rotation based on load conditions, reducing unnecessary power consumption by up to 15%. Advanced control systems that maintain optimal pulp density and feed rates not only enhance recovery but also minimize energy waste. Some operations have begun incorporating renewable energy sources, particularly solar and wind power, to reduce the carbon intensity of their grinding circuits.

Water conservation strategies have become increasingly sophisticated, with closed-loop water systems now standard in modern operations. These systems can achieve water recycling rates exceeding 85%, significantly reducing freshwater withdrawal requirements. Advanced thickeners and filter technologies enable more efficient water recovery from tailings, while also producing drier waste material that requires less storage area and poses reduced risk of containment failure.

Grinding media selection has evolved to include more durable materials that reduce wear rates and subsequent waste generation. Some operations have implemented programs to recover and recycle worn grinding media, creating a circular materials flow that reduces both waste and raw material demand. Noise and vibration dampening technologies have also been deployed to minimize impacts on surrounding communities and wildlife.

The industry is increasingly adopting life cycle assessment methodologies to quantify the environmental footprint of ball mill operations and identify improvement opportunities. This holistic approach enables operators to make informed decisions that balance production requirements with environmental stewardship goals, supporting both regulatory compliance and corporate sustainability commitments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!