Battery management systems optimization in mild hybrid vehicles

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Evolution in HEVs

The evolution of Battery Management Systems (BMS) in Hybrid Electric Vehicles (HEVs) has been a critical factor in the advancement of automotive technology. Initially, BMS in early HEVs were relatively simple, focusing primarily on basic battery monitoring and protection functions. These systems were designed to ensure safe operation and prevent overcharging or over-discharging of the battery pack.

As HEV technology progressed, BMS capabilities expanded significantly. The introduction of more sophisticated battery chemistries, particularly lithium-ion batteries, necessitated more complex management systems. These advanced BMS incorporated features such as cell balancing, state-of-charge (SOC) estimation, and state-of-health (SOH) monitoring. These improvements allowed for more efficient utilization of battery capacity and extended battery life.

The advent of mild hybrid vehicles brought about a new set of challenges and opportunities for BMS evolution. Mild hybrids, which typically use smaller battery packs and lower voltage systems compared to full hybrids, required BMS that could operate efficiently within these constraints. This led to the development of more compact and cost-effective BMS solutions, optimized for the specific needs of mild hybrid architectures.

One significant advancement in BMS for mild hybrids has been the integration of more accurate SOC and SOH estimation algorithms. These algorithms utilize advanced modeling techniques and machine learning to provide more precise predictions of battery performance and longevity. This has enabled automakers to optimize battery usage, improve fuel efficiency, and extend the overall lifespan of the battery pack.

Another key area of BMS evolution in mild hybrids has been the improvement of thermal management systems. As mild hybrid vehicles often operate in start-stop conditions and experience frequent charge-discharge cycles, effective thermal management is crucial for maintaining battery performance and longevity. Modern BMS in mild hybrids incorporate sophisticated thermal modeling and control strategies to ensure optimal battery temperature under various operating conditions.

The integration of BMS with other vehicle systems has also been a significant trend in mild hybrid vehicles. Advanced BMS now communicate seamlessly with the vehicle's powertrain control unit, energy management system, and other onboard systems. This integration allows for more holistic energy management strategies, optimizing the balance between electric and combustion power sources to maximize efficiency and performance.

Looking forward, the evolution of BMS in mild hybrid vehicles is expected to continue, with a focus on further optimization and integration. Future BMS are likely to incorporate more advanced predictive capabilities, leveraging big data and artificial intelligence to anticipate battery behavior and adapt management strategies in real-time. Additionally, as mild hybrid systems become more prevalent across various vehicle segments, BMS will need to be increasingly adaptable and scalable to meet diverse requirements.

As HEV technology progressed, BMS capabilities expanded significantly. The introduction of more sophisticated battery chemistries, particularly lithium-ion batteries, necessitated more complex management systems. These advanced BMS incorporated features such as cell balancing, state-of-charge (SOC) estimation, and state-of-health (SOH) monitoring. These improvements allowed for more efficient utilization of battery capacity and extended battery life.

The advent of mild hybrid vehicles brought about a new set of challenges and opportunities for BMS evolution. Mild hybrids, which typically use smaller battery packs and lower voltage systems compared to full hybrids, required BMS that could operate efficiently within these constraints. This led to the development of more compact and cost-effective BMS solutions, optimized for the specific needs of mild hybrid architectures.

One significant advancement in BMS for mild hybrids has been the integration of more accurate SOC and SOH estimation algorithms. These algorithms utilize advanced modeling techniques and machine learning to provide more precise predictions of battery performance and longevity. This has enabled automakers to optimize battery usage, improve fuel efficiency, and extend the overall lifespan of the battery pack.

Another key area of BMS evolution in mild hybrids has been the improvement of thermal management systems. As mild hybrid vehicles often operate in start-stop conditions and experience frequent charge-discharge cycles, effective thermal management is crucial for maintaining battery performance and longevity. Modern BMS in mild hybrids incorporate sophisticated thermal modeling and control strategies to ensure optimal battery temperature under various operating conditions.

The integration of BMS with other vehicle systems has also been a significant trend in mild hybrid vehicles. Advanced BMS now communicate seamlessly with the vehicle's powertrain control unit, energy management system, and other onboard systems. This integration allows for more holistic energy management strategies, optimizing the balance between electric and combustion power sources to maximize efficiency and performance.

Looking forward, the evolution of BMS in mild hybrid vehicles is expected to continue, with a focus on further optimization and integration. Future BMS are likely to incorporate more advanced predictive capabilities, leveraging big data and artificial intelligence to anticipate battery behavior and adapt management strategies in real-time. Additionally, as mild hybrid systems become more prevalent across various vehicle segments, BMS will need to be increasingly adaptable and scalable to meet diverse requirements.

Market Trends for MHEVs

The market for mild hybrid electric vehicles (MHEVs) has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent emissions regulations worldwide. This trend is expected to continue as automakers seek cost-effective solutions to meet fuel efficiency standards and reduce carbon emissions.

In the passenger car segment, MHEVs have gained traction as a bridge technology between conventional internal combustion engine vehicles and full hybrids or battery electric vehicles. Major automotive markets, including Europe, China, and North America, have shown strong adoption rates for MHEVs. The European market, in particular, has seen rapid growth due to the implementation of stricter CO2 emissions targets.

The commercial vehicle sector is also embracing MHEV technology, with increasing applications in light commercial vehicles, trucks, and buses. This adoption is driven by the need for improved fuel economy and reduced operating costs in fleet operations. The construction and agricultural equipment industries are exploring MHEV solutions to enhance the efficiency of their machinery while meeting emissions standards.

Market analysts project that the global MHEV market will continue to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is supported by advancements in battery technology, power electronics, and electric motor designs, which are making MHEV systems more efficient and cost-effective.

The Asia-Pacific region is expected to dominate the MHEV market, with China leading in terms of production and adoption. European countries, particularly Germany and France, are also significant players in the MHEV market, driven by supportive government policies and consumer demand for more fuel-efficient vehicles.

Key market trends include the integration of more powerful electric motors and higher voltage systems in MHEVs, enabling extended electric-only operation and improved fuel savings. There is also a growing focus on developing standardized MHEV architectures to reduce costs and simplify manufacturing processes across different vehicle models.

The competitive landscape of the MHEV market is characterized by collaborations between automotive OEMs and technology suppliers to develop innovative MHEV solutions. Major players are investing in research and development to enhance battery management systems, improve energy recovery efficiency, and optimize the integration of electric components with conventional powertrains.

As battery costs continue to decline and energy density improves, the line between MHEVs and full hybrids is becoming increasingly blurred. This trend is leading to the development of more sophisticated MHEV systems that offer enhanced electric driving capabilities while maintaining cost advantages over full hybrid systems.

In the passenger car segment, MHEVs have gained traction as a bridge technology between conventional internal combustion engine vehicles and full hybrids or battery electric vehicles. Major automotive markets, including Europe, China, and North America, have shown strong adoption rates for MHEVs. The European market, in particular, has seen rapid growth due to the implementation of stricter CO2 emissions targets.

The commercial vehicle sector is also embracing MHEV technology, with increasing applications in light commercial vehicles, trucks, and buses. This adoption is driven by the need for improved fuel economy and reduced operating costs in fleet operations. The construction and agricultural equipment industries are exploring MHEV solutions to enhance the efficiency of their machinery while meeting emissions standards.

Market analysts project that the global MHEV market will continue to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is supported by advancements in battery technology, power electronics, and electric motor designs, which are making MHEV systems more efficient and cost-effective.

The Asia-Pacific region is expected to dominate the MHEV market, with China leading in terms of production and adoption. European countries, particularly Germany and France, are also significant players in the MHEV market, driven by supportive government policies and consumer demand for more fuel-efficient vehicles.

Key market trends include the integration of more powerful electric motors and higher voltage systems in MHEVs, enabling extended electric-only operation and improved fuel savings. There is also a growing focus on developing standardized MHEV architectures to reduce costs and simplify manufacturing processes across different vehicle models.

The competitive landscape of the MHEV market is characterized by collaborations between automotive OEMs and technology suppliers to develop innovative MHEV solutions. Major players are investing in research and development to enhance battery management systems, improve energy recovery efficiency, and optimize the integration of electric components with conventional powertrains.

As battery costs continue to decline and energy density improves, the line between MHEVs and full hybrids is becoming increasingly blurred. This trend is leading to the development of more sophisticated MHEV systems that offer enhanced electric driving capabilities while maintaining cost advantages over full hybrid systems.

BMS Challenges in MHEVs

Battery management systems (BMS) in mild hybrid electric vehicles (MHEVs) face unique challenges due to the specific operational characteristics and requirements of these vehicles. One of the primary challenges is the need for rapid and accurate state estimation. MHEVs frequently switch between electric and combustion engine power, requiring the BMS to quickly assess the battery's state of charge (SOC) and state of health (SOH) to ensure optimal performance and longevity.

The dynamic nature of MHEV operation also presents challenges in thermal management. The frequent charge and discharge cycles, coupled with varying power demands, can lead to significant heat generation. The BMS must effectively monitor and regulate battery temperature to prevent overheating and maintain efficiency. This is particularly challenging in compact MHEV designs where space for cooling systems is limited.

Power management is another critical challenge for BMS in MHEVs. The system must balance the power distribution between the electric motor and the internal combustion engine, optimizing for fuel efficiency while meeting performance demands. This requires sophisticated algorithms that can adapt to different driving conditions and user preferences in real-time.

Durability and lifespan management pose significant challenges for BMS in MHEVs. The frequent cycling and high power demands can accelerate battery degradation. The BMS must implement strategies to mitigate this wear and tear, such as intelligent charge/discharge protocols and adaptive usage patterns based on driving conditions.

Integration with other vehicle systems is a complex challenge for MHEV battery management. The BMS must communicate seamlessly with the engine control unit, transmission control, and other onboard systems to ensure harmonious operation. This requires robust communication protocols and system architecture that can handle high-speed data exchange without latency.

Safety management is paramount in MHEV battery systems. The BMS must continuously monitor for potential hazards such as overcharging, over-discharging, or internal short circuits. Implementing fail-safe mechanisms and emergency shutdown procedures in the compact and integrated MHEV environment presents unique design challenges.

Lastly, cost optimization remains a significant challenge for BMS in MHEVs. Manufacturers aim to offer the benefits of hybrid technology at a competitive price point. This necessitates the development of cost-effective BMS solutions that do not compromise on performance or safety, often requiring innovative approaches to sensor technology, computational efficiency, and system integration.

The dynamic nature of MHEV operation also presents challenges in thermal management. The frequent charge and discharge cycles, coupled with varying power demands, can lead to significant heat generation. The BMS must effectively monitor and regulate battery temperature to prevent overheating and maintain efficiency. This is particularly challenging in compact MHEV designs where space for cooling systems is limited.

Power management is another critical challenge for BMS in MHEVs. The system must balance the power distribution between the electric motor and the internal combustion engine, optimizing for fuel efficiency while meeting performance demands. This requires sophisticated algorithms that can adapt to different driving conditions and user preferences in real-time.

Durability and lifespan management pose significant challenges for BMS in MHEVs. The frequent cycling and high power demands can accelerate battery degradation. The BMS must implement strategies to mitigate this wear and tear, such as intelligent charge/discharge protocols and adaptive usage patterns based on driving conditions.

Integration with other vehicle systems is a complex challenge for MHEV battery management. The BMS must communicate seamlessly with the engine control unit, transmission control, and other onboard systems to ensure harmonious operation. This requires robust communication protocols and system architecture that can handle high-speed data exchange without latency.

Safety management is paramount in MHEV battery systems. The BMS must continuously monitor for potential hazards such as overcharging, over-discharging, or internal short circuits. Implementing fail-safe mechanisms and emergency shutdown procedures in the compact and integrated MHEV environment presents unique design challenges.

Lastly, cost optimization remains a significant challenge for BMS in MHEVs. Manufacturers aim to offer the benefits of hybrid technology at a competitive price point. This necessitates the development of cost-effective BMS solutions that do not compromise on performance or safety, often requiring innovative approaches to sensor technology, computational efficiency, and system integration.

Current BMS Solutions

01 Thermal management optimization

Battery Management Systems (BMS) can be optimized by improving thermal management strategies. This includes advanced cooling systems, temperature monitoring, and heat distribution control to maintain optimal battery performance and longevity. Efficient thermal management helps prevent overheating, extends battery life, and ensures safe operation under various conditions.- Thermal management optimization: Battery Management Systems (BMS) can be optimized by improving thermal management strategies. This includes advanced cooling systems, temperature monitoring, and heat distribution control to maintain optimal battery performance and longevity. Efficient thermal management helps prevent overheating, extends battery life, and ensures safe operation under various conditions.

- State of charge (SOC) and state of health (SOH) estimation: Accurate estimation of battery state of charge and state of health is crucial for BMS optimization. Advanced algorithms and machine learning techniques can be employed to improve the precision of these estimations. This enables better power management, extends battery life, and enhances overall system efficiency.

- Cell balancing techniques: Optimizing cell balancing within battery packs is essential for BMS performance. Advanced balancing algorithms and hardware solutions can be implemented to ensure uniform charge distribution among cells. This helps maximize capacity utilization, prolongs battery life, and improves overall system reliability.

- Predictive maintenance and fault detection: Implementing predictive maintenance and fault detection capabilities in BMS can significantly optimize system performance. This involves using data analytics, machine learning, and sensor technologies to anticipate potential issues before they occur. Such proactive approaches can reduce downtime, extend battery life, and improve overall system reliability.

- Energy management and power distribution: Optimizing energy management and power distribution strategies within BMS can enhance overall system efficiency. This includes implementing advanced algorithms for load balancing, power routing, and demand response. Such optimizations can lead to improved energy utilization, extended battery life, and better integration with renewable energy sources.

02 State of charge (SOC) and state of health (SOH) estimation

Accurate estimation of battery state of charge and state of health is crucial for BMS optimization. Advanced algorithms and machine learning techniques can be employed to improve the precision of SOC and SOH predictions. This enables better power management, extends battery life, and enhances overall system efficiency.Expand Specific Solutions03 Cell balancing techniques

Optimizing cell balancing methods within a battery pack is essential for BMS improvement. Advanced balancing algorithms can ensure uniform charge distribution among cells, prevent overcharging or undercharging, and maximize the overall capacity utilization of the battery pack. This leads to improved performance and extended battery life.Expand Specific Solutions04 Predictive maintenance and fault detection

Implementing predictive maintenance and fault detection systems can significantly optimize BMS performance. By utilizing data analytics and machine learning algorithms, potential issues can be identified before they become critical. This proactive approach reduces downtime, improves safety, and extends the overall lifespan of the battery system.Expand Specific Solutions05 Energy management and power distribution

Optimizing energy management and power distribution strategies within BMS can lead to improved overall system efficiency. This includes intelligent charging and discharging algorithms, load balancing techniques, and adaptive power management based on usage patterns and environmental conditions. Such optimizations can result in extended battery life and enhanced performance of the entire system.Expand Specific Solutions

MHEV BMS Key Players

The battery management systems optimization in mild hybrid vehicles market is in a growth phase, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. The market size is expanding rapidly, with major automotive manufacturers and suppliers investing heavily in this technology. Companies like AUDI AG, Toyota Motor Corp., and Renault SA are leading the way in developing advanced battery management systems for mild hybrid vehicles. The technology is maturing quickly, with firms such as Samsung SDI Co., Ltd. and Robert Bosch GmbH contributing significant innovations. However, there is still room for improvement and optimization, as evidenced by ongoing research and development efforts from companies like BYD Co., Ltd. and Hyundai Motor Co., Ltd.

AUDI AG

Technical Solution: Audi's Battery Management System for mild hybrid vehicles focuses on seamless integration with the vehicle's powertrain for enhanced performance and efficiency. Their system utilizes a predictive energy management strategy that takes into account route information, traffic conditions, and driving style to optimize battery usage[7]. Audi's BMS incorporates a high-precision voltage and current measurement system that allows for more accurate state of charge estimation, enabling better utilization of the battery's capacity[9]. The system also features an advanced thermal management solution that uses waste heat from the engine to maintain optimal battery temperature, improving overall system efficiency[11].

Strengths: Highly integrated with vehicle systems, precise battery state estimation, and efficient thermal management. Weaknesses: Reliance on external data for optimal performance may limit effectiveness in areas with poor connectivity.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a unique Battery Management System for their mild hybrid vehicles, focusing on maximizing energy recuperation and minimizing fuel consumption. Their system employs a dual-mode operation strategy that switches between series and parallel hybrid modes based on driving conditions[2]. Toyota's BMS incorporates machine learning algorithms that adapt to individual driving patterns over time, optimizing energy usage for each specific user[4]. The system also features a thermal management solution that maintains optimal battery temperature, even in extreme weather conditions, ensuring consistent performance and longevity[6].

Strengths: Personalized energy optimization, excellent thermal management, and proven reliability. Weaknesses: May require longer learning periods to achieve optimal performance for individual users.

BMS Innovations for MHEVs

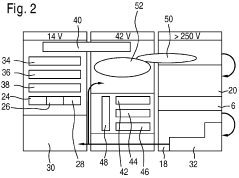

LDC-integrated battery management device and method for 48v mild hybrid system

PatentPendingEP3848226A1

Innovation

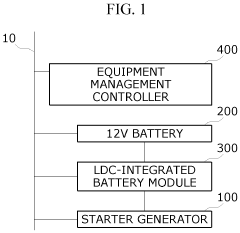

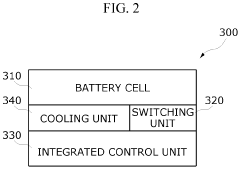

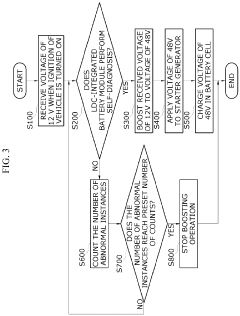

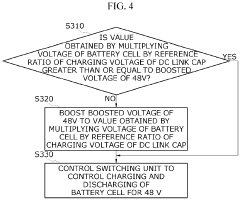

- An LDC-integrated battery management device that integrates the 48V LDC and battery management system under a single electronic control unit, allowing for unified control and removal of pre-charging relays and resistors, enabling self-diagnosis and voltage conversion from 12V to 48V for the battery cell and MHSG.

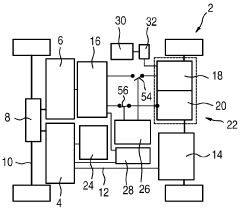

Hybrid-driven motor vehicle and method for operating said vehicle

PatentWO2007000362A1

Innovation

- The use of two distinct batteries - an energy-optimized NiMH battery with thick electrode plates for energy storage and a performance-optimized supercapacitor battery with a large electrode area - allows for optimized energy and power delivery, with a battery controller managing which battery is connected to the electric machine based on operating conditions to minimize stress and extend service life.

MHEV Emissions Regulations

Emissions regulations for Mild Hybrid Electric Vehicles (MHEVs) have become increasingly stringent in recent years, driving the need for more advanced battery management systems (BMS) optimization. These regulations aim to reduce greenhouse gas emissions and improve overall vehicle efficiency, particularly in urban environments where MHEVs can offer significant benefits.

The European Union has been at the forefront of implementing strict emissions standards for vehicles, including MHEVs. The Euro 6d standard, introduced in 2020, sets limits on various pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These regulations have pushed manufacturers to develop more sophisticated BMS solutions to maximize the efficiency of the hybrid powertrain and minimize emissions.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind MHEV development. These standards require automakers to achieve specific fleet-wide fuel economy targets, which has led to increased adoption of mild hybrid technologies. The Environmental Protection Agency (EPA) has also implemented emissions standards that align with CAFE requirements, further emphasizing the importance of optimized BMS in MHEVs.

China, the world's largest automotive market, has introduced its own set of emissions regulations for MHEVs. The China 6 standard, implemented in phases starting from 2019, imposes strict limits on pollutants and fuel consumption. This has spurred rapid development in BMS technology among Chinese automakers and suppliers, as they seek to meet these challenging requirements.

The impact of these regulations on BMS optimization in MHEVs has been significant. Manufacturers have been compelled to develop more advanced control algorithms that can precisely manage the interaction between the internal combustion engine and the electric motor. This includes optimizing energy recuperation during braking, improving start-stop functionality, and enhancing overall powertrain efficiency.

Furthermore, emissions regulations have led to the integration of more sophisticated sensors and monitoring systems in MHEVs. These systems provide real-time data on vehicle performance and emissions, allowing the BMS to make dynamic adjustments to optimize efficiency and minimize pollutant output. This has resulted in the development of predictive control strategies that can anticipate driving conditions and adjust the powertrain accordingly.

As emissions regulations continue to evolve, the role of BMS optimization in MHEVs will become even more critical. Future standards are expected to focus on lifecycle emissions, including the production and disposal of batteries. This will likely drive further innovation in BMS technology, with a focus on extending battery life, improving thermal management, and enhancing overall system efficiency to meet increasingly stringent regulatory requirements.

The European Union has been at the forefront of implementing strict emissions standards for vehicles, including MHEVs. The Euro 6d standard, introduced in 2020, sets limits on various pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These regulations have pushed manufacturers to develop more sophisticated BMS solutions to maximize the efficiency of the hybrid powertrain and minimize emissions.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a driving force behind MHEV development. These standards require automakers to achieve specific fleet-wide fuel economy targets, which has led to increased adoption of mild hybrid technologies. The Environmental Protection Agency (EPA) has also implemented emissions standards that align with CAFE requirements, further emphasizing the importance of optimized BMS in MHEVs.

China, the world's largest automotive market, has introduced its own set of emissions regulations for MHEVs. The China 6 standard, implemented in phases starting from 2019, imposes strict limits on pollutants and fuel consumption. This has spurred rapid development in BMS technology among Chinese automakers and suppliers, as they seek to meet these challenging requirements.

The impact of these regulations on BMS optimization in MHEVs has been significant. Manufacturers have been compelled to develop more advanced control algorithms that can precisely manage the interaction between the internal combustion engine and the electric motor. This includes optimizing energy recuperation during braking, improving start-stop functionality, and enhancing overall powertrain efficiency.

Furthermore, emissions regulations have led to the integration of more sophisticated sensors and monitoring systems in MHEVs. These systems provide real-time data on vehicle performance and emissions, allowing the BMS to make dynamic adjustments to optimize efficiency and minimize pollutant output. This has resulted in the development of predictive control strategies that can anticipate driving conditions and adjust the powertrain accordingly.

As emissions regulations continue to evolve, the role of BMS optimization in MHEVs will become even more critical. Future standards are expected to focus on lifecycle emissions, including the production and disposal of batteries. This will likely drive further innovation in BMS technology, with a focus on extending battery life, improving thermal management, and enhancing overall system efficiency to meet increasingly stringent regulatory requirements.

BMS Cost-Efficiency

Cost-efficiency is a critical factor in the optimization of battery management systems (BMS) for mild hybrid vehicles. The pursuit of cost-effective solutions has become increasingly important as automakers strive to balance performance, reliability, and affordability in their hybrid offerings.

One of the primary approaches to enhancing BMS cost-efficiency is through the integration of advanced microcontrollers and semiconductors. These components offer improved processing capabilities and energy efficiency, allowing for more sophisticated control algorithms without significantly increasing hardware costs. By leveraging the latest advancements in semiconductor technology, manufacturers can achieve better performance-to-cost ratios in their BMS designs.

Another key strategy involves the optimization of battery cell monitoring systems. Traditional methods often require individual voltage and temperature sensors for each cell, leading to increased complexity and cost. However, innovative approaches such as multiplexed sensing and distributed BMS architectures can significantly reduce the number of components required, thereby lowering overall system costs without compromising accuracy or reliability.

The development of more efficient power conversion and management circuits also plays a crucial role in BMS cost-efficiency. By improving the efficiency of DC-DC converters and charge balancing systems, manufacturers can reduce energy losses and thermal management requirements. This not only enhances the overall efficiency of the hybrid powertrain but also allows for the use of smaller, less expensive cooling systems.

Software optimization is another area where significant cost savings can be realized. Advanced algorithms for state-of-charge (SOC) and state-of-health (SOH) estimation can improve battery utilization and lifespan, reducing the need for oversized battery packs. Additionally, the implementation of over-the-air (OTA) update capabilities allows for continuous improvement of BMS functionality without the need for hardware replacements or recalls.

The adoption of standardized communication protocols and interfaces is also contributing to BMS cost-efficiency. By utilizing industry-standard protocols such as CAN-FD or Automotive Ethernet, manufacturers can reduce development costs and improve interoperability between different vehicle systems. This standardization also facilitates easier integration of third-party components, potentially leading to more competitive pricing in the supply chain.

Lastly, the implementation of advanced manufacturing techniques and automation in BMS production is driving down costs. Techniques such as automated optical inspection (AOI) and in-circuit testing (ICT) help to reduce defects and improve yield rates, while modular design approaches allow for greater flexibility and economies of scale in production.

One of the primary approaches to enhancing BMS cost-efficiency is through the integration of advanced microcontrollers and semiconductors. These components offer improved processing capabilities and energy efficiency, allowing for more sophisticated control algorithms without significantly increasing hardware costs. By leveraging the latest advancements in semiconductor technology, manufacturers can achieve better performance-to-cost ratios in their BMS designs.

Another key strategy involves the optimization of battery cell monitoring systems. Traditional methods often require individual voltage and temperature sensors for each cell, leading to increased complexity and cost. However, innovative approaches such as multiplexed sensing and distributed BMS architectures can significantly reduce the number of components required, thereby lowering overall system costs without compromising accuracy or reliability.

The development of more efficient power conversion and management circuits also plays a crucial role in BMS cost-efficiency. By improving the efficiency of DC-DC converters and charge balancing systems, manufacturers can reduce energy losses and thermal management requirements. This not only enhances the overall efficiency of the hybrid powertrain but also allows for the use of smaller, less expensive cooling systems.

Software optimization is another area where significant cost savings can be realized. Advanced algorithms for state-of-charge (SOC) and state-of-health (SOH) estimation can improve battery utilization and lifespan, reducing the need for oversized battery packs. Additionally, the implementation of over-the-air (OTA) update capabilities allows for continuous improvement of BMS functionality without the need for hardware replacements or recalls.

The adoption of standardized communication protocols and interfaces is also contributing to BMS cost-efficiency. By utilizing industry-standard protocols such as CAN-FD or Automotive Ethernet, manufacturers can reduce development costs and improve interoperability between different vehicle systems. This standardization also facilitates easier integration of third-party components, potentially leading to more competitive pricing in the supply chain.

Lastly, the implementation of advanced manufacturing techniques and automation in BMS production is driving down costs. Techniques such as automated optical inspection (AOI) and in-circuit testing (ICT) help to reduce defects and improve yield rates, while modular design approaches allow for greater flexibility and economies of scale in production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!