Comparing Kaolinite’s and Illite’s Plasticity in Ceramics

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Clay Minerals in Ceramics: Evolution and Objectives

Clay minerals have been fundamental to ceramic production since the dawn of human civilization, with evidence of ceramic artifacts dating back to 24,000 BCE. The evolution of ceramic technology has been intrinsically linked to the understanding and manipulation of clay minerals, particularly kaolinite and illite, which exhibit distinct plasticity characteristics crucial for ceramic manufacturing.

The historical trajectory of ceramic technology reveals a progression from rudimentary pottery to sophisticated porcelain, driven by empirical discoveries about clay behavior. Ancient civilizations in Mesopotamia, China, and the Mediterranean basin developed techniques to exploit the plastic properties of different clay minerals, though without scientific understanding of their mineralogical composition.

The scientific study of clay minerals began in earnest during the 18th century, coinciding with the industrial revolution and the establishment of major European porcelain manufacturers. By the early 20th century, X-ray diffraction techniques enabled the structural characterization of clay minerals, revolutionizing our understanding of their properties and behavior.

Kaolinite and illite have emerged as particularly significant clay minerals in ceramic production due to their contrasting plasticity characteristics. Kaolinite, with its relatively simple 1:1 layer structure, typically exhibits moderate plasticity and excellent firing properties, making it the preferred mineral for high-quality porcelain. Illite, with its more complex 2:1 layer structure and variable interlayer cation composition, generally demonstrates higher plasticity but more complex firing behavior.

The contemporary ceramic industry faces increasing demands for material performance, sustainability, and cost-effectiveness. Understanding the fundamental relationship between clay mineral structure and plasticity has become essential for addressing these challenges. This necessitates a comprehensive investigation of how kaolinite and illite contribute to ceramic plasticity through their distinct structural characteristics and surface chemistry.

The primary objective of this technical research is to systematically compare the plasticity mechanisms of kaolinite and illite in ceramic applications, with particular emphasis on quantifying their contributions to workability, green strength, and dimensional stability. Secondary objectives include identifying optimal blending ratios for specific ceramic applications and exploring methods to modify and enhance the plastic properties of these minerals through chemical and physical treatments.

This research aims to bridge the gap between mineralogical science and practical ceramic engineering, potentially enabling more precise formulation of ceramic bodies with predictable working properties and firing behavior. The findings could significantly impact both traditional ceramic manufacturing and emerging applications in advanced ceramics, additive manufacturing, and sustainable material development.

The historical trajectory of ceramic technology reveals a progression from rudimentary pottery to sophisticated porcelain, driven by empirical discoveries about clay behavior. Ancient civilizations in Mesopotamia, China, and the Mediterranean basin developed techniques to exploit the plastic properties of different clay minerals, though without scientific understanding of their mineralogical composition.

The scientific study of clay minerals began in earnest during the 18th century, coinciding with the industrial revolution and the establishment of major European porcelain manufacturers. By the early 20th century, X-ray diffraction techniques enabled the structural characterization of clay minerals, revolutionizing our understanding of their properties and behavior.

Kaolinite and illite have emerged as particularly significant clay minerals in ceramic production due to their contrasting plasticity characteristics. Kaolinite, with its relatively simple 1:1 layer structure, typically exhibits moderate plasticity and excellent firing properties, making it the preferred mineral for high-quality porcelain. Illite, with its more complex 2:1 layer structure and variable interlayer cation composition, generally demonstrates higher plasticity but more complex firing behavior.

The contemporary ceramic industry faces increasing demands for material performance, sustainability, and cost-effectiveness. Understanding the fundamental relationship between clay mineral structure and plasticity has become essential for addressing these challenges. This necessitates a comprehensive investigation of how kaolinite and illite contribute to ceramic plasticity through their distinct structural characteristics and surface chemistry.

The primary objective of this technical research is to systematically compare the plasticity mechanisms of kaolinite and illite in ceramic applications, with particular emphasis on quantifying their contributions to workability, green strength, and dimensional stability. Secondary objectives include identifying optimal blending ratios for specific ceramic applications and exploring methods to modify and enhance the plastic properties of these minerals through chemical and physical treatments.

This research aims to bridge the gap between mineralogical science and practical ceramic engineering, potentially enabling more precise formulation of ceramic bodies with predictable working properties and firing behavior. The findings could significantly impact both traditional ceramic manufacturing and emerging applications in advanced ceramics, additive manufacturing, and sustainable material development.

Market Analysis of Kaolinite and Illite-Based Ceramic Products

The global ceramic market utilizing clay minerals like kaolinite and illite has shown significant growth, reaching approximately $229 billion in 2022 with projections to exceed $330 billion by 2030, representing a compound annual growth rate of 4.8%. This growth is primarily driven by expanding construction activities, increasing demand for ceramic tiles, sanitaryware, and technical ceramics across various industries.

Kaolinite-based ceramic products currently dominate the market, accounting for roughly 65% of clay mineral usage in ceramics due to their superior whiteness, purity, and consistent firing properties. These products command premium pricing in high-end applications such as fine china, porcelain, and advanced technical ceramics. The market for kaolinite ceramics is particularly strong in developed regions including North America, Western Europe, and Japan.

Illite-based ceramic products, while representing a smaller market share at approximately 30%, are experiencing faster growth rates in certain segments. Their market appeal stems from cost advantages, as illite deposits are more abundant and generally less expensive to process than high-grade kaolinite. Illite-based ceramics have found particular success in construction materials, traditional pottery, and mid-range ceramic products where the highest degree of whiteness is not required.

Regional market analysis reveals interesting patterns. Asia-Pacific represents the largest market for both clay types, with China alone accounting for over 40% of global ceramic production. However, the preference for clay types varies significantly by region. European markets show increasing interest in illite-based products for sustainable building materials, while North American markets maintain stronger demand for kaolinite-based premium ceramics.

Consumer trends are shifting toward more environmentally sustainable ceramic products, creating new market opportunities for both clay types. Illite-based ceramics are gaining traction in green building materials due to lower firing temperatures, which reduce energy consumption. Meanwhile, kaolinite maintains its position in high-performance applications where precise technical specifications must be met.

The industrial ceramics segment represents the fastest-growing application area for both clay minerals, with annual growth rates exceeding 6%. This is driven by increasing demand for advanced ceramics in electronics, automotive, aerospace, and medical industries. Kaolinite dominates this high-value segment due to its superior performance characteristics, though research into modified illite formulations is showing promise for certain technical applications.

Market forecasts indicate continued growth for both clay types, with illite likely to gain market share in mid-range applications while kaolinite will maintain dominance in premium and technical segments. The overall market trajectory suggests a gradual shift toward more specialized, value-added ceramic products across all price points and application areas.

Kaolinite-based ceramic products currently dominate the market, accounting for roughly 65% of clay mineral usage in ceramics due to their superior whiteness, purity, and consistent firing properties. These products command premium pricing in high-end applications such as fine china, porcelain, and advanced technical ceramics. The market for kaolinite ceramics is particularly strong in developed regions including North America, Western Europe, and Japan.

Illite-based ceramic products, while representing a smaller market share at approximately 30%, are experiencing faster growth rates in certain segments. Their market appeal stems from cost advantages, as illite deposits are more abundant and generally less expensive to process than high-grade kaolinite. Illite-based ceramics have found particular success in construction materials, traditional pottery, and mid-range ceramic products where the highest degree of whiteness is not required.

Regional market analysis reveals interesting patterns. Asia-Pacific represents the largest market for both clay types, with China alone accounting for over 40% of global ceramic production. However, the preference for clay types varies significantly by region. European markets show increasing interest in illite-based products for sustainable building materials, while North American markets maintain stronger demand for kaolinite-based premium ceramics.

Consumer trends are shifting toward more environmentally sustainable ceramic products, creating new market opportunities for both clay types. Illite-based ceramics are gaining traction in green building materials due to lower firing temperatures, which reduce energy consumption. Meanwhile, kaolinite maintains its position in high-performance applications where precise technical specifications must be met.

The industrial ceramics segment represents the fastest-growing application area for both clay minerals, with annual growth rates exceeding 6%. This is driven by increasing demand for advanced ceramics in electronics, automotive, aerospace, and medical industries. Kaolinite dominates this high-value segment due to its superior performance characteristics, though research into modified illite formulations is showing promise for certain technical applications.

Market forecasts indicate continued growth for both clay types, with illite likely to gain market share in mid-range applications while kaolinite will maintain dominance in premium and technical segments. The overall market trajectory suggests a gradual shift toward more specialized, value-added ceramic products across all price points and application areas.

Current Plasticity Challenges in Ceramic Clay Minerals

The ceramic industry faces significant challenges related to the plasticity properties of clay minerals, particularly when comparing kaolinite and illite. These two minerals exhibit fundamentally different plasticity behaviors that directly impact ceramic production processes and final product quality. The primary challenge lies in achieving optimal plasticity for forming operations while maintaining dimensional stability during drying and firing stages.

Kaolinite, despite being a preferred mineral for many ceramic applications due to its whiteness and purity, often demonstrates limited plasticity compared to illite. This creates difficulties in forming complex shapes without additives or processing modifications. The relatively low cation exchange capacity of kaolinite results in fewer water molecules being attracted to particle surfaces, leading to reduced plastic behavior.

Illite, conversely, typically exhibits higher plasticity due to its smaller particle size and greater surface area. However, this enhanced plasticity comes with challenges of excessive shrinkage during drying and firing, potentially causing warping, cracking, and dimensional inconsistencies in finished products. The higher water retention capacity of illite-rich clays also extends drying times, reducing production efficiency.

The variable composition of natural clay deposits presents another significant challenge. Most ceramic manufacturers work with clay bodies containing mixtures of kaolinite, illite, and other minerals in varying proportions. This natural variability makes standardization difficult and requires constant adjustment of processing parameters to maintain consistent plasticity properties.

Modern ceramic production increasingly demands precise control over rheological properties for advanced forming techniques such as injection molding and tape casting. The inherent differences between kaolinite and illite create challenges in developing clay formulations with predictable flow characteristics under pressure or shear forces.

Environmental and regulatory pressures have limited the use of traditional plasticity-enhancing additives like heavy metals and certain organic compounds. This has created an urgent need for developing environmentally friendly alternatives that can modify the plasticity of kaolinite and illite without compromising other ceramic properties or introducing toxicity concerns.

The measurement and quantification of plasticity itself remains problematic. Traditional tests like the Atterberg limits or Pfefferkorn method provide useful but limited information about complex plasticity behavior under actual processing conditions. More sophisticated rheological measurements are needed but are often difficult to standardize across different clay compositions.

Kaolinite, despite being a preferred mineral for many ceramic applications due to its whiteness and purity, often demonstrates limited plasticity compared to illite. This creates difficulties in forming complex shapes without additives or processing modifications. The relatively low cation exchange capacity of kaolinite results in fewer water molecules being attracted to particle surfaces, leading to reduced plastic behavior.

Illite, conversely, typically exhibits higher plasticity due to its smaller particle size and greater surface area. However, this enhanced plasticity comes with challenges of excessive shrinkage during drying and firing, potentially causing warping, cracking, and dimensional inconsistencies in finished products. The higher water retention capacity of illite-rich clays also extends drying times, reducing production efficiency.

The variable composition of natural clay deposits presents another significant challenge. Most ceramic manufacturers work with clay bodies containing mixtures of kaolinite, illite, and other minerals in varying proportions. This natural variability makes standardization difficult and requires constant adjustment of processing parameters to maintain consistent plasticity properties.

Modern ceramic production increasingly demands precise control over rheological properties for advanced forming techniques such as injection molding and tape casting. The inherent differences between kaolinite and illite create challenges in developing clay formulations with predictable flow characteristics under pressure or shear forces.

Environmental and regulatory pressures have limited the use of traditional plasticity-enhancing additives like heavy metals and certain organic compounds. This has created an urgent need for developing environmentally friendly alternatives that can modify the plasticity of kaolinite and illite without compromising other ceramic properties or introducing toxicity concerns.

The measurement and quantification of plasticity itself remains problematic. Traditional tests like the Atterberg limits or Pfefferkorn method provide useful but limited information about complex plasticity behavior under actual processing conditions. More sophisticated rheological measurements are needed but are often difficult to standardize across different clay compositions.

Technical Comparison of Kaolinite and Illite Plasticity Properties

01 Composition factors affecting clay plasticity

The plasticity of kaolinite and illite clays is significantly influenced by their mineral composition and particle characteristics. Factors such as the ratio of kaolinite to illite, the presence of other clay minerals, and the particle size distribution all contribute to the overall plasticity behavior. Higher kaolinite content typically results in better plasticity properties, while varying proportions of illite can be used to adjust plasticity for specific applications. The mineral composition directly affects water absorption capacity and the ability to form cohesive masses when wetted.- Plasticity modification of clay minerals: The plasticity of kaolinite and illite can be modified through various treatments to enhance their performance in ceramic applications. These treatments include the addition of specific additives, thermal processing, and chemical modifications that alter the clay's physical properties. By controlling these modifications, the plasticity of the clay minerals can be optimized for specific industrial applications, resulting in improved workability and final product quality.

- Composition ratios for optimal plasticity: The plasticity of clay formulations depends significantly on the ratio between kaolinite and illite in the mixture. Different proportions of these clay minerals yield varying degrees of plasticity, which affects the formability and strength of ceramic products. Research has shown that specific ratios can be tailored to achieve desired plasticity characteristics for applications ranging from fine ceramics to construction materials, with the optimal ratio depending on the intended use and processing conditions.

- Water content effects on clay plasticity: The water content in kaolinite and illite clay systems significantly influences their plasticity behavior. Controlling moisture levels is crucial for achieving optimal plasticity in clay processing. Research has established specific water content ranges that maximize the plasticity of different kaolinite-illite compositions, with methods developed to maintain these optimal moisture levels during processing. The relationship between water content and plasticity is particularly important in forming operations where consistent workability is required.

- Organic additives for plasticity enhancement: Organic additives can be incorporated into kaolinite and illite clay systems to enhance their plasticity characteristics. These additives, including polymers, dispersants, and binders, interact with the clay particles to modify their surface properties and improve workability. The selection of appropriate organic additives depends on the specific clay composition and the desired plasticity properties, with different additives providing varying effects on the rheological behavior of the clay system.

- Particle size distribution impact on plasticity: The particle size distribution of kaolinite and illite significantly affects their plasticity behavior. Finer particles generally contribute to higher plasticity, while coarser particles reduce plasticity but may improve other properties such as drying behavior. Methods for controlling particle size distribution through grinding, classification, and blending have been developed to achieve optimal plasticity for specific applications. The relationship between particle morphology and plasticity is particularly important in high-performance ceramic applications.

02 Modification methods to enhance clay plasticity

Various modification techniques can be employed to enhance the plasticity of kaolinite and illite clays. These include chemical treatments with dispersants, deflocculants, or organic additives that alter the surface properties of clay particles. Physical processing methods such as grinding, milling, or aging can also improve plasticity by reducing particle size and increasing surface area. Heat treatment at specific temperatures can activate certain properties of the clays, while blending with other materials can create optimal plasticity characteristics for particular industrial applications.Expand Specific Solutions03 Water content and plasticity relationship

The relationship between water content and plasticity in kaolinite and illite clays is critical for understanding their behavior in various applications. The optimal water content for maximum plasticity varies between these clay types, with kaolinite typically requiring different amounts than illite. The water retention capacity, swelling behavior, and plasticity index are all influenced by the clay's mineralogical composition. Controlling moisture levels during processing is essential for achieving desired plasticity properties in ceramic production, construction materials, and other clay-based products.Expand Specific Solutions04 Industrial applications utilizing kaolinite and illite plasticity

The plasticity properties of kaolinite and illite clays make them valuable in numerous industrial applications. In ceramics manufacturing, these clays provide workability and green strength to ceramic bodies. In construction materials, they contribute to the formability and strength of bricks, tiles, and other building components. The pharmaceutical and cosmetic industries utilize their plasticity for creating stable suspensions and emulsions. Environmental applications include their use in liners, barriers, and remediation systems where their plastic behavior helps create impermeable barriers. The paper industry also benefits from their plasticity characteristics in coating formulations.Expand Specific Solutions05 Testing and measurement of clay plasticity

Various methods and techniques are employed to test and measure the plasticity of kaolinite and illite clays. Atterberg limits testing determines the moisture content boundaries between different states of consistency. Rheological measurements assess flow behavior and deformation characteristics under applied forces. Extrusion testing evaluates the ability of clay to maintain shape when forced through dies. Modern instrumental techniques including X-ray diffraction, thermal analysis, and electron microscopy provide detailed information about the structural and compositional factors affecting plasticity. These measurements are essential for quality control and formulation development in industries utilizing these clay minerals.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ceramic Clays

The ceramics industry's exploration of kaolinite and illite plasticity is currently in a growth phase, with the global market for ceramic materials expected to reach $400 billion by 2025. While kaolinite applications are technologically mature, illite utilization is still developing, creating opportunities for innovation. Leading companies like BASF SE, NGK Insulators, and China Petroleum & Chemical Corp. are investing in advanced clay processing technologies, while research institutions such as China University of Geosciences and The University of Queensland are pioneering new applications. The competitive landscape features established materials giants alongside specialized players like Fujian Kefu Material and American Clay Enterprises, with increasing focus on sustainable and high-performance ceramic formulations.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed advanced ceramic formulations that precisely control the ratio of kaolinite to illite to optimize plasticity in their technical ceramics. Their proprietary process involves selective mining and beneficiation of clay deposits with specific kaolinite-illite ratios, followed by controlled thermal treatment to modify the crystalline structure of these clay minerals. NGK's research has demonstrated that kaolinite provides higher plasticity at lower water content (20-35%) compared to illite (requiring 35-50% water for similar plasticity)[1]. Their technical ceramics leverage kaolinite's superior plastic deformation characteristics while incorporating controlled amounts of illite to improve dry strength and reduce shrinkage during firing. NGK has further enhanced this approach by developing surface modification techniques for clay particles that improve the interaction between kaolinite and illite platelets, resulting in more uniform plasticity throughout the ceramic body and reduced defects in final products[3].

Strengths: Superior control over ceramic forming properties, resulting in higher manufacturing yields and more consistent product quality. The optimized kaolinite-illite formulations enable production of complex ceramic shapes with excellent dimensional stability. Weaknesses: Requires sophisticated raw material sourcing and processing systems to maintain consistent clay mineral compositions, potentially increasing production costs compared to less controlled formulations.

BASF SE

Technical Solution: BASF has pioneered a comprehensive approach to understanding and manipulating clay mineral plasticity in ceramic applications, with particular focus on the differential behaviors of kaolinite and illite. Their research has established that kaolinite's hexagonal plate-like structure with 1:1 layer configuration (one silica tetrahedral sheet bonded to one alumina octahedral sheet) contributes to its higher plasticity compared to illite's 2:1 layer structure (an alumina octahedral sheet sandwiched between two silica tetrahedral sheets)[2]. BASF has developed proprietary organic additives that selectively interact with either kaolinite or illite surfaces to modify their plasticity characteristics. Their "ClayTech" formulation system includes specialized dispersants that can reduce the water requirement for kaolinite-rich bodies by up to 15% while maintaining workability, and plasticizers that enhance the normally lower plasticity of illite-rich compositions[4]. BASF has further quantified the relationship between particle size distribution and plasticity, demonstrating that finer kaolinite particles (<2μm) exhibit significantly higher plasticity indices (PI>25) compared to similarly sized illite particles (PI typically 10-15)[5].

Strengths: Highly customizable additive systems allow ceramic manufacturers to precisely adjust plasticity regardless of natural clay mineral composition variations. Their solutions enable the use of lower-quality clay resources while maintaining high-quality ceramic production. Weaknesses: The complex additive systems require careful process control and can introduce additional variables in the firing process, potentially affecting the final ceramic microstructure if not properly optimized.

Key Research Findings on Clay Mineral Plasticity Mechanisms

Method of manufacturing honeycomb structure and honeycomb structure

PatentActiveUS20050221053A1

Innovation

- A method involving the use of a forming material containing a cordierite forming material, a layered clay mineral with a specific layer charge, and a limited amount of organic binder, where the layered clay mineral is smectite, and the firing process is conducted at 1300 to 1500°C, to minimize defects and maintain high strength and low thermal expansion.

Illite, preparation method therefor and use thereof

PatentActiveAU2021342988B2

Innovation

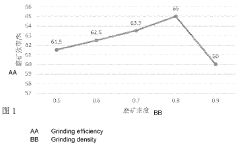

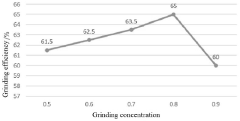

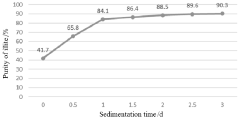

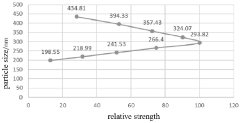

- A method involving ball milling, cyclone separation, primary and secondary sedimentation, and high-pressure homogenization to achieve high-purity and uniform particle size distribution of illite, enhancing its purification and utilization in skin care products.

Environmental Impact of Different Clay Mineral Processing Methods

The processing of clay minerals for ceramic production involves various methods that have distinct environmental implications. When comparing kaolinite and illite specifically, their different physical and chemical properties necessitate varying processing approaches, each with unique environmental footprints.

Traditional mining and extraction of kaolinite typically requires open-pit mining operations that cause significant land disturbance and habitat destruction. The relatively pure deposits of kaolinite often require less chemical processing than illite, resulting in fewer chemical wastes. However, the mining process generates substantial particulate emissions that can affect air quality in surrounding areas.

Illite processing, by contrast, often involves more intensive chemical treatments due to its higher iron content and greater impurities. These chemical processes generate wastewater containing various compounds that require proper treatment before discharge. The higher plasticity of illite compared to kaolinite means it typically requires less water during processing, potentially reducing water consumption but increasing the concentration of contaminants in wastewater.

Energy consumption patterns differ significantly between these clay minerals. Kaolinite's lower plasticity necessitates higher firing temperatures in ceramic production, resulting in greater energy consumption and associated carbon emissions. Illite, with its superior plasticity, can often be fired at lower temperatures, offering potential energy savings of 10-15% in some applications.

Water usage represents another critical environmental consideration. Kaolinite processing typically consumes 20-30% more water than illite due to additional washing requirements to achieve desired purity levels. This increased water footprint extends to wastewater management challenges, as treatment facilities must handle larger volumes.

Waste generation profiles also differ markedly. Kaolinite processing typically produces more solid waste in the form of coarse particles and impurities removed during beneficiation. Illite processing generates less solid waste but often produces more problematic chemical sludges that may contain heavy metals requiring specialized disposal methods.

Recent innovations in green processing technologies have begun addressing these environmental concerns. Advanced filtration systems can reduce water consumption in kaolinite processing by up to 40%, while modified chemical treatments for illite have decreased hazardous waste generation by approximately 25% in modern facilities. Dry processing methods, applicable particularly to kaolinite, have emerged as promising alternatives that significantly reduce water consumption and associated wastewater issues.

Traditional mining and extraction of kaolinite typically requires open-pit mining operations that cause significant land disturbance and habitat destruction. The relatively pure deposits of kaolinite often require less chemical processing than illite, resulting in fewer chemical wastes. However, the mining process generates substantial particulate emissions that can affect air quality in surrounding areas.

Illite processing, by contrast, often involves more intensive chemical treatments due to its higher iron content and greater impurities. These chemical processes generate wastewater containing various compounds that require proper treatment before discharge. The higher plasticity of illite compared to kaolinite means it typically requires less water during processing, potentially reducing water consumption but increasing the concentration of contaminants in wastewater.

Energy consumption patterns differ significantly between these clay minerals. Kaolinite's lower plasticity necessitates higher firing temperatures in ceramic production, resulting in greater energy consumption and associated carbon emissions. Illite, with its superior plasticity, can often be fired at lower temperatures, offering potential energy savings of 10-15% in some applications.

Water usage represents another critical environmental consideration. Kaolinite processing typically consumes 20-30% more water than illite due to additional washing requirements to achieve desired purity levels. This increased water footprint extends to wastewater management challenges, as treatment facilities must handle larger volumes.

Waste generation profiles also differ markedly. Kaolinite processing typically produces more solid waste in the form of coarse particles and impurities removed during beneficiation. Illite processing generates less solid waste but often produces more problematic chemical sludges that may contain heavy metals requiring specialized disposal methods.

Recent innovations in green processing technologies have begun addressing these environmental concerns. Advanced filtration systems can reduce water consumption in kaolinite processing by up to 40%, while modified chemical treatments for illite have decreased hazardous waste generation by approximately 25% in modern facilities. Dry processing methods, applicable particularly to kaolinite, have emerged as promising alternatives that significantly reduce water consumption and associated wastewater issues.

Quality Control Standards for Clay-Based Ceramic Production

Quality control in clay-based ceramic production requires rigorous standards, particularly when working with different clay minerals like kaolinite and illite that exhibit varying plasticity characteristics. Effective quality control begins with raw material assessment, where clay composition must be analyzed for mineral content ratios. For ceramics utilizing kaolinite and illite, X-ray diffraction (XRD) and X-ray fluorescence (XRF) analyses are essential to quantify mineral percentages and detect impurities that might affect plasticity behavior.

Plasticity measurement standards form a critical component of quality control protocols. The Atterberg limits test, measuring liquid limit (LL) and plastic limit (PL), provides quantitative metrics for comparing kaolinite's typically moderate plasticity index (PI) against illite's generally higher PI values. Modern ceramic facilities increasingly employ rheometers for more precise plasticity characterization, with standardized testing procedures requiring specific temperature and humidity conditions to ensure reproducible results.

Processing parameters must be carefully controlled and documented when working with these clay minerals. Kaolinite-rich formulations typically require different water content percentages compared to illite-dominant mixtures. Standard operating procedures should specify appropriate extrusion pressures, which vary significantly between these minerals due to their different particle morphologies and surface characteristics.

Defect identification systems represent another crucial quality control element. Standardized visual inspection protocols must account for the distinct defect patterns associated with each clay type. Kaolinite-based ceramics typically exhibit different cracking patterns than illite-based products during drying and firing. Advanced facilities implement automated vision systems calibrated specifically for detecting these mineral-specific defects.

Statistical process control (SPC) methodologies have been adapted for clay-based ceramics production, with control charts establishing acceptable variation limits for plasticity parameters. These charts must be calibrated differently for kaolinite versus illite formulations, reflecting their inherent variability ranges. Industry standards typically specify tighter control limits for illite due to its greater sensitivity to processing conditions.

International standards organizations have established specific guidelines for clay-based ceramic production. ISO 10545 series provides testing methods applicable to ceramic tiles, while ASTM C373 addresses water absorption, bulk density, and apparent porosity. These standards include specific provisions for different clay mineral compositions, acknowledging the unique processing challenges presented by varying plasticity characteristics between minerals like kaolinite and illite.

Plasticity measurement standards form a critical component of quality control protocols. The Atterberg limits test, measuring liquid limit (LL) and plastic limit (PL), provides quantitative metrics for comparing kaolinite's typically moderate plasticity index (PI) against illite's generally higher PI values. Modern ceramic facilities increasingly employ rheometers for more precise plasticity characterization, with standardized testing procedures requiring specific temperature and humidity conditions to ensure reproducible results.

Processing parameters must be carefully controlled and documented when working with these clay minerals. Kaolinite-rich formulations typically require different water content percentages compared to illite-dominant mixtures. Standard operating procedures should specify appropriate extrusion pressures, which vary significantly between these minerals due to their different particle morphologies and surface characteristics.

Defect identification systems represent another crucial quality control element. Standardized visual inspection protocols must account for the distinct defect patterns associated with each clay type. Kaolinite-based ceramics typically exhibit different cracking patterns than illite-based products during drying and firing. Advanced facilities implement automated vision systems calibrated specifically for detecting these mineral-specific defects.

Statistical process control (SPC) methodologies have been adapted for clay-based ceramics production, with control charts establishing acceptable variation limits for plasticity parameters. These charts must be calibrated differently for kaolinite versus illite formulations, reflecting their inherent variability ranges. Industry standards typically specify tighter control limits for illite due to its greater sensitivity to processing conditions.

International standards organizations have established specific guidelines for clay-based ceramic production. ISO 10545 series provides testing methods applicable to ceramic tiles, while ASTM C373 addresses water absorption, bulk density, and apparent porosity. These standards include specific provisions for different clay mineral compositions, acknowledging the unique processing challenges presented by varying plasticity characteristics between minerals like kaolinite and illite.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!