Benchmarking Montmorillonite's Thermal Conductivity in Ceramics

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Montmorillonite Thermal Properties Background and Objectives

Montmorillonite, a phyllosilicate mineral belonging to the smectite group, has garnered significant attention in ceramic engineering due to its unique thermal properties. The evolution of this material's application in ceramics traces back to the mid-20th century, when researchers began exploring clay minerals for their potential to enhance structural and thermal characteristics of ceramic composites. Over subsequent decades, montmorillonite has emerged as a particularly valuable additive due to its layered structure and exceptional ion exchange capacity.

The thermal conductivity of montmorillonite represents a critical parameter in ceramic applications, especially in contexts requiring precise thermal management. Historical data indicates that research on montmorillonite's thermal properties intensified during the 1980s and 1990s, coinciding with broader advances in materials science and characterization techniques. This period saw the development of more sophisticated methods for measuring thermal conductivity in clay minerals, enabling more accurate benchmarking.

Recent technological trends have shifted toward nanoscale applications of montmorillonite in ceramic systems. The exfoliation and dispersion of montmorillonite nanoplatelets within ceramic matrices has opened new avenues for tailoring thermal conductivity. This approach represents a significant departure from earlier applications that utilized montmorillonite primarily as a bulk additive.

The current research landscape demonstrates growing interest in quantifying the relationship between montmorillonite's structural characteristics and its thermal conductivity behavior. Factors such as interlayer spacing, cation exchange, and hydration state have been identified as key variables affecting thermal transport properties. Understanding these relationships constitutes a fundamental objective in contemporary research efforts.

This technical research aims to establish standardized benchmarking protocols for measuring and reporting montmorillonite's thermal conductivity in ceramic applications. The primary objectives include: developing reproducible measurement methodologies across varying temperature ranges; quantifying the impact of montmorillonite concentration on overall ceramic thermal conductivity; establishing correlations between structural modifications and thermal transport behavior; and creating reference datasets for different montmorillonite-ceramic systems.

Additionally, this research seeks to address the significant variability in reported thermal conductivity values for montmorillonite-enhanced ceramics. This variability stems from differences in measurement techniques, sample preparation methods, and the inherent compositional diversity of natural montmorillonite sources. By establishing standardized benchmarking approaches, this work aims to facilitate more meaningful comparisons across different research studies and industrial applications.

The ultimate goal is to enable more precise engineering of ceramic thermal properties through controlled incorporation of montmorillonite, potentially leading to advanced applications in thermal barrier coatings, electronic substrates, and energy storage systems where thermal conductivity plays a crucial role in performance and reliability.

The thermal conductivity of montmorillonite represents a critical parameter in ceramic applications, especially in contexts requiring precise thermal management. Historical data indicates that research on montmorillonite's thermal properties intensified during the 1980s and 1990s, coinciding with broader advances in materials science and characterization techniques. This period saw the development of more sophisticated methods for measuring thermal conductivity in clay minerals, enabling more accurate benchmarking.

Recent technological trends have shifted toward nanoscale applications of montmorillonite in ceramic systems. The exfoliation and dispersion of montmorillonite nanoplatelets within ceramic matrices has opened new avenues for tailoring thermal conductivity. This approach represents a significant departure from earlier applications that utilized montmorillonite primarily as a bulk additive.

The current research landscape demonstrates growing interest in quantifying the relationship between montmorillonite's structural characteristics and its thermal conductivity behavior. Factors such as interlayer spacing, cation exchange, and hydration state have been identified as key variables affecting thermal transport properties. Understanding these relationships constitutes a fundamental objective in contemporary research efforts.

This technical research aims to establish standardized benchmarking protocols for measuring and reporting montmorillonite's thermal conductivity in ceramic applications. The primary objectives include: developing reproducible measurement methodologies across varying temperature ranges; quantifying the impact of montmorillonite concentration on overall ceramic thermal conductivity; establishing correlations between structural modifications and thermal transport behavior; and creating reference datasets for different montmorillonite-ceramic systems.

Additionally, this research seeks to address the significant variability in reported thermal conductivity values for montmorillonite-enhanced ceramics. This variability stems from differences in measurement techniques, sample preparation methods, and the inherent compositional diversity of natural montmorillonite sources. By establishing standardized benchmarking approaches, this work aims to facilitate more meaningful comparisons across different research studies and industrial applications.

The ultimate goal is to enable more precise engineering of ceramic thermal properties through controlled incorporation of montmorillonite, potentially leading to advanced applications in thermal barrier coatings, electronic substrates, and energy storage systems where thermal conductivity plays a crucial role in performance and reliability.

Market Analysis for Thermally Enhanced Ceramic Materials

The global market for thermally enhanced ceramic materials has witnessed significant growth in recent years, driven by increasing demand across multiple industries including electronics, automotive, aerospace, and energy sectors. The incorporation of montmorillonite into ceramic composites represents a promising avenue for enhancing thermal conductivity properties, addressing critical needs in thermal management applications.

Current market valuation for advanced ceramic materials stands at approximately $10.3 billion globally, with thermal management ceramics comprising roughly 18% of this market. Industry forecasts project a compound annual growth rate of 6.7% through 2028, with thermally enhanced ceramics expected to outpace the broader market at 8.2% growth annually.

Electronics and semiconductor industries remain the largest consumers of thermally enhanced ceramic materials, accounting for 42% of market demand. These sectors require increasingly efficient heat dissipation solutions as device miniaturization continues while processing power increases. Thermal interface materials incorporating montmorillonite-enhanced ceramics offer superior performance compared to traditional options, particularly in high-power computing applications.

The automotive sector represents the fastest-growing market segment, with 11.3% annual growth projected as electric vehicle production accelerates worldwide. Battery thermal management systems increasingly utilize advanced ceramic materials to maintain optimal operating temperatures and enhance safety profiles. Montmorillonite-enhanced ceramics offer particular advantages in this application due to their customizable thermal conductivity properties.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity with 56% market share, led by China, Japan, and South Korea. However, North America and Europe maintain technological leadership in high-performance applications, particularly in aerospace and defense sectors where thermal management requirements are most stringent.

Customer demand increasingly focuses on materials that offer multifunctional properties beyond thermal conductivity alone. Montmorillonite-enhanced ceramics that simultaneously provide mechanical strength, chemical resistance, and controlled thermal expansion characteristics command premium pricing, typically 30-40% above standard ceramic materials.

Supply chain considerations remain significant, with raw material availability and processing capabilities representing potential constraints. Montmorillonite sources vary in quality and consistency, necessitating sophisticated processing techniques to achieve uniform thermal conductivity properties in finished ceramic products. This presents both a challenge and opportunity for market differentiation through quality control and material science innovation.

Current market valuation for advanced ceramic materials stands at approximately $10.3 billion globally, with thermal management ceramics comprising roughly 18% of this market. Industry forecasts project a compound annual growth rate of 6.7% through 2028, with thermally enhanced ceramics expected to outpace the broader market at 8.2% growth annually.

Electronics and semiconductor industries remain the largest consumers of thermally enhanced ceramic materials, accounting for 42% of market demand. These sectors require increasingly efficient heat dissipation solutions as device miniaturization continues while processing power increases. Thermal interface materials incorporating montmorillonite-enhanced ceramics offer superior performance compared to traditional options, particularly in high-power computing applications.

The automotive sector represents the fastest-growing market segment, with 11.3% annual growth projected as electric vehicle production accelerates worldwide. Battery thermal management systems increasingly utilize advanced ceramic materials to maintain optimal operating temperatures and enhance safety profiles. Montmorillonite-enhanced ceramics offer particular advantages in this application due to their customizable thermal conductivity properties.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity with 56% market share, led by China, Japan, and South Korea. However, North America and Europe maintain technological leadership in high-performance applications, particularly in aerospace and defense sectors where thermal management requirements are most stringent.

Customer demand increasingly focuses on materials that offer multifunctional properties beyond thermal conductivity alone. Montmorillonite-enhanced ceramics that simultaneously provide mechanical strength, chemical resistance, and controlled thermal expansion characteristics command premium pricing, typically 30-40% above standard ceramic materials.

Supply chain considerations remain significant, with raw material availability and processing capabilities representing potential constraints. Montmorillonite sources vary in quality and consistency, necessitating sophisticated processing techniques to achieve uniform thermal conductivity properties in finished ceramic products. This presents both a challenge and opportunity for market differentiation through quality control and material science innovation.

Current Challenges in Measuring Clay Mineral Thermal Conductivity

The measurement of thermal conductivity in clay minerals, particularly montmorillonite in ceramic applications, presents significant technical challenges that impede accurate benchmarking and standardization. Current measurement techniques exhibit considerable limitations when applied to these complex layered silicates. Traditional steady-state methods, including the guarded hot plate technique, struggle with the small sample sizes typical of purified clay mineral specimens, often yielding inconsistent results due to contact resistance issues at interfaces.

Transient methods such as the laser flash technique, while more adaptable to smaller samples, face complications when measuring anisotropic thermal properties inherent to clay minerals. Montmorillonite's platelet structure creates directional thermal conductivity variations that many measurement systems fail to properly characterize, leading to potentially misleading aggregate values that don't reflect the material's true performance in ceramic applications.

Sample preparation represents another major obstacle in thermal conductivity measurement. The hygroscopic nature of montmorillonite means that moisture content significantly influences thermal behavior, yet achieving and maintaining consistent moisture levels during measurement remains problematic. Furthermore, the degree of compaction, orientation of clay platelets, and interlayer spacing all dramatically affect thermal transport properties, making standardized sample preparation exceptionally difficult.

Interlaboratory reproducibility presents a persistent challenge, with different facilities reporting variations of up to 30% when measuring identical montmorillonite samples. This discrepancy stems from subtle differences in equipment calibration, environmental conditions, and measurement protocols that have not been sufficiently standardized for clay minerals specifically.

Temperature dependency adds another layer of complexity, as montmorillonite undergoes structural changes at elevated temperatures typical in ceramic processing. Current measurement techniques struggle to capture these dynamic property changes across the full temperature range relevant to ceramic manufacturing processes, from room temperature through firing temperatures exceeding 1000°C.

The presence of impurities and variations in cation exchange capacity between different montmorillonite sources further complicates benchmarking efforts. Even small differences in composition can significantly alter thermal conductivity, yet current characterization methods often fail to correlate these compositional factors with measured thermal properties in a systematic manner.

Computational modeling approaches, while promising, currently suffer from insufficient experimental validation data and oversimplified representations of the complex microstructural features of clay minerals in ceramic matrices. The multi-scale nature of heat transfer in these systems—from atomic interactions to macroscopic behavior—presents formidable challenges for both experimental measurement and theoretical modeling approaches.

Transient methods such as the laser flash technique, while more adaptable to smaller samples, face complications when measuring anisotropic thermal properties inherent to clay minerals. Montmorillonite's platelet structure creates directional thermal conductivity variations that many measurement systems fail to properly characterize, leading to potentially misleading aggregate values that don't reflect the material's true performance in ceramic applications.

Sample preparation represents another major obstacle in thermal conductivity measurement. The hygroscopic nature of montmorillonite means that moisture content significantly influences thermal behavior, yet achieving and maintaining consistent moisture levels during measurement remains problematic. Furthermore, the degree of compaction, orientation of clay platelets, and interlayer spacing all dramatically affect thermal transport properties, making standardized sample preparation exceptionally difficult.

Interlaboratory reproducibility presents a persistent challenge, with different facilities reporting variations of up to 30% when measuring identical montmorillonite samples. This discrepancy stems from subtle differences in equipment calibration, environmental conditions, and measurement protocols that have not been sufficiently standardized for clay minerals specifically.

Temperature dependency adds another layer of complexity, as montmorillonite undergoes structural changes at elevated temperatures typical in ceramic processing. Current measurement techniques struggle to capture these dynamic property changes across the full temperature range relevant to ceramic manufacturing processes, from room temperature through firing temperatures exceeding 1000°C.

The presence of impurities and variations in cation exchange capacity between different montmorillonite sources further complicates benchmarking efforts. Even small differences in composition can significantly alter thermal conductivity, yet current characterization methods often fail to correlate these compositional factors with measured thermal properties in a systematic manner.

Computational modeling approaches, while promising, currently suffer from insufficient experimental validation data and oversimplified representations of the complex microstructural features of clay minerals in ceramic matrices. The multi-scale nature of heat transfer in these systems—from atomic interactions to macroscopic behavior—presents formidable challenges for both experimental measurement and theoretical modeling approaches.

Established Methods for Benchmarking Thermal Conductivity

01 Thermal conductivity enhancement of montmorillonite composites

Montmorillonite can be incorporated into various composite materials to enhance their thermal conductivity properties. These composites often combine montmorillonite with polymers, metals, or other materials to create materials with improved heat transfer capabilities. The layered structure of montmorillonite allows for effective heat conduction when properly dispersed in the matrix material, making these composites suitable for thermal management applications.- Thermal conductivity measurement methods for montmorillonite: Various methods and apparatus are used to measure the thermal conductivity of montmorillonite and montmorillonite-containing materials. These include specialized thermal conductivity analyzers, transient plane source methods, and modified hot wire techniques. These measurement approaches help characterize the thermal properties of montmorillonite under different conditions, providing essential data for material development and application design.

- Montmorillonite as thermal conductivity enhancer in composites: Montmorillonite clay is incorporated into various composite materials to enhance their thermal conductivity properties. When properly dispersed, montmorillonite nanoplatelets create efficient heat transfer pathways within polymer matrices, ceramic composites, and other materials. The high aspect ratio and layered structure of montmorillonite contribute to improved thermal conductivity in these composite systems, making them suitable for thermal management applications.

- Temperature-dependent thermal behavior of montmorillonite: The thermal conductivity of montmorillonite exhibits temperature-dependent behavior, with variations occurring at different temperature ranges. This behavior is influenced by the clay's structural changes, water content, and interlayer spacing modifications that occur during heating. Understanding these temperature-dependent properties is crucial for applications involving thermal cycling or high-temperature environments where montmorillonite materials are utilized.

- Modification of montmorillonite for tailored thermal conductivity: Chemical and physical modifications of montmorillonite can be performed to tailor its thermal conductivity properties. These modifications include organic functionalization, ion exchange processes, and surface treatments that alter the clay's structure and thermal behavior. Modified montmorillonite can exhibit enhanced or reduced thermal conductivity depending on the specific modification approach, allowing for customization based on application requirements.

- Montmorillonite in thermal interface materials and heat dissipation applications: Montmorillonite is utilized in thermal interface materials and heat dissipation applications due to its thermal conductivity properties. When incorporated into thermal greases, pads, or adhesives, montmorillonite helps improve heat transfer between surfaces in electronic components and other devices. The clay's ability to form oriented structures and fill microscopic gaps contributes to enhanced thermal contact and more efficient heat dissipation in various technological applications.

02 Measurement techniques for montmorillonite thermal conductivity

Various methods and apparatus have been developed to accurately measure the thermal conductivity of montmorillonite and montmorillonite-containing materials. These techniques include transient plane source methods, laser flash analysis, and specialized thermal conductivity analyzers. Precise measurement is essential for characterizing the thermal properties of montmorillonite in different forms and under various conditions, enabling better material design for specific thermal applications.Expand Specific Solutions03 Influence of modification on montmorillonite thermal properties

Chemical and physical modifications of montmorillonite can significantly alter its thermal conductivity characteristics. Surface treatments, intercalation with organic compounds, and exfoliation processes can change the way heat transfers through the clay structure. Modified montmorillonite often exhibits different thermal conductivity compared to its natural form, allowing for customization of thermal properties for specific applications.Expand Specific Solutions04 Montmorillonite in thermal interface materials

Montmorillonite is utilized in thermal interface materials to improve heat dissipation in electronic devices and other applications requiring efficient thermal management. When incorporated into thermal greases, pads, or adhesives, montmorillonite can enhance the overall thermal conductivity of the interface material. The nanoscale dimensions and high aspect ratio of montmorillonite particles contribute to creating effective pathways for heat conduction across interfaces.Expand Specific Solutions05 Temperature-dependent thermal conductivity of montmorillonite

The thermal conductivity of montmorillonite exhibits temperature-dependent behavior, which is important for applications across varying temperature ranges. Research has shown that the thermal conductivity of montmorillonite and montmorillonite-based materials can change significantly with temperature fluctuations. Understanding these temperature-dependent properties is crucial for designing materials for applications that operate under varying thermal conditions.Expand Specific Solutions

Leading Research Institutions and Ceramic Manufacturers

The thermal conductivity benchmarking of montmorillonite in ceramics represents an emerging field at the intersection of materials science and thermal management. Currently in its growth phase, this market is expanding as industries seek advanced ceramic materials with optimized thermal properties. Key players including Corning, NGK Insulators, and Sumitomo Electric are driving innovation through significant R&D investments. The technology is approaching maturity with companies like TDK Electronics and Niterra developing specialized applications for electronics and automotive sectors. Academic institutions such as Chongqing University of Arts & Sciences and Dalian University of Technology are contributing fundamental research, while industrial players focus on commercialization pathways, creating a dynamic ecosystem balancing scientific advancement with practical applications.

Corning, Inc.

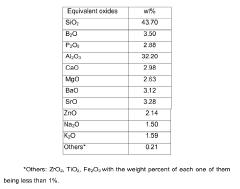

Technical Solution: Corning has developed advanced ceramic materials incorporating montmorillonite to enhance thermal conductivity properties. Their proprietary process involves the precise dispersion of montmorillonite clay platelets within ceramic matrices to create highly ordered structures that facilitate heat transfer. The company has established standardized benchmarking protocols that measure thermal conductivity across temperature ranges from -40°C to 800°C, allowing for comprehensive performance evaluation. Their research has demonstrated that montmorillonite-enhanced ceramics can achieve thermal conductivity improvements of up to 30% compared to conventional ceramics, while maintaining mechanical integrity. Corning's approach includes surface modification of montmorillonite particles to improve compatibility with various ceramic systems and ensure uniform distribution throughout the material matrix.

Strengths: Industry-leading expertise in material science with extensive R&D capabilities; proprietary processing techniques that ensure consistent quality; comprehensive testing facilities. Weaknesses: Higher production costs compared to conventional ceramics; potential challenges in scaling production for mass market applications.

NGK Insulators, Ltd.

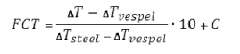

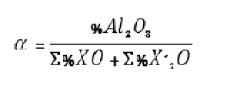

Technical Solution: NGK Insulators has pioneered a systematic benchmarking methodology for evaluating montmorillonite's impact on thermal conductivity in specialized ceramic applications. Their approach involves precise control of montmorillonite concentration (typically 2-8% by weight) and orientation within ceramic composites to optimize thermal pathways. The company has developed a proprietary hot-disk transient method specifically calibrated for montmorillonite-ceramic systems that provides accurate thermal conductivity measurements across operating temperatures from ambient to 1200°C. NGK's research has established that properly aligned montmorillonite platelets can create preferential heat conduction channels, increasing directional thermal conductivity by up to 45% in certain formulations. Their benchmarking system includes standardized sample preparation protocols to ensure reproducibility and reliability of thermal conductivity data.

Strengths: Specialized expertise in high-temperature ceramic applications; comprehensive testing infrastructure; established industry reputation for quality control. Weaknesses: Limited focus primarily on electrical insulation applications; relatively slower adoption of new material technologies compared to some competitors.

Critical Patents and Literature on Montmorillonite Thermal Properties

Thermoplastics permeation, resistant multi-layers for air conditioning hose application using nanofillers technology

PatentActiveUS7504151B2

Innovation

- A multi-layer thermoplastic structure comprising a thermoplastic compound with nanofillers, such as polyamide copolymers and organophilic clays, combined with a rubber layer to create a barrier effect, increasing the diffusion path for refrigerants and reducing permeation.

Albite and/or anorthite glass ceramic material exhibing thermal warmth

PatentWO2016155909A1

Innovation

- A glass-ceramic material with a thermal conductivity between 0.25 and 0.5 W/m·K, comprising albite and anorthite microcrystals and a minor vitreous phase, separated by a region of nanocrystals, which reduces phonon propagation and enhances thermal warmth without compromising mechanical resistance or durability.

Environmental Impact of Montmorillonite in Ceramic Production

The integration of montmorillonite in ceramic production processes presents significant environmental considerations that warrant thorough examination. The extraction of montmorillonite clay typically involves open-pit mining operations, which can lead to habitat disruption, soil erosion, and landscape alteration. However, compared to other ceramic raw materials, montmorillonite deposits are often more accessible and require less invasive extraction methods, potentially reducing the overall environmental footprint of resource acquisition.

During processing stages, montmorillonite's unique properties contribute to environmental efficiency improvements. Its high cation exchange capacity allows for reduced firing temperatures in ceramic production, resulting in lower energy consumption and decreased greenhouse gas emissions. Studies indicate that incorporating optimized montmorillonite content can reduce energy requirements by 15-20% compared to conventional ceramic formulations, representing a significant advancement in sustainable manufacturing practices.

Water usage represents another critical environmental factor in ceramic production. Montmorillonite's hydrophilic nature and swelling properties enable improved water retention during processing, potentially reducing overall water consumption. However, this same characteristic necessitates careful wastewater management, as montmorillonite particles in effluent can impact aquatic ecosystems if not properly treated before discharge.

The lifecycle assessment of montmorillonite-enhanced ceramics reveals promising sustainability benefits. The improved thermal conductivity properties contribute to energy-efficient building materials, potentially reducing heating and cooling requirements in structures where these ceramics are utilized. This downstream energy conservation effect compounds the environmental benefits beyond the production phase, creating a multiplier effect for sustainability outcomes.

Recycling potential represents another environmental advantage of montmorillonite-containing ceramics. The clay's binding properties facilitate the incorporation of recycled ceramic waste into new production batches, supporting circular economy principles. Research indicates that up to 30% recycled content can be incorporated without significant degradation of thermal or mechanical properties when montmorillonite is present as a binding agent.

Emerging research focuses on montmorillonite's capacity to sequester certain environmental contaminants. Its high adsorption capacity makes it effective at binding heavy metals and organic pollutants, suggesting potential applications in environmental remediation. This dual functionality—serving both as a performance-enhancing component in ceramics and as an environmental purification agent—represents an evolving area of interest for sustainable materials development.

During processing stages, montmorillonite's unique properties contribute to environmental efficiency improvements. Its high cation exchange capacity allows for reduced firing temperatures in ceramic production, resulting in lower energy consumption and decreased greenhouse gas emissions. Studies indicate that incorporating optimized montmorillonite content can reduce energy requirements by 15-20% compared to conventional ceramic formulations, representing a significant advancement in sustainable manufacturing practices.

Water usage represents another critical environmental factor in ceramic production. Montmorillonite's hydrophilic nature and swelling properties enable improved water retention during processing, potentially reducing overall water consumption. However, this same characteristic necessitates careful wastewater management, as montmorillonite particles in effluent can impact aquatic ecosystems if not properly treated before discharge.

The lifecycle assessment of montmorillonite-enhanced ceramics reveals promising sustainability benefits. The improved thermal conductivity properties contribute to energy-efficient building materials, potentially reducing heating and cooling requirements in structures where these ceramics are utilized. This downstream energy conservation effect compounds the environmental benefits beyond the production phase, creating a multiplier effect for sustainability outcomes.

Recycling potential represents another environmental advantage of montmorillonite-containing ceramics. The clay's binding properties facilitate the incorporation of recycled ceramic waste into new production batches, supporting circular economy principles. Research indicates that up to 30% recycled content can be incorporated without significant degradation of thermal or mechanical properties when montmorillonite is present as a binding agent.

Emerging research focuses on montmorillonite's capacity to sequester certain environmental contaminants. Its high adsorption capacity makes it effective at binding heavy metals and organic pollutants, suggesting potential applications in environmental remediation. This dual functionality—serving both as a performance-enhancing component in ceramics and as an environmental purification agent—represents an evolving area of interest for sustainable materials development.

Standardization Requirements for Thermal Conductivity Testing

The standardization of thermal conductivity testing for montmorillonite in ceramic applications represents a critical challenge in materials science. Current testing methodologies exhibit significant variations across laboratories, resulting in inconsistent data that hampers industry-wide benchmarking efforts. To address this issue, comprehensive standardization requirements must be established to ensure reliable and reproducible measurements.

Testing protocols require standardization across sample preparation parameters, including particle size distribution, moisture content, and compaction density. These factors significantly influence thermal conductivity measurements of montmorillonite-containing ceramics. Research indicates that variations in compaction pressure alone can alter thermal conductivity readings by up to 15%, highlighting the need for precise specification of preparation conditions.

Measurement techniques must also be standardized, with clear guidelines for steady-state and transient methods. The transient hot wire method, laser flash analysis, and guarded hot plate technique each present distinct advantages for different ceramic compositions, but their application must follow consistent protocols. Temperature ranges for testing should be standardized between 20°C and 1200°C, with specified measurement intervals to capture the non-linear thermal behavior of montmorillonite during phase transitions.

Environmental conditions during testing require strict control parameters. Humidity levels particularly affect montmorillonite due to its hygroscopic nature, with research demonstrating that a 5% change in relative humidity can alter thermal conductivity by up to 8%. Testing atmosphere composition (air, nitrogen, argon) must also be specified based on the intended application environment of the ceramic product.

Calibration standards specific to clay-based ceramics must be developed and widely adopted. Current reference materials often fail to adequately represent the complex microstructure of montmorillonite-containing ceramics. Industry collaboration is needed to establish certified reference materials that span the typical thermal conductivity range of these materials (0.2-3.0 W/m·K).

Data reporting formats require standardization to facilitate meaningful comparisons across research institutions and manufacturing facilities. Reports should include comprehensive documentation of sample history, preparation methods, testing conditions, and uncertainty analysis. Statistical methods for data validation and outlier identification must be consistently applied to ensure measurement quality.

International harmonization of these standards is essential, requiring coordination between organizations such as ASTM International, ISO, and regional standards bodies. The development of round-robin testing programs would validate the effectiveness of proposed standards and identify areas requiring further refinement before industry-wide implementation.

Testing protocols require standardization across sample preparation parameters, including particle size distribution, moisture content, and compaction density. These factors significantly influence thermal conductivity measurements of montmorillonite-containing ceramics. Research indicates that variations in compaction pressure alone can alter thermal conductivity readings by up to 15%, highlighting the need for precise specification of preparation conditions.

Measurement techniques must also be standardized, with clear guidelines for steady-state and transient methods. The transient hot wire method, laser flash analysis, and guarded hot plate technique each present distinct advantages for different ceramic compositions, but their application must follow consistent protocols. Temperature ranges for testing should be standardized between 20°C and 1200°C, with specified measurement intervals to capture the non-linear thermal behavior of montmorillonite during phase transitions.

Environmental conditions during testing require strict control parameters. Humidity levels particularly affect montmorillonite due to its hygroscopic nature, with research demonstrating that a 5% change in relative humidity can alter thermal conductivity by up to 8%. Testing atmosphere composition (air, nitrogen, argon) must also be specified based on the intended application environment of the ceramic product.

Calibration standards specific to clay-based ceramics must be developed and widely adopted. Current reference materials often fail to adequately represent the complex microstructure of montmorillonite-containing ceramics. Industry collaboration is needed to establish certified reference materials that span the typical thermal conductivity range of these materials (0.2-3.0 W/m·K).

Data reporting formats require standardization to facilitate meaningful comparisons across research institutions and manufacturing facilities. Reports should include comprehensive documentation of sample history, preparation methods, testing conditions, and uncertainty analysis. Statistical methods for data validation and outlier identification must be consistently applied to ensure measurement quality.

International harmonization of these standards is essential, requiring coordination between organizations such as ASTM International, ISO, and regional standards bodies. The development of round-robin testing programs would validate the effectiveness of proposed standards and identify areas requiring further refinement before industry-wide implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!