How To Scale A Ball Mill From Lab To Production (Step-By-Step)

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ball Mill Scale-up Background and Objectives

Ball mill technology has evolved significantly since its inception in the late 19th century, transitioning from simple grinding devices to sophisticated equipment essential for various industries including mining, cement production, pharmaceuticals, and ceramics. The fundamental principle remains unchanged—utilizing rotating cylinders filled with grinding media to reduce material particle size—but advancements in design, materials, and control systems have dramatically improved efficiency and precision.

The evolution of ball mill technology has been driven by industrial demands for higher throughput, energy efficiency, and product consistency. Early ball mills were characterized by simple mechanical designs with limited control capabilities. Modern systems incorporate advanced materials for mill linings and grinding media, sophisticated automation systems, and optimized geometries that significantly enhance performance while reducing energy consumption.

Current technological trends in ball mill development focus on sustainability, digitalization, and process integration. Innovations include smart monitoring systems utilizing IoT sensors, AI-driven predictive maintenance, and designs that minimize environmental impact through reduced energy consumption and noise generation. These advancements align with global industrial sustainability initiatives and increasing regulatory pressures.

The primary objective of ball mill scale-up is to successfully transition laboratory-scale grinding processes to full production capacity while maintaining or improving product quality, consistency, and economic viability. This transition presents significant challenges due to the complex, non-linear relationships between operational parameters at different scales. Effective scale-up requires systematic methodology that accounts for mechanical, chemical, and thermodynamic factors.

Specific technical goals for successful ball mill scale-up include: establishing reliable scale-up factors for critical parameters such as mill dimensions, rotation speed, and media loading; developing predictive models that accurately forecast production-scale performance based on laboratory data; optimizing energy efficiency to minimize operational costs; ensuring consistent particle size distribution across scales; and implementing robust control systems that maintain process stability despite variations in feed characteristics.

The scale-up process must also address practical considerations including equipment footprint, integration with existing production lines, maintenance requirements, and operator training needs. A comprehensive approach to scale-up encompasses not only technical parameters but also economic factors, regulatory compliance, and long-term operational sustainability.

The evolution of ball mill technology has been driven by industrial demands for higher throughput, energy efficiency, and product consistency. Early ball mills were characterized by simple mechanical designs with limited control capabilities. Modern systems incorporate advanced materials for mill linings and grinding media, sophisticated automation systems, and optimized geometries that significantly enhance performance while reducing energy consumption.

Current technological trends in ball mill development focus on sustainability, digitalization, and process integration. Innovations include smart monitoring systems utilizing IoT sensors, AI-driven predictive maintenance, and designs that minimize environmental impact through reduced energy consumption and noise generation. These advancements align with global industrial sustainability initiatives and increasing regulatory pressures.

The primary objective of ball mill scale-up is to successfully transition laboratory-scale grinding processes to full production capacity while maintaining or improving product quality, consistency, and economic viability. This transition presents significant challenges due to the complex, non-linear relationships between operational parameters at different scales. Effective scale-up requires systematic methodology that accounts for mechanical, chemical, and thermodynamic factors.

Specific technical goals for successful ball mill scale-up include: establishing reliable scale-up factors for critical parameters such as mill dimensions, rotation speed, and media loading; developing predictive models that accurately forecast production-scale performance based on laboratory data; optimizing energy efficiency to minimize operational costs; ensuring consistent particle size distribution across scales; and implementing robust control systems that maintain process stability despite variations in feed characteristics.

The scale-up process must also address practical considerations including equipment footprint, integration with existing production lines, maintenance requirements, and operator training needs. A comprehensive approach to scale-up encompasses not only technical parameters but also economic factors, regulatory compliance, and long-term operational sustainability.

Market Analysis for Industrial Ball Mill Applications

The global ball mill market is experiencing robust growth, driven by expanding applications across multiple industries including mining, cement production, chemical processing, and pharmaceuticals. Current market valuation stands at approximately 2.3 billion USD with projections indicating a compound annual growth rate of 4.7% through 2028. This growth trajectory is primarily fueled by increasing mineral extraction activities worldwide and the rising demand for finely ground materials in various manufacturing processes.

Regional analysis reveals that Asia-Pacific dominates the industrial ball mill market, accounting for over 40% of global demand. This dominance is attributed to rapid industrialization in countries like China and India, where extensive mining operations and cement production facilities require substantial grinding equipment. North America and Europe follow as significant markets, with particular emphasis on technological advancements and efficiency improvements in ball mill designs.

The mining sector represents the largest application segment, constituting roughly 35% of the total market share. This is followed closely by the cement industry at approximately 30%, with chemical processing, ceramics, and pharmaceuticals making up the remainder. Notably, pharmaceutical applications are showing the fastest growth rate as precision grinding becomes increasingly critical for drug formulation processes.

Customer demand patterns indicate a clear shift toward energy-efficient ball mill systems that offer reduced operational costs over equipment lifetime. End-users are increasingly prioritizing mills with advanced control systems that optimize grinding parameters automatically based on feed characteristics and desired output specifications. Additionally, there is growing interest in hybrid grinding solutions that combine ball mill technology with other comminution methods to achieve superior efficiency.

Market segmentation by mill type shows that wet grinding ball mills hold a larger market share compared to dry grinding variants, particularly in mineral processing applications where slurry handling offers process advantages. However, dry grinding systems are gaining traction in cement production and certain chemical applications due to simplified material handling and reduced water consumption requirements.

Pricing trends reveal that while initial capital investment for industrial-scale ball mills remains substantial, manufacturers are increasingly focusing on total cost of ownership models that demonstrate long-term economic benefits through improved energy efficiency and reduced maintenance requirements. This shift in marketing approach is particularly evident in competitive markets where differentiation beyond basic grinding capability has become essential for equipment suppliers.

Regional analysis reveals that Asia-Pacific dominates the industrial ball mill market, accounting for over 40% of global demand. This dominance is attributed to rapid industrialization in countries like China and India, where extensive mining operations and cement production facilities require substantial grinding equipment. North America and Europe follow as significant markets, with particular emphasis on technological advancements and efficiency improvements in ball mill designs.

The mining sector represents the largest application segment, constituting roughly 35% of the total market share. This is followed closely by the cement industry at approximately 30%, with chemical processing, ceramics, and pharmaceuticals making up the remainder. Notably, pharmaceutical applications are showing the fastest growth rate as precision grinding becomes increasingly critical for drug formulation processes.

Customer demand patterns indicate a clear shift toward energy-efficient ball mill systems that offer reduced operational costs over equipment lifetime. End-users are increasingly prioritizing mills with advanced control systems that optimize grinding parameters automatically based on feed characteristics and desired output specifications. Additionally, there is growing interest in hybrid grinding solutions that combine ball mill technology with other comminution methods to achieve superior efficiency.

Market segmentation by mill type shows that wet grinding ball mills hold a larger market share compared to dry grinding variants, particularly in mineral processing applications where slurry handling offers process advantages. However, dry grinding systems are gaining traction in cement production and certain chemical applications due to simplified material handling and reduced water consumption requirements.

Pricing trends reveal that while initial capital investment for industrial-scale ball mills remains substantial, manufacturers are increasingly focusing on total cost of ownership models that demonstrate long-term economic benefits through improved energy efficiency and reduced maintenance requirements. This shift in marketing approach is particularly evident in competitive markets where differentiation beyond basic grinding capability has become essential for equipment suppliers.

Technical Challenges in Ball Mill Scale-up

Scaling up a ball mill from laboratory to production scale presents numerous technical challenges that must be systematically addressed to ensure successful implementation. The fundamental physics of ball milling changes significantly with scale, creating complex engineering problems that require careful consideration.

The primary challenge lies in maintaining grinding efficiency across different scales. Laboratory mills typically operate with volumes of 1-5 liters, while production mills may exceed 100 cubic meters. This dramatic increase affects critical parameters including ball trajectory, impact energy, and residence time distribution. Engineers often observe that the grinding efficiency per unit energy decreases as mill diameter increases, necessitating compensatory adjustments.

Heat management becomes increasingly problematic at larger scales. Production-scale mills generate substantial thermal energy that can alter material properties, cause premature wear of components, and even create safety hazards. Cooling systems must be properly scaled, considering that the heat generation increases with volume while heat dissipation capacity only increases with surface area.

Material flow patterns represent another significant challenge. The cascading and cataracting motion of grinding media behaves differently in larger mills, affecting grinding performance. Computational fluid dynamics (CFD) and discrete element method (DEM) simulations can help predict these changes, but validation remains difficult due to the opacity of the mill shell and the harsh internal environment.

Mechanical design considerations intensify with scale-up. Larger mills experience greater stress on components such as trunnions, bearings, and drive systems. The mill shell thickness must increase disproportionately with diameter to maintain structural integrity, affecting overall weight and foundation requirements. Vibration analysis becomes critical as resonance frequencies change with scale.

Control systems face increased complexity in production environments. Laboratory mills typically operate in batch mode with manual parameter adjustments, while production mills require sophisticated automated control systems to maintain consistent product quality. The response time to parameter changes increases with mill size, complicating process control strategies.

Material sampling and quality monitoring present additional challenges. Representative sampling becomes more difficult in larger mills, potentially masking process variations. Online monitoring technologies must be adapted for the harsher conditions and larger volumes of production-scale operations.

Addressing these technical challenges requires a multidisciplinary approach combining mechanical engineering, process engineering, materials science, and control systems expertise. Successful scale-up typically involves intermediate pilot-scale testing to validate models and identify unforeseen issues before committing to full production implementation.

The primary challenge lies in maintaining grinding efficiency across different scales. Laboratory mills typically operate with volumes of 1-5 liters, while production mills may exceed 100 cubic meters. This dramatic increase affects critical parameters including ball trajectory, impact energy, and residence time distribution. Engineers often observe that the grinding efficiency per unit energy decreases as mill diameter increases, necessitating compensatory adjustments.

Heat management becomes increasingly problematic at larger scales. Production-scale mills generate substantial thermal energy that can alter material properties, cause premature wear of components, and even create safety hazards. Cooling systems must be properly scaled, considering that the heat generation increases with volume while heat dissipation capacity only increases with surface area.

Material flow patterns represent another significant challenge. The cascading and cataracting motion of grinding media behaves differently in larger mills, affecting grinding performance. Computational fluid dynamics (CFD) and discrete element method (DEM) simulations can help predict these changes, but validation remains difficult due to the opacity of the mill shell and the harsh internal environment.

Mechanical design considerations intensify with scale-up. Larger mills experience greater stress on components such as trunnions, bearings, and drive systems. The mill shell thickness must increase disproportionately with diameter to maintain structural integrity, affecting overall weight and foundation requirements. Vibration analysis becomes critical as resonance frequencies change with scale.

Control systems face increased complexity in production environments. Laboratory mills typically operate in batch mode with manual parameter adjustments, while production mills require sophisticated automated control systems to maintain consistent product quality. The response time to parameter changes increases with mill size, complicating process control strategies.

Material sampling and quality monitoring present additional challenges. Representative sampling becomes more difficult in larger mills, potentially masking process variations. Online monitoring technologies must be adapted for the harsher conditions and larger volumes of production-scale operations.

Addressing these technical challenges requires a multidisciplinary approach combining mechanical engineering, process engineering, materials science, and control systems expertise. Successful scale-up typically involves intermediate pilot-scale testing to validate models and identify unforeseen issues before committing to full production implementation.

Current Scale-up Methodologies and Approaches

01 Scale-up parameters and methodologies

The scale-up of ball mills requires careful consideration of various parameters to ensure consistent performance between laboratory and industrial scales. These parameters include mill dimensions, ball size distribution, rotational speed, filling degree, and material properties. Mathematical models and scaling laws are used to predict the performance of larger mills based on smaller scale tests, with particular attention to maintaining similar grinding kinetics and energy efficiency across different scales.- Scale-up parameters and methodologies: When scaling up ball mill operations from laboratory to industrial scale, specific parameters and methodologies must be considered to maintain grinding efficiency. These include adjusting the ball size distribution, mill rotation speed, and filling ratio according to mathematical models that preserve the energy transfer mechanisms. Proper scale-up methodologies ensure that the grinding performance observed in small-scale tests can be reliably reproduced in larger industrial operations.

- Design modifications for increased capacity: Structural and mechanical design modifications are essential for successful ball mill scale-up. These include optimizing the mill shell diameter-to-length ratio, implementing advanced liner designs, and incorporating improved discharge systems. Such modifications help maintain grinding efficiency while increasing throughput capacity. Enhanced structural support systems are also necessary to handle the increased mechanical stresses associated with larger mill operations.

- Energy efficiency optimization: Energy consumption is a critical factor in ball mill scale-up, as power requirements increase exponentially with mill size. Techniques for optimizing energy efficiency include implementing variable speed drives, utilizing advanced control systems for real-time adjustment of operational parameters, and designing specialized grinding media. These approaches help minimize energy consumption while maintaining product quality and throughput in scaled-up operations.

- Material handling and feed systems: Scaling up ball mill operations requires proportional enhancement of material handling and feed systems. This includes designing appropriate feed chutes, implementing controlled feeding mechanisms, and developing efficient material transport systems. Advanced feed distribution systems ensure uniform material presentation to the grinding media, which is crucial for maintaining product quality consistency when operating at increased capacities.

- Process control and monitoring systems: Advanced process control and monitoring systems are essential for successful ball mill scale-up. These include acoustic monitoring for mill fill level detection, load cells for weight measurement, and sophisticated software algorithms for real-time process optimization. Implementation of digital twins and predictive maintenance systems helps maintain operational stability and product quality consistency in scaled-up operations, while reducing downtime and maintenance costs.

02 Energy efficiency optimization in scaled-up ball mills

When scaling up ball mills, energy efficiency becomes a critical factor. Techniques to optimize energy consumption include adjusting the ball charge composition, optimizing mill speed relative to critical speed, and implementing advanced control systems. The relationship between power draw and grinding efficiency must be carefully balanced to ensure that the scaled-up mill operates at optimal energy efficiency while maintaining product quality specifications.Expand Specific Solutions03 Material feed characteristics and control systems

The characteristics of the feed material significantly impact ball mill scale-up success. Factors such as hardness, moisture content, particle size distribution, and feed rate must be carefully controlled when transitioning to larger mills. Advanced control systems incorporating real-time monitoring of mill load, product fineness, and throughput help maintain consistent operation in scaled-up ball mills, with automated adjustments to compensate for variations in feed material properties.Expand Specific Solutions04 Mechanical design considerations for larger ball mills

Scaling up ball mills introduces significant mechanical design challenges. Larger mills require reinforced structures to handle increased loads, specialized bearing designs to support heavier components, and more robust drive systems. The liner design must be optimized to withstand higher impact forces while promoting efficient grinding action. Structural resonance and vibration issues become more pronounced at larger scales and must be addressed through proper foundation design and dynamic analysis.Expand Specific Solutions05 Product quality consistency across scales

Maintaining consistent product quality when scaling up ball mills requires careful attention to grinding media selection, residence time distribution, and classification efficiency. The particle size distribution, surface properties, and mineral liberation characteristics must remain consistent despite the change in scale. Techniques such as compartmentalization, modified liner designs, and optimized ball size distributions help ensure that the scaled-up mill produces material with properties equivalent to those achieved in smaller scale operations.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The ball mill scaling landscape is currently in a mature phase with established methodologies, though continuous innovation persists. The global market is substantial, estimated at over $2 billion, driven by mining, cement, and chemical processing industries. Technologically, companies demonstrate varying maturity levels: China National Building Material Group and Hefei Cement Research & Design Institute represent advanced expertise with comprehensive scaling solutions, while CNBM (Hefei) Powder Technology Equipment specializes in industrial-scale implementation with 60+ years of experience. Academic institutions like Beijing University of Chemical Technology and Shandong University contribute fundamental research, creating a competitive ecosystem balancing established methodologies with ongoing innovation in efficiency and sustainability.

Hefei Cement Research & Design Institute Corp. Ltd.

Technical Solution: Hefei Cement Research & Design Institute has pioneered a systematic ball mill scale-up methodology specifically tailored for cement production. Their approach begins with laboratory characterization using specialized grinding tests to determine material-specific grinding parameters. The institute has developed proprietary mathematical models that correlate lab-scale grinding efficiency with production-scale performance, accounting for factors such as mill diameter, length-to-diameter ratio, and liner configurations. Their scale-up process incorporates a three-stage validation approach: first using bench-scale mills (5-50kg capacity), then pilot plants (1-5 tons/hour), before full production implementation. A key innovation in their methodology is the "dynamic similarity principle" which maintains consistent energy distribution patterns across different mill sizes. The institute has documented success in scaling mills from laboratory (10kg batch) to production capacities exceeding 150 tons/hour while achieving energy efficiency improvements of 15-20% compared to traditional scaling methods.

Strengths: Highly specialized expertise in cement grinding applications with proven success in numerous industrial implementations. Their three-stage validation approach significantly reduces scale-up risks and optimization time. Weaknesses: Their methodology is heavily focused on cement materials and may require substantial modification for applications involving materials with significantly different grinding characteristics or requiring finer particle specifications.

China National Building Material Group Co., Ltd.

Technical Solution: China National Building Material Group (CNBM) has developed a comprehensive ball mill scaling methodology that integrates digital simulation with physical testing. Their approach begins with laboratory characterization of material grindability using Bond Work Index tests and batch grinding studies to establish baseline parameters. For scale-up, CNBM employs proprietary computational models that account for mill geometry, grinding media selection, and material flow dynamics. Their process involves creating dimensionless scaling factors based on power intensity, residence time distribution, and breakage kinetics to maintain consistent product quality across different scales. CNBM's methodology incorporates real-time monitoring systems with advanced sensors to track critical parameters during scale-up, allowing for continuous optimization. The company has successfully implemented this approach in numerous cement and building material production facilities, achieving production capacities of up to 200 tons per hour while maintaining precise particle size distribution.

Strengths: Extensive practical experience in cement and building materials industries provides CNBM with robust empirical data for accurate scaling predictions. Their integrated digital-physical approach minimizes scale-up risks. Weaknesses: Their methodology is heavily optimized for mineral processing and may require significant adaptation for pharmaceutical or specialty chemical applications where material properties differ substantially.

Critical Parameters and Scale-up Equations

An EDEM-based optimization method for mining ball mill working parameters

PatentActiveCN113392478B

Innovation

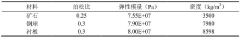

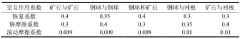

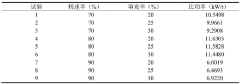

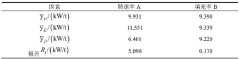

- EDEM discrete element simulation software was used to establish a three-dimensional model of the ball mill, set material properties and interaction parameters, optimize the design of rotation rate and filling rate, and use the control variable method and range method to analyze the grinding efficiency under different parameters to determine the optimal Excellent parameter matching.

Method for calculating the ball diameter of grinding balls of ball mill

PatentActiveZA202308016B

Innovation

- A method that calculates optimal ball diameter based on ore hardness characteristics and particle size analysis of feed and discharge materials, improving grinding efficiency.

- Determination of weight ratio of different ball diameters according to the weight ratio of grouped particle sizes, enabling customized ball charge composition.

- Reduction of over-grinding phenomenon through precise ball diameter selection, resulting in power and grinding media consumption savings.

Energy Efficiency Considerations in Production-Scale Mills

Energy efficiency represents a critical factor in the successful scaling of ball mills from laboratory to production environments. As production-scale operations consume significantly more power, optimizing energy usage becomes essential for both economic viability and environmental sustainability. Modern ball mill designs incorporate various energy-saving features, including improved liner configurations that maximize grinding efficiency while minimizing power consumption. These advanced liners can reduce energy requirements by 10-15% compared to traditional designs.

Variable speed drives (VSDs) offer another substantial opportunity for energy optimization, allowing operators to adjust mill speed according to feed characteristics and desired product specifications. This dynamic control capability can yield energy savings of 15-30% compared to fixed-speed operations, particularly during periods of varying throughput or when processing materials with different hardness indices.

Load monitoring systems play a crucial role in maintaining optimal energy efficiency by continuously measuring the mill's filling level and adjusting operational parameters accordingly. When integrated with automated control systems, these monitoring solutions prevent overloading scenarios that typically result in energy waste and reduced grinding efficiency. Studies indicate that maintaining optimal ball charge levels can improve energy efficiency by up to 20%.

Advanced grinding media selection represents another significant factor in energy optimization. High-density ceramic or composite media can increase grinding efficiency while reducing the energy required per ton of processed material. The shape, size distribution, and material composition of grinding media should be carefully engineered to match specific production requirements, potentially reducing energy consumption by 10-25% compared to standard steel balls.

Heat recovery systems present an emerging opportunity for enhancing overall energy efficiency. The considerable heat generated during large-scale milling operations can be captured and repurposed for preheating feed materials or supporting other facility processes. Implementation of comprehensive heat recovery systems has demonstrated potential energy savings of 5-15% in production environments.

Predictive maintenance strategies, supported by real-time monitoring and machine learning algorithms, enable operators to identify energy efficiency deviations before they significantly impact operational costs. By detecting worn liners, suboptimal ball charges, or mechanical issues early, facilities can maintain peak energy efficiency throughout the equipment lifecycle, avoiding the 5-30% efficiency losses commonly associated with degraded mill components.

Variable speed drives (VSDs) offer another substantial opportunity for energy optimization, allowing operators to adjust mill speed according to feed characteristics and desired product specifications. This dynamic control capability can yield energy savings of 15-30% compared to fixed-speed operations, particularly during periods of varying throughput or when processing materials with different hardness indices.

Load monitoring systems play a crucial role in maintaining optimal energy efficiency by continuously measuring the mill's filling level and adjusting operational parameters accordingly. When integrated with automated control systems, these monitoring solutions prevent overloading scenarios that typically result in energy waste and reduced grinding efficiency. Studies indicate that maintaining optimal ball charge levels can improve energy efficiency by up to 20%.

Advanced grinding media selection represents another significant factor in energy optimization. High-density ceramic or composite media can increase grinding efficiency while reducing the energy required per ton of processed material. The shape, size distribution, and material composition of grinding media should be carefully engineered to match specific production requirements, potentially reducing energy consumption by 10-25% compared to standard steel balls.

Heat recovery systems present an emerging opportunity for enhancing overall energy efficiency. The considerable heat generated during large-scale milling operations can be captured and repurposed for preheating feed materials or supporting other facility processes. Implementation of comprehensive heat recovery systems has demonstrated potential energy savings of 5-15% in production environments.

Predictive maintenance strategies, supported by real-time monitoring and machine learning algorithms, enable operators to identify energy efficiency deviations before they significantly impact operational costs. By detecting worn liners, suboptimal ball charges, or mechanical issues early, facilities can maintain peak energy efficiency throughout the equipment lifecycle, avoiding the 5-30% efficiency losses commonly associated with degraded mill components.

Quality Control Systems for Consistent Grinding Performance

Quality control systems are essential for maintaining consistent grinding performance when scaling ball mill operations from laboratory to production scale. These systems must be designed to monitor and control critical process parameters that directly impact the grinding efficiency and product quality. Real-time monitoring technologies, including particle size analyzers, load cells, and acoustic sensors, provide continuous feedback on mill performance. These instruments detect variations in grinding conditions, allowing operators to make immediate adjustments to maintain optimal grinding parameters.

Statistical process control (SPC) methodologies play a crucial role in quality assurance for ball mill operations. By establishing control charts for key parameters such as particle size distribution, grinding time, and energy consumption, manufacturers can identify process deviations before they result in quality issues. Upper and lower control limits must be established based on laboratory validation studies and early production runs to define acceptable operating ranges.

Automated sampling systems represent another vital component of quality control infrastructure. These systems should be strategically positioned to collect representative samples at various stages of the grinding process. Modern sampling technologies can be integrated with laboratory information management systems (LIMS) to streamline data collection and analysis, enabling faster response to quality deviations.

Calibration protocols for all measurement instruments must be rigorously maintained to ensure data accuracy. Regular calibration schedules should be established based on equipment specifications and operational conditions. Documentation of calibration activities is essential for regulatory compliance and process validation, particularly in industries with strict quality requirements such as pharmaceuticals and advanced materials manufacturing.

Operator training programs constitute a fundamental aspect of quality control systems. Personnel must be thoroughly trained on standard operating procedures, equipment functionality, and troubleshooting techniques. Comprehensive training ensures consistent application of quality control measures across different production shifts and reduces operator-dependent variability in mill performance.

Feedback loops between quality control data and process parameters enable continuous process optimization. Advanced control systems can automatically adjust mill operating conditions based on quality measurements, maintaining consistent grinding performance despite variations in feed material properties. These adaptive control strategies are particularly valuable when processing materials with inherent variability in hardness or composition.

Documentation and traceability systems complete the quality control framework. Each production batch should be fully documented with processing parameters, quality measurements, and any process adjustments made during operation. This information provides valuable historical data for process improvement initiatives and facilitates root cause analysis when quality deviations occur.

Statistical process control (SPC) methodologies play a crucial role in quality assurance for ball mill operations. By establishing control charts for key parameters such as particle size distribution, grinding time, and energy consumption, manufacturers can identify process deviations before they result in quality issues. Upper and lower control limits must be established based on laboratory validation studies and early production runs to define acceptable operating ranges.

Automated sampling systems represent another vital component of quality control infrastructure. These systems should be strategically positioned to collect representative samples at various stages of the grinding process. Modern sampling technologies can be integrated with laboratory information management systems (LIMS) to streamline data collection and analysis, enabling faster response to quality deviations.

Calibration protocols for all measurement instruments must be rigorously maintained to ensure data accuracy. Regular calibration schedules should be established based on equipment specifications and operational conditions. Documentation of calibration activities is essential for regulatory compliance and process validation, particularly in industries with strict quality requirements such as pharmaceuticals and advanced materials manufacturing.

Operator training programs constitute a fundamental aspect of quality control systems. Personnel must be thoroughly trained on standard operating procedures, equipment functionality, and troubleshooting techniques. Comprehensive training ensures consistent application of quality control measures across different production shifts and reduces operator-dependent variability in mill performance.

Feedback loops between quality control data and process parameters enable continuous process optimization. Advanced control systems can automatically adjust mill operating conditions based on quality measurements, maintaining consistent grinding performance despite variations in feed material properties. These adaptive control strategies are particularly valuable when processing materials with inherent variability in hardness or composition.

Documentation and traceability systems complete the quality control framework. Each production batch should be fully documented with processing parameters, quality measurements, and any process adjustments made during operation. This information provides valuable historical data for process improvement initiatives and facilitates root cause analysis when quality deviations occur.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!