Grinding Media Wear Analysis: Sampling, Measurement, And Prediction

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Grinding Media Wear Technology Background and Objectives

Grinding media wear analysis has evolved significantly over the past several decades, transitioning from rudimentary visual inspections to sophisticated predictive modeling systems. The historical development of this field traces back to the early 20th century when mineral processing operations began implementing systematic approaches to monitor equipment degradation. Initially, wear assessment relied heavily on reactive maintenance strategies, where grinding media would only be replaced after significant performance deterioration was observed.

The technological advancement in materials science during the 1970s and 1980s marked a pivotal shift in grinding media development, introducing more wear-resistant alloys and composite materials. This period also witnessed the emergence of more structured sampling methodologies and measurement techniques, laying the groundwork for quantitative wear analysis. By the 1990s, computational capabilities had advanced sufficiently to enable preliminary predictive models based on empirical data.

Current technological trends in grinding media wear analysis focus on real-time monitoring systems, non-destructive testing methods, and machine learning algorithms for predictive maintenance. The integration of IoT sensors within grinding equipment has revolutionized data collection processes, enabling continuous monitoring rather than periodic sampling. Advanced imaging technologies, including 3D scanning and high-resolution photography, have significantly improved measurement accuracy and repeatability.

The primary objective of modern grinding media wear analysis is to optimize the operational efficiency of mineral processing operations while minimizing downtime and replacement costs. This involves developing reliable sampling protocols that accurately represent wear patterns across the entire grinding system without disrupting production. Additionally, measurement standardization remains a critical goal to ensure consistency across different operational environments and equipment types.

Predictive capabilities represent perhaps the most ambitious technological objective in this field. The development of models that can accurately forecast grinding media degradation based on operational parameters, material properties, and historical performance data would enable truly proactive maintenance scheduling. Such predictive systems aim to identify the optimal replacement timing that balances wear-related performance degradation against the costs of media replacement and operational disruption.

Environmental considerations have also emerged as an important factor in grinding media technology development. Reducing the environmental footprint of mining operations through improved media longevity and recyclability has become increasingly prioritized. This includes research into bio-compatible materials and wear-resistant coatings that minimize contamination of processed materials while maintaining operational efficiency.

The technological advancement in materials science during the 1970s and 1980s marked a pivotal shift in grinding media development, introducing more wear-resistant alloys and composite materials. This period also witnessed the emergence of more structured sampling methodologies and measurement techniques, laying the groundwork for quantitative wear analysis. By the 1990s, computational capabilities had advanced sufficiently to enable preliminary predictive models based on empirical data.

Current technological trends in grinding media wear analysis focus on real-time monitoring systems, non-destructive testing methods, and machine learning algorithms for predictive maintenance. The integration of IoT sensors within grinding equipment has revolutionized data collection processes, enabling continuous monitoring rather than periodic sampling. Advanced imaging technologies, including 3D scanning and high-resolution photography, have significantly improved measurement accuracy and repeatability.

The primary objective of modern grinding media wear analysis is to optimize the operational efficiency of mineral processing operations while minimizing downtime and replacement costs. This involves developing reliable sampling protocols that accurately represent wear patterns across the entire grinding system without disrupting production. Additionally, measurement standardization remains a critical goal to ensure consistency across different operational environments and equipment types.

Predictive capabilities represent perhaps the most ambitious technological objective in this field. The development of models that can accurately forecast grinding media degradation based on operational parameters, material properties, and historical performance data would enable truly proactive maintenance scheduling. Such predictive systems aim to identify the optimal replacement timing that balances wear-related performance degradation against the costs of media replacement and operational disruption.

Environmental considerations have also emerged as an important factor in grinding media technology development. Reducing the environmental footprint of mining operations through improved media longevity and recyclability has become increasingly prioritized. This includes research into bio-compatible materials and wear-resistant coatings that minimize contamination of processed materials while maintaining operational efficiency.

Market Demand for Advanced Wear Analysis Solutions

The global market for advanced grinding media wear analysis solutions is experiencing significant growth, driven primarily by the mining and cement industries' increasing focus on operational efficiency and cost reduction. These industries collectively spend billions annually on grinding media, with wear-related costs representing a substantial portion of their operational expenses. Recent market research indicates that optimizing grinding media performance through advanced wear analysis can reduce overall processing costs by 15-20%, creating a compelling value proposition for potential customers.

Mining operations, particularly in copper, gold, and iron ore extraction, represent the largest market segment for wear analysis solutions. With commodity price volatility putting pressure on operational margins, mining companies are increasingly investing in technologies that can extend equipment lifespan and optimize replacement schedules. The cement industry follows closely, where grinding operations account for approximately 40% of total electricity consumption, making wear optimization a critical factor in both cost control and sustainability efforts.

Regionally, Australia, Chile, Canada, and South Africa lead market demand due to their extensive mining operations, while China and India are emerging as rapidly growing markets driven by infrastructure development and industrial expansion. The market is further segmented between large-scale operations seeking comprehensive integrated solutions and smaller operations requiring more affordable, targeted analysis tools.

Current market offerings primarily consist of traditional physical measurement systems, laboratory analysis services, and emerging digital solutions. However, customer feedback reveals significant unmet needs, particularly in real-time monitoring capabilities, predictive analytics, and integration with existing plant control systems. Industry surveys show that over 70% of operations managers consider current wear analysis methods inadequate for optimizing grinding efficiency.

The market is also being shaped by broader industry trends, including the push toward automation, digital transformation, and sustainability. Environmental regulations regarding waste reduction and energy efficiency are creating additional demand for solutions that can optimize material usage and reduce the environmental footprint of grinding operations.

From a competitive standpoint, the market remains relatively fragmented, with specialized equipment manufacturers, analytical service providers, and emerging technology startups all competing for market share. This fragmentation presents opportunities for companies that can offer comprehensive, integrated solutions addressing the full spectrum of wear analysis needs.

Mining operations, particularly in copper, gold, and iron ore extraction, represent the largest market segment for wear analysis solutions. With commodity price volatility putting pressure on operational margins, mining companies are increasingly investing in technologies that can extend equipment lifespan and optimize replacement schedules. The cement industry follows closely, where grinding operations account for approximately 40% of total electricity consumption, making wear optimization a critical factor in both cost control and sustainability efforts.

Regionally, Australia, Chile, Canada, and South Africa lead market demand due to their extensive mining operations, while China and India are emerging as rapidly growing markets driven by infrastructure development and industrial expansion. The market is further segmented between large-scale operations seeking comprehensive integrated solutions and smaller operations requiring more affordable, targeted analysis tools.

Current market offerings primarily consist of traditional physical measurement systems, laboratory analysis services, and emerging digital solutions. However, customer feedback reveals significant unmet needs, particularly in real-time monitoring capabilities, predictive analytics, and integration with existing plant control systems. Industry surveys show that over 70% of operations managers consider current wear analysis methods inadequate for optimizing grinding efficiency.

The market is also being shaped by broader industry trends, including the push toward automation, digital transformation, and sustainability. Environmental regulations regarding waste reduction and energy efficiency are creating additional demand for solutions that can optimize material usage and reduce the environmental footprint of grinding operations.

From a competitive standpoint, the market remains relatively fragmented, with specialized equipment manufacturers, analytical service providers, and emerging technology startups all competing for market share. This fragmentation presents opportunities for companies that can offer comprehensive, integrated solutions addressing the full spectrum of wear analysis needs.

Current Challenges in Grinding Media Wear Assessment

Despite significant advancements in grinding technology, the assessment of grinding media wear remains plagued by several critical challenges that impede accurate analysis and prediction. One of the foremost difficulties lies in the sampling methodology, where obtaining representative samples from operational grinding mills presents considerable logistical hurdles. The harsh operating environment inside mills, characterized by high temperatures, extreme pressures, and continuous motion, makes direct sampling during operation nearly impossible without disrupting the grinding process itself.

Measurement techniques for quantifying wear also face substantial limitations. Traditional weight loss measurements, while straightforward, fail to capture the spatial distribution of wear across media surfaces. Advanced techniques such as 3D scanning and laser profilometry offer improved precision but remain costly and time-intensive, making them impractical for routine industrial monitoring. Furthermore, the irregular geometries that develop as grinding media wear progresses complicate consistent measurement protocols.

The heterogeneous nature of grinding environments introduces additional complexity. Variations in ore hardness, particle size distribution, slurry density, and chemical composition create a multivariable system that defies simplistic modeling approaches. These parameters fluctuate not only between different operations but also within the same mill over time, rendering standardized wear assessment frameworks inadequate.

Prediction models for grinding media wear suffer from significant accuracy limitations. Current models predominantly rely on empirical correlations derived from specific operational conditions, making their applicability across different milling environments questionable. Physics-based models, while theoretically more robust, struggle to incorporate the full spectrum of wear mechanisms simultaneously occurring during grinding operations, including impact wear, abrasion, corrosion, and their synergistic effects.

Data integration represents another substantial challenge. The disconnect between laboratory testing conditions and actual industrial environments creates a validation gap that undermines confidence in wear predictions. Real-time monitoring systems capable of continuously tracking media wear remain underdeveloped, with most operations still dependent on periodic inspections that provide only snapshot insights into wear progression.

Economic considerations further complicate wear assessment practices. The trade-off between assessment accuracy and operational disruption often leads to compromised sampling frequencies and measurement protocols. Additionally, the industry lacks standardized methodologies for translating wear measurements into actionable maintenance decisions and media replacement strategies, resulting in suboptimal resource utilization and unnecessary production losses.

Measurement techniques for quantifying wear also face substantial limitations. Traditional weight loss measurements, while straightforward, fail to capture the spatial distribution of wear across media surfaces. Advanced techniques such as 3D scanning and laser profilometry offer improved precision but remain costly and time-intensive, making them impractical for routine industrial monitoring. Furthermore, the irregular geometries that develop as grinding media wear progresses complicate consistent measurement protocols.

The heterogeneous nature of grinding environments introduces additional complexity. Variations in ore hardness, particle size distribution, slurry density, and chemical composition create a multivariable system that defies simplistic modeling approaches. These parameters fluctuate not only between different operations but also within the same mill over time, rendering standardized wear assessment frameworks inadequate.

Prediction models for grinding media wear suffer from significant accuracy limitations. Current models predominantly rely on empirical correlations derived from specific operational conditions, making their applicability across different milling environments questionable. Physics-based models, while theoretically more robust, struggle to incorporate the full spectrum of wear mechanisms simultaneously occurring during grinding operations, including impact wear, abrasion, corrosion, and their synergistic effects.

Data integration represents another substantial challenge. The disconnect between laboratory testing conditions and actual industrial environments creates a validation gap that undermines confidence in wear predictions. Real-time monitoring systems capable of continuously tracking media wear remain underdeveloped, with most operations still dependent on periodic inspections that provide only snapshot insights into wear progression.

Economic considerations further complicate wear assessment practices. The trade-off between assessment accuracy and operational disruption often leads to compromised sampling frequencies and measurement protocols. Additionally, the industry lacks standardized methodologies for translating wear measurements into actionable maintenance decisions and media replacement strategies, resulting in suboptimal resource utilization and unnecessary production losses.

Established Sampling and Measurement Methodologies

01 Material composition for wear-resistant grinding media

Various material compositions can be used to create wear-resistant grinding media. These include ceramic materials, metal alloys, and composite materials that offer superior hardness and durability. The selection of appropriate materials can significantly reduce wear rates during grinding operations, extending the service life of the grinding media and improving operational efficiency. These materials often incorporate elements that enhance hardness, toughness, and resistance to abrasive wear under high-stress grinding conditions.- Material composition for wear-resistant grinding media: Various material compositions are used to create wear-resistant grinding media. These include specialized alloys, ceramic materials, and composite structures that offer superior hardness and durability under grinding conditions. The materials are designed to withstand high impact forces and abrasive environments while maintaining their structural integrity over extended periods of use. These compositions often incorporate elements that enhance hardness, such as chromium, tungsten, or ceramic particles in a metal matrix.

- Structural design improvements for grinding media: Innovative structural designs can significantly reduce wear in grinding media. These designs include specialized shapes, internal reinforcements, and optimized geometries that distribute impact forces more effectively. Some designs incorporate hollow cores, layered structures, or variable density distributions to improve performance while reducing weight. The structural improvements focus on maximizing the useful life of the grinding media while maintaining or enhancing grinding efficiency.

- Surface treatment and coating technologies: Surface treatments and specialized coatings can significantly enhance the wear resistance of grinding media. These treatments include hardening processes, application of wear-resistant layers, and surface modification techniques that create a protective barrier against abrasion. Some approaches involve thermal treatments, chemical processes, or the application of advanced ceramic or metallic coatings. These surface enhancements can extend the operational life of grinding media while maintaining grinding performance.

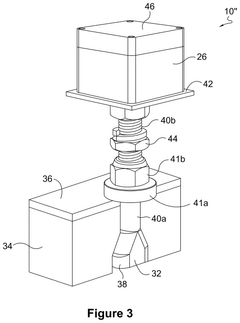

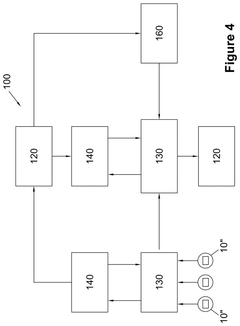

- Monitoring and measurement systems for wear detection: Advanced monitoring and measurement systems are developed to detect and track grinding media wear. These systems employ various technologies including sensors, imaging systems, and data analysis tools to provide real-time information about the condition of grinding media. By continuously monitoring wear patterns and rates, operators can optimize replacement schedules and grinding parameters. Some systems can predict remaining useful life and identify abnormal wear patterns before catastrophic failure occurs.

- Grinding process optimization to reduce media wear: Optimizing the grinding process itself can significantly reduce media wear. This includes adjustments to operational parameters such as rotation speed, media loading, and slurry composition. Advanced control systems can maintain optimal grinding conditions that minimize unnecessary impacts and abrasion. Some approaches involve staged grinding processes, specialized media segregation techniques, or modified mill designs that create more favorable grinding environments while achieving the desired particle size reduction.

02 Structural design improvements for grinding media

Innovative structural designs can enhance the wear resistance of grinding media. These designs include specialized shapes, internal reinforcements, and optimized surface geometries that distribute grinding forces more evenly. By improving the structural integrity and force distribution characteristics, these design innovations can significantly reduce wear rates and extend the operational lifespan of grinding media in various industrial applications.Expand Specific Solutions03 Surface treatment and coating technologies

Surface treatment and coating technologies can be applied to grinding media to enhance wear resistance. These treatments include hardening processes, application of wear-resistant coatings, and surface modification techniques that create a protective layer on the grinding media. These technologies can significantly improve the durability and performance of grinding media by providing an additional barrier against abrasive wear while maintaining the core structural properties of the base material.Expand Specific Solutions04 Monitoring and measurement systems for wear detection

Advanced monitoring and measurement systems can be employed to detect and track grinding media wear. These systems utilize sensors, imaging technologies, and data analysis to provide real-time information about the condition of grinding media. By enabling early detection of wear patterns, these systems allow for timely replacement or maintenance of grinding media, optimizing operational efficiency and preventing unexpected failures due to excessive wear.Expand Specific Solutions05 Specialized grinding media for specific applications

Specialized grinding media designed for specific applications can offer improved wear resistance in targeted environments. These application-specific designs consider factors such as the material being ground, operating conditions, and required fineness of the ground product. By tailoring the properties of grinding media to specific applications, wear rates can be minimized while optimizing grinding performance for particular industrial processes.Expand Specific Solutions

Leading Companies in Grinding Media and Wear Analysis

The grinding media wear analysis market is currently in a growth phase, characterized by increasing demand for predictive maintenance solutions in mining and industrial sectors. The global market size is expanding due to rising mineral processing activities and the need for operational efficiency. Technologically, the field is advancing from traditional sampling methods to sophisticated measurement and prediction techniques. Leading players like Metso Outotec Finland Oy and FLSmidth A/S are driving innovation in wear-resistant materials and monitoring systems, while companies such as Thejo Engineering and Moly-Cop USA specialize in grinding media solutions. Academic institutions including Dalian University of Technology and Northwestern Polytechnical University are contributing research advancements, while technology firms like FANUC and OMRON are integrating AI and automation capabilities to enhance wear prediction accuracy.

Metso Outotec Finland Oy

Technical Solution: Metso Outotec has developed an advanced grinding media wear analysis system that combines physical sampling techniques with digital monitoring solutions. Their approach utilizes automated sampling devices installed at strategic points in grinding circuits to collect media samples without process interruption. The company employs 3D laser scanning technology to measure volumetric loss with precision up to 0.01mm, enabling accurate wear rate calculation. Their predictive models incorporate machine learning algorithms that analyze historical wear data alongside operational parameters (mill speed, load, ore characteristics) to forecast media consumption. Metso's SmartTag RFID technology tracks individual grinding media pieces throughout their lifecycle, providing unprecedented insights into wear patterns. The system integrates with their Metso Metrics platform, allowing real-time monitoring and adjustment of grinding parameters to optimize media life while maintaining grinding efficiency.

Strengths: Comprehensive integration with existing mill control systems; extensive database of ore characteristics and their impact on media wear; ability to provide real-time recommendations for process optimization. Weaknesses: Higher implementation cost compared to traditional methods; requires significant historical data for accurate predictions; system calibration needs periodic expert intervention.

Weir Minerals Netherlands BV

Technical Solution: Weir Minerals has pioneered a comprehensive grinding media wear analysis solution centered around their proprietary Synertrex® digital ecosystem. Their approach begins with systematic sampling protocols using automated extraction mechanisms that retrieve media samples at predetermined intervals based on tonnage processed rather than time-based schedules. For measurement, they employ high-precision 3D optical scanning technology combined with weight-loss analysis to create detailed wear profiles of individual grinding media. Their predictive modeling incorporates computational fluid dynamics (CFD) simulations of the mill environment to understand impact forces and abrasion patterns. The system correlates operational parameters with wear rates using advanced statistical methods and machine learning algorithms that continuously improve through feedback loops. Weir's technology can distinguish between different wear mechanisms (impact, abrasion, corrosion) and recommend specific interventions for each. The platform integrates with their MARS (Mill Asset Resource System) to provide comprehensive mill performance optimization.

Strengths: Highly accurate differentiation between wear mechanisms; integration with mill operation controls allows for automated adjustments; extensive material science expertise informing predictive models. Weaknesses: System requires significant initial calibration period; higher complexity may require specialized training for operators; more suited to larger operations where the investment can be justified by scale.

Key Innovations in Wear Prediction Algorithms

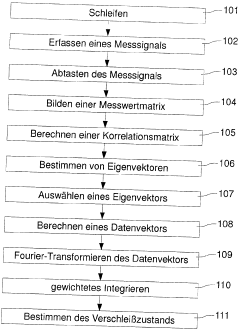

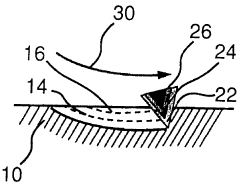

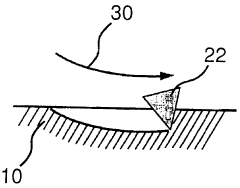

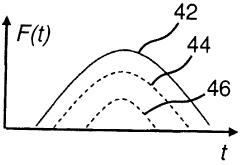

Grinding tool's wear condition detecting method, involves sampling measurement signal at number of time points, and calculating components of data vector as weighted sum of measurement values

PatentInactiveDE102008062081A1

Innovation

- A method involving the sampling of measurement signals during grinding to calculate a data vector as a weighted sum of measurement values, using eigenvectors and spectral analysis to determine the wear state of the grinding tool, allowing continuous use until the predetermined threshold is reached.

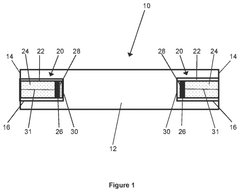

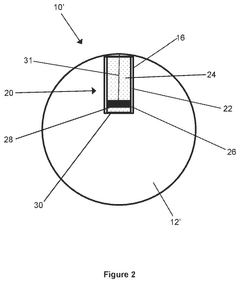

Grinding media, system and method for optimising comminution circuit

PatentActiveUS12097503B2

Innovation

- The development of freely moving grinding media equipped with sensors to measure and transmit physical characteristics such as temperature, impact, and vibration data within comminution apparatuses, enabling real-time data collection and optimization of comminution circuit processes.

Material Science Advancements for Wear-Resistant Media

Recent advancements in materials science have revolutionized the development of wear-resistant grinding media, significantly enhancing performance and longevity in industrial grinding operations. The evolution of these materials has been driven by the need to reduce operational costs associated with frequent media replacement and process inefficiencies caused by excessive wear.

High-chromium white cast iron has emerged as a leading material for grinding media due to its exceptional hardness and wear resistance. The microstructure of these alloys, characterized by chromium carbides dispersed in a martensitic matrix, provides superior protection against abrasive wear mechanisms. Recent innovations have focused on optimizing the chromium content (typically 12-30%) and the addition of molybdenum, vanadium, and titanium to enhance carbide formation and stability.

Ceramic materials represent another significant advancement, with alumina-based media demonstrating remarkable wear resistance in certain applications. Silicon nitride and zirconia-toughened alumina composites have shown particular promise, offering up to 30% longer service life compared to conventional media in laboratory tests. These materials excel in high-impact grinding environments where metallic media typically suffer accelerated wear.

Surface treatment technologies have evolved to complement base material properties. Techniques such as thermal spray coating, physical vapor deposition, and nitriding processes can create wear-resistant surface layers without compromising the mechanical integrity of the grinding media. Recent developments in nano-structured coatings have demonstrated wear rate reductions of 15-25% in field trials across various mineral processing operations.

Computational materials science has accelerated the development cycle through predictive modeling of wear behavior. Finite element analysis and molecular dynamics simulations now enable researchers to predict material performance under specific grinding conditions before physical prototyping. These models incorporate parameters such as impact energy, abrasive particle characteristics, and chemical environment to optimize material composition for specific applications.

Hybrid and composite materials represent the cutting edge of wear-resistant media development. These materials combine the beneficial properties of different material classes, such as the toughness of steel with the wear resistance of ceramics. Functionally graded materials with tailored properties across their cross-section have shown particular promise, with laboratory tests indicating potential service life improvements of 40-60% compared to homogeneous materials.

The correlation between microstructural features and wear performance has become increasingly understood, allowing for more precise material design. Parameters such as carbide size, distribution, and morphology can now be controlled during manufacturing to optimize wear resistance for specific grinding conditions and mineral types.

High-chromium white cast iron has emerged as a leading material for grinding media due to its exceptional hardness and wear resistance. The microstructure of these alloys, characterized by chromium carbides dispersed in a martensitic matrix, provides superior protection against abrasive wear mechanisms. Recent innovations have focused on optimizing the chromium content (typically 12-30%) and the addition of molybdenum, vanadium, and titanium to enhance carbide formation and stability.

Ceramic materials represent another significant advancement, with alumina-based media demonstrating remarkable wear resistance in certain applications. Silicon nitride and zirconia-toughened alumina composites have shown particular promise, offering up to 30% longer service life compared to conventional media in laboratory tests. These materials excel in high-impact grinding environments where metallic media typically suffer accelerated wear.

Surface treatment technologies have evolved to complement base material properties. Techniques such as thermal spray coating, physical vapor deposition, and nitriding processes can create wear-resistant surface layers without compromising the mechanical integrity of the grinding media. Recent developments in nano-structured coatings have demonstrated wear rate reductions of 15-25% in field trials across various mineral processing operations.

Computational materials science has accelerated the development cycle through predictive modeling of wear behavior. Finite element analysis and molecular dynamics simulations now enable researchers to predict material performance under specific grinding conditions before physical prototyping. These models incorporate parameters such as impact energy, abrasive particle characteristics, and chemical environment to optimize material composition for specific applications.

Hybrid and composite materials represent the cutting edge of wear-resistant media development. These materials combine the beneficial properties of different material classes, such as the toughness of steel with the wear resistance of ceramics. Functionally graded materials with tailored properties across their cross-section have shown particular promise, with laboratory tests indicating potential service life improvements of 40-60% compared to homogeneous materials.

The correlation between microstructural features and wear performance has become increasingly understood, allowing for more precise material design. Parameters such as carbide size, distribution, and morphology can now be controlled during manufacturing to optimize wear resistance for specific grinding conditions and mineral types.

Economic Impact of Grinding Media Lifecycle Optimization

The economic implications of grinding media wear extend far beyond the immediate replacement costs. In mining and mineral processing operations, grinding media typically accounts for 30-45% of the total operational expenditure in comminution circuits. Optimizing the lifecycle of grinding media presents a significant opportunity for cost reduction and operational efficiency improvement across the industry.

When analyzing the economic impact, it's crucial to consider the direct costs associated with media consumption. A typical large-scale mining operation may consume several thousand tons of grinding media annually, representing millions of dollars in direct procurement costs. The ability to extend media life by even 5-10% through improved wear prediction and management can translate to annual savings of $500,000-$1,000,000 for a single operation.

Beyond direct replacement costs, secondary economic impacts must be factored into the total cost equation. Unplanned downtime due to premature media failure can cost operations $10,000-$50,000 per hour in lost production. Additionally, inconsistent grinding performance resulting from suboptimal media management leads to inefficiencies in downstream processes, particularly affecting recovery rates in flotation circuits.

Energy consumption represents another significant economic consideration. Grinding operations typically account for 35-50% of a mine's total energy usage. Optimized media selection and replacement strategies can reduce energy consumption by 3-8%, delivering substantial cost savings while simultaneously reducing the operation's carbon footprint – an increasingly important factor as environmental regulations tighten globally.

The economic benefits of lifecycle optimization extend to inventory management as well. Accurate wear prediction models enable just-in-time inventory practices, reducing working capital requirements and storage costs. For multinational mining companies, this optimization across multiple sites can free up millions in capital that would otherwise be tied up in excessive grinding media inventory.

Quality considerations also play a crucial role in the economic equation. Premium grinding media may command a 15-30% price premium but often delivers superior wear resistance and performance consistency. The total cost of ownership analysis frequently demonstrates that higher initial investment yields better long-term economic outcomes through extended service life and improved process stability.

Finally, the implementation of advanced monitoring technologies for grinding media wear analysis typically shows return on investment periods of 6-18 months, with ongoing benefits accumulating throughout the operational life of the processing plant. These economic advantages make grinding media lifecycle optimization one of the most financially attractive improvement initiatives available to mineral processing operations.

When analyzing the economic impact, it's crucial to consider the direct costs associated with media consumption. A typical large-scale mining operation may consume several thousand tons of grinding media annually, representing millions of dollars in direct procurement costs. The ability to extend media life by even 5-10% through improved wear prediction and management can translate to annual savings of $500,000-$1,000,000 for a single operation.

Beyond direct replacement costs, secondary economic impacts must be factored into the total cost equation. Unplanned downtime due to premature media failure can cost operations $10,000-$50,000 per hour in lost production. Additionally, inconsistent grinding performance resulting from suboptimal media management leads to inefficiencies in downstream processes, particularly affecting recovery rates in flotation circuits.

Energy consumption represents another significant economic consideration. Grinding operations typically account for 35-50% of a mine's total energy usage. Optimized media selection and replacement strategies can reduce energy consumption by 3-8%, delivering substantial cost savings while simultaneously reducing the operation's carbon footprint – an increasingly important factor as environmental regulations tighten globally.

The economic benefits of lifecycle optimization extend to inventory management as well. Accurate wear prediction models enable just-in-time inventory practices, reducing working capital requirements and storage costs. For multinational mining companies, this optimization across multiple sites can free up millions in capital that would otherwise be tied up in excessive grinding media inventory.

Quality considerations also play a crucial role in the economic equation. Premium grinding media may command a 15-30% price premium but often delivers superior wear resistance and performance consistency. The total cost of ownership analysis frequently demonstrates that higher initial investment yields better long-term economic outcomes through extended service life and improved process stability.

Finally, the implementation of advanced monitoring technologies for grinding media wear analysis typically shows return on investment periods of 6-18 months, with ongoing benefits accumulating throughout the operational life of the processing plant. These economic advantages make grinding media lifecycle optimization one of the most financially attractive improvement initiatives available to mineral processing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!