Building Efficient Solar Panels with Laminar Flow Applications

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Panel Evolution

Solar panel technology has undergone significant evolution since its inception in the mid-20th century. The journey began with the discovery of the photovoltaic effect by Alexandre Edmond Becquerel in 1839, but it wasn't until 1954 that Bell Labs produced the first practical silicon solar cell. This marked the beginning of modern solar panel development.

In the 1960s and 1970s, solar panels found their first practical applications in space technology, powering satellites and spacecraft. The high cost of production limited their terrestrial use to niche applications. However, the oil crisis of the 1970s sparked renewed interest in solar energy, leading to increased research and development efforts.

The 1980s and 1990s saw steady improvements in solar cell efficiency and manufacturing processes. Thin-film technologies emerged as a potential alternative to traditional silicon cells, offering the possibility of cheaper production and flexible applications. During this period, the first grid-connected photovoltaic systems were installed, paving the way for larger-scale solar energy adoption.

The turn of the millennium brought about a dramatic acceleration in solar panel evolution. Advances in materials science and manufacturing techniques led to significant cost reductions and efficiency improvements. The introduction of polycrystalline silicon cells offered a balance between cost and efficiency, while monocrystalline cells continued to push the boundaries of performance.

In recent years, the focus has shifted towards maximizing energy conversion efficiency and developing more sustainable production methods. Perovskite solar cells have emerged as a promising technology, offering the potential for high efficiency at lower costs. Multi-junction cells, which stack different materials to capture a broader spectrum of light, have achieved record-breaking efficiencies in laboratory settings.

The integration of smart technologies and the Internet of Things (IoT) has also played a crucial role in solar panel evolution. Modern solar systems now incorporate advanced monitoring and control features, optimizing energy production and consumption in real-time.

As we look to the future, the evolution of solar panels is increasingly intertwined with other technological advancements. The concept of building-integrated photovoltaics (BIPV) is gaining traction, where solar cells are seamlessly incorporated into building materials. Additionally, research into novel materials and structures, such as quantum dot solar cells and organic photovoltaics, continues to push the boundaries of what's possible in solar energy conversion.

In the 1960s and 1970s, solar panels found their first practical applications in space technology, powering satellites and spacecraft. The high cost of production limited their terrestrial use to niche applications. However, the oil crisis of the 1970s sparked renewed interest in solar energy, leading to increased research and development efforts.

The 1980s and 1990s saw steady improvements in solar cell efficiency and manufacturing processes. Thin-film technologies emerged as a potential alternative to traditional silicon cells, offering the possibility of cheaper production and flexible applications. During this period, the first grid-connected photovoltaic systems were installed, paving the way for larger-scale solar energy adoption.

The turn of the millennium brought about a dramatic acceleration in solar panel evolution. Advances in materials science and manufacturing techniques led to significant cost reductions and efficiency improvements. The introduction of polycrystalline silicon cells offered a balance between cost and efficiency, while monocrystalline cells continued to push the boundaries of performance.

In recent years, the focus has shifted towards maximizing energy conversion efficiency and developing more sustainable production methods. Perovskite solar cells have emerged as a promising technology, offering the potential for high efficiency at lower costs. Multi-junction cells, which stack different materials to capture a broader spectrum of light, have achieved record-breaking efficiencies in laboratory settings.

The integration of smart technologies and the Internet of Things (IoT) has also played a crucial role in solar panel evolution. Modern solar systems now incorporate advanced monitoring and control features, optimizing energy production and consumption in real-time.

As we look to the future, the evolution of solar panels is increasingly intertwined with other technological advancements. The concept of building-integrated photovoltaics (BIPV) is gaining traction, where solar cells are seamlessly incorporated into building materials. Additionally, research into novel materials and structures, such as quantum dot solar cells and organic photovoltaics, continues to push the boundaries of what's possible in solar energy conversion.

Market Demand Analysis

The market demand for efficient solar panels with laminar flow applications has been steadily increasing in recent years, driven by the global push for renewable energy sources and the need for more sustainable power generation solutions. This technology combines the established field of solar energy with innovative laminar flow concepts, aiming to enhance the overall efficiency and performance of solar panels.

The solar energy market has experienced significant growth, with a compound annual growth rate (CAGR) of over 20% in the past decade. As countries worldwide set ambitious targets for reducing carbon emissions and transitioning to clean energy, the demand for advanced solar technologies continues to rise. The integration of laminar flow applications in solar panel design represents a promising avenue for addressing some of the key challenges faced by traditional photovoltaic systems.

One of the primary drivers of market demand for this technology is the potential for increased energy conversion efficiency. Conventional solar panels typically operate at efficiencies ranging from 15% to 22%, leaving substantial room for improvement. By incorporating laminar flow principles, researchers and manufacturers aim to optimize heat dissipation and reduce energy losses, potentially boosting efficiency by several percentage points. This improvement could translate to significant gains in power output and cost-effectiveness, making solar energy more competitive with traditional fossil fuel-based power generation.

The building-integrated photovoltaics (BIPV) sector presents a particularly promising market for laminar flow-enhanced solar panels. As urban areas seek to maximize energy production within limited spaces, the demand for high-efficiency, aesthetically pleasing solar solutions has grown. Laminar flow applications could enable the development of more compact and visually appealing solar panels, opening up new opportunities in architectural design and urban planning.

Furthermore, the increasing focus on energy independence and resilience has led to a growing market for off-grid and microgrid solutions. In these applications, maximizing energy production from limited surface area is crucial. Efficient solar panels with laminar flow technology could provide a competitive edge in this market segment, offering higher power output and potentially reducing the number of panels required for a given energy demand.

The automotive industry also represents a potential growth market for this technology. As electric vehicles gain popularity, there is increasing interest in integrating solar panels into vehicle designs to extend range and reduce charging requirements. Laminar flow-enhanced solar panels could offer improved performance in the challenging conditions of mobile applications, where space constraints and aerodynamics play critical roles.

While the market potential for efficient solar panels with laminar flow applications is significant, it is important to note that the technology is still in its early stages of development. As such, the market demand is currently driven more by potential and expectations rather than established products. However, as research progresses and prototypes demonstrate tangible benefits, industry analysts project a rapid increase in market interest and investment in this technology over the next five to ten years.

The solar energy market has experienced significant growth, with a compound annual growth rate (CAGR) of over 20% in the past decade. As countries worldwide set ambitious targets for reducing carbon emissions and transitioning to clean energy, the demand for advanced solar technologies continues to rise. The integration of laminar flow applications in solar panel design represents a promising avenue for addressing some of the key challenges faced by traditional photovoltaic systems.

One of the primary drivers of market demand for this technology is the potential for increased energy conversion efficiency. Conventional solar panels typically operate at efficiencies ranging from 15% to 22%, leaving substantial room for improvement. By incorporating laminar flow principles, researchers and manufacturers aim to optimize heat dissipation and reduce energy losses, potentially boosting efficiency by several percentage points. This improvement could translate to significant gains in power output and cost-effectiveness, making solar energy more competitive with traditional fossil fuel-based power generation.

The building-integrated photovoltaics (BIPV) sector presents a particularly promising market for laminar flow-enhanced solar panels. As urban areas seek to maximize energy production within limited spaces, the demand for high-efficiency, aesthetically pleasing solar solutions has grown. Laminar flow applications could enable the development of more compact and visually appealing solar panels, opening up new opportunities in architectural design and urban planning.

Furthermore, the increasing focus on energy independence and resilience has led to a growing market for off-grid and microgrid solutions. In these applications, maximizing energy production from limited surface area is crucial. Efficient solar panels with laminar flow technology could provide a competitive edge in this market segment, offering higher power output and potentially reducing the number of panels required for a given energy demand.

The automotive industry also represents a potential growth market for this technology. As electric vehicles gain popularity, there is increasing interest in integrating solar panels into vehicle designs to extend range and reduce charging requirements. Laminar flow-enhanced solar panels could offer improved performance in the challenging conditions of mobile applications, where space constraints and aerodynamics play critical roles.

While the market potential for efficient solar panels with laminar flow applications is significant, it is important to note that the technology is still in its early stages of development. As such, the market demand is currently driven more by potential and expectations rather than established products. However, as research progresses and prototypes demonstrate tangible benefits, industry analysts project a rapid increase in market interest and investment in this technology over the next five to ten years.

Laminar Flow Challenges

Laminar flow applications in solar panel construction present several significant challenges that researchers and engineers must overcome to enhance efficiency and performance. One of the primary obstacles is maintaining consistent laminar flow across the entire surface of the solar panel. Variations in surface texture, temperature gradients, and environmental factors can disrupt the desired flow patterns, leading to reduced heat transfer efficiency and overall panel performance.

Another critical challenge lies in optimizing the fluid dynamics within the laminar flow system. Achieving the ideal balance between flow rate, fluid viscosity, and channel dimensions is crucial for maximizing heat transfer while minimizing pumping power requirements. This optimization process is complex and often requires extensive computational fluid dynamics (CFD) simulations and experimental validations.

Material selection poses an additional hurdle in laminar flow solar panel design. The materials used must not only withstand prolonged exposure to solar radiation and varying weather conditions but also possess excellent thermal conductivity properties. Furthermore, these materials need to be compatible with the working fluid used in the laminar flow system, ensuring long-term durability and preventing corrosion or degradation.

Scale-up and manufacturing challenges also present significant obstacles in the widespread adoption of laminar flow solar panels. Transitioning from small-scale prototypes to large-scale production requires overcoming issues related to uniform flow distribution, sealing techniques, and quality control. Ensuring consistent performance across larger panel areas while maintaining cost-effectiveness remains a key concern for manufacturers.

The integration of laminar flow systems with existing solar panel technologies presents another set of challenges. Retrofitting conventional panels with laminar flow cooling mechanisms or developing entirely new panel designs that incorporate laminar flow from the ground up requires careful consideration of factors such as weight, structural integrity, and overall system complexity.

Addressing the thermal management challenges associated with laminar flow solar panels is crucial for improving their efficiency. While laminar flow can enhance heat transfer, managing temperature gradients across the panel surface and preventing localized hot spots remain ongoing challenges. Developing advanced thermal management strategies that can adapt to varying environmental conditions and solar intensities is essential for optimizing panel performance.

Finally, the economic viability of laminar flow solar panels presents a significant challenge. The additional complexity and components required for laminar flow systems can increase manufacturing costs and potentially offset the efficiency gains. Striking a balance between improved performance and cost-effectiveness is crucial for the widespread adoption of this technology in the competitive solar energy market.

Another critical challenge lies in optimizing the fluid dynamics within the laminar flow system. Achieving the ideal balance between flow rate, fluid viscosity, and channel dimensions is crucial for maximizing heat transfer while minimizing pumping power requirements. This optimization process is complex and often requires extensive computational fluid dynamics (CFD) simulations and experimental validations.

Material selection poses an additional hurdle in laminar flow solar panel design. The materials used must not only withstand prolonged exposure to solar radiation and varying weather conditions but also possess excellent thermal conductivity properties. Furthermore, these materials need to be compatible with the working fluid used in the laminar flow system, ensuring long-term durability and preventing corrosion or degradation.

Scale-up and manufacturing challenges also present significant obstacles in the widespread adoption of laminar flow solar panels. Transitioning from small-scale prototypes to large-scale production requires overcoming issues related to uniform flow distribution, sealing techniques, and quality control. Ensuring consistent performance across larger panel areas while maintaining cost-effectiveness remains a key concern for manufacturers.

The integration of laminar flow systems with existing solar panel technologies presents another set of challenges. Retrofitting conventional panels with laminar flow cooling mechanisms or developing entirely new panel designs that incorporate laminar flow from the ground up requires careful consideration of factors such as weight, structural integrity, and overall system complexity.

Addressing the thermal management challenges associated with laminar flow solar panels is crucial for improving their efficiency. While laminar flow can enhance heat transfer, managing temperature gradients across the panel surface and preventing localized hot spots remain ongoing challenges. Developing advanced thermal management strategies that can adapt to varying environmental conditions and solar intensities is essential for optimizing panel performance.

Finally, the economic viability of laminar flow solar panels presents a significant challenge. The additional complexity and components required for laminar flow systems can increase manufacturing costs and potentially offset the efficiency gains. Striking a balance between improved performance and cost-effectiveness is crucial for the widespread adoption of this technology in the competitive solar energy market.

Current Laminar Solutions

01 Improved solar cell structure

Enhancing the structure of solar cells to increase their efficiency. This includes optimizing the arrangement of layers, using advanced materials, and implementing novel designs to capture more sunlight and convert it into electricity more effectively.- Improved solar cell structure: Enhancing the structure of solar cells to increase light absorption and conversion efficiency. This includes optimizing the arrangement of layers, using advanced materials, and implementing novel designs to maximize photon capture and electron generation.

- Tracking and positioning systems: Implementing advanced tracking and positioning systems that allow solar panels to follow the sun's movement throughout the day. This ensures optimal angle of incidence for sunlight, maximizing energy capture and overall system efficiency.

- Advanced materials and coatings: Utilizing innovative materials and coatings to enhance light absorption, reduce reflection, and improve overall panel performance. This includes the development of new semiconductor materials, anti-reflective coatings, and surface treatments to boost efficiency.

- Thermal management techniques: Implementing effective thermal management strategies to regulate solar panel temperature and maintain optimal operating conditions. This includes the use of cooling systems, heat-dissipating materials, and innovative panel designs to mitigate efficiency losses due to overheating.

- Integration of power electronics: Incorporating advanced power electronics and smart inverter technologies to optimize power output, reduce losses, and enhance overall system performance. This includes the use of microinverters, power optimizers, and intelligent control systems to maximize energy harvest and grid integration efficiency.

02 Tracking and positioning systems

Implementing solar tracking and positioning systems to maximize sunlight exposure throughout the day. These systems adjust the angle and orientation of solar panels to follow the sun's path, increasing energy capture and overall efficiency.Expand Specific Solutions03 Advanced power electronics

Utilizing sophisticated power electronics and inverter technologies to optimize power conversion and management. This includes implementing smart grid integration, maximum power point tracking (MPPT), and efficient energy storage solutions to enhance overall system performance.Expand Specific Solutions04 Nanotechnology and quantum dots

Incorporating nanotechnology and quantum dots in solar cell design to enhance light absorption and electron generation. These advanced materials can improve the spectral response of solar cells and potentially exceed traditional efficiency limits.Expand Specific Solutions05 Cooling and temperature management

Implementing effective cooling and temperature management systems to maintain optimal operating conditions for solar panels. This includes using heat sinks, passive cooling designs, and active cooling technologies to prevent efficiency losses due to high temperatures.Expand Specific Solutions

Key Industry Players

The market for efficient solar panels utilizing laminar flow applications is in a growth phase, driven by increasing demand for renewable energy solutions. The global solar panel market is projected to reach significant scale, with major players like DuPont de Nemours, Trina Solar, and JinkoSolar leading technological advancements. The technology's maturity is progressing rapidly, with companies such as Canadian Solar and SolAero Technologies pushing innovation boundaries. Research institutions like Beihang University and the University of Kassel are contributing to the field's development. As the technology evolves, we can expect increased efficiency and cost-effectiveness, potentially revolutionizing the solar energy sector.

DuPont de Nemours, Inc.

Technical Solution: DuPont has applied its extensive materials science expertise to develop laminar flow applications for solar panel production. Their approach focuses on creating advanced materials that work synergistically with laminar flow processes to enhance panel efficiency and longevity. DuPont has developed specialized photovoltaic metallization pastes that, when applied under laminar flow conditions, result in more uniform and efficient cell contacts. The company has also created innovative encapsulant materials that, when used in conjunction with laminar flow during panel assembly, provide superior protection against environmental factors. DuPont's research extends to the development of self-cleaning surface treatments that maintain their effectiveness longer due to the precise application enabled by laminar flow techniques[7].

Strengths: Advanced materials science integration, improved panel longevity, and enhanced environmental resistance. Weaknesses: Potential higher costs associated with premium materials and the need for continuous R&D investment.

Trina Solar Co., Ltd.

Technical Solution: Trina Solar has developed advanced laminar flow techniques for their solar panel production, focusing on improving efficiency and reducing costs. Their approach involves using laminar flow in the manufacturing process to create a more uniform and controlled environment for cell deposition and module assembly. This results in higher quality solar panels with improved performance. Trina Solar's laminar flow application includes precise control of air flow and temperature during the production process, which minimizes contamination and ensures consistent cell quality[1]. The company has also implemented automated robotic systems that work in conjunction with laminar flow technology to enhance precision and reduce human error in the manufacturing process[2].

Strengths: Improved panel efficiency, reduced manufacturing costs, and enhanced quality control. Weaknesses: High initial investment in advanced manufacturing equipment and potential complexity in scaling up production.

Core Laminar Innovations

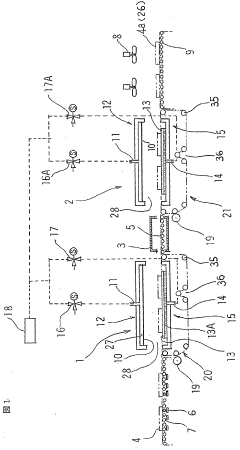

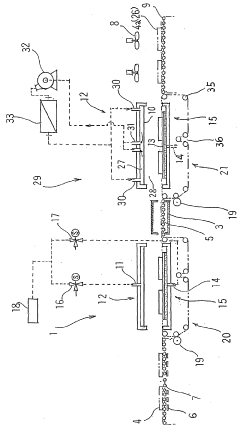

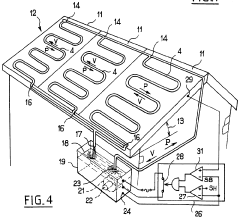

Laminating apparatus

PatentWO2007116504A1

Innovation

- A laminating device with an upper chamber having a diaphragm and air supply/exhaust port, and a lower chamber with a heating plate and air supply/exhaust port, connected in series, allowing for semi-continuous production by dividing the lamination process into stages, using heated and pressurized air for efficient lamination, and reducing equipment costs by eliminating the need for multiple heating and cooling lines.

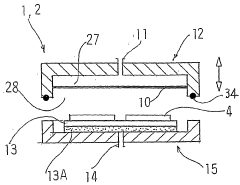

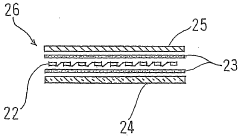

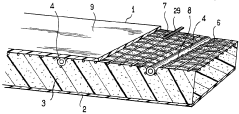

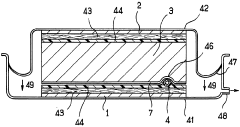

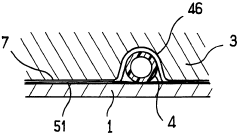

Solar cell panel and solar energy collecting device

PatentWO1999054671A1

Innovation

- A solar panel design featuring a front plate, a thermally insulating layer, a permeable thermally conductive sheet, and a flexible tubular network for heat transfer fluid circulation, where the conductive sheet is integral to the laminate interface, allowing for self-supporting panels without additional frameworks and efficient energy collection.

Environmental Impact

The integration of laminar flow applications in solar panel construction presents significant environmental implications that extend beyond energy production efficiency. This innovative approach to solar panel design has the potential to reduce the overall environmental footprint associated with solar energy systems throughout their lifecycle.

One of the primary environmental benefits of incorporating laminar flow principles in solar panel construction is the potential reduction in material usage. By optimizing fluid dynamics within the panel structure, manufacturers can potentially decrease the amount of raw materials required for production. This reduction in material consumption translates to lower resource extraction and processing, which in turn minimizes the environmental impact associated with mining, refining, and transportation of these materials.

Furthermore, the enhanced efficiency of solar panels utilizing laminar flow applications could lead to a decrease in the total land area required for solar farms. As panels become more efficient at converting sunlight into electricity, fewer panels may be needed to generate the same amount of power. This reduction in land use can help preserve natural habitats and ecosystems, mitigating the environmental impact of large-scale solar installations on local flora and fauna.

The improved thermal management facilitated by laminar flow applications may also contribute to extended solar panel lifespans. By effectively dissipating heat and reducing thermal stress on panel components, these systems could potentially last longer before requiring replacement. This longevity would result in fewer panels entering the waste stream over time, alleviating the burden on recycling facilities and landfills.

Additionally, the enhanced efficiency of solar panels incorporating laminar flow principles could accelerate the transition away from fossil fuel-based energy sources. As these panels generate more electricity per unit area, they become increasingly competitive with traditional energy sources, potentially leading to faster adoption rates of solar technology. This shift towards cleaner energy production would contribute to reduced greenhouse gas emissions and air pollution associated with conventional power generation methods.

However, it is important to consider potential environmental trade-offs. The manufacturing process for more complex solar panel designs incorporating laminar flow elements may require additional energy or specialized materials. A comprehensive life cycle assessment would be necessary to fully understand the net environmental impact of these advanced solar panels compared to traditional designs.

In conclusion, the application of laminar flow principles in solar panel construction holds promise for significant environmental benefits, including reduced material consumption, decreased land use, extended product lifespans, and accelerated adoption of clean energy. These advantages must be carefully weighed against any potential increases in manufacturing complexity to ensure a net positive environmental impact.

One of the primary environmental benefits of incorporating laminar flow principles in solar panel construction is the potential reduction in material usage. By optimizing fluid dynamics within the panel structure, manufacturers can potentially decrease the amount of raw materials required for production. This reduction in material consumption translates to lower resource extraction and processing, which in turn minimizes the environmental impact associated with mining, refining, and transportation of these materials.

Furthermore, the enhanced efficiency of solar panels utilizing laminar flow applications could lead to a decrease in the total land area required for solar farms. As panels become more efficient at converting sunlight into electricity, fewer panels may be needed to generate the same amount of power. This reduction in land use can help preserve natural habitats and ecosystems, mitigating the environmental impact of large-scale solar installations on local flora and fauna.

The improved thermal management facilitated by laminar flow applications may also contribute to extended solar panel lifespans. By effectively dissipating heat and reducing thermal stress on panel components, these systems could potentially last longer before requiring replacement. This longevity would result in fewer panels entering the waste stream over time, alleviating the burden on recycling facilities and landfills.

Additionally, the enhanced efficiency of solar panels incorporating laminar flow principles could accelerate the transition away from fossil fuel-based energy sources. As these panels generate more electricity per unit area, they become increasingly competitive with traditional energy sources, potentially leading to faster adoption rates of solar technology. This shift towards cleaner energy production would contribute to reduced greenhouse gas emissions and air pollution associated with conventional power generation methods.

However, it is important to consider potential environmental trade-offs. The manufacturing process for more complex solar panel designs incorporating laminar flow elements may require additional energy or specialized materials. A comprehensive life cycle assessment would be necessary to fully understand the net environmental impact of these advanced solar panels compared to traditional designs.

In conclusion, the application of laminar flow principles in solar panel construction holds promise for significant environmental benefits, including reduced material consumption, decreased land use, extended product lifespans, and accelerated adoption of clean energy. These advantages must be carefully weighed against any potential increases in manufacturing complexity to ensure a net positive environmental impact.

Cost-Benefit Analysis

The cost-benefit analysis of implementing laminar flow applications in solar panel construction reveals a complex interplay of economic factors. Initial investment costs for integrating laminar flow technology into solar panel manufacturing processes are substantial, primarily due to the need for specialized equipment and potential retooling of production lines. However, these upfront expenses are offset by the long-term benefits of increased panel efficiency and durability.

Laminar flow applications in solar panel construction lead to improved heat dissipation, which directly correlates with enhanced panel performance. By maintaining lower operating temperatures, panels can achieve higher conversion efficiencies, resulting in increased energy output over their lifetime. This boost in energy production translates to greater revenue generation for solar farm operators and faster return on investment for individual consumers.

The durability improvements offered by laminar flow technology also contribute significantly to the cost-benefit equation. Panels with better thermal management experience less thermal stress, reducing the likelihood of microcracks and other degradation factors. This increased lifespan extends the period over which panels generate electricity, effectively lowering the levelized cost of energy (LCOE) and improving the overall economic viability of solar installations.

Maintenance costs are another area where laminar flow applications show promise. The reduction in thermal hotspots and more uniform temperature distribution across the panel surface can lead to fewer panel failures and less frequent replacement needs. This translates to lower operational expenses over the system's lifetime, further enhancing the technology's economic appeal.

From a manufacturing perspective, the integration of laminar flow principles may lead to more streamlined production processes. While initial setup costs are high, the potential for increased automation and precision in panel assembly could result in long-term cost savings and improved product consistency. This could potentially lower per-unit production costs as manufacturing scales up.

Environmental benefits, while not directly monetary, also factor into the cost-benefit analysis. The increased efficiency and longevity of solar panels with laminar flow applications contribute to a reduction in electronic waste and a lower carbon footprint per unit of energy produced. These factors can lead to improved brand perception and potential regulatory advantages, indirectly benefiting the bottom line.

In conclusion, while the initial costs of implementing laminar flow applications in solar panel construction are significant, the long-term benefits in terms of increased energy output, extended panel lifespan, reduced maintenance needs, and potential manufacturing efficiencies present a compelling economic case. As the technology matures and production scales up, the cost-benefit ratio is expected to improve further, solidifying the position of laminar flow applications as a valuable innovation in the solar energy sector.

Laminar flow applications in solar panel construction lead to improved heat dissipation, which directly correlates with enhanced panel performance. By maintaining lower operating temperatures, panels can achieve higher conversion efficiencies, resulting in increased energy output over their lifetime. This boost in energy production translates to greater revenue generation for solar farm operators and faster return on investment for individual consumers.

The durability improvements offered by laminar flow technology also contribute significantly to the cost-benefit equation. Panels with better thermal management experience less thermal stress, reducing the likelihood of microcracks and other degradation factors. This increased lifespan extends the period over which panels generate electricity, effectively lowering the levelized cost of energy (LCOE) and improving the overall economic viability of solar installations.

Maintenance costs are another area where laminar flow applications show promise. The reduction in thermal hotspots and more uniform temperature distribution across the panel surface can lead to fewer panel failures and less frequent replacement needs. This translates to lower operational expenses over the system's lifetime, further enhancing the technology's economic appeal.

From a manufacturing perspective, the integration of laminar flow principles may lead to more streamlined production processes. While initial setup costs are high, the potential for increased automation and precision in panel assembly could result in long-term cost savings and improved product consistency. This could potentially lower per-unit production costs as manufacturing scales up.

Environmental benefits, while not directly monetary, also factor into the cost-benefit analysis. The increased efficiency and longevity of solar panels with laminar flow applications contribute to a reduction in electronic waste and a lower carbon footprint per unit of energy produced. These factors can lead to improved brand perception and potential regulatory advantages, indirectly benefiting the bottom line.

In conclusion, while the initial costs of implementing laminar flow applications in solar panel construction are significant, the long-term benefits in terms of increased energy output, extended panel lifespan, reduced maintenance needs, and potential manufacturing efficiencies present a compelling economic case. As the technology matures and production scales up, the cost-benefit ratio is expected to improve further, solidifying the position of laminar flow applications as a valuable innovation in the solar energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!